Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Tesla Semi ATIS Patent

Cargado por

Maria Merano100%(1)100% encontró este documento útil (1 voto)

19K vistas19 páginasTesla Semi ATIS Patent

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoTesla Semi ATIS Patent

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

100%(1)100% encontró este documento útil (1 voto)

19K vistas19 páginasTesla Semi ATIS Patent

Cargado por

Maria MeranoTesla Semi ATIS Patent

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

Está en la página 1de 19

«2 United States Patent

Furtado

‘USO11254170B2

US 11,254,170 B2

Feb. 22, 2022

(10) Patent No.:

(4s) Date of Patent:

(54) AUTOMATIC TIRE INFLATION SYSTEM.

WITH THRU-HUB AIR FEED

(7D) Applicant: Testa, Ine, Austin, TX (US)

(72) Inventor: John Furtado, San Francisco, CA (US)

(73) Assignoe: ‘Testa, Ine. Austin, TX (US)

(4) Notice: Subject to any disclaimer the tem of this

patent is extended or adjusted under 35

USC. 184(b) by 224 days

(21) Appl. No. 189952,366

(22) Filed: Apr. 13, 2018

ws) Prior Publication Data

US 201810297423 AL et. 18, 2018

Related U.S. Application Data

(60) Provisional application No. 62/485,272, fled on Apr.

13,2017

(1) Ine.

BoC 2300 (2006.01)

‘Boon 2700 (2006.01)

FIC 19236 (2006.01)

FI6C 19/38 (2006.01)

(2) Us.CL.

CPC) Rear 28000363 (202005), BoB 270047

(2013.01); Boon 27/0073 (2013.01. B6OC

23/0084 (2020.05). BoB 27/001 (2013.01)

BOOB 2380/14 (2013.01); BOOB 2380/64

(2013.01); FI6C 19/364 (2013.01); F16C

198385 (2013.01)

(58) Field of Classification Seareh

23100354; FI6C 19/364; BGO 27/001;

1608 2380/14: B6OE 2380/64; BOOB

2710073; BODE 27/0037

‘See application file for complete seurc history

60) Referenees Cited

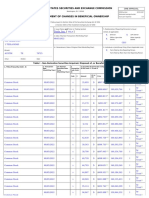

US. PATENT DOCUMENTS.

294457 4 + 71960. Wunibald eae 25008

126

459107 A+ 441986. Scully BB50C 25.09

1524815

5287906 A 21904 och

Same A 11905 Stok

S50nAaD A * 41996 Callaut Be 25003 |

1524817

$538.08 A 711996 Stoh

Seto A 121996 Ingram

(Continued)

Primary Esaminer — Kip T Kowter

(74) Atornes, Agent, or Firm — Kuobe, Martens, Olson

& Bear, LLP

on ABSTRACT

An Automatic Tire Inflation System (ATIS) for use with a

Vehicle includes 4 controller, valves controlled by the con

twoller and, for at least one drive axle having inner bearings

and outer bearings, a channel formed in a spindle, frst

hosing coupling controlled by the controller tothe channel

‘ormed inthe spindle, channel formed ina hub, a rotary ir

seal coupling the channel formed in the spindle to the

channel formed in che hub, and second hosing coupling the

channel formed in the hub to a least one wheel, The rotary

air seal may transition from a sealed state that forms a seal

between the spindle and the hub to support air How between

the channel formed in the spindle and the ehannel formed in

hhub and reside in an unsealed state to negate the scal

Deween the spindle and the hub.

cre 'B6OC 28008; B6OC: 23/007: B6OC

23/0087; BOOC 23100863; BOOT 14 Claims, 10 Drawing Sheets

bd

a

202 208 22

© ro mRE(s)

US 11,254,170 B2

Page 2

66) References Cited

USS. PATENT DOCUMENTS.

579797 A 811908 Quinn

SRosRT A 21989 Bradley

6262691 Bi 2001 Sowaldhe ea

oassa3e BL £2002

faunas 22004

892.78 B2_ $2008

D2ig9s B22 122015 Hs0¢ 2v04s

2mo1st739 AL* 72010 "BED 23.003

280 124.95

2oisiorsi9a7 ait 2015, 50029502

spat?

20190200086 AL* 102015 Taberidis Fig 19324

1217

20190382911 AL* 122018. Bitlingmaier ... BOOB 2710073

12417

* cited by examiner

US 11,254,170 B2

Sheet 1 of 10

Feb. 22, 2022

U.S. Patent

‘DIA

agLb~f pbb

‘O9Lb f OPLL 4

I pl

Ovor avor 3) awauiva Voor

x8 x08 xa

uvz0 v39 wv39

l | Orr NBISAS NOLLTANI ll

! Ser zor ULL OLLWNOLNY vor

' YOLOW YOLOWN XOLON

3ATNa 3arud BOF solNouLoava 3arua

l ! —TT

VObL

aoLL—t

Webb

‘avlb

Vel

ool

US 11,254,170 B2

Sheet 2 of 10

Feb. 22, 2022

U.S. Patent

@ Old

SIATA

YATIONNOD —L gqz

208

002,

U.S. Patent Feb. 22, 2022 Sheet 3 of 10 US 11,254,170 B2

No eee om *

a 7 302

U.S. Patent Feb. 22, 2022 Sheet 4 of 10 US 11,254,170 B2

400

ons

1

IS

aw

US 11,254,170 B2

Sof 10

Sheet

Feb. 22, 2022

U.S. Patent

U.S. Patent Feb. 22, 2022 Sheet 6 of 10 US 11,254,170 B2

600

MONITOR AIR PRESSURE

IN WHEELS/TIRES

‘SUPPLY PRESSURIZED AIR TO

WHEELS/TIRES REQUIRING AIR

FIG. 6

U.S. Patent Feb. 22, 2022 Sheet 7 of 10 US 11,254,170 B2

U.S. Patent Feb. 22,2022 Sheet 8 of 10 US 11,254,170 B2

=>

i- FR

I

I ;

ae

12 4

eset eee eee

FIG. 7B

708

-

I I

I |

I I

714 u

KN .

VME

U.S. Patent Feb. 22, 2022 Sheet 9 of 10 US 11,254,170 B2

800

\

FIG. 8A

U.S. Patent Feb. 22, 2022 Sheet 10 of 10 US 11,254,170 B2

=n

Se

at

—— EG AC —si0 —__ !

---17997-3

4

I

r

1

1

:

I

US 11,254,170 B2

1

AUTOMATIC TIRE INFLATION SYSTEM

WITH THRU-HUB AIR FEED

CROSS-REFERENCE TO RELATED

"APPLICATION

‘he present application claims priority pursuant to 35

USC, 120 to US, Provisional Patent Application No.

62/485,272, entitled “AUTOMATIC TIRE. INFLATION

SYSTEM WITH THRU-HUB AIR FEED", filed 13 Ape

2017, which is incorporated herein by reference in its

‘entirety for all pueposes

BACKGROUND

Technical Field

The present invention relates to vehicles; and more par-

ticularly to the automatic inflation of vehicle tires

Description of Related Art

Cars and tucks have wheels and sires that interface with

roadways. The tires are typically inf listed with aor another

s. Generally, tires are most ellcient and provide the best

fnlerface when inflated to a target pressure(s). Some land

based vehicles include more than four wheels, eg., semi

tractors that include four, eight, more rear wheels. All of

these rear wheels are typically powered, with four wheels

and tres driven by a single axle or via a single diflereatil

AA single engine may drive the ear whovls via one or more

‘drive shafts and differentials. Maintaining the taget pressure

(6) on all of these ties is dificult, Thus, Automatic Tire

Inflation Systems (ATISs) have been developed in. un

attemp to maintain the target air pressure in all of the tres,

Examples of such prior ATISs are disclosed in one or more

‘of prior U.S. Pat. Nos. 5,287,906, 5,584,949, 5,797,398,

5,797,979, 6,698,482, 5,377,736, 5,538,062, 5868881,

6.260.601; 6,435,238 and 6,892,778

“These prior solutions had a numberof shortcomings, With

some prior aft technigues ai was fed through hollow drive

axles to a fting located on the end thereof. The fiting Was

then coupled to the air inlets of the tires. To couple the air

‘nto the hollow drive axles, a rotatingly attached fing

‘coupled air fom an sir storage to the inside of the hollow

ales. This fitting was subject to Jeakewe of contaminants,

‘These contaminants interfered with the operaion of the

ATIS and eventually caused the ATIS to fal,

SUMMARY,

Ths, in order to overcome the shortcomings described

‘above among other shortcomings, an Automatic Tige laf

tion System (TIS) for use witha vehicle searing toa fist

‘described embodiment includes a controller, valves con-

trolled by the controller, the valves having an air supply

‘ne, and a plurality of air outlets. Purther the ATIS includes,

for at least one drive axle having inner bearings and outer

bearings, channel formed ina spindle first hosing coupling

a valve of the valves controlled by the controller © the

‘channel formed in the spindle, a channel formed in a hub, 3

rotary air seal residing between the inner bearings and the

‘outer bearings and coupling the ehannel formed in the

spindle tothe channel formed inthe hub, and second hosing

‘coupling the channel formed inthe hub to at least one wheel

“Ths, as compared tothe prior ATIS systems, the ATIS of

the frst embodiment, significantly reduces contamination i

0

o

2

the ATIS sir stream, Redction in contamination extends the

life of the ATIS, extends spindle life, extends hub life, and

extends serviced wheeVire lives and extends maintenance

intervals

“Accoeding to some optional aspects of the first embod

ment, fist iting couples the first hosing to the channel

formed in the spindle, 8 second fitting couples the second

hosing to the channel formed in the hub, andr the second

hosing provides connections for multiple wheels.

‘According to another optional aspect of te frst embodi-

‘ment, the spindle is tapered, the inner bearings comprise

inner tpered roller bearings, and the outer bearings com-

prise outer tapered roller bearing,

According to sill another optional aspect, the spindle is

straight and the inner bearings and outer bearings comprise

8 unitized bearing set. With this optional aspect, 2 frst

channel couples the channel formes! in the spindle to the

‘lary ar seal and a second channel that couples the channel

formed in the hub to the rotary ar sel

‘According (© yet another optional aspect of the fest

embodiment, the rotary air seal is configured to reside in a

sled state to form a seal between the spindle and the bub

fo support sir How between the channel formed in the

spindle and the channel formed in hub and reside in an

‘unsealed state to negate the seal berween the spindle and the

hub. With this optional aspect, tansiioning the rotary air

seal from the unsealed state to the sealed state may be

performed only when a serviced vehicle is stationary oF a

Speed of the serviced vehicle is below a threshold speed.

Funter, with this optional aspect, the rotary air seal may be

periodically transitioned between the sealed state and the

‘unsealed state

“According to still another optional aspect of the frst

embodiment, the rotary air seal includes first side and a

second side, each of the first side and the second side

including a fist stationary portion sealed to an inner wall of

the hub, a second stationary partion sealed to an inner wall

of the spindle, and a movable portion coupled t0 the first

Stationary portion

"According to a socond embodiment of the present diselo-

sure, an ATIS inelules a cont central by the

controll, the valves hav

plurality fair outlets. The ATIS of the second embodiment

Turther includes, for at least one deve axle, hub, a spindle,

4 unitized bearing set having inner bearings and outer

bearings coupled between the spindle and the hub, a frst

channel, and’ a second channel, a channel formed in the

spindle and coupled to the first channel of the unitized

bearing set frst hosing coupling a valve of the valves

controlled by the controller to the channel formed in the

spindle, channel formed in a hub coupled to the second

channel ofthe unitized bearing se, rotary air veal residing

Within the unitized bearing set coupling the frst channel of

the tnitized bearing set othe second channel of the united

bearing set, and second hosing coupling the channel formed

inthe hub to at feast one wheel

‘The second embodiment as well as the third and fourth

embodiments deseribed later herein provide benefits sub-

Stanially the same a those of the frst embodiment. The

reader will appreciate that the second through fourth

embodiments may provide additonal benefits a well,

“According oa ist optional aspect of the second embodi-

‘ment, the rotary air seal is configured to reside in a sealed

state to form a seal between the first channel ofthe united

bearing and the second ehiaane of the unitized bearing and

reside in an unsealed state to negate the seal betwen the frst

channel of the unitized bearing and the second channel ofthe

US 11,254,170 B2

3

nitized bearing. Wi this first optional aspect, the rotary a

seal may include a first side and a second side, each of the

first side and the second side including a first stationary

portion seafed 1 first inner wall ofa unitized bearing set,

‘a second stationary portion sealed to a second inner wall of

the unitized bearing set, and a movable portion coupled 10

the frst stationary portion,

“According to third embodiment of the present disclo-

sure, a method for operating an ATIS for use witha vehicle

includes monitoring air pressure of atleast one tire, doter

‘ining that inflation of the at last one tre is required, and

‘opening at least one valve to allow aieto Row. Te ai Hows

‘along. a path from an air supply to a channel formed in a

spindle via frst hosing, from the channel formed in the

spindle to a rotary ait seul, from the rotary ai seal to @

‘channel formed in hub, and from the channel formed in the

hub to the atleast one tire via second hosing,

"Aceoing to fist optional aspect of the third embod

rent, prior to the opening of the at least one valve to allow

tir to low, transitioning the rotary air seal from an unsealed

Sate to a sealed slate to establish a seal between a channel

ormed inthe spindle to the channel formed in the hub, and

after infladon is completed, transitioning the rotary ai seal

from the sealed state tothe unsealed state to negate the seal

between a channel formed in the spindle to the channel

ormed inthe bub, Transitioning the rotary ai seal from the

unsealed state to the sealed state may be performed only

when a serviced vehicle is stationary or a speed of the

serviced vehicle is below a threshold speed. Alternately, oF

in addition, the rotary ai seal may periodically transition

between the sealed state andthe unsealed state.

“According toa fourth embodiment ofthe present diselo-

sure, a method for operating an ATIS for use witha vehicle

includes monitoring air pressure of atleast one tre, deter

‘mining that inflation of the at least one tee is required, and

‘opening atleast one valve to allow aieto low. The air flows,

from an air supply toa channel formed ina spindle vi frst

hosing, from the channel formed in the spindle to a fist

‘channel of a unitized bearing, from the fist channel of the

‘nitized bearing to a rotary ai seal, from the rotary aie seal

twa second channel ofthe unitized bearing, fom the second

‘canal of de unitized bearing o a chanel Formed in a bub,

land from the channel formed in the hub to the atleast one

tire via second hosing.

“According to frst optional aspect of the fourth embod

iment, prior to the opening of the at least one valve to allow

tir to How, transitioning the rlary air seal from an unsealed

Sate to a sealed slate lo establish a seal between a fist

‘channel of a unitized bearing and a second channel of the

‘unitized bearing and after inflation is completed, tanstion-

ing the rotary sir seal from the sealed state tothe unsealed

state to negate the seal between the first channel of the

tnitized hearing and the second channel of the unitized

bearing

‘According to a second optional aspect of the fourth

‘embodiment, transitioning the rotary air seal from the

tunscaled state to the scaled state is performed only when &

serviced vehicle is stationary or a speed of the serviced

Vehicle is below a threshold speed. Alternately, or in addi-

tion, the rotary air seal may periodically transition beeen

the sealed state and the unsealed sate,

BRIEF DESCRIPTION OF THE SEVERAL

VIEWS OF THE DRAWINGS

FIG. 1 illustrates the basic components of battery

powered electric vehicle,

0

4

FIG, 2 illustrates an Automatic Tire Inllation Syste

(ATIS) constructed and operating according (at least one

sisclosed embodiment

FIG. 3 is a partial cross-sectional view of a spindle, 3

unitized bearing set, and a rotary air seal according 10 a

eseribed embodiment

FIG. 4 is a partial cross-sectional view of an avle, 2

unitizod bearing set, and a rotary ai seal according 10 a

described embodiment

FIG. 8A is a panial cross-sectional view of an axle,

united bearing set, and a rotary air sel in an unsealed state

sccording ta described embodiment

FIG. 8B is a partial crosssectional view of an axle, a

mitized hearing sel, and rotary air sal in a sealed state

according to a deseribed embodiment

FIG. 6 is a flow char illustrating operation of an ATIS.

according 9 one or more described embodiments

FIG. 7A isa partial erss-sectional view of an axle of an

ATIS according to a deseribed embodiment

FIG. 7H is a partial erosesectional view detailing the

tized bearing set of FIG. 7A,

PIG. 7C is 8 partial crost-sectional view detailing 3

portion ofthe unitized bearing set of FIGS. 7A and 7B.

FIG. 8A isa paral crossrectional view of an anle of an

ATIS according to a deseribed embodiment

FIG. 8B is a partial crost-sectional view detwiling a

packed bearing set of FIG. BA.

FIG. 8C is # partial crost-seetional view detsiling 3

portion ofthe packed bearing set of FIGS. 8A and 8B.

DETAILED DESCRIPTION OF TH

DISCLOSURE

FIG, 1 illustrates the basic components of a batery

powered electric vehicle (electric vehicle) 100. The electic

Vehicle 100 includes at least one drive motor (action

moter) 102A, 1028 andlor 102C, at least one gear box

104A, 1048, andlor 104C coupled toa corresponding dive

motor 102A, 1028, andor 102C, a battery 106 and elec-

{ironies 108. Generally, the battery 106 provides electricity to

the electronics 108 of the electric vehicle 100 and to propel

the electric vehicle 100 using the drive motors 102A, 1028

andlor 102C. The elecisic vehicle 100 includes a lange

‘oumber of iter components that are not described. herein

‘but nown to one or ordinary skill. While the eonsiruet of the

clectrc vehicle 100 of FIG. 1 is shown to have ten whook,

Aifering electri vehicles may have fewer or more than ten

‘whools Further, differing typos of electric vehicles 100 may

incorporate the inventive concepts deseribed herein,

The vehicle also includes an ATIS 110 that provides

controlled inflation to tires 112A, 112B, 4A. 114B, 114C.

TAD, 6A, 6B, 116C, and 116D. According toa fist

aspect of the present disclosure, the ATIS 110 ineludes

controller and valves controlled by the controller, the valves

having an air supply inlet, and a plurality of air outlets

Funker, the ATIS includes, for at feast one drive axle having

inner bearings and outer bearings, a channel formed in

spindle, firs hosing coupling the valves to the channel

{ormed in the spindle, channel formed ina hub, a rotary ar

seal residing between the inner bearings and the outer

bearings and coupling the channel formed in the spindle to

the channel formed inthe hub, and second hosing coupling

the channel formed inthe hob to at least one fre. Various

aspects of the ATIS of the present disclosure will be

‘eseribed further with reference to FIGS. 2 through 6. By

{eding air through the channel foamed in the spindle, the

rolary ae seal that resides between the inner bearing and the

US 11,254,170 B2

5

‘outer bearing, and the channel formed in the spindle, the isk

‘of contamination is significantly reduced, Particularly. the

inner bearing and outer bearing include seals that assist in

preventing contamination of the rotary air seal, Further,

‘without the requizement of hollow axle, the complexity of

the ATIS ofthe present diselosure as compared to the prior

ATISs is reduced.

IG, 2 illustrates an ATIS 200 constricted and operating

according 1 a disclosed embodiment. ‘Two difering

‘embodiments of the ATIS 200 are showa in FIG. 2. A first,

‘embovdiment ofthe ATIS 202 is for a rst drive configuration

having tapered spindle with tapered roller bearings and dhe

second embodiment ofthe ATIS 282 is fora straight spindle

with a unitized bearing set 268. A single air tank 204

‘contoller 208, and valves 209 service both embodiments

202 and 282,

The first embodiment of the ATIS 202 includes the

‘controller 205 and valves 209, The valves 209 are controlled

by the controller 208, have an air supply inlet, anda plurality

Oo ai outlets, Each air outlet couples to eomesponding >

hosing 206, 210, 212, and 208. Further, the TIS. 202

includes, for at least one drive axle 214 having inner

bearings 222 and outer bearings 223, a channel 207 formed

Jina spindle 216, first hosing 206 coupling the valves 209 10

the channel 207 formed in the spindle 216, a channel 224

Tormed in a hb 218, a rotary air seal 226 residing betwee!

the inner bearings 222 and the outer bearings 223 and

‘coupling the channel 207 formed in the spindle 216 to the

‘channel 224 formed in the hub 218, and second hosing 228

‘coupling the channel 224 formed in the hub 218 to at leat

‘one wheelie (not shown in FIG. 2 but shown in FIG. 1),

The ATIS 202 may also include a first fiting coupling the

first hosing 206 to the channel 207 formed in the spindle

216, The ATIS may also ineludea second fiting coupling the

second hosing 228 tothe channel 224 formed in the hub 218.

‘The second hosing may include connections for multiple

tires such as those illustrated in FIG. 1, The hosing inclaes

‘chock valves that allow air to be supplied to the serviced

tires and to prevent the back-flow of air frm the serviced

tires to the servicing hosing. The ATIS 202 (or 252) may

include one or more one-way check valves to support How

‘of air from the ae tank 204 to the ties and to prevent air low

fom the tres back into the ATIS 202 (or 252). In other

‘embodiments, sir is allowed (0 conttollably flow in the

reverse direction to reduve ar pressure in the serviced ties

With the ATIS 202 of the first embodiment, the spindle

216 is tapered and the inner bearings 222 and the outer

bearings 223 are tapered roller bearings that couple the

Spindle 216 to the hb 218, The bearings 222 and 223, the

spindle 216, and the hub create a volume 225 that is

substantially isolated ffom the external environment. The

rotary air seal 226 resides within this volume 225 and,

because it is isolated from the external environment, bas

extended life

‘As will be described with reference to FIGS. 3 and 4, the

rotary air seal 226 may be operable in two states; a sealed

‘ate and an unsealed state In the sealed state, the rary

seal 226 provides a substantially sittight seal between the

spindle 216 and the hub 218 10 support the tansfer of ait

from the channel 207 inthe spindle 216 to the channel 224

Jn the hub 218, Inthe unsealed state, the rotary air seal 226

‘does not provide such a sea. In various operations, in onder

‘o support the inflation ofthe serviced tre and to extend life

‘of the rotary ar seal 226, the rotary air seal 226 may be kept

jn the unsealed state unl wireless sensom in the serviced

tires indicate tht inflation ofthe tires is required. In sch

‘eae, the roaty’ air seal 226 would be transitioned to the

0

o

6

sealed state to provide air for inflation. The controller 208

‘may control the state of the rotary sit seal 226.

‘Various rules may be implemented to maximize life of the

rary air seal 226, In one operation, the rotary sir sel 226

‘would be transitioned from the unsealed state to the sealed

state only when the serviced vehicle is trveling at a rela-

tively low speed or stopped. Altematively the rotary ar seal

226 would be transitioned from the unsealed state to the

sealed state when a tire requires inflation and transitioned

back to the unsealed state after inflation is completed,

independent of the movement ofthe vehicle, Further, there

may be differing levels of the sealed state, based upon the

required air pressure needed to inflate the serviced ties,

Which would also extend the life ofthe rotary aie eal 226

‘The ATIS 252 of the second embodiment incades ele

‘meats similar to those of the ATIS 202 of the first embod

‘meat. However, with the ATIS 282 of the second embed

‘ment, the spindle 284 is not tapered and the inner bearings

and outer bearings comprise a unitized bearing set 268 that

‘couples the spindle 254 to he hub 288. With the ATIS 282,

the unitized bearing set 268 includes a channel 286 that

couples the channe! 287 formed in the spindle 284 to the

charine! 260 formed a the hub 258 vi a rotary ai seal 272

Funher, the witized bearing set 268 creates a volume 270 in

Which the rotary air seal 272 resides, the volume 270

protecting the rotary ar seal 272 fom the exteral environ-

‘meat, The rotary aie seal 272 ofthe ATIS 282 may further be

‘operable in both a sealed state and an unsealed state

‘With the embodiments of FIG. 2, air pressure sensors at

cach wheel may detet air pressure in a tre andlor temper-

ture of the tre and wirelessly broadeast this information to

the controller 205, The controller 205 then controls the

valves 209 0 contol pressure at each wheel end indepen-

ently to direct si to serviced tires 0 that they ate at

selected air pressure, For dual tires, ¢, H4AVI14B, 116A)

6B, 14C/114D, or H6C/IL6D of FIG. 1, a single whoo!

end may service two (or more tres). Further, valves may be

tached to or integrated into each wheel end that may be

‘opened through wireless or pneumatic signal to allow pres-

strized air to flow fom the ar tank 204 tothe wheel ends

to inflate serviced tires. In such eas, the valves 208 may be

replaced or augmented by controllable valves at the wheel

ends,

FIG. 3 is a partial cross-sectional view of a spindle, a

unitized bearing set, and a rotary aie seal according 10 a

‘eseribed embodiment, The strctire 300 of FG. 3 inelides

‘a unitized beating set 302 that resides berwcen spindle 304

‘nd hub (not shown). Channel 308 is formed in the spindle

to support the fow of ar from an air supply through a frst

channel 312 formed in an inner portion of the unitized

bearing set 302, through a rotary air seal 306, and through

‘second channel 310 formed inthe unitized bearing set 302

‘This air path is employed to inflate one o more serviced

"The rotary air seal 306 may be operable in two states; a

sealed state and an unseated state, In the sealed stat, the

rotary air seal 306 provides a substantially airtight seal

between the spindle 304 and the nl suppor the tanster

‘of sir from the channel 308 in the spindle 304 to a channel

in the hub Inthe unsealed state, the rotary air seal 306 does

not provide such a seal. In various operations, in order 10

support the inflation of the serviced tres and to extend life

‘ofthe totay ar seal 306, the rotary ar seal 306 may be kept

in the unsealed state unil wireless sensors in the serviced

tires indicate that inflation ofthe tres is required. In sich

case, the rotary air seal 306 would be transitioned to the

También podría gustarte

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Twitter Claps Back at Elon Musk's Termination of $44B DealDocumento7 páginasTwitter Claps Back at Elon Musk's Termination of $44B DealMaria MeranoAún no hay calificaciones

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2259)

- Inflation Reduction Act 2022Documento273 páginasInflation Reduction Act 2022Maria MeranoAún no hay calificaciones

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (266)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- Tesla Semi MY2023 VIN DecoderDocumento3 páginasTesla Semi MY2023 VIN DecoderMaria MeranoAún no hay calificaciones

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- Final Verified Complaint - TwitterDocumento62 páginasFinal Verified Complaint - TwitterZerohedge100% (1)

- Starlink Gets Contract With US Air Force After Proving Its Metal in UkraineDocumento5 páginasStarlink Gets Contract With US Air Force After Proving Its Metal in UkraineMaria Merano100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (345)

- Lucid Fourth Quarter and Full Year 2022 Financial ResultsDocumento6 páginasLucid Fourth Quarter and Full Year 2022 Financial ResultsMaria MeranoAún no hay calificaciones

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2104)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (589)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (842)

- Economic Transformational Report - September 2023Documento208 páginasEconomic Transformational Report - September 2023Julia HuffmanAún no hay calificaciones

- Twitter Argues Against Elon Musk's Plea To Schedule Trial in 2023Documento10 páginasTwitter Argues Against Elon Musk's Plea To Schedule Trial in 2023Maria MeranoAún no hay calificaciones

- 2022 Tesla Impact ReportDocumento224 páginas2022 Tesla Impact ReportMaria Merano100% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (401)

- Tesla Considers Building Battery Grade Lithium Refining Facility in TXDocumento46 páginasTesla Considers Building Battery Grade Lithium Refining Facility in TXMaria Merano100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5806)

- The Boring Company Wastewater Disposal PermitDocumento8 páginasThe Boring Company Wastewater Disposal PermitMaria MeranoAún no hay calificaciones

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1091)

- Tesla Hornsdale Battery The First To Deliver Inertia Services at ScaleDocumento48 páginasTesla Hornsdale Battery The First To Deliver Inertia Services at ScaleMaria MeranoAún no hay calificaciones

- NHTSA Releases AEB System Requirements To Be Implemented by 2029Documento317 páginasNHTSA Releases AEB System Requirements To Be Implemented by 2029Maria MeranoAún no hay calificaciones

- Western Australia Zero Emission Vehicle Rebate (E120) ApplicationDocumento2 páginasWestern Australia Zero Emission Vehicle Rebate (E120) ApplicationMaria MeranoAún no hay calificaciones

- Part 573 Safety Recall Report 22V-333Documento3 páginasPart 573 Safety Recall Report 22V-333Joey KlenderAún no hay calificaciones

- Car Insurance - Rise of EVs ReportDocumento6 páginasCar Insurance - Rise of EVs ReportMaria MeranoAún no hay calificaciones

- RIVIAN R1T Release Note 2023.38.0Documento2 páginasRIVIAN R1T Release Note 2023.38.0Maria MeranoAún no hay calificaciones

- US Treasury's Anticipated Battery Guidance For EV Tax CreditsDocumento8 páginasUS Treasury's Anticipated Battery Guidance For EV Tax CreditsMaria MeranoAún no hay calificaciones

- Rivian R1S Camp Kitchen PatentDocumento28 páginasRivian R1S Camp Kitchen PatentMaria MeranoAún no hay calificaciones

- Toyota Sets Ambitious BEV Sales Goal by 2026Documento2 páginasToyota Sets Ambitious BEV Sales Goal by 2026Maria MeranoAún no hay calificaciones

- RCLRPT 23V110 3395 PDFDocumento4 páginasRCLRPT 23V110 3395 PDFMaria MeranoAún no hay calificaciones

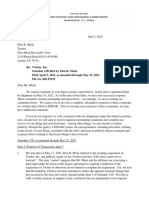

- Letter From US Securities Exchange Commission Feb 22 2023Documento2 páginasLetter From US Securities Exchange Commission Feb 22 2023Maria MeranoAún no hay calificaciones

- BFF 12Documento5 páginasBFF 12Maria MeranoAún no hay calificaciones

- RCLRPT 23V040 5903Documento3 páginasRCLRPT 23V040 5903Maria MeranoAún no hay calificaciones

- N 22 46Documento21 páginasN 22 46Maria MeranoAún no hay calificaciones

- Arcimoto Bankruptcy WarningDocumento32 páginasArcimoto Bankruptcy WarningMaria MeranoAún no hay calificaciones

- Agenda Item Report and Backup Information PDFDocumento8 páginasAgenda Item Report and Backup Information PDFMaria MeranoAún no hay calificaciones

- Elon Musk Form 4 Filings August 5 2022Documento15 páginasElon Musk Form 4 Filings August 5 2022Maria MeranoAún no hay calificaciones

- Faraday Future Delays Production of Debut EV Citing Supply Chain IssuesDocumento44 páginasFaraday Future Delays Production of Debut EV Citing Supply Chain IssuesMaria MeranoAún no hay calificaciones

- SEC Questioned Elon Musk's Commitment To The Twitter Deal in JuneDocumento2 páginasSEC Questioned Elon Musk's Commitment To The Twitter Deal in JuneMaria MeranoAún no hay calificaciones