Documentos de Académico

Documentos de Profesional

Documentos de Cultura

International Journal of Computing and Corporate Research IJCCR India

Cargado por

admin2146Descripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

International Journal of Computing and Corporate Research IJCCR India

Cargado por

admin2146Copyright:

Formatos disponibles

International Journal of Computing and Corporate Research IJCCR India

JIT PRACTICES IN INDIAN INDUSTRIES: A SURVEY

Bhupesh Lohar PhD Research Scholar, M.Com

ABSTRACT This paper examines the implementation of Just-in-Time (JIT) based managerial philosophies in the Indian industries. Specifically, JIT benefits and reasons for slow implementation of JIT in Indian industries are investigated through a on-line survey using www.questionpro.com. The results of this survey support the notion that JIT has potential to increase the organizational performance of Indian industries. However, to achieve this potential, Indian industry must be willing to modify their procedures and operations. In this research paper, the critical elements of the JIT in the context of Indian manufacturing industries were identified using a online survey approach. The online questionnaire was sent to the 78 industries and 33 industries responded. On the basis of the responses, critical elements were identified. Attempts have been made to examine the degree of importance and degree of difficulties in adoption of JIT; solutions were also suggested to overcome some of these problems. Keywords: companies, Critical elements, Just-in-time, JIT purchasing, JIT manufacturing

INTRODUCTION

Increasing international competition has forced the small companies to seek new ways to develop a competitive edge. Indian industries have also been adopting new

International Journal of Computing and Corporate Research IJCCR India

manufacturing approaches, managerial philosophies and information technology to survive in the emerging competitive market. However, Indian industries have not yet tested the full effect of popular JIT approach on performance of production system due to its limited implementation. Considering its potential in enhancing performance of organizing, investigation on the important JIT issues is essential. Survey has shown that JIT philosophy has the potential for increasing organization efficiency and productivity. However, JIT benefits do not just happen. Before an organization enjoys with the benefits of JIT, it must accept JIT as an organizational philosophy. This may require the organization to change its operational procedures, production system and in most cases work culture also. In this context, in many cases the plants layouts have to be changes, relations with suppliers and Kanban have to be implemented. Many researchers have reported that JIT has potential of reducing inventory- carrying costs. It is also instrumental in reducing lead time, decreasing set ups time, improving production quality, increasing productivity and enhancing customer responsiveness. Motivated by potential benefits of successful implementation of the JIT to the organizations and lack of research addressing the implementation problems in Indian context, survey of 33 industries was conducted. This survey has thrown some light on the degree of difficulty in implementation of JIT based managerial philosophy in Indian industries. The expected JIT benefit is really recognized that implementation is also examined in the study. Although it is really recognized that implementation of JIT in Indian industries is not an easy job yet number of attempts are being made in several Indian industries to implement the JIT in phased manner with belief that it would be helpful in facing the global competition.

PAST STUDIES IN INDIAN CONTEXT

A few papers are available on JIT practices which highlight the positive impact of JIT on Indian industries. Sharma and Singhvi (2009) conducted a case study on two Indian

International Journal of Computing and Corporate Research IJCCR India

agricultural equipment manufacturing companies, which have implemented JIT. In one case the profits of the company were found to have increased by 10%. While in the second case the company was successful in reducing the level of inventory by over 20% and reduction of waste up to 5%. The lead-time was also reduced to over 20%. Yasin and Small (2006) conducted on the basis of investigation of 86 organization of US public sector, that JIT is a form of managerialism, has the potential to increase the operational efficiency, service quality and organizational effectiveness of public sector organizations. Garg et al. (1998) have conducted a survey of 31 Indian industries to analyze the importance of the attributes pertaining to JIT purchasing and supplier evaluation criteria. The surveyed companies has given great importance to some attributes such as high quality, mutual trust, cooperated relationship, on time deliveries, supplier evaluation, stable production schedule, reliable network of suppliers, reduced delivery time, longterm contract and continuous improvement. The study has also indicated the scope of JIT as 70 on scale (0-100), which is predicted better compared to earlier studies. Chandra and Kodali (1997) have developed a multi-attribute decision model using analytical hierarchy process (AHP) for justification of JIT manufacturing system in Indian industries. The selection of important JIT attributes and sub-attributes were then used in AHP to achieve the related benefits. The results of the study have quantified the JIT benefits in descending order: increased profit margin, improved competitive position, quality improvement and reduction in inventory. Deshmukh (1996) has attempted review on the state of the art of JIT and its possible ramifications in the purchasing and manufacturing systems. It has been pointed out that JIT from a system perspective requires that suppliers and manufacturing functions must be in relation with design, planning and control. JIT must be viewed as a binding force coupling all the activities from incoming raw material to the finished goods.

International Journal of Computing and Corporate Research IJCCR India

Garg et al. (1996) have conducted a case study in JIT implementation of an Indian tractor assembly industry. Records of company have indicated that significant benefits are achieved by improvement in quality and productivity and reduction in inventory, material movement, space, manpower, work-in-process and lead-time. The key elements in JIT implementation were extensive training of employee on pull concepts; identification of key performance parameters; new layout based on U-shaped cells, visual control and multi-skill training. Garg et al. (1994) has explored the specific cultural required in JIT implementation and also reported their presence in Indian industries. They have stated that trust, locality, responsibility, development, motivation, authority, long-term relationship, and respect for human beings mark work culture required in JIT environment. It is critical for industries to make conscious efforts to change the work culture for successful implementation of JIT. These changes require top management commitment and worker participation in decision making and massive education and training to the people concerned. Vrat et al. (1993) have conducted a Delphi study to assess the applicability of implementing JIT elements in Indian context. The results have shown that quality circles and good communication are not very difficult to implement having a rating 30 and above on a 40 point scale. Top management attitude, multifunctional workers, long-term relationship with supplier and support from worker have high rating, which indicates that JIT implementation in India is not an impossible task. The study has also stressed on focusing more on error prevention, reduced set up time, Kanban system and quality of incoming material.

SURVEY OF JIT PRACTICES

JIT imposes a different set of requirements on the typical work culture. Work culture reflects the way of life of people, their norms and values regarding work in an organizational setting where technology and social cultural forces jointly, determine

International Journal of Computing and Corporate Research IJCCR India

managerial style and practices. In other words, work culture plays a significant role in successful implementation of JIT. Peoples and managers of different countries think differently, according to their social and cultural principles. Therefore the implementation of JIT in India may be different from its implementation in western countries. Such dissimilarity cause different types of implementation problems that would not be found in other society. This research paper, therefore attempts to analyze some important JIT issues in Indian context by conducting a on-line survey of 33 industries. The main objectives of this survey were: 1. To identify those elements, which are highly difficult to implement in Indian industries. 2. To search out most accountable reasons for its slow implementation in India. 3. To highlight the most expected JIT benefits.

RESEARCH METHODOLOGY

This study includes four phases: (a) On-line Questionnaire, (b) Data Collection, (c) Data Analysis and (d) Conclusions. First phase of this study was to review the literature related to JIT from several books, journals, reviews and relevant websites. Based on this reviews, various dimensions and related elements of this concept was identified. At last, using on-line survey, a questionnaire was prepared. The questions were on the companys profile, JIT benefits, JIT implementation and related problems. This on-line survey questionnaire was emailed to 78 industries located globally. Initially responses were poor. To get more responses various social networking websites were used and emails were sent to concern specific persons. In all 33 industries responses were completed and found suitable for study, making responses rate 80 per cent. The general profile of selected companies is given in table 1.

Table 1: General Profile of Companies

International Journal of Computing and Corporate Research IJCCR India

Types of Company

Automobile:7,

Heavy

Machines:9,

Electronics:6, Others:12 Awareness about JIT JIT purchasing Yes: 20, No: 11, May be: 2 Agree: 67%, Strongly Agree: 23%,

Disagree: 10% Training to employees Yes: 35%, No: 65%

Among 33 companies surveyed, seven were automobiles, nine heavy machines, six electronics and eleven others. Most of the respondents were aware about JIT.

ANALYSIS

The t-test is conducted at 5 per cent level of significance to analyze JIT issues such as difficulty in implementing the JIT elements, expected benefits of JIT implementation and reasons for the slow implementation of JIT in Indian industries. The following hypothesis was formulated for t-test: 1. H0 : No element of JIT listed in Table 2, is difficult to implement in Indian industry (The null hypothesis (H0) will rejected if JIT element subjected under test is not difficult to implement). 2. H0: All JIT benefits listed in Table 3 could not be achieved through JIT implementation (The H0 will be rejected if surveyed companies have achieved any expected JIT benefits). 3. H0: All causes listed in Table 4, are not responsible for slow implementation of JIT in Indian industries (The H0 will be rejected if surveyed companies face similar problem). Table 2: Degree of Difficulty in Implementing JIT Attributes by the Respondents

International Journal of Computing and Corporate Research IJCCR India

S.N0

JIT element s

Degree of difficult y Low High

No Respon se

Mean Score

t-value Calcula ted

Result Let H0=3

1

1. Automation

2 5 5 3 2 4 8 10 12 9

3 1 4 0 0 0 1 0 7 7

4 19 13 20 12 21 17 14 4 13

5 7 8 7 16 4 2 9 3 1 1 3 3 3 4 5 0 5 3 3.75 3.45 3.67 4.00 3.39 2.93 3.67 2.36 2.91 3.795* 1.763* 2.722* 3.829* 1.509

*

0

& reliable

H0= Rejected H1= Accepted

2.

Frequent delivery

0 0 0 0 0 0 2 0

H0= Accepted

3.

JIT purchasing

H0= Rejected H1= Accepted

4.

Kanban card or system

H0= Rejected H1= Accepted

5.

Set up time reduction

H0= Accepted

6.

Small lot sizes

-0.223* 3.217* -2.514* -0.406*

H0= Accepted

7.

Strong

buyer-supplier

H0= Rejected H1= Accepted

relationship 8. U-cells / Layout

H0= Accepted

improvement 9. Scheduling flexibility H0= Accepted

Significant at 5% level.

Table 3: Expected benefits of JIT implementation as perceived by respondents

International Journal of Computing and Corporate Research IJCCR India

S.N0

Expect ed Benefit s

Degree of difficult y Low High

No Respon se

Mean Score

t-value Calcula ted

Result Let H0=3

1

1. Improved Position 2. Increased inventory turn Competition

2 3

3 0

4 16

5 13 1 4.09 1 5.554* 3.260* 0.883* 3.032*

H0= Rejected H1= Accepted H0= Rejected H1= Accepted H0= Accepted

20

3.73 7

3.

Increased productivity

14

3.27 3

4.

Increased profit margin

15

12

3.81 8

H0= Rejected H1= Accepted

5.

Low scrap rate

17

2.96 9

0.112* 5.013* 2.029* 5.013* 2.727* 3.212*

H0= Accepted

6.

Reduced Inventories

15

11

3.75 7

H0= Rejected H1= Accepted H0= Accepted

7.

Reduced production lead time

18

3.48 5

8.

Reduced size

purchase

lot

22

3.90 9

H0= Rejected H1= Accepted H0= Rejected H1= Accepted H0= Rejected H1= Accepted

9.

Reduced material/parts

raw

15

10

3.69 6

10 .

*

Reduced work-in-process

19

3.78 7

Significant at 5% level.

International Journal of Computing and Corporate Research IJCCR India

Table 4: Reasons for slow implementation of JIT

S.N0 Reason s Degree of difficult y Low High No Respon se Mean Score t-value Calcula ted Result Let H0=3

1

1. High cost of

2 0 17

3 1 0

4 13 8

5 17 1 2 1 4.242 2.333 5.824* 3.148*

H0= Rejected H1= Accepted

0 6

implementation 2. Lack of production

H0= Accepted

technology 3. Lack of support from

14

11

2.394

2.789* 0.356* 4.321*

H0= Accepted

supervisors 4. Lack of support from

0 8

14 15

1 2

9 5

7 1

2 2

3.091 2.091

H0= Accepted

suppliers 5. Lack HRD of support and form R&D H0= Accepted

department 6. Lack of top management

10

14

1.939

5.326* 0.263* 4.458*

H0= Accepted

7.

Lack of training

0

JIT

12 4

2 0

14 21

3 7

2 1

3.060 3.848

H0= Accepted

8.

Lack

of

H0= Rejected H1= Accepted

understanding

International Journal of Computing and Corporate Research IJCCR India

9.

Traditional

methods

of

14

12

3.484

3.387*

H0= Rejected H1= Accepted

quality control

*

Significant at 5% level.

The result of t-test was given in table 2 to 4. The study indicates the JIT on 0-5 scale, implying that perfect implementation of JIT is slightly difficult in Indian industries. It has been found that JIT elements such as automation, JIT purchasing, Kanban system, strong buyer-supplier relationship are difficult to implement while other elements such as frequent and reliable delivery, set up time reduction, small lot sizes, U-cell/ layout improvement and scheduling flexibility are easy to implement in Indian industries. Similarly JIT benefits such as improved competition position, increased inventory turn, increased profits margin, reduced inventories, reduced purchase lot sizes, reduced raw material/parts and reduced work in progress are expected benefits. The results of the survey indicates that high cost of implementation, lack of JIT understanding and traditional methods of quality control are the major traditional reasons for slow implementation of JIT in Indian industries. Even with these problems, Indian industries are expecting significant benefits from JIT implementation. Statistical test confirm that scope of JIT in India is good. So attention must be focused on critical elements of JIT to reap maximum benefits.

DISADVANTAGE OF JIT IMPLEMENTATION

For more than a decade, JIT has been routed as prime way to keep costs down and assembly lines running smoothly. However, some researchers criticized that JIT methods have been considerable negative implication at various levels. Indian industries should be examined these issues prior to the implementation of JIT. These are: 1. Implementation of JIT does not automatically increase profits because benefits derived from JIT adoption may be offset by its many direct and indirect costs. In

International Journal of Computing and Corporate Research IJCCR India

addition the industries cannot expect favorable results just by implementation the JIT because it demands appropriate fit between new manufacturing practices and industry design structure and processes. Its success also depends critically on management commitment and employee empowerment. 2. JIT demands the delivery of high quality parts/raw material in small lots. The small lot size production requires increase in efficiency and reliability of production sustem to unrealistic level because multiple sourcing becomes difficult under JIT. 3. JIT programmes not one-time efforts that can be quickly implemented. Such programmes need continuous assessment to achieve a sustained improvement in quality. They require continuous close cooperation and communication at all levels of industries. 4. The JIT information system, kanban requires longer time to transmit any new information through the system as compared to centralized information processing system.

CONCLUSIONS AND RECOMMENDATIONS

The results of this survey support the notion that JIT has the potential to increase the operational efficiency, quality and organizational effectiveness of Indian industries while its some basic elements are slightly difficult to implement in existing production system of industries. To gain the benefits of JIT, Indian industries must be willing to modify their procedure for dealing with supplier, analysis of operations to identify the areas of standardization, simplification and automation and reengineering of operational processes and procedures are some important issues, which should be examined prior to implementation of JIT. If these issues are not adequately addresses the JIT efforts is bound to encounter human and supplier related problems. The potential benefits of JIT to Indian industries are not in doubt. However, the art of designing the right strategy for

International Journal of Computing and Corporate Research IJCCR India

implementation the JIT in Indian industries is debatable. Therefore, issues related to these concern are worthy of future research.

REFERENCES

1. Chandra, S. and Kodali, R. (1997): Implementation of JIT manufacturing system: An overview, Journal of Productivity, Vol.38, pp.312-321. 2. Deshmukh, S.G. (1996): Just-in-time: A survey, proc second SERC school advanced manufacturing techniques, Indian Institute of Technology, Bombay, pp.140-148. 3. Garg, D., Deshmukh, S.G. and Koul, O.N. (1996): Attributes for JIT purchasing and supplier evaluation: A survey, Journal of Productivity, Vol.38, pp.322-326. 4. Garg, D., Koul, O.N. and Deshmukh, S.G. (1998): JIT implementation a case study, Journal of Production and Inventory Management, Vol.22, pp.26-31. 5. Garg, S., Vart, P. and Kanda, A. (1994): Work culture in JIT environment, Journal of Productivity, Vol.35, pp.463-466. 6. Kaujalgi, V.B. and Lingraj, B.P. (1997): Implementation of JIT systems: A Case Study, Journal of Industrial Engineering, Vol.26, pp.8-11. 7. Mahadevan, B. (1997): Are Indian companies ready for just-in-time?, Management Review, July-Sept, pp.85-92. 8. Prasad, B. (1995): JIT quality matrices for strategic planning and

implementation, International Journal of Operation and Production Management, Vol.15, pp.116-142. 9. Sanjay Sharma and D.K. Singh, (2009), The scope of JIT implementation, Journal of Productivity, Vol.45, pp.628-633. 10. Singhvi, S, (1992): Employee involvement in JIT success: Eicher experience, Journl of Productivity, Vol.33, pp.369-371.

International Journal of Computing and Corporate Research IJCCR India

11. Voburba, R.J. and Davis, R.A. (1996): Just-in-time: The evolution of a philosophy. Journal of Production and Inventory Management, Vol.31, pp.57-69. 12. Vrat, P., Mittal, S. and Tyagi, K. (1993): Implementation of JIT in Indian environment: A Delphi study, Journal of Productivity, Vol.34, pp.251-256. 13. Yasin, M.M. and Wafa, M.A. (2006): An empirical examination of factors influencing JIT success, International Journal of Operations and Production Management, Vol.16, pp.23-24.

También podría gustarte

- Organization Development: Developing the Processes and Resources for High-Tech BusinessesDe EverandOrganization Development: Developing the Processes and Resources for High-Tech BusinessesAún no hay calificaciones

- Just in Time in Indian ContextDocumento8 páginasJust in Time in Indian ContextLithin GeorgeAún no hay calificaciones

- Effectiveness in Project Portfolio ManagementDe EverandEffectiveness in Project Portfolio ManagementCalificación: 5 de 5 estrellas5/5 (1)

- Jsir 63 (8) 655-662 PDFDocumento8 páginasJsir 63 (8) 655-662 PDFNaren RajAún no hay calificaciones

- Study of Jit Implementation Issues in Indian Manufacturing IndustriesDocumento5 páginasStudy of Jit Implementation Issues in Indian Manufacturing IndustriesRAJA RAMAún no hay calificaciones

- Jit in Indian Automobile IndustryDocumento10 páginasJit in Indian Automobile IndustryRoshni PatelAún no hay calificaciones

- JIT Techniques Practiced in Service IndustryDocumento4 páginasJIT Techniques Practiced in Service IndustrymechidreamAún no hay calificaciones

- A Road Map For The Implementation of Integrated JIT Lean Practices in Indian Manufacturing Industries Using The Best Worst Method ApproachDocumento18 páginasA Road Map For The Implementation of Integrated JIT Lean Practices in Indian Manufacturing Industries Using The Best Worst Method ApproachfaizanAún no hay calificaciones

- Performance Measures For Manufacturing Industries in India: A Case Study AnalysisDocumento12 páginasPerformance Measures For Manufacturing Industries in India: A Case Study AnalysisTJPRC PublicationsAún no hay calificaciones

- An Evaluation of Just in Time JIT ImplemDocumento17 páginasAn Evaluation of Just in Time JIT Implemaditya kaulAún no hay calificaciones

- An Analysis On JIT in Indian IndustriesDocumento3 páginasAn Analysis On JIT in Indian IndustriesInternational Journal of Innovative Science and Research Technology100% (1)

- Ejtaer 2 04Documento11 páginasEjtaer 2 04bijoyalokkan123Aún no hay calificaciones

- Jit ThesisDocumento4 páginasJit Thesisnikhil c pAún no hay calificaciones

- 03 Literature ReviewDocumento14 páginas03 Literature ReviewShweta Gupta100% (1)

- Tugas Introduction Literatur Review Research MethodDocumento6 páginasTugas Introduction Literatur Review Research MethodEvi Purnama Sari NstAún no hay calificaciones

- 196 IETET-385 PPDocumento6 páginas196 IETET-385 PPashifali777Aún no hay calificaciones

- Jasdeep SynopsisDocumento8 páginasJasdeep SynopsisNageshwar SinghAún no hay calificaciones

- Synopsis ON "A Detailed Study On Just in Time Production To Reduce Inventory Level in Cipla Limitd"Documento8 páginasSynopsis ON "A Detailed Study On Just in Time Production To Reduce Inventory Level in Cipla Limitd"Nageshwar SinghAún no hay calificaciones

- 17099761Documento37 páginas17099761Rosefazila RosliAún no hay calificaciones

- JIT Implements in Manufacturing Industry - A ReviewDocumento4 páginasJIT Implements in Manufacturing Industry - A ReviewMuhammadYazidBasthomiAún no hay calificaciones

- Uncertain Supply Chain Management: Theoretical Analysis of JIT Elements For Implementation in Maintenance SectorDocumento14 páginasUncertain Supply Chain Management: Theoretical Analysis of JIT Elements For Implementation in Maintenance Sectorvcpc2008Aún no hay calificaciones

- Bhaskar 2018Documento30 páginasBhaskar 2018Madhava RaoAún no hay calificaciones

- Project Management in CompaniesDocumento24 páginasProject Management in CompaniesMalvina GageanuAún no hay calificaciones

- Theoretical Analysis of JIT Elements For ImplementDocumento15 páginasTheoretical Analysis of JIT Elements For Implementartt211213Aún no hay calificaciones

- The Behavioral Aspect of Mergers andDocumento12 páginasThe Behavioral Aspect of Mergers andnisarg_Aún no hay calificaciones

- BPR HLBDocumento31 páginasBPR HLBMariam AlraeesiAún no hay calificaciones

- Uncertain Supply Chain Management: A State of Art Review On Optimization Techniques in Just in TimeDocumento12 páginasUncertain Supply Chain Management: A State of Art Review On Optimization Techniques in Just in Timevcpc2008Aún no hay calificaciones

- Just in Time Revisited: Literature Review and Agenda For Future ResearchDocumento5 páginasJust in Time Revisited: Literature Review and Agenda For Future ResearchJATINAún no hay calificaciones

- Barriers and Enablers in Implementation of Lean Six Sigma in Indian Manufacturing IndustriesDocumento9 páginasBarriers and Enablers in Implementation of Lean Six Sigma in Indian Manufacturing IndustriesIAEME PublicationAún no hay calificaciones

- Production Management Cia 1 Componment 1: Ravikrishnan. R 1520329 6 BBA CDocumento4 páginasProduction Management Cia 1 Componment 1: Ravikrishnan. R 1520329 6 BBA CNickAún no hay calificaciones

- Final Airtel ProjectDocumento93 páginasFinal Airtel ProjectSahil GuptaAún no hay calificaciones

- Assessing Benefits of Lean Six Sigma Approach in Manufacturing Industries: An Indian ContextDocumento19 páginasAssessing Benefits of Lean Six Sigma Approach in Manufacturing Industries: An Indian ContextstudentAún no hay calificaciones

- A Survey Study: Important Factors in Just-in-Time ImplementationDocumento7 páginasA Survey Study: Important Factors in Just-in-Time ImplementationSherly TriAún no hay calificaciones

- A Study of Lean Manufacturing Practice With Reference To Indian ManufacturingDocumento11 páginasA Study of Lean Manufacturing Practice With Reference To Indian ManufacturingRahul Ramesh PareraoAún no hay calificaciones

- 1 Implementation of BenchmarkingDocumento10 páginas1 Implementation of Benchmarkingpdhananjaya007Aún no hay calificaciones

- Success of Manufacturing Industries - Role of Six Sigma: N. Venkatesh and C. SumangalaDocumento15 páginasSuccess of Manufacturing Industries - Role of Six Sigma: N. Venkatesh and C. SumangalaPaneAún no hay calificaciones

- Jjmie: Japanese Manufacturing Techniques and Practices: An Indian PerspectiveDocumento8 páginasJjmie: Japanese Manufacturing Techniques and Practices: An Indian PerspectiveMego PlamoniaAún no hay calificaciones

- Performance Improvement Through 5S in Small Scale Industry: A Case StudyDocumento8 páginasPerformance Improvement Through 5S in Small Scale Industry: A Case Studyr s ojhaAún no hay calificaciones

- The Impact of Just in Time On The Inventory Management: The Case of Al Tayar Plastic Mfg. CoDocumento9 páginasThe Impact of Just in Time On The Inventory Management: The Case of Al Tayar Plastic Mfg. CoMuhammad HamzaAún no hay calificaciones

- The Relationship Between JIT Production and Manufacturing Strategy and Their Impact On JIT Performance Ayman Bahjat Abdallah and Yoshiki MatsuiDocumento35 páginasThe Relationship Between JIT Production and Manufacturing Strategy and Their Impact On JIT Performance Ayman Bahjat Abdallah and Yoshiki Matsuidanni_bbAún no hay calificaciones

- Jit - cASE STUDY PDFDocumento12 páginasJit - cASE STUDY PDFprakruthiAún no hay calificaciones

- Technology-Productivity Conundrum in India'S Manufacturing Under Globalization A Preliminary Exploration Using Innovation System PerspectiveDocumento25 páginasTechnology-Productivity Conundrum in India'S Manufacturing Under Globalization A Preliminary Exploration Using Innovation System PerspectiveFernando Hernández TaboadaAún no hay calificaciones

- Application of Goal Programming in Manufaturing SystemDocumento17 páginasApplication of Goal Programming in Manufaturing SystemCboy GamingAún no hay calificaciones

- Intelligent SourcingDocumento14 páginasIntelligent SourcingthereisaneedAún no hay calificaciones

- Manufacturing Performance Improvement Through Lean Production-2009Documento11 páginasManufacturing Performance Improvement Through Lean Production-2009Juan BarronAún no hay calificaciones

- Continuous Improvement in Just in Time Manufacturing (Jit), A Systematic Literature ReviewDocumento19 páginasContinuous Improvement in Just in Time Manufacturing (Jit), A Systematic Literature ReviewAlisson Huamanchumo CruzAún no hay calificaciones

- 153 523 2 PBDocumento7 páginas153 523 2 PBmoshrafAún no hay calificaciones

- Continuous Improvement Approach - State-Of-Art Review and Future ImplicationsDocumento24 páginasContinuous Improvement Approach - State-Of-Art Review and Future Implicationsnouamane beghitiAún no hay calificaciones

- The Role of Accounting Information SysteDocumento17 páginasThe Role of Accounting Information SysteJean Diane JoveloAún no hay calificaciones

- A Systematic Review On Just in Time (JIT) : Swapnil S. Dange Prof. Prashant N. Shende, Chetan S. SethiaDocumento5 páginasA Systematic Review On Just in Time (JIT) : Swapnil S. Dange Prof. Prashant N. Shende, Chetan S. SethiaputrilarastikaAún no hay calificaciones

- Jit Production To Reduce Inventory Level-SynopsisDocumento5 páginasJit Production To Reduce Inventory Level-SynopsisNageshwar SinghAún no hay calificaciones

- Facilitating Lean Top Management 01030220132Documento10 páginasFacilitating Lean Top Management 01030220132Unnathi ShettyAún no hay calificaciones

- Researchpaper DR - NausheenNizamiDocumento18 páginasResearchpaper DR - NausheenNizamiEr Devender RajputAún no hay calificaciones

- Lean Manufacturing Case 01Documento13 páginasLean Manufacturing Case 01Astrid KumalaAún no hay calificaciones

- PROJECT On Mutual FundDocumento60 páginasPROJECT On Mutual Fundroopa deviAún no hay calificaciones

- International Journal of Management (Ijm) : ©iaemeDocumento9 páginasInternational Journal of Management (Ijm) : ©iaemeIAEME PublicationAún no hay calificaciones

- Reflective Review of Total Quality Management, Information Technology Organizational Performance Relationship in Jordanian CourtsDocumento8 páginasReflective Review of Total Quality Management, Information Technology Organizational Performance Relationship in Jordanian CourtsAllen CarlAún no hay calificaciones

- Tugas Introduction Literatur ReviewDocumento4 páginasTugas Introduction Literatur ReviewEvi Purnama Sari NstAún no hay calificaciones

- Factors affecting future of JIT inventory management in automobile industryDocumento34 páginasFactors affecting future of JIT inventory management in automobile industrynikhil c pAún no hay calificaciones

- Capital Budgeting Decisions Impact on Manufacturing Firm ProfitabilityDocumento11 páginasCapital Budgeting Decisions Impact on Manufacturing Firm ProfitabilitysidAún no hay calificaciones

- 9Documento10 páginas9admin2146Aún no hay calificaciones

- Project Mismanagement: Eight To Late: International Journal of Computing and Corporate Research IJCCR IndiaDocumento8 páginasProject Mismanagement: Eight To Late: International Journal of Computing and Corporate Research IJCCR Indiaadmin2146Aún no hay calificaciones

- Balance Sheet of The Next Millennium - Perspective, Possibilities and ProblemsDocumento7 páginasBalance Sheet of The Next Millennium - Perspective, Possibilities and Problemsadmin2146Aún no hay calificaciones

- Web Search Engines Evaluation Based On Features and End-User ExperienceDocumento19 páginasWeb Search Engines Evaluation Based On Features and End-User Experienceadmin2146Aún no hay calificaciones

- 6Documento27 páginas6admin2146Aún no hay calificaciones

- Fuzzy Cognitive Maps Based Cricket Player Performance EvaluatorDocumento15 páginasFuzzy Cognitive Maps Based Cricket Player Performance Evaluatoradmin2146Aún no hay calificaciones

- 4Documento14 páginas4admin2146Aún no hay calificaciones

- 7Documento17 páginas7admin2146Aún no hay calificaciones

- International Journal of Computing and Corporate Research IJCCR IndiaDocumento20 páginasInternational Journal of Computing and Corporate Research IJCCR Indiaadmin2146Aún no hay calificaciones

- 3Documento15 páginas3admin2146Aún no hay calificaciones

- 112Documento15 páginas112Jai ShankarAún no hay calificaciones

- A Common Fixed Point Theorems in 2-Metric Spaces Satisfying Integral Type Implicit RelationDocumento12 páginasA Common Fixed Point Theorems in 2-Metric Spaces Satisfying Integral Type Implicit Relationadmin2146Aún no hay calificaciones

- Analysis and Study of Incremental DBSCAN Clustering AlgorithmDocumento15 páginasAnalysis and Study of Incremental DBSCAN Clustering Algorithmadmin2146Aún no hay calificaciones

- Security and Ethical Issues in It: An Organization'S PerspectiveDocumento13 páginasSecurity and Ethical Issues in It: An Organization'S Perspectiveadmin2146Aún no hay calificaciones

- 41Documento15 páginas41admin2146Aún no hay calificaciones

- Analysis of Literature Review of Consumption Pattern - An Important Indicator of Economic DevelopmentDocumento14 páginasAnalysis of Literature Review of Consumption Pattern - An Important Indicator of Economic Developmentadmin2146Aún no hay calificaciones

- Secure Data in Wireless Sensor Network Via DesDocumento25 páginasSecure Data in Wireless Sensor Network Via Desadmin2146Aún no hay calificaciones

- Comparative Study of Distribution of Indian Stock Market With Other Asian MarketsDocumento20 páginasComparative Study of Distribution of Indian Stock Market With Other Asian Marketsadmin2146Aún no hay calificaciones

- Green Information Technology: A Strategy To Become Socially Responsible Software OrganizationDocumento17 páginasGreen Information Technology: A Strategy To Become Socially Responsible Software Organizationadmin2146Aún no hay calificaciones

- Image Fusion Algorithm Based On Biorthogonal Wavelet: Vol. 1 Issue 2 January 2011Documento6 páginasImage Fusion Algorithm Based On Biorthogonal Wavelet: Vol. 1 Issue 2 January 2011admin2146Aún no hay calificaciones

- Emerging Cloud Computing: Vol. 1 Issue 2 January 2011Documento17 páginasEmerging Cloud Computing: Vol. 1 Issue 2 January 2011admin2146Aún no hay calificaciones

- A Comparative Study of Performance Measurement in Selected Professional Management Institutions: A Case Study of Karad CityDocumento6 páginasA Comparative Study of Performance Measurement in Selected Professional Management Institutions: A Case Study of Karad Cityadmin2146Aún no hay calificaciones

- Faculty Recruitment and Retention: A Key For Managing Talent in Higher EducationDocumento14 páginasFaculty Recruitment and Retention: A Key For Managing Talent in Higher Educationadmin2146Aún no hay calificaciones

- 36Documento19 páginas36admin2146Aún no hay calificaciones

- Counselling: A Key Tool For Today'S Managers: Vol. 1 Issue 2 January 2011Documento13 páginasCounselling: A Key Tool For Today'S Managers: Vol. 1 Issue 2 January 2011admin2146Aún no hay calificaciones

- This Way or That Way - A Re-Look at Some Popular Formulae in Finance and CostingDocumento9 páginasThis Way or That Way - A Re-Look at Some Popular Formulae in Finance and Costingadmin2146Aún no hay calificaciones

- Effect of Distance Measures in Pca Based Face: RecognitionDocumento15 páginasEffect of Distance Measures in Pca Based Face: Recognitionadmin2146Aún no hay calificaciones

- Intelligent Illumination System To Prevail Over Possible Diseases Due To Over-And Under-IlluminationDocumento15 páginasIntelligent Illumination System To Prevail Over Possible Diseases Due To Over-And Under-Illuminationadmin2146Aún no hay calificaciones

- Wireless Cellular Technologies For Enhancement of Spectral Density at Reduced CostDocumento14 páginasWireless Cellular Technologies For Enhancement of Spectral Density at Reduced Costadmin2146Aún no hay calificaciones

- EBRD-Business Environment Performance Survey 2008-2009Documento276 páginasEBRD-Business Environment Performance Survey 2008-2009dmaproiectAún no hay calificaciones

- Dissertation Project Report On Spencer's FinalDocumento95 páginasDissertation Project Report On Spencer's FinalShubhansh Sahai100% (4)

- Third Culture KidsDocumento26 páginasThird Culture KidsJoar BonifacioAún no hay calificaciones

- Crane Failure and Accident in ConstructionDocumento14 páginasCrane Failure and Accident in ConstructionKien Trung NguyenAún no hay calificaciones

- Job PreferenceDocumento18 páginasJob PreferenceSamima AkteriAún no hay calificaciones

- MATH-7_Q4_M2Documento4 páginasMATH-7_Q4_M2reynaldoanub9Aún no hay calificaciones

- Dettol - Consumer Evaluation For Brand ExtensionDocumento9 páginasDettol - Consumer Evaluation For Brand ExtensionRohit0% (1)

- @final Dissertation PDFDocumento69 páginas@final Dissertation PDFT.Wai NgAún no hay calificaciones

- Caribbean Studies Internal AssessmentDocumento31 páginasCaribbean Studies Internal AssessmentSarah SeunarineAún no hay calificaciones

- Pre Oral-DissertationDocumento17 páginasPre Oral-DissertationLeizel CustodioAún no hay calificaciones

- Sonalika Rhino-Rx Market AnalysisDocumento86 páginasSonalika Rhino-Rx Market AnalysisVivek ThakurAún no hay calificaciones

- JMJ Marist Brothers College of Business Administration Notre Dame of Marbel UniversityDocumento16 páginasJMJ Marist Brothers College of Business Administration Notre Dame of Marbel Universitytim mendoza0% (1)

- Thesis New Feb 1, 2013Documento50 páginasThesis New Feb 1, 2013ramilfleco97% (35)

- Differences Between Qualitative and Quantitative ResearchDocumento13 páginasDifferences Between Qualitative and Quantitative ResearchBea Cassandra EdnilaoAún no hay calificaciones

- Bovee bct12 tb13Documento31 páginasBovee bct12 tb13MahmoudTahboubAún no hay calificaciones

- (Bill Gillham) Research Interview (Real World Rese (BookFi) PDFDocumento105 páginas(Bill Gillham) Research Interview (Real World Rese (BookFi) PDFrolando jordan100% (1)

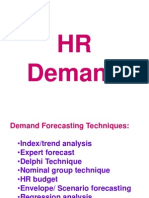

- HRDocumento9 páginasHRniranjanaAún no hay calificaciones

- Reviewer in PR 2Documento11 páginasReviewer in PR 2Ciara ManangoAún no hay calificaciones

- Action Paper g2 Final OutputDocumento67 páginasAction Paper g2 Final Outputjay diazAún no hay calificaciones

- Compressed Report PDFDocumento42 páginasCompressed Report PDFSiddhant PanditAún no hay calificaciones

- Food Safety and Sanitation in Toril Public MarketDocumento31 páginasFood Safety and Sanitation in Toril Public MarketJocelyn BalsaAún no hay calificaciones

- SASADocumento22 páginasSASAJelly Mea VillenaAún no hay calificaciones

- Final exam ABHSDocumento20 páginasFinal exam ABHStemesgen AsmamawAún no hay calificaciones

- A Measure of Service Quality For Retail Stores - Scale Development and Validation (Dabholkar 1995) PDFDocumento14 páginasA Measure of Service Quality For Retail Stores - Scale Development and Validation (Dabholkar 1995) PDFJoe NguyenAún no hay calificaciones

- Research Proposal Cats EyeDocumento11 páginasResearch Proposal Cats EyeMOHAMMAD SAIFUL ISLAM100% (1)

- Advertising Creativity MattersDocumento13 páginasAdvertising Creativity MattersDiana LeheneAún no hay calificaciones

- TTLM - MARKET RESEARCHDocumento46 páginasTTLM - MARKET RESEARCHPrafful MehraAún no hay calificaciones

- Shubhamfunde Final ProjectDocumento45 páginasShubhamfunde Final Projectshiv infotech100% (2)

- New Recipe for Healthier SumanDocumento55 páginasNew Recipe for Healthier SumanRich Bagui73% (11)

- Learner GuideDocumento53 páginasLearner Guidesegwate manasoAún no hay calificaciones