Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Valvula de Compuerta Api 150 Tapa Atornillada Con Bridas BW

Cargado por

sergio abel ramirez zapataTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Valvula de Compuerta Api 150 Tapa Atornillada Con Bridas BW

Cargado por

sergio abel ramirez zapataCopyright:

Formatos disponibles

Gate Valve Type Bolted Bonnet

Fig. CBB150 CLASS 150 DN 50-600 (2”–24”)

Carbon Alloy & Stainless Steel

API 600, API 603,

ASME B16.34 & BS 1414

JLX VALVE ,S.L. TD-JLX-DS-CBB150 Rev.0

e-mail: info@jlx-valve.com Data given can be changed without notice.

Web : www.jlx-valve.com

Page 1 / 4

Gate Valve Type Bolted Bonnet

Fig. CBB150 CLASS 150 DN 50-600 (2”–24”)

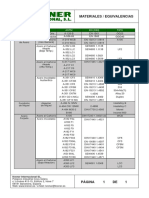

Parts & Materials

Material of construction *

Item Description

Carbon Steel Carbon Steel (Low Tem p.) Alloy Steel Stainless Steel

1 Body A 216 Gr.WCB A 352 Gr.LCB A 217 Gr.C5 A 351 Gr.CF8M

2 Bonnet A 216 Gr.WCB A 352 Gr.LCB A 217 Gr.C5 A 351 Gr.CF8M

3 Wedge A 216 Gr.WCB + ER410 A 352 Gr.LCB + ER308 A 217 Gr.C5 + ER410 A 351 Gr.CF8M

4 Yoke A 216 Gr.WCB A 352 Gr.LCB A 217 Gr.C5 A 351 Gr.CF8M

5 Stem A 182 Gr.F6a A 182 Gr.F304 A 182 Gr.F6a A 182 Gr.F316

6 Seat Ring A 105 + Stellite A 182 Gr.F304 A 182 Gr.F6a + Stellite -----

7 Stem Nut B 148 / A 439 Gr.D2 B 148 / A 439 Gr.D2 B 148 / A 439 Gr.D2 B 148 / A 439 Gr.D2

8 Backseat A182 Gr.F6a A182 Gr.F304 A 182 Gr.F6a -----

9 Gland A 105 A 105 A 182 Gr.F6a A 182 Gr.F316

10 Gland Flange A 105 A 105 A 105 A 182 Gr.F304

11 Stem Packing Graphite Graphite Graphite Graphite

12 Gasket SS 304 / Graphite SS 304 / Graphite SS 304 / Graphite SS 316 / Graphite

13 Bonnet Bolt & Nut A 193 Gr.B7 / A 194 Gr.2H A320 Gr. L7 / A194 Gr. 7 A 193 Gr.B7 / A 194 Gr.2H A 193 Gr.B7 / A 194 Gr.2H (3)

14 Eye Bolt & Nut A 193 Gr.B7 / A 194 Gr.2H A 193 Gr.B7 / A 194 Gr.2H A 193 Gr.B7 / A 194 Gr.2H A 193 Gr.B7 / A 194 Gr.2H

15 Handw heel Carbon Steel Carbon Steel Carbon Steel Carbon Steel

(3) Zinc coating

* Standard constructions with Trim 8, 2 and 10, other options are available

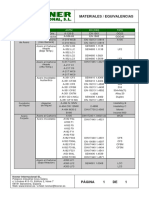

API 600 Stem

Nom inal Trim Seating Surface Body/Wedge

Trim No. Backseat (1)

1 F6 13Cr 13Cr

2 304 18Cr-8Ni 18Cr-8Ni

3 F310 25Cr-20Ni 25Cr-20Ni

4 Hard F6 13Cr Hard 13Cr

5 Hardfaced 13Cr Co-Cr A (2)

5A Hardfaced 13Cr Ni-Cr

6 F6 and Cu-Ni 13Cr 13Cr and Cu-Ni

7 F6 and Hard F6 13Cr 13Cr and Hard 13Cr

8 F6 and Hardfaced 13Cr 13Cr and Co-Cr A (2)

8A F6 and Hardfaced 13Cr 13Cr and Ni-Cr

9 Monel Ni-Cu Alloy Ni-Cu Alloy

10 316 18Cr-8Ni-Mo 18Cr-8Ni-Mo

11 Monel and Hardfaced Ni-Cu Alloy Ni-Cu Alloy and Trim 5 or 5A

12 316 and Hardfaced 18Cr-8Ni-Mo 18Cr-8Ni-Mo and Trim 5 or 5A

13 Alloy 20 19Cr-29Ni 19Cr-29Ni

14 Alloy 20 and Hardfaced 19Cr-29Ni 19Cr-29Ni and Trim 5 or 5A

15 Hardfaced 18Cr-8Ni Co-Cr A (2)

16 Hardfaced 18Cr-8Ni-Mo Co-Cr A (2)

17 Hardfaced 18Cr-10Ni-Cb Co-Cr A (2)

18 Hardfaced 19Cr-29Ni Co-Cr A (2)

(1) and small internal parts that no rmally co ntact the service fluid

(2) Trademark material Stellite 6

Carbon &

Stainless Steel

Construction Alloy Steel

Construction

JLX VALVE ,S.L. TD-JLX-DS-CBB150 Rev.0

e-mail: info@jlx-valve.com Data given can be changed without notice.

Web : www.jlx-valve.com

Page 2 / 4

Gate Valve Type Bolted Bonnet

Fig. CBB150 CLASS 150 DN 50-600 (2”–24”)

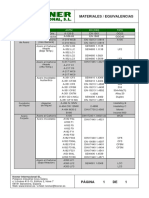

Dimensions

DN A B C ØD WEIGHT

50 (2”) 178 216 386 200 17

65 (2½") 190 241 435 200 27

80 (3”) 203 282,5 483 250 33

100 (4”) 229 305 587 250 48

125 (5") 254 381 673 300 65

150 (6”) 267 403 767 300 78

200 (8”) 292 419 955 350 120

250 (10”) 330 457 1146 450 176

300 (12”) 356 502 1328 500 260

350 (14") 381 572 1519 460 380

400 (16") 406 610 1721 460 530

450 (18") 432 660 1900 460 620

500 (20") 457 711 2116 610 810

550 (22") 483 762 2315 610 1050

600 (24") 508 813 2480 610 1150

650 (26") 559 -- 2700 610 1380

700 (28") 610 -- 2975 610 1980

750 (30") 610 -- 3102 610 2200

900 (36") 711 -- 3668 710 2800

(*) Dimensions in mm and weight in kg

For other sizes consult to the technical department.

JLX VALVE ,S.L. TD-JLX-DS-CBB150 Rev.0

e-mail: info@jlx-valve.com Data given can be changed without notice.

Web : www.jlx-valve.com

Page 3 / 4

Gate Valve Type Bolted Bonnet

Fig. CBB150 CLASS 150 DN 50-600 (2”–24”)

General Characteristics, CV & PT Rating

DESIGN STANDARDS

Valves design API 600 API 603 ASME B16.34 EN ISO 10434

End to End Dimensions ASME B16.10 ISO 5752

Flanged Dimensions ASME B16.5 ISO 7005- Pat. 1 BS 3293 MSS SP-44

Buttw eld Dimensions ASME B16.25

Visual Inspection MSS SP- 55

Marking MSS SP-25 ISO 5209

TESTS AND CERTIFICATES

Pressure testing API 598 ISO 5208 EN 12266-1 MSS SP-61

Others CE

Cv VALUES IN US Gallons/min

DN Cv DN Cv

50 (2”) 250 300 (12”) 12050

65 (2½") 450 350 (14") 15100

80 (3”) 620 400 (16") 20300

100 (4”) 1160 450 (18") 25000

125 (5") 1900 500 (20") 32500

150 (6”) 2700 550 (22") 40000

200 (8”) 5100 600 (24") 48500

250 (10”) 8050

PRESSURE - TEMPERATURE (Standard Class According to ASME B16.34)

Pressure-Tem perature (STANDARD CLASS According to ASME B16.34)

MATERIAL

Tem p

A216 WCB A352 LCB A217 C5 A351 CF8M (**)

ºC Bar Bar Bar Bar

-29 to 38 19,6 18,3 20,0 18,9

95 17,9 17,2 17,9 16,2

150 15,8 15,8 15,8 14,8

205 13,8 13,8 13,8 13,4

260 11,7 11,7 11,7 11,7

315 9,6 9,6 9,6 9,6

345 8,6 8,6 8,6 8,6

375 7,6 7,6 7,6

400 6,5 6,5 6,5

425 5,5 5,5 5,5

450 4,5 4,5 4,5

485 3,4 3,4 3,4

510 2,4 2,4 2,4

540 1,4 1,4 1,4

565 1,4 * 1,4 *

595 1,4 * 1,4 *

620 1,4 * 1,4 *

650 1,4 * 1,4 *

675 1,4 *

705 1,4 *

735 1,4 *

760 1,4 *

790 1,4 *

815 1,4 *

* FOR WELD END VALVES ONLY. FLANGED END RATINGS TERMINATE AT 540ºC

JLX VALVE ,S.L. TD-JLX-DS-CBB150 Rev.0

e-mail: info@jlx-valve.com Data given can be changed without notice.

Web : www.jlx-valve.com

Page 4 / 4

También podría gustarte

- Soldadura MAG de estructuras de acero al carbono. FMEC0210De EverandSoldadura MAG de estructuras de acero al carbono. FMEC0210Aún no hay calificaciones

- Bladesmithing: Secretos del tratamiento térmico de la forja de cuchillosDe EverandBladesmithing: Secretos del tratamiento térmico de la forja de cuchillosAún no hay calificaciones

- Mat EqDocumento1 páginaMat EqIván Gómez de la CruzAún no hay calificaciones

- Caracteristicas AceroDocumento1 páginaCaracteristicas AceroGerman DiBaccoAún no hay calificaciones

- Equivalencia MaterialesDocumento1 páginaEquivalencia MaterialesGuillermo GutierrezAún no hay calificaciones

- Equivalencia MaterialesDocumento1 páginaEquivalencia MaterialesGuillermo GutierrezAún no hay calificaciones

- Materiales Equivalentes, AcerosDocumento1 páginaMateriales Equivalentes, AcerosJuan Pablo SanchezAún no hay calificaciones

- Especificacion de Materiales y Tabla de CompatibilidadDocumento2 páginasEspecificacion de Materiales y Tabla de CompatibilidadLis RincónAún no hay calificaciones

- Tabla Especificacion de Materiales y Tabla de CompatibilidadDocumento2 páginasTabla Especificacion de Materiales y Tabla de CompatibilidadArmando JoyaAún no hay calificaciones

- Ecoline GT 125E - C600.1 - 1-30Documento4 páginasEcoline GT 125E - C600.1 - 1-30Ruddy Fabrizio Galvez JustinianoAún no hay calificaciones

- TABLA ASTM Designación de MaterialesDocumento5 páginasTABLA ASTM Designación de MaterialesCesar Soto100% (2)

- 12 SoldaduraDocumento16 páginas12 SoldaduraEdgard Miguel Vizcaíno BermejoAún no hay calificaciones

- Resumen Proceso GmawDocumento9 páginasResumen Proceso GmawJuan Carlos Quiñonez LaraAún no hay calificaciones

- Walworth 5301Documento2 páginasWalworth 5301jonathan jose barrios alvarezAún no hay calificaciones

- Valvulas de GloboDocumento4 páginasValvulas de GloboSebastian Pedraza RamirezAún no hay calificaciones

- Walworth Compuerta A126 #125Documento3 páginasWalworth Compuerta A126 #125JOSE GABRIELAún no hay calificaciones

- Válvula de Retención - Clase 600 - WALWORTHDocumento1 páginaVálvula de Retención - Clase 600 - WALWORTHiMaJeniDeasAún no hay calificaciones

- ARTICULO: 2229A Válvula de Compuerta Con Extremos Bridados ANSI 150Documento3 páginasARTICULO: 2229A Válvula de Compuerta Con Extremos Bridados ANSI 150prancesiAún no hay calificaciones

- ARTICULO: 2229A Válvula de Compuerta Con Extremos Bridados ANSI 150Documento3 páginasARTICULO: 2229A Válvula de Compuerta Con Extremos Bridados ANSI 150Ecuatoriana de ComercioAún no hay calificaciones

- Silo - Tips Valvulas de Compuerta Clase 150Documento5 páginasSilo - Tips Valvulas de Compuerta Clase 150jackmarko castillo rosalesAún no hay calificaciones

- Compuerta API EspDocumento5 páginasCompuerta API EspSQUALO_122Aún no hay calificaciones

- Valvulas Compuerta Api Esp PDFDocumento5 páginasValvulas Compuerta Api Esp PDFJR RZAún no hay calificaciones

- Vayremex Valvula de Seguridad Roscada 211 Hoja TecnicaDocumento2 páginasVayremex Valvula de Seguridad Roscada 211 Hoja Tecnicacarlos___smAún no hay calificaciones

- Astm GradesDocumento2 páginasAstm Gradeswilber gomezAún no hay calificaciones

- Vayremex Filtro Roscado S CatalogoDocumento6 páginasVayremex Filtro Roscado S CatalogoFrancisco Misael Vasquez RanirezAún no hay calificaciones

- Compuerta 300 API 603Documento5 páginasCompuerta 300 API 603Martin AndradeAún no hay calificaciones

- Equivalencias de AcerosDocumento1 páginaEquivalencias de AcerosRaul AliasAún no hay calificaciones

- Especificaciones AstmDocumento8 páginasEspecificaciones Astmrambo1978Aún no hay calificaciones

- Pub011-001-04 - 1104 SPDocumento8 páginasPub011-001-04 - 1104 SPCARLOS CASTILLO MARTINEZAún no hay calificaciones

- Valvulas de Cortina PDFDocumento5 páginasValvulas de Cortina PDFChristian VegaAún no hay calificaciones

- Cubicacion CañeriasDocumento8 páginasCubicacion CañeriasJose LibrosAún no hay calificaciones

- Manual Tecnico de Electrodos AJUSTADO 4.0Documento117 páginasManual Tecnico de Electrodos AJUSTADO 4.0david50% (2)

- VálvulasDocumento2 páginasVálvulasenriqueAún no hay calificaciones

- Catalgo de Tornillo y TuercasDocumento131 páginasCatalgo de Tornillo y TuercasAdrian Franco MolinaAún no hay calificaciones

- ChapasDocumento13 páginasChapasglarrea5535Aún no hay calificaciones

- Válvulas HD 1 Páginas 8 9Documento2 páginasVálvulas HD 1 Páginas 8 9emmanuel799Aún no hay calificaciones

- Walworth 5275 CatalogoDocumento2 páginasWalworth 5275 Catalogojonathan jose barrios alvarezAún no hay calificaciones

- Conversión de RotulasDocumento6 páginasConversión de RotulasjaimeAún no hay calificaciones

- Valvula Esclusa F5Documento2 páginasValvula Esclusa F5juan mattiacciAún no hay calificaciones

- Binoxvip082400 15Documento3 páginasBinoxvip082400 15Javier GalvezAún no hay calificaciones

- I InformaciónDocumento64 páginasI InformaciónAlex VelillaAún no hay calificaciones

- Válvulas Globo PDFDocumento9 páginasVálvulas Globo PDFDamianAún no hay calificaciones

- Equivalencia de MaterialesDocumento1 páginaEquivalencia de MaterialesFernando ChavezAún no hay calificaciones

- SOLDADURADocumento28 páginasSOLDADURARobert Caro88% (8)

- Bolher Welding SSDocumento40 páginasBolher Welding SSvictor torres camizanAún no hay calificaciones

- 8 - 1 Carburo de CalcioDocumento8 páginas8 - 1 Carburo de CalcioTai FloresAún no hay calificaciones

- Válvulas Acero PDFDocumento8 páginasVálvulas Acero PDFRoberto PelaezAún no hay calificaciones

- Comparativo ValvulasDocumento2 páginasComparativo ValvulasEduard John Vega LisencioAún no hay calificaciones

- Métodos de unión y desunión de elementos fijos estructurales. TMVL0309De EverandMétodos de unión y desunión de elementos fijos estructurales. TMVL0309Calificación: 5 de 5 estrellas5/5 (1)

- Oficios Artísticos. Forja: Las técnicas de la forja explicadas paso a pasoDe EverandOficios Artísticos. Forja: Las técnicas de la forja explicadas paso a pasoCalificación: 5 de 5 estrellas5/5 (1)

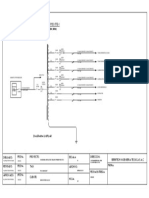

- Informe Tecnico de Instalaciones Electricas en LocalDocumento1 páginaInforme Tecnico de Instalaciones Electricas en Localsergio abel ramirez zapataAún no hay calificaciones

- InformeDocumento9 páginasInformesergio abel ramirez zapataAún no hay calificaciones

- Cuadro de CargasDocumento1 páginaCuadro de Cargassergio abel ramirez zapataAún no hay calificaciones

- Medidor Trifasico Hexing HXE33K ADocumento4 páginasMedidor Trifasico Hexing HXE33K Asergio abel ramirez zapataAún no hay calificaciones

- Diagrama UnifilarDocumento1 páginaDiagrama Unifilarsergio abel ramirez zapataAún no hay calificaciones

- s71200 System Manual es-ES es-ES PDFDocumento1658 páginass71200 System Manual es-ES es-ES PDFAlberto LiottaAún no hay calificaciones

- La Tecnología EducativaDocumento2 páginasLa Tecnología Educativaalfredo uzcateguiAún no hay calificaciones

- W 26-180 MVT 606473260 Amoladora Angular EspagnolDocumento2 páginasW 26-180 MVT 606473260 Amoladora Angular EspagnolEduardo Antonio Duran SepulvedaAún no hay calificaciones

- Las Mujeres en Ciencias, Técnologia, Ingenería y Matemáticas en América Latina y El CaribeDocumento98 páginasLas Mujeres en Ciencias, Técnologia, Ingenería y Matemáticas en América Latina y El CaribeMario BenitezAún no hay calificaciones

- Practica 1 Arranque de Un MotorDocumento12 páginasPractica 1 Arranque de Un MotorIEA-1-Jorge Díez BarcenillaAún no hay calificaciones

- EjerciciosTema1 2 ResueltosDocumento4 páginasEjerciciosTema1 2 ResueltosMayte MerchanAún no hay calificaciones

- El Agustino TM - Comunicado N°29 2022Documento8 páginasEl Agustino TM - Comunicado N°29 2022Teka ProductionsAún no hay calificaciones

- 5 Movimiento Parabólico 1Documento6 páginas5 Movimiento Parabólico 1Carmen PárragaAún no hay calificaciones

- "Minicartilla de Word".Documento9 páginas"Minicartilla de Word".Blanca Zoraida Mahecha BenitoAún no hay calificaciones

- Metodo de Kaplan - MeierDocumento11 páginasMetodo de Kaplan - MeierMarcoOrozcoBritoAún no hay calificaciones

- 1.2 Circuito Serie, Paralelo y MixtoDocumento5 páginas1.2 Circuito Serie, Paralelo y MixtoMartha SánchezAún no hay calificaciones

- Granulometría EscalonadoDocumento15 páginasGranulometría EscalonadoDaniel AquizeAún no hay calificaciones

- Taller 4 Estadística I (Industrial G2)Documento1 páginaTaller 4 Estadística I (Industrial G2)Daniela Rodriguez EscobarAún no hay calificaciones

- 07 Modelo 3D BIMDocumento9 páginas07 Modelo 3D BIMAlexandra Miranda HuertaAún no hay calificaciones

- 283 856 1 PBDocumento18 páginas283 856 1 PBDiana Maria Fernandez PerezAún no hay calificaciones

- MATEMATICASDocumento3 páginasMATEMATICASSalatyel Verde LópezAún no hay calificaciones

- 1 Tecnologia JunioDocumento2 páginas1 Tecnologia JunioRoberto Antonio Doncel RuizAún no hay calificaciones

- Efb PPP MuñoamoscosoangelapilarDocumento2 páginasEfb PPP MuñoamoscosoangelapilarDiviertete y aprende con LucianaAún no hay calificaciones

- Crucigrama 2Documento6 páginasCrucigrama 2jaime Andres Ortega RodriguezAún no hay calificaciones

- Actividad #5 - Factores de RiesgosDocumento7 páginasActividad #5 - Factores de RiesgosPerdomo ManuelAún no hay calificaciones

- Sebastian Londoño Requerimiento Eventos 2021Documento6 páginasSebastian Londoño Requerimiento Eventos 2021diego armando rojas gomezAún no hay calificaciones

- Transporte Anedk S.A.C. E001-108Documento1 páginaTransporte Anedk S.A.C. E001-108Juan Edwin Navarro PerezAún no hay calificaciones

- Comprension Lectora Cuaderno de Trabajo Secundaria 5Documento26 páginasComprension Lectora Cuaderno de Trabajo Secundaria 5jenny ivonne silupu lazoAún no hay calificaciones

- Acu Eficiente Gestion Turistica de La Zona Ecologica de Chancay BañosDocumento2 páginasAcu Eficiente Gestion Turistica de La Zona Ecologica de Chancay BañosIsaías Irigoín BarbozaAún no hay calificaciones

- HiveDocumento6 páginasHiveManuel CorreaAún no hay calificaciones

- Actividad3 - Calculo Diferencialeintegral PDFDocumento10 páginasActividad3 - Calculo Diferencialeintegral PDFjose luisAún no hay calificaciones

- Guia de Ejercicios FPDocumento3 páginasGuia de Ejercicios FPleunam1987Aún no hay calificaciones

- MQ-01 Manual-Calidad ESCO Argentina S.A. Rev.09 PDFDocumento24 páginasMQ-01 Manual-Calidad ESCO Argentina S.A. Rev.09 PDFMartin ArganarazAún no hay calificaciones

- Manual de Normas y Procedimientos Que Rigen Las Bases Legales de La MMCVDocumento56 páginasManual de Normas y Procedimientos Que Rigen Las Bases Legales de La MMCVDailiana QuintAFAún no hay calificaciones

- Estructuración Del Proyecto Del Sistema en DesarrolloDocumento11 páginasEstructuración Del Proyecto Del Sistema en Desarrollojunior 1026Aún no hay calificaciones

- Foda Coordinación Técnica 2023Documento4 páginasFoda Coordinación Técnica 2023Andrea GALLARDO C.Aún no hay calificaciones