Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Introduction To ITM Manufacturing

Cargado por

Swapnil DhandeDescripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Introduction To ITM Manufacturing

Cargado por

Swapnil DhandeCopyright:

Formatos disponibles

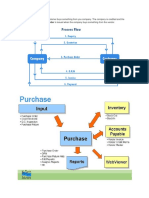

Introduction to ITM Manufacturing ITM Manufacturing is an integral part of the ITM software.

The manufacturing module works in tight integration with other modules of ITM as single system. Modules, which help ITM manufacturing for its completeness, are ITM Inventory, ITM Materials and ITM Finance. Based on the required business process, all the above can be configured to work with their full functionality. What is ITM MANUFACTURING? ITM Manufacturing provides you with a tool for your daily manufacturing activities. It helps you to achieve control over various activities carried out for planning the production, starting the batch, issuing the material to production, receiving finished goods from production. ITM Manufacturing and the organization The enterprise is divided into various sites. The plant or factory is defined in ITM as a site, where manufacturing activities are to be carried out. The site is further sub divided into departments or functions that carry out a defined role and has some responsibility. In the manufacturing process various departments like production, quality control, inventory control can perform their role in the respective option in the system. The system co-ordinates and provides information to each other in the entire process of managing the business. Quality Control function is an integral part of the ITM Manufacturing module. The Functionality ITM deals with the procedure followed by the company covering all the area of manufacturing operations. A set of areas are grouped under a technically manageable sub-module, In ITM manufacturing there are following sub-modules Shop floor control Quality Control Each of the above sub-modules automats a set of activities as follows. Shop floor control Defining Bill of Material Starting Manufacturing Issuing material to manufacturing Returning materials from manufacturing Receiving finished product from manufacturing Quality Control Analyzing the finished goods Analyzing the parched materials Other related functions automated by other modules are: Taking a purchase receipt ITM Materials Returning a purchased material to supplier ITM Materials Planning for Manufacturing, Capacity, Material Requirement ITM Planning

Each of these areas consists of various transactions, which are integrated with each other across all the modules of ITM. There are pre-defined business processes in ITM, which help you in performing your business activities and manage data flow among transactions. Apart from the above-defined operations there are some other activities which are required for manufacturing to be done at enterprise level are as follows: Defining business rules Defining items for finished goods Defining items for various kinds of materials Manufacturing Basics A typical manufacturing process, which ITM manufacturing automates, can be defined briefly as follows: Before beginning with the day to day activities of manufacturing, the master definitions in he system are required to enables the system for the activities. All the products that are manufactured need their definition in the item master. Also, the materials required to make the products again need to be defined in the item master. The bill of material for each finished product is required to issue materials to production. A plan is prepared in the beginning of the month, specifying what is to be manufactured in the next one month in terms of product, quantity and the date by which it is to be manufactured. Based on the plan, work order is created to specify the different batches that need to be taken. The work order, which is created for planning should be firm planned. When the work order is firm planned, ITM manufacturing treats that the order is decided to be executed. When you firm plan a work order, the route in which manufacturing is to be done is created & the material required get calculated. It also allocates the stock to the work order, so that there is no stock out while making the finished goods. Machines required for manufacturing are reserved to avoid over booking of machines. When the actual manufacturing starts for a batch, the finished goods batch number must be assigned to the work order and it should be released. The manufacturing is done with multiple operations and for each operation materials needs to be issued. The materials are issued from stores based on a request raised by the production department. Sometimes additional materials need to be issued to production, which is over and the requirements defined in the bill of materials. Such issue of material are called deviation issue. Stores do deviation issue only after special authorization from the designated person. The completion of each process is tracked in the system and detailed feedback is captured about the various parameters and time taken for manufacturing. Also the resources utilized like manpower. Machine can be specified in work order feedback for each operation.

ITM tracks stoppages/Breakdowns in the shop floor the reason and improve in preventive maintenance.

Planning

MPS

Work Order

Sub Assembly Work Order

Firm Plan

Work Order Bill Work Order Route

Work Order Relies

Work Center Allocation Material Allocation

Enhanceme nt

Inventory Issue

Production Feedback

Inventory

Work Order Receipt

By Product Receipt

QC Order

Inventory

After completion of all the operation the finished goods are received which are kept under quarantine. After the testing of the finished goods by quality control, if it passes it is transferred to finished goods stored. From finished goods stores, depending on the business needs, the material is sold or transferred to each other sites. When the material are received by way of purchase receipt from supplier, it is kept under quarantine. For each of the batches of supplier intimation is given to Quality testing department to draw sample for analysis. QC draws a sample and carries out testing as per the specification of item. After the testing, if it is approved, it is transferred to usable raw material stores, from where the materials can be issued to production. At the time of QC approval the potency assignment is done to the items, which requires the potency matching. Potency is a number, which defines the usability or strength of the quality. A less potency does not mean impure, a lower potency of an item can be compensated with quality. Potency of each of the raw materials purchased are assigned when quality control approval is done, the same item may have a different potency for different lot number (AR number). Quantity is to be matched while issuing or allocating stock to work orders based on potency. Materials, (which are issued excess to production), if not used, are returned to stores. When the material is returned to stores, it again goes to quarantine, similar to the purchase receipt. At the time of return from production intimation is sent to QC to draw the sample. On approval of quality control it is transferred to useable stores. Some of the finished products give by-products or recovery. Such items like any other finished products are received from production. By-products are also analyzed by QC and after approval can be used. ITM Manufacturing (Mater)

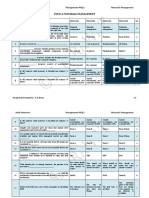

Bill of Material What is Bill of Material? Bill of Material is a list of materials which are required to produce a finished good. Each bill of material is defined by a unique code which is for a product. Every time a new product needs to be manufactured, the bill of material required for the new product should be defined in the bill of material master. In the system once the bill is improved, the bill of material for a product may undergo a change, on quality control approval. In such cases a new bill of material to be created with a new code and the product should be assigned the new bill of material code. The latest bill of material is used by the system while issuing goods to production. For the same product there may be different bill of materials co-existing for re-work of different types. The bill of material to be used for re-work can be specified at the time of creation of work order. How to define the bill of material

Assign a new bill of material code; create a new entry in bill of material master. Define all the items, which are required for the finished goods for which you are creating the bill of material. The bill of material can be used in work order only after it is confirmed. BOM Code BOM Code is a unique code to identify the bill of materials. Type Ingredient should be selected to define the bill of material for shop floor control purpose. The other options are used in other modules of ITM, which is not relevant in this context. Description Description of the bill of material. Normally it should contain the description of the product for which bill of material is bring defined, with the purpose like re-work, fresh or any such specific information. Item Code Item code in the main screen is the code of product for which the bill of material is being defined. Batch Qty

The batch size defined in the bill of material, is the standard batch size of the product for which bill of material is defined. While taking actual production if the batch size is increased, automatically, the requirements of the materials change as per defined rule. Similarly if the batch size reduces automatically, the material required reduces as per rule for the work order. The batch size defined in the bill of material goes by default in work order. It can be changed only with required authority. Batch Option Not applicable should be left blank. Item Code Item code is the of the material, which is required in manufacturing of above defined finished goods. You can specify another bill of material in item code. Such bill of material are called subbill of material and while exploding ITM includes all the items defined in sub-bill of material as a part of main bill of material. Item reference If the same item is required in same bill of material in multiple instances different item reference can be specified to differentiate and allow the same item to re-appear. Quantity per Required quantity for the batch size. Effective from Effective from is the starting date from which this item is to be considered a part of material. Valid upto Valid upto is the end date till which this item is a part of bill of material. The effective period can be used to use an item in a experimental basis, which is not a very critical component of manufacturing. Type The way the quantity per will change in relation to the batch size should be defined in this. Different possible values are Proportionate: The quantity should change proportionately with the batch size Fixed: Required quantity does not change even if the batch size increases or decreases Slab: When the item is defined with the slab option, the quantity gets multiplied, only when the batch size is multiplied. Option The operation number of the manufacturing, in which this item is used. This is very critical for issue of material. While issuing material all the materials of one operation are issued together. Lend time After how many days of starting manufacturing this material is required. The lead time is used for planning for material.

Unit Unit measure in which the quantity is to be issued (Display only information) Min Qty Minimum Quantity, when the quantity as per the calculation, comes below the minimum quantity, the minimum quantity is taken as the requirement. Critical Item The possible values are Yes or No, whether it is critical item or not. When a critical item in not available in stock at the time of firm plan, system does not allow to make the work order firm plan. The critical items are defined, to control the loss in production due to stock out For example if some material is required in a production process in the second or third operation of production. And it not available at that time, and the production had already completed the first two operation. If the material is such that, if it is not available then work in progress material of first two operation will go waste, then, such type of materials should be classified as critical item and production should be classified as critical item and production should be started when the material is available. Auto Order Not used in this version of ITM Match Potency It should be defined whether potency matching of the item should be done or not if the stock is found with less potency, system automatically allocates and issues more quantity of material to match the requirement For example 20 KG of a raw material (say ABC) is required to manufacture a batch of 100 KG for a finished goods (say XYZ). In this the standard potency of material ABC is 100. When the stock is found with a lot of ABC with 80 potency. TO match the requirement of 100 potency, instead of 10 KG, 2.44 KG extra will be issued to match the potency of 100. Adjust Potency When in one item, to match the potency, extra quantity of material is issued, it may be required to reduce (adjust) the quantity in another filler type of item. The quantity can be adjusted in multiple items proportionately. In above example ( in match potency column) the extra quantity of 2.44KG should be possible to be adjusted in two other raw materials like water and solvent PQR. If 15 KG water and 5 KG of solvent PQR 4.39 (5-61). System allows adjusting the excess quantity of multiple items in requirement of multiple items. Adjust potency is a starting data which is defined against the item which requires a potency matching. The same string should also be defined in all those items where the excess quantity issue to be adjusted. In the items where potency to be adjusted, the match potency should be defined as No The standard potency (100 in above example) can be defined in item master for the raw material.

Round If the final quantity required for the work order needs to be rounded the rounding method can be defined. The round option defines how it is to be rounded. Not Round Next Round to Previous Next : : : : Not to be rounded Rounding to be done to next number. The number should be defined in Rounding to be done to previous number Rounding to be done to nearest number defined in round to.

Round to The number to which rounding to be done. For example, if the round to is defined as defined as 0.01, and round is next, 15.093 will be rounded to 15.10. If the rounding is defined as previous the same quantity will be rounded to 15.99 and it is defined as near it will get rounded to 16.00. When the round to is defined as 0.50 the same number with Previous will get rounded to 15.50. Use inv Use inventory option defines the inventory to be used. When there is re-work done the main material, which is to be issued to production is a normally a rejected material. By rule an item, which is rejected by quality control can be issued to production. This flag can be used to handle such cases. IF it is defined as Non usable and usable a rejected material can be issued to production. While defining this information you must be extremely careful to avoid dangerous mistakes. Usage type The way issue of material to be done, can be Regular or On Demand. There are items, which are defined in batch manufacturing record as requirement in slab. In bill of material the requirement in slab. In bill of material the requirement quantity should be defined in two parts. The minimum quantity of the slab should be defined as Regular requirement, which should be issued automatically when material is asked for the operation. The remaining part of the items where the requirement is conditional should be requirement changes to case. Alloc Type Allocation type defines how the stock to be allocated to the work order when making the work order Firm Plan. There can be three possible in this column. Allocate Original Item Stock Do not Allocate Allocate Any Stock When you select Allocate Original Item Stock system allocated only when the stock is found for the item which is defined in BOM itself. In other words, while making a work order firm plan, if stock is not found in the main item of the BOM and it finds an alternate item in the alternate BOM definition, the stock in such case will not get it will do the allocation. This option

can be selected in a situation where you are expecting some item to reach before the day it is actually required in the manufacturing and even if alternate items are available you do not wish to use alternate. Do not Allocate if selected will not allocate the stock to the work order even if it finds the stock. Allocate Any Stock option is to specify that in case the main item stock is not there and alternate item is picked up, allocation should be done. Consider Partial (Yes/No) This parameter of bill of material specifies whether material allocation to be done while making the order firm plan when found partial. For example you are using 500Kgs of an item A in a finished goods. If item A is not available you can also use B or C or D. If only 200Kgs of A is available, how should the system allocate the balance requirement between B & C. If this flag is set to yes it will take 200 of A and 300 of B. If No it will skip the 200 quantity of A and skip to B and look for the full requirement in B. See alternate bill of material for more details. Location usage type Location usage type is used to indicate which location of storage to be taken into consideration while allocating the stock. Take for example, there is an item, which a user buy locally and import. For a specific product he would like to use the imported. What can be done is store the imported goods in a specific location called Imported, enter location type as Always from defined location, enter the location code in the work order. System will automatically pick up the stock from imported location. The values for this parameter could be. Always from defined location This will allocate stock to this item only from the location which, is entered in the work order. Even if there is stock in order location system will not use that. If stock is not available in defined location it will treat as if stock is not found. Not Applicable Do not use this definition Preference from defined location This parameter will prefer to use from the defined location, if stock is not available in defined location, system will take the stock from other location. Consider Issue Lot no If a specific batch item to be issued, this can be set to Yes. For example, I want to make a finished good from two different semi-finished goods and want to use specific batch number of semi-finished item. For the semi-finished item code this flag can be set to Yes, in work order the batch from which the semi-finished items to be picked up should be entered. This can be relevant for packing batches also. When I am taking a packing batch the main item should be issued only

from the batch which I am packing, so that in packed goods also same batch number is maintained. Dimension The item to be issued if needs to have a minimum physical dimension, this can be entered in Dimension. For example, I would like a packing material with 2 ft width material. The dimension of B can be specified as 4, so that if item with less than 4 ft width is found in stock will not be used for B. Confirmation of bill of material and linking it to the product Once the bill of material is prepared, before it can used it must be confirmed in the system by quality control. To confirm the bill of material select the bill of material which needs to be confirmed and click on confirm button. After the bill of material is confirmed, the bill of material code should be defines in site item master to link the product to the bill of material. Once it is linked, every time a work order is created for the product then the assigned bill of material comes by default Alternate Bill of Material Alternate bill of material is the definition to specify items that can be used when an item from the bill of material is not available. For each of the item bill of material alternates can be defined. In a situation where if one item is not available, multiple alternate items possibility is there, then, it can be defined. Multiple items can be entered with different sequence to defined multiple alternate.

If the item for which alternate is being defined and it has a flag to allocate stock the alternate item will be selected at the time of firm plan of the order, otherwise it will be decided at the time of making the issue. Item Code Item code is the code of item (material of BOM) for which alternate is being defined. In one bill of material there can be multiple items, for each items multiple alternate items can be defined. The item being entered must be existing in the selected bill of material Item Reference In bill of material if the same item is used multiple times, for each occurrence of the item, different alternates can be defined. For example an item A is used in operation 1 and again the same item is used in operation 3. Alternate at operation 1 can be different from alternate at operation 3. This can happen as the role of the same item at different stages of manufacturing may be different. For example an item is used for reaction in operation 1. If an item is to be issued, just before charging to production, it can be defined as on-demand issue. This is generally applicable for item, which requires special storage or handling. Items whose quantity requirement is in range

Items, which are required in range, like 10 to 20 KG, in the example 10 is fixed requirement and 2 may be required, may not be required. Additional 2 can be issued if required. In this case 10 quantities can be defined as Regular and 2 as On demand, Deviation issue When the material required is more than what is defined in bill of material, the issue can be done with deviation issue. This kind of issue may be required to handle various un- expected business compulsions. General reasons why this may happen is i. Loss of stock after issue is done and before charging to production ii. Adding extra material to observe an experiment at the time of scale up iii. Correct a technical mistake in production and so on For whatever reason deviation issue is done it should be entered in the deviation issue transaction. Item and quantity required should be specified for deviation issue. The lot number is allocated by the system. In deviation issue system does not use stock which is already allocated to a work order. As per the same logic of allocation as defined earlier in this document, system allocates the lot number (AR Number). Confirmation Work Order Issue For any of the mode once issue document is stored user will get to view the issue documents which are created. After checking for the issue document, a pick list from the system to be printed which are created. After checking for the issue document, a pick list from the system to be printed which contains the list of materials with lot number (AR number) that needs to be picked up for dispensing in. After the goods are picked up, the order issue document needs to be confirmed in the system, and issue slip with material issue document should be printed.

On confirmation of the issue transaction, the system should expect a bar code scanning on the bar code printed on the coupon of physical material. The coupons should be printed at the time of quality control approval of the item. If the scanning is not done on any of the lot number of any of the items, which is issued in the document, system will not allow confirming the issue. The stock get reduced from inventory at the time of confirmation of issue of all the material, which are there in the work order issue document. Allocating/ De-allocating of material to a lot Allocating is done by inventory reserve option

De-allocation is done by production menu (manufacturing)

Production feedback For each operation production feedback can capture resource utilized in the operation. Also a feedback can be entered to track that it is completed and moved to the next. This information is used to project the expected date of completion of the work order. For example to complete the manufacturing if it is expected to take 10 days, the initial due date is calculated by adding 10 days to the release date of the work order. If the first operation is completed by consuming 1 extra day then the due date gets re-calculated by adding 1 day to it. When a feedback is entered, if there is QC required is defined in the process, system creates a QC order automatically. The resource utilized can be captured in items of following. Time: From date time to date time taken for completing the operation. The deference between the standard time and actual time taken is reflected as deviation. Manpower: Manpower can be specified by number of man hours utilized or it can be specified by the employee code. Work center: The work center actually used can be specified in production feedback. The actual machine utilization is updated for the work center. Route Alteration

Route alteration provides flexibility to change the machine set up ( previously allocated) in a pre defined route of production in case the defined machine is faulty. Which all machines can be replaced by which other machines, that can be defined in alter machines master. Sometimes the route alteration is done to balance the workload across the work centers. In the work order route master for the operation the work center code can be changed to give this effect. The new work center load is increased by adding the operation to it. Return of materials to stores

Raw materials which are issued for a particular work order but not used or materials which is issued extra can be returned to stores by entering the return details in work order issue/return. System captures the return information and generates a QC order, so that it does not get mixes with usable materials before it is approved by Quality Control. The returned item goes to quarantine location and transferred to approve location only after the material is approved by Quality Control. If the material is rejected by Quality Control, it is moved to rejected location. In one work order return document the system allows to include multiple items which were issued in one operation. On selection of operation, system all the issues those were done in that operation, and allows selecting the item, which is to be returned. The system allows return of such material which was issued with specific item code, lot number and lot serial. Additionally the system checks the

issued quantity with the returned quantity. The return can be done in the same option, for which the actual issue may have been done from deviation, automatic or on-demand. In case, when excess issue is done, to much the article size, it may be returned after completion of the operation. There may be multiple returns for the same material and for one issue. Receipt of finished goods from production Once all the production stages are over and finished goods are ready, work receipt entry should be done in the system. Work order receipt can be done only after all the operations are over. System captures all the information about the receipt and closes the

Work order. Once work order is closed, no more transactions can be carried out against the work order. For one work order the receipt can be done in multiple stages. For each time the receipt is done a receipt entry should be done in the system. System automatically closes the work order once the full batch quantity is received. System should calculate the expiry date of the items based on the shelf life of the item and expiry date basis. The expiry date basis is defined in the item master of the finished goods, which defines on what basis expiry date is to be calculated i.e. 1. Start manufacturing 2. End manufacturing

The system adds shelf life to the specified date and calculates the expiry date. The shelf life can be defined in the item master in term of number of months for each finished goods. The system creates a QC order as soon as the production receipt is confirmed. Also the stock of finished goods in quarantine location is updated. On approval of QC the stock moves from quarantine to usable location. Once work order receipt is confirmed, it cannot be changed. Receipt of by-product and recoveries Once one operation of production is over, if there is any recovery, recovery receipt entry should be done in the system. System captures all the information about the receipt using the same entry screen of receipt. The type of receipt in this case should be selected as By-product, When a byproduct or recovery entry is done system allows selecting the product code which is being recovered. Also a master specifying which item can be taken as recovery from which product is defined. System allows selecting products from defined master. The received stock from recovery is tracked is tracked with a lot number. The lot number of the recovery receipt item can be specified in work order receipt. The recovery item stock is updated on confirmation of the recovery receipt entry exactly the way a finished goods stock is received. A QC order gets generated to test recovery item. On approval the item moves from quarantine to usable stock. On Line Rejection ITM Manufacturing provides tracking of rejection that takes place during manufacturing process. The quantity of rejection of various items taken place can be tracked operation wise and reason wise.

Quality Control Quality Control Order Quality Control is a transaction, which is generated in the system to carry out some testing activity with some items. The test can be done for a raw material, packing material, intermediate product or finished goods. The QC Order gets generated in ITM from following sources automatically On confirmation of receipt of an item when QC approval is required for that item On confirmation of a finished goods or by-products On confirmation of a work order return- goods returned from production When a material requires re-testing to be done.

Also apart from all above if there is a requirement to test some item, where none of the above transaction has taken place. A QC order can be entered in the system manually. When QC Order is generated following key information are created by default Quantity. The QC Order quantity. The full lot quantity of material which is being tested is shown as quantity. From the full quantity a representative sample is drawn to decide the quality of the full lot. If in a purchase receipt 500 drums are received which amounts to 5000 KGS the QC order will be created for 5000 KGS. From this a sample of 50 grams may be drawn, which represent the full 5000 KGS Item Code Item code, which is to be tested. Location This is the original analytical report number which was assigned to the lot when it was inspected for the first time. In case of finished goods this is the batch number. Qty Sample Quantity of sample that is to be drawn for testing, this is an item master information. Before the QC order is confirmed following information must be entered in the system

Qty Passed The quantity which is to be approved Qty Rejected Quantity rejected, this can be the full quantity or partial Aprv location The location to which the item should be stored when there is approval Rej location The location where item to be stored when there is an rejection. Whatever item is defined in QC order, basically when the QC Order is confirmed the order quantity gets approved or partially approved. In ITM the usability of stock the stock is linked with a location code. Location code can be a physical location ( part of the warehouse) where the goods are stored or can be a logical with different properties. If it is physical location there should a separate area for quarantine and approved. There can be multiple quarantine and multiple approved locations. When physical area for quarantine and approved are not different, for system use at least one quarantine, one approved and one rejected location should be created. On approval of QC Order the Quantity Passed goes to approved location, quantity rejected goes to quarantine location and sample quantity gets consumed. In the QC order for raw material inward inspection, if the material is fully or partly approved the re-test date must be entered, which defines the date on which the approved material needs to be re-tested before used. The item in which potency matching is done, potency must be entered after testing. The potency is updated in inventory from here and used at the time of creation of work order issue. While issuing the material, the quantity should be matched to the potency adjustable quantity.

Cinfrim (M) PO

SO confirmed

Dist. Order

Dist. Issue

Dist. Receipt

BOM

También podría gustarte

- Practical Guide To Production Planning & Control [Revised Edition]De EverandPractical Guide To Production Planning & Control [Revised Edition]Calificación: 1 de 5 estrellas1/5 (1)

- SAP PP - IntroductionDocumento8 páginasSAP PP - IntroductionKoustubha KhareAún no hay calificaciones

- Cost of Goods SoldDocumento9 páginasCost of Goods SoldAmitava SahaAún no hay calificaciones

- SAP PP FlowDocumento13 páginasSAP PP FlowMayankAún no hay calificaciones

- Production & Planning - SynopsisDocumento22 páginasProduction & Planning - Synopsisbrijesh99Aún no hay calificaciones

- Product Design DepartmentDocumento4 páginasProduct Design DepartmentNikhil BvAún no hay calificaciones

- BBP For PP Module ProcessDocumento4 páginasBBP For PP Module ProcesspaiashokAún no hay calificaciones

- Sap PP Tutorials - GuruDocumento97 páginasSap PP Tutorials - GuruKishor Kolhe100% (1)

- S. V. Institute of ManagementDocumento48 páginasS. V. Institute of ManagementGaurav GagwaniAún no hay calificaciones

- Enterprise Resource PlanningDocumento9 páginasEnterprise Resource PlanningRobbin HaidenAún no hay calificaciones

- MTS & MtoDocumento4 páginasMTS & MtokalidasmAún no hay calificaciones

- SAP MRP 2 ViewDocumento7 páginasSAP MRP 2 ViewVivek Malik100% (1)

- Repitive Man-Sap LibraryDocumento15 páginasRepitive Man-Sap LibraryPrateek SehgalAún no hay calificaciones

- Bill of MaterialDocumento4 páginasBill of Materialonlinelearn sapAún no hay calificaciones

- UNIT 1: Navigation in SAP S/4HANA: Application TypesDocumento42 páginasUNIT 1: Navigation in SAP S/4HANA: Application TypesjihanemkaAún no hay calificaciones

- About The ProjectDocumento4 páginasAbout The ProjectAnonymous PHCzwD8eAOAún no hay calificaciones

- inoERP BomDocumento6 páginasinoERP BomendyAún no hay calificaciones

- Acctg201 JobOrderCostingLectureNotesDocumento20 páginasAcctg201 JobOrderCostingLectureNotesaaron manacapAún no hay calificaciones

- Sap B1 - ProductionDocumento13 páginasSap B1 - ProductionRhon Ryan TamondongAún no hay calificaciones

- How To Close A Production Order: Step 1: Calculation of WIP AmountDocumento51 páginasHow To Close A Production Order: Step 1: Calculation of WIP Amounttapas100% (1)

- PP DimpDocumento50 páginasPP DimpAhmed HassanAún no hay calificaciones

- CHAPTER IV Code BreakerDocumento15 páginasCHAPTER IV Code BreakerREYNALD TANOAún no hay calificaciones

- List of Business Processes To Be Implemented: 1.1 Master DataDocumento41 páginasList of Business Processes To Be Implemented: 1.1 Master DataSowjanya KAún no hay calificaciones

- Sap & Finance - Sap Fico Interview Questions - Product CostingDocumento8 páginasSap & Finance - Sap Fico Interview Questions - Product CostingA KAún no hay calificaciones

- Bom PinpointDocumento5 páginasBom PinpointSam8544Aún no hay calificaciones

- How To Create BOM For Subcontracting in @SAP CLOUD: Mickael QuesnotDocumento9 páginasHow To Create BOM For Subcontracting in @SAP CLOUD: Mickael QuesnotSUBHOJIT BANERJEEAún no hay calificaciones

- 5 Master Data in PPDocumento7 páginas5 Master Data in PPprashantsdpikiAún no hay calificaciones

- PP Basics UnderstandingDocumento7 páginasPP Basics UnderstandingprashantsdpikiAún no hay calificaciones

- Configuration Basics of Discrete ManufacturingDocumento6 páginasConfiguration Basics of Discrete ManufacturinggvlaxmipathiAún no hay calificaciones

- SAP MM - Inventory Management ProcessDocumento50 páginasSAP MM - Inventory Management Processjuventus fans club indonesia100% (1)

- Controlling Module, Create Material NewDocumento18 páginasControlling Module, Create Material NewPooja MandhanAún no hay calificaciones

- Planning of Production Logistics Systems - KOALM327 - Final ExamDocumento19 páginasPlanning of Production Logistics Systems - KOALM327 - Final ExamAna Paula CarvalhoAún no hay calificaciones

- 5 Cost Accounting CycleDocumento16 páginas5 Cost Accounting CycleZenCamandang67% (3)

- Sap MMDocumento5 páginasSap MMPrathap ReddyAún no hay calificaciones

- Functions of Material ManagementDocumento3 páginasFunctions of Material ManagementAnkkit BafnaAún no hay calificaciones

- Manufacturing ProcessDocumento127 páginasManufacturing Processtayybi01Aún no hay calificaciones

- Technical Proposal INVENTORY WarehouseDocumento17 páginasTechnical Proposal INVENTORY WarehouseHaseeb AshrafAún no hay calificaciones

- Production Planning Document - MainDocumento3 páginasProduction Planning Document - MainSureshAún no hay calificaciones

- Sap MMDocumento202 páginasSap MMMayuri Srivastava67% (3)

- SAP Production Planning (PP)Documento17 páginasSAP Production Planning (PP)manasiAún no hay calificaciones

- 1 - Jit & Backflush (g2)Documento23 páginas1 - Jit & Backflush (g2)Ain Alam Ain AlamAún no hay calificaciones

- Sap MM IqDocumento56 páginasSap MM IqLavanya Hari Krishnan100% (1)

- SAP-MM-RealTime Problems & Solutions - Part1Documento53 páginasSAP-MM-RealTime Problems & Solutions - Part1sbhanuprathap86% (88)

- Manufacturing System - Unit 1Documento47 páginasManufacturing System - Unit 1savita100% (1)

- Production Order in SAP CO01 MD16 CO02 CO15Documento13 páginasProduction Order in SAP CO01 MD16 CO02 CO15Muhammad GamalAún no hay calificaciones

- What Does Backflush Costing Mean?Documento3 páginasWhat Does Backflush Costing Mean?Pankaj GoelAún no hay calificaciones

- 101Documento2 páginas101Jan Michael PastorAún no hay calificaciones

- Sales OrderDocumento17 páginasSales OrderRafdi Raziq100% (1)

- Understanding Production Order Variance Part 1Documento26 páginasUnderstanding Production Order Variance Part 1Sisir PradhanAún no hay calificaciones

- MM Config TipsDocumento71 páginasMM Config TipsHimanshu Singh100% (2)

- Discrete Manufacturing - The Made To Order Cycle and Make TO Stock CycleDocumento3 páginasDiscrete Manufacturing - The Made To Order Cycle and Make TO Stock Cyclealbertoca990Aún no hay calificaciones

- Learn To Bill of MaterialsDocumento1 páginaLearn To Bill of MaterialsShaik MustafaAún no hay calificaciones

- PTC CH7 Intro To CAMDocumento30 páginasPTC CH7 Intro To CAMManoj Kumar NayakAún no hay calificaciones

- Product CostingDocumento12 páginasProduct CostinghanumaAún no hay calificaciones

- BUSINESS PROCESS: Calibration Process Overview: ASISDocumento4 páginasBUSINESS PROCESS: Calibration Process Overview: ASISVikas SharmaAún no hay calificaciones

- Creating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowDe EverandCreating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowCalificación: 4 de 5 estrellas4/5 (1)

- IATF 16949:2016 Audit Guide and Checklist 2nd EditionDe EverandIATF 16949:2016 Audit Guide and Checklist 2nd EditionCalificación: 4.5 de 5 estrellas4.5/5 (10)

- SAP PR Release Strategy Concept and Configuration Guide: A Case StudyDe EverandSAP PR Release Strategy Concept and Configuration Guide: A Case StudyCalificación: 4 de 5 estrellas4/5 (6)

- EVORA - Feasibility StudyDocumento11 páginasEVORA - Feasibility StudyEvora, Sichem D.Aún no hay calificaciones

- Product Life Cycle of Nestle MaggiDocumento3 páginasProduct Life Cycle of Nestle MaggiPRAPTI TIWARIAún no hay calificaciones

- Black and Decker Robotic Vacuums CaseDocumento14 páginasBlack and Decker Robotic Vacuums CaseTharun ReddyAún no hay calificaciones

- Distribution Planning and Control Managing in The Era of Supply Chain Management PDFDocumento935 páginasDistribution Planning and Control Managing in The Era of Supply Chain Management PDFthanhvan3486% (14)

- 05-1 - EPC-GE-PTC-3-PR-00181 - Rev D2 Commissioning & Handover Execution PlanDocumento55 páginas05-1 - EPC-GE-PTC-3-PR-00181 - Rev D2 Commissioning & Handover Execution PlanHaianh PhamAún no hay calificaciones

- NX9523 - Biz Professional Practise Coursework (w21068666) - 05112022Documento12 páginasNX9523 - Biz Professional Practise Coursework (w21068666) - 05112022Jorris NgAún no hay calificaciones

- Workday Standard Reports - NivasDocumento294 páginasWorkday Standard Reports - NivasAnnam Raju Sai GopiAún no hay calificaciones

- Tutorial Relevant Costs For StudentsDocumento3 páginasTutorial Relevant Costs For StudentsJihan RafiqaAún no hay calificaciones

- InnopreneurshipDocumento9 páginasInnopreneurshipmarissa casareno almuete100% (1)

- Six Sigma - Lean Manufacturing and Six Sigma Definitions PDFDocumento3 páginasSix Sigma - Lean Manufacturing and Six Sigma Definitions PDFsanjaigAún no hay calificaciones

- Understanding Service Operations StrategyDocumento35 páginasUnderstanding Service Operations StrategyJOHN DAVID DELTOAún no hay calificaciones

- JES2-JES3 Compare CommandsDocumento37 páginasJES2-JES3 Compare CommandsAntonyAún no hay calificaciones

- Supplement 1 - Interim View of An Interpreter's Guide For eTOM and ITIL Practitioners PDFDocumento54 páginasSupplement 1 - Interim View of An Interpreter's Guide For eTOM and ITIL Practitioners PDFShantamAún no hay calificaciones

- How I Built An Ecom Store From $0 To $3 MillionDocumento55 páginasHow I Built An Ecom Store From $0 To $3 Millionwegah96976Aún no hay calificaciones

- Afzal, 2013Documento7 páginasAfzal, 2013Abdul SamiAún no hay calificaciones

- SolidCAM 2021 Modules OverviewDocumento111 páginasSolidCAM 2021 Modules OverviewJuan Carlos CandelarioAún no hay calificaciones

- Module 1. Prelims Workshop Theory and Practice 1ADocumento7 páginasModule 1. Prelims Workshop Theory and Practice 1AmanuelAún no hay calificaciones

- Sipoc Diagram: Best-In-Class Template Analysis and RecommendationDocumento12 páginasSipoc Diagram: Best-In-Class Template Analysis and RecommendationrinsuastiAún no hay calificaciones

- WK 1 CLO 1 - Describe The Purposes and Roles Warehouses and Distribution Centres (DCS) Have in The Supply ChainDocumento31 páginasWK 1 CLO 1 - Describe The Purposes and Roles Warehouses and Distribution Centres (DCS) Have in The Supply ChainShravanAún no hay calificaciones

- All Section Quality Flow-ChartDocumento5 páginasAll Section Quality Flow-ChartRashedul islam ReazAún no hay calificaciones

- CRM Section Sheet OneDocumento5 páginasCRM Section Sheet Oneyoumna yasser ismailAún no hay calificaciones

- Pricing Strategy GROUP 6Documento38 páginasPricing Strategy GROUP 6Claire Erica GaniganAún no hay calificaciones

- ECO111-CHAPTER 16-Monopolistic CompetitionDocumento26 páginasECO111-CHAPTER 16-Monopolistic CompetitionPhung Anh Do (K18 DN)Aún no hay calificaciones

- Job Description - Master Production SchedulerDocumento3 páginasJob Description - Master Production SchedulerRicardo PirelaAún no hay calificaciones

- Topic 6: Materials ManagementDocumento21 páginasTopic 6: Materials Managementcareermotions50% (2)

- Unit 2 - Classification of Production SystemDocumento20 páginasUnit 2 - Classification of Production SystemUrwashiAún no hay calificaciones

- European Steel and Alloy Grades: 70mnmocr8 (1.2824)Documento2 páginasEuropean Steel and Alloy Grades: 70mnmocr8 (1.2824)farshid KarpasandAún no hay calificaciones

- Anubhav Final ResumeDocumento2 páginasAnubhav Final ResumeAnubhav AroraAún no hay calificaciones

- GE8077 Total Quality Management L T P C 3 0 0 3Documento20 páginasGE8077 Total Quality Management L T P C 3 0 0 3Santosh SAún no hay calificaciones

- Metal CastingDocumento93 páginasMetal CastinghashimtkmceAún no hay calificaciones

![Practical Guide To Production Planning & Control [Revised Edition]](https://imgv2-2-f.scribdassets.com/img/word_document/235162742/149x198/2a816df8c8/1709920378?v=1)