Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Concrete Preparation General

Cargado por

Tahar BerrachediDescripción original:

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Concrete Preparation General

Cargado por

Tahar BerrachediCopyright:

Formatos disponibles

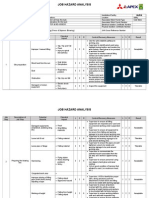

JOB SAFETY ANALYSIS– Part 1

Company details

Company Name: IRMASUD Traveux Constructions Contact Name, Position

Email info@irmasud.com and phone number:

Address: City 11 December 1960 Guemar 39400 El Oued

Project details

Project: GEG Exploration Area: Guern El Guessa Labiadh Sidi Cheikh

Job Address: GEG Block

Job Description: Concrete Preparation operations Pertaining to Civil Work

Activity: Concrete Preparation – General

This JSA has been developed in consultation with: JSA Approved by: Page 1 of 12

Name: Signature: Job Title: Date: Name:

Tahar Berrachedi BG HSE Client 21-04-2011 Signature:

Date:

Personnel responsible for monitoring and managing activity: Overall Risk Rating After 1: Low 2:Medium

Site supervisor Controls

IRMASUD HSE SUPV 3:High

ALL PERSONS INVOLVED IN TASK MUST HAVE THIS JSA COMMUNICATED TO THEM PRIOR TO WORK COMMENCING

JSA NO: ACTIVITY : REVIEW NO: DATE:

Authorized by: Page 1- Version 7.0

Signature: Date:

• Regular inspections and observations will be conducted by IRMASUD HSE FIELD SUPV to ensure JSA is being complied with.

• Daily Tool Box Talks will be undertaken to identify, control and communicate additional site hazards.

• Work must cease immediately if incident or near miss occurs. JSA must be amended in consultation with relevant persons.

• Amendments must be approved by IRMASUD/BG Management and communicated to all affected workers before work resumes.

Personal Protective Equipment

Foot Hearing High Head Eye Hand Protective

Protection Protection Visibility Protection Protection Protection Clothing

General:

Safety footwear, gloves, protective clothing (overalls), eye protection. Dust masks ,

Where required:

Hearing protection, high visibility shirt or vest, hard hat, Rubber gloves ,breathing protection, disposable masks, rubber boots and safety goggles.

Safety Notes

1. Fresh concrete has a very powerful caustic effect on skin owing to the alkaline nature of cement. Freshly mixed concrete, mortar, grout and slurry may

cause skin irritation including alkaline burning and dermatitis.

2. The abrasive effects of sand and aggregate in the concrete aggravate the condition and effects range from dry skin, irritant contact dermatitis and

allergic contact dermatitis to severe burns.

3. These burns can take several hours to occur and can be very painful.

JSA NO: ACTIVITY : REVIEW NO: DATE:

Authorized by: Page 2- Version 7.0

Signature: Date:

4. Avoid contact with skin by wearing suitable clothing and PVC gloves.

5. All site safety notices are to be clearly visible

6. MSDS sheets available on site

7. Eye Wash station

8. Suitable / approved ladders and or scaffolding to be made available when carrying out cellar construction

9. All electrical equipment must be tested prior to use by a certified electrician (Mixer , Vibrator Generator )

Scale Assessment Description

3 High The controls in place are weak and are not mitigating the risk.

There is scope for significant improvement of controls.

2 Medium The controls in place are partially mitigating the risk.

There is scope for some improvement of controls.

1 Low Controls are deemed to be able to reduce Residual Risk to a low level; Risk

Response Action Plans being actively and successfully managed.

There is little or no scope for improvement of controls.

JSA NO: ACTIVITY : REVIEW NO: DATE:

Authorized by: Page 3- Version 7.0

Signature: Date:

Possible Safety or Responsible

Procedure (in

Environmental RB Control Measures to Reduce risk RA Officer

steps):

Hazards

NOTE: RB = Risk Rating before controls implemented - RA = Risk Rating after controls are implemented.

Personnel Inexperienced or Training:

requirements untrained workers pose Should include:

a risk of unsafe Initial Induction - Specific Site induction-

operation. TBT before commencing work

Safe work procedures. Including housekeeping site rules & PPE

Legislation breach Review BG life savers modules relevant to BG safe system of work.

Fitting of personal protective equipment.

Manual handling.

Repertory related issues awareness (Inhalation Cement dust)

Hand injury avoidance

Slips,Trips,Falls

Risk assessment. Personal injury Note:

All types To be performed and documented by the controller of worksite.

Legislation breach Hazard Identification:

Job site layout

Interaction of contractors – including front end loader

Slips trips and falls

Site access and egress.

Access and egress considerations when working on cellar

(ladder)

JSA NO: ACTIVITY : REVIEW NO: DATE:

Authorized by: Page 4- Version 7.0

Signature: Date:

Possible Safety or Responsible

Procedure (in

Environmental RB Control Measures to Reduce risk RA Officer

steps):

Hazards

NOTE: RB = Risk Rating before controls implemented - RA = Risk Rating after controls are implemented.

Formwork checks Personal injury Note:

before pouring. Falls ‘Formwork’ includes:

Crush • the forms on which concrete is poured;

Hit by • the supports to withstand the loads imposed by the forms

and concrete; and

Legislation breach • Any bracing added to ensure stability.

Litigation

Ensure:

All materials and equipment used are fit for their intended

purpose and meet design specifications.

Formwork complies with the design. i.e. either a ‘formwork

designer’ or a ‘professional engineer’s specification.

Specifically:

• Base is stable.

• Suspended slabs are able to safely support loads that

might be applied during pouring.

• Frames, props and timbers are correctly spaced.

• Joist and bearer sizes are correct.

• Jack extensions are acceptable; and

• There is adequate bracing to ensure stability.

JSA NO: ACTIVITY : REVIEW NO: DATE:

Authorized by: Page 5- Version 7.0

Signature: Date:

Possible Safety or Responsible

Procedure (in

Environmental RB Control Measures to Reduce risk RA Officer

steps):

Hazards

NOTE: RB = Risk Rating before controls implemented - RA = Risk Rating after controls are implemented.

Reinforcing mesh Personal injury Manual handling:

Strains and sprains; Ensure loads are light enough for individuals to carry or there is

Eye injury help available.

Electrical shock & fire Cutting/Welding

hazard Ensure safety glasses/ear protection is worn when cutting with

bolt cutters or power grinder. Ensure all electrical tools are fit

for purpose. Welders should ensure suitable eye protection is

worn (welding mask)

Where required a PTW (hot work) should be opened and fire

hazards have been addressed – fire extinguisher, fire screen –

spotter in place at all times

Supporting mesh:

Place reinforcing mesh supports, where required, in place on

the day of the concrete pour to reduce tripping hazard

Concrete delivery – Personal injury: Area to be:

Suitable location: Electric shock Easily accessible.

Struck by Reasonably level with a firm base.

Must be able to support the fully loaded delivery trucks.

Legislation breach Must have clearance from obstructions, power lines and

excavations.

Traffic control where required – Example: When reversing, low

clearance, obstacles, tight access or high vehicle and/or

pedestrian traffic situations.

JSA NO: ACTIVITY : REVIEW NO: DATE:

Authorized by: Page 6- Version 7.0

Signature: Date:

Possible Safety or Responsible

Procedure (in

Environmental RB Control Measures to Reduce risk RA Officer

steps):

Hazards

NOTE: RB = Risk Rating before controls implemented - RA = Risk Rating after controls are implemented.

Concrete Pumping Personal injury: Ensure:

Struck by No people, other than those workers directly involved in the

concrete pumping/Mixing operation, are in the operational

safety zone.

End hose is fitted with a suitable stop or end cap if it is being

manoeuvred over people.

Hopper grill is in the closed position.

Pump flow rates match discharge rates of concrete delivery

trucks.

That the directions of the hose-hand are followed.

JSA NO: ACTIVITY : REVIEW NO: DATE:

Authorized by: Page 7- Version 7.0

Signature: Date:

Possible Safety or Responsible

Procedure (in

Environmental RB Control Measures to Reduce risk RA Officer

steps):

Hazards

NOTE: RB = Risk Rating before controls implemented - RA = Risk Rating after controls are implemented.

Concrete working Personal injury: Ensure:

and placement Sprains and strains PPE fits correctly – Example - waterproof boots should be high

Fatigue enough to keep concrete from flowing into them.

Skin rash or Formwork maintains line, level, plumb, shape, etc during

allergy/dermatitis; concreting.

Concrete burns

Placing concrete:

Note – To reduce manual handling concrete should be placed as

close as possible to its final destination.

Shovels - Square ended shovels are recommended for evenly

spreading concrete. (Round edged shovels will not spread the

concrete evenly.)

Flat, Even Sites - Start placing at the furthermost corner of the

formwork from where the concrete is mixed or delivered.

Always work towards the source of concrete supply, never

away from it.

Sloping Sites Start at the lowest point and work upwards to the

highest point.

Formwork – Do not exceed the maximum rate of permitted

placement.

Height - Not higher than required by the boxing. This will reduce

the amount of manual handling of wet concrete. Do not lift

concrete with a shovel, rather rake or push as required.

Lift reinforcing mesh – where required - by pulling it up with a

large hook to centre of the final slab.

Vibrating:

Ensure that the edges are well vibrated to remove any air

JSA NO: ACTIVITY : pockets. REVIEW NO: DATE:

Authorized by: Page 8- Version 7.0

Signature: Date:

Possible Safety or Responsible

Procedure (in

Environmental RB Control Measures to Reduce risk RA Officer

steps):

Hazards

NOTE: RB = Risk Rating before controls implemented - RA = Risk Rating after controls are implemented.

Concrete working Personal injury: Screed:

and placement – Sprains and strains Concrete by pulling a suitable aluminium or wood straight edge

Continued Fatigue across the wet concrete. Screeding removes excess concrete

Skin rash or and identifies low positions.

allergy/dermatitis;

Concrete burns Bullfloat:

Eliminates high and low spots and embeds large aggregate

particles immediately after strike off. Should be finished before

excess moisture or bleed water appears on the surface

Concrete finishing Personal injury: Note:

Sprains and strains Do not finish concrete while there is bleed water on the surface

as this will increase the water to cement ratio which can cause

Contract breach crazing.

Poor concrete finish Do not start final finishing until the concrete can support the

weight of a person, leaving only slight surface imprints.

Prevent indentations being formed in the concrete.

Float / Trowelling:

Floats are usually made of timber, trowels of steel. Use to even

out any minor lumps on the concrete. Sweep it in an arc-

shaped motion, keeping the edge at the front of your sweep

slightly raised, lest the float dig into the concrete.

JSA NO: ACTIVITY : REVIEW NO: DATE:

Authorized by: Page 9- Version 7.0

Signature: Date:

Possible Safety or Responsible

Procedure (in

Environmental RB Control Measures to Reduce risk RA Officer

steps):

Hazards

NOTE: RB = Risk Rating before controls implemented - RA = Risk Rating after controls are implemented.

On Completion – Personal injury:

Stripping Crush Sides:

formwork / boxing Can be removed after several hours to enable trowelling of

Structural collapse of exposed edges.

poured floor

Floor:

The time between pouring and formwork stripping depends on

the job specifications, the cure required, and whether the form

is supporting any weight, but is usually at least seven days

after the pour has been completed.

On Completion – Personal injury: Personal Hygiene:

Clean up Concrete burns Wash all exposed skin – ensure coveralls are washed

separately from other clothing, wash hands before eating

Tools:

Wash all tools

Excess Concrete:

Place in small stacks (about a shovel full) and allow to dry for

safe removal.

Empty cement sacks

All empty bags/sacks are to be disposed of as per site instructions

JSA NO: ACTIVITY : REVIEW NO: DATE:

Authorized by: Page 10- Version 7.0

Signature: Date:

Possible Safety or Responsible

Procedure (in

Environmental RB Control Measures to Reduce risk RA Officer

steps):

Hazards

NOTE: RB = Risk Rating before controls implemented - RA = Risk Rating after controls are implemented.

First aid Contact:

Skin - Wash immediately with clean water.

Eye wash station Eyes - Wash immediately and repeatedly with eyewash solution

MSDS Sheet or clear water. If irritation persists seek medical attention.

Rescue equipment

including spinal Note:

boards if working in Indirect contact through clothing can be as serious as direct

excavations (cellar) contact. Promptly rinse out wet concrete, mortar, cement or

cement mixtures from clothing.

Transporting Personal injury Driving:

Possible fatality. Only trained competent operators may drive loaders (licenses

(Cement loader) Struck by. to be checked prior to employment)

The loader must be operated in accordance with site regulations

Incorrect operation of at all times

plant. Speed limits, obligatory and recommended, are to be observed.

Traffic violation Personnel are NOT to be:

Carried in the cabin

Lifted in or in anyway operate from within the buckets.

Walk under raised attachments

Cleaning

Loaders are to be cleaned in accordance with site specific

regulations

JSA NO: ACTIVITY : REVIEW NO: DATE:

Authorized by: Page 11- Version 7.0

Signature: Date:

JOB SAFETY ANALYSIS– Part 2

Personal Qualifications and Experience Duties and Responsibilities of those Training Required to Complete the Work:

required for the job: employees undertaking the task: (All employees must be trained in relevant procedures.)

Appropriate license and certificate. Site specific inductions.

Relevant training. Training in this JSA

Performing BG life saver presentation relevant to

BG safe system of work.

Details of regulatory permits/licenses Engineering Details/Certificates/Work

Codes of Practice, Legislation:

required: Cover Approvals:

-

PPE to comply with relevant Standards

JSA NO: ACTIVITY : REVIEW NO: DATE:

Authorized by: Page 12- Version 7.0

Signature: Date:

Plant/Tools/Equipment: (List plant and equipment to be used on the job.) Maintenance Details: (Include maintenance on cranes, forklifts, electrical

equipment etc.)

JSA NO: ACTIVITY : REVIEW NO: DATE:

Authorized by: Page 13- Version 7.0

Signature: Date:

Employee Sign-off

This JSA has been developed through consultation with employees. I have read the above JSA and I understand its contents. I confirm that I have

the skills and training, including relevant certification to conduct the task as described. I agree to comply with safety requirements within this JSA

including safe work instructions and Personal Protective Equipment described.

Name Qualifications Signature Date Time Employer

Review No. 1 2 3 4 5 6 7 8 9

Name and

initials

Date

JSA NO: ACTIVITY : REVIEW NO: DATE:

Authorized by: Page 14- Version 7.0

Signature: Date:

También podría gustarte

- Scaffolding-Fixed and Mobile: Safety Operating ProceduresDocumento1 páginaScaffolding-Fixed and Mobile: Safety Operating Proceduresmohammed muzammilAún no hay calificaciones

- JSA ScaffoldingDocumento2 páginasJSA ScaffoldingHrishikesh UnnikrishnanAún no hay calificaciones

- Jsa For The Installation of I EamDocumento5 páginasJsa For The Installation of I EamMohammed MinhajAún no hay calificaciones

- Manual HandlingDocumento15 páginasManual HandlingNithun Deenadayalan100% (2)

- Scaffolding JSADocumento10 páginasScaffolding JSAlabaimathuatqn2000Aún no hay calificaciones

- Risk Assessment New Site Lifting Operations 07-06-2015Documento3 páginasRisk Assessment New Site Lifting Operations 07-06-2015ANAND MLAún no hay calificaciones

- JHA Blowing PressDocumento5 páginasJHA Blowing PressLuqman OsmanAún no hay calificaciones

- Job Safety Analysis: Hot Jobs (Welding Cutting & Grinding)Documento3 páginasJob Safety Analysis: Hot Jobs (Welding Cutting & Grinding)Perwez21Aún no hay calificaciones

- Safe Work Procedure, Gem MaintenanceDocumento46 páginasSafe Work Procedure, Gem MaintenanceAsif Khanzada100% (1)

- Rigging JSA SafetyDocumento5 páginasRigging JSA SafetyaQiLGunawanAún no hay calificaciones

- DLF RCC HiraDocumento8 páginasDLF RCC HiraskfahimuddinAún no hay calificaciones

- Completed Example of A Risk Assessment - Example 1Documento3 páginasCompleted Example of A Risk Assessment - Example 1Rahil Tasawar0% (1)

- 112 D HSE Bulletin Safe Working at HeightDocumento1 página112 D HSE Bulletin Safe Working at HeightOws AnishAún no hay calificaciones

- Jsa forOperatingAForkliftDocumento2 páginasJsa forOperatingAForkliftsupahing supahingAún no hay calificaciones

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSDocumento2 páginasProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSJohn100% (1)

- Hand Tools SHE Risk AssessmentDocumento3 páginasHand Tools SHE Risk AssessmentMuhammed yahiyaAún no hay calificaciones

- Sogetrap JSA Lifting Cabin by ForkliftDocumento2 páginasSogetrap JSA Lifting Cabin by ForkliftTSP HSEAún no hay calificaciones

- SWP-20 Usage of Ladder DaimanDocumento1 páginaSWP-20 Usage of Ladder DaimanHassan AbdullahAún no hay calificaciones

- Job Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityDocumento2 páginasJob Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityJayendra PatelAún no hay calificaciones

- JSO Cable Drum (02 Sept.'07)Documento2 páginasJSO Cable Drum (02 Sept.'07)Francis Enriquez TanAún no hay calificaciones

- Working at Height Training ModuleDocumento41 páginasWorking at Height Training ModuleYudha kurniawanAún no hay calificaciones

- SWP-06 Lifting Operation DaimanDocumento4 páginasSWP-06 Lifting Operation DaimanHassan AbdullahAún no hay calificaciones

- 07 - JSA Compaction and BackfillingDocumento4 páginas07 - JSA Compaction and Backfillingsatti100% (2)

- Ra02 - Container OffloadingDocumento3 páginasRa02 - Container OffloadingSamAún no hay calificaciones

- Risk Assess T-23 - Hilti Cartridge Tool OperationDocumento2 páginasRisk Assess T-23 - Hilti Cartridge Tool OperationMAB Ali100% (1)

- Safety Alert 260 - Unsafe Cradle Installation and UsageDocumento2 páginasSafety Alert 260 - Unsafe Cradle Installation and UsageAbdulKatherAún no hay calificaciones

- Aerial Lifts FactsheetDocumento2 páginasAerial Lifts Factsheetomar santosAún no hay calificaciones

- Scaffold - Erection, Use & Dismantling-RADocumento15 páginasScaffold - Erection, Use & Dismantling-RAAl AminAún no hay calificaciones

- 9 - Work at Height Review Checklist ToolDocumento2 páginas9 - Work at Height Review Checklist ToolAbdul Hamid100% (3)

- SFPSG-Rescue Persons From MEWPsDocumento10 páginasSFPSG-Rescue Persons From MEWPsLyle KorytarAún no hay calificaciones

- Play It SAFE: Working AT HeightDocumento20 páginasPlay It SAFE: Working AT Heightandi permanaAún no hay calificaciones

- Generic TRA For Mobile Elevating Work PlatformDocumento4 páginasGeneric TRA For Mobile Elevating Work PlatformKhawaja Arslan Ahmed100% (1)

- Ironbark: Safe Work Method Statement No. WMS-570 Task: Work Practice - Epoxy FlooringDocumento12 páginasIronbark: Safe Work Method Statement No. WMS-570 Task: Work Practice - Epoxy Flooringklp_kedarpAún no hay calificaciones

- Genie E Series Slab Scissor Lift OperationDocumento11 páginasGenie E Series Slab Scissor Lift OperationSanket Arun MoreAún no hay calificaciones

- Safe Use of Work PlatformsDocumento5 páginasSafe Use of Work PlatformsFrancis Enriquez TanAún no hay calificaciones

- Risk Assessment IIIDocumento1 páginaRisk Assessment IIIJosh Booth100% (2)

- 04, Use of Hand ToolsDocumento2 páginas04, Use of Hand ToolsFrancis K BonfulAún no hay calificaciones

- Tool Box Talk - MK - Emergency Response ProceduresDocumento2 páginasTool Box Talk - MK - Emergency Response ProceduresPaul McGahanAún no hay calificaciones

- Instructions For Using The Risk Assessment FormDocumento9 páginasInstructions For Using The Risk Assessment FormMalik Khuram ShazadAún no hay calificaciones

- Steel Erection JSADocumento5 páginasSteel Erection JSASalah Abd Eldayem100% (1)

- Presentation Day 2 - HSE ChallengeDocumento26 páginasPresentation Day 2 - HSE ChallengeIwan HerawanAún no hay calificaciones

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Documento3 páginasKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelAún no hay calificaciones

- CraneOperations PDFDocumento2 páginasCraneOperations PDFIrshad AkhterAún no hay calificaciones

- Safety AlertDocumento2 páginasSafety Alertjo123nAún no hay calificaciones

- Subject: Work at Height: Unit: Maihar Cement WorksDocumento3 páginasSubject: Work at Height: Unit: Maihar Cement Workskaka100% (1)

- Hot Works: Risk Assesment Form For Rolling ShutterDocumento1 páginaHot Works: Risk Assesment Form For Rolling Shutterchandanprakash30Aún no hay calificaciones

- Ra & Jsa FormatDocumento19 páginasRa & Jsa Formatspecpro50% (2)

- Tower Crane Dismantling JSA HSE ProfessionalsDocumento2 páginasTower Crane Dismantling JSA HSE ProfessionalsnabeelAún no hay calificaciones

- SWMS Scaffold FixedDocumento11 páginasSWMS Scaffold FixedEdha AliAún no hay calificaciones

- Task /activity: Installation of Abseil HooksDocumento10 páginasTask /activity: Installation of Abseil HooksfrancisbautistaAún no hay calificaciones

- JSA NO 3-Pile CapDocumento8 páginasJSA NO 3-Pile Capknabpsho50% (2)

- Toolbox Talks Lifting Safety EnglishDocumento1 páginaToolbox Talks Lifting Safety EnglishkimlynroseAún no hay calificaciones

- EHS Alert 010 - Concrete Placing Boom OperationDocumento1 páginaEHS Alert 010 - Concrete Placing Boom OperationAbdulKatherAún no hay calificaciones

- Excavation (Company Name) : Phase Hazard AnalysisDocumento11 páginasExcavation (Company Name) : Phase Hazard AnalysisDenease CrummieAún no hay calificaciones

- 9.7 Ladder Inspection ChecklistDocumento1 página9.7 Ladder Inspection ChecklistArshad MahmoodAún no hay calificaciones

- Site Inspection Workplace Trasport ChecklistDocumento6 páginasSite Inspection Workplace Trasport ChecklisttipuAún no hay calificaciones

- JHA Maintenance Tech HVACDocumento2 páginasJHA Maintenance Tech HVACMdavaAún no hay calificaciones

- Company Details: Job Safety Analysis - Part 1Documento14 páginasCompany Details: Job Safety Analysis - Part 1usman khalidAún no hay calificaciones

- JSA Installation-Fire-Alarm-SystemDocumento12 páginasJSA Installation-Fire-Alarm-Systemuz9143895Aún no hay calificaciones

- HSE-RA-005 Working at Heights - Rev - 0Documento8 páginasHSE-RA-005 Working at Heights - Rev - 0عمروAún no hay calificaciones

- OrthoDocumento22 páginasOrthosivaleela gAún no hay calificaciones

- Preventive Dentistry - Terms and PhrasesDocumento2 páginasPreventive Dentistry - Terms and PhrasesYoan MladenovAún no hay calificaciones

- Spark by John Ratey - Chapter 1 PDFDocumento25 páginasSpark by John Ratey - Chapter 1 PDFRobert CazoniAún no hay calificaciones

- Childrens Law EnglandDocumento4 páginasChildrens Law EnglandNatalieAún no hay calificaciones

- Medical Parasitology QuestionsDocumento5 páginasMedical Parasitology Questionsskeltenboi74% (19)

- CHCECE002 Theory Tasks v8Documento46 páginasCHCECE002 Theory Tasks v8Palvi Sharma100% (1)

- Basic Su Jok TherapyDocumento10 páginasBasic Su Jok Therapytalhahameed8580% (5)

- Women and Mental HealthDocumento15 páginasWomen and Mental HealthMAMTA SANODIYA100% (1)

- 2022 FWN Magazine - Most Influential Filipina Women in The World Commemorative IssueDocumento52 páginas2022 FWN Magazine - Most Influential Filipina Women in The World Commemorative IssueFilipina Women's NetworkAún no hay calificaciones

- Strahlenfolter Stalking - TI - Bibliotecapleyades - Net - Psychotronic Weapons - Brain Manipulation From A DistanceDocumento5 páginasStrahlenfolter Stalking - TI - Bibliotecapleyades - Net - Psychotronic Weapons - Brain Manipulation From A DistanceHans-Georg-JakobsonAún no hay calificaciones

- 1 s2.0 S0160252722000693 MainDocumento9 páginas1 s2.0 S0160252722000693 MainjohnsmithdosAún no hay calificaciones

- MSDS FSC-2FDocumento3 páginasMSDS FSC-2FSagu Lempeng100% (1)

- Autismand PDDDocumento229 páginasAutismand PDDIan BrownAún no hay calificaciones

- Control of Nonconforming Work019 Af.r4Documento6 páginasControl of Nonconforming Work019 Af.r4Massimiliano PorcelliAún no hay calificaciones

- American Embryo Transfer Association: Certification Program GuidelinesDocumento8 páginasAmerican Embryo Transfer Association: Certification Program GuidelinesFelipe MendozaAún no hay calificaciones

- The Yemen Crisis: Uscri BackgrounderDocumento11 páginasThe Yemen Crisis: Uscri BackgrounderJessareth CapacioAún no hay calificaciones

- Soal 1 SD 100Documento53 páginasSoal 1 SD 100spitfireconradAún no hay calificaciones

- Deep Learning For The Detection of Diabetic RetinopathyDocumento10 páginasDeep Learning For The Detection of Diabetic RetinopathyIJRASETPublicationsAún no hay calificaciones

- Basal Level of Anti-Müllerian Hormone Is Associated With Oocyte Quality in Stimulated CyclesDocumento5 páginasBasal Level of Anti-Müllerian Hormone Is Associated With Oocyte Quality in Stimulated CyclesCherysaAún no hay calificaciones

- Medicle Bill Dec28Documento2 páginasMedicle Bill Dec28pises97155Aún no hay calificaciones

- Cna Research Final DraftDocumento142 páginasCna Research Final DraftDaniel P. EstrelladoAún no hay calificaciones

- Diabetes Ditress Screening ScaleDocumento2 páginasDiabetes Ditress Screening ScaleIrwan HadiAún no hay calificaciones

- B-Medium Opening ActivatorDocumento31 páginasB-Medium Opening ActivatorAbiha Ali100% (1)

- HOPE 4 Module 8 Training PlanDocumento10 páginasHOPE 4 Module 8 Training PlanAJ Bacarisas RochaAún no hay calificaciones

- Biomedical Admissions Test (Bmat) : Section 1Documento14 páginasBiomedical Admissions Test (Bmat) : Section 1zozo 55Aún no hay calificaciones

- Political SelfDocumento53 páginasPolitical SelfMelizza Fajardo BañanoAún no hay calificaciones

- El LHDocumento2 páginasEl LHMaherAún no hay calificaciones

- Presented By: Bhawna Joshi Msc. Nursing 1 YearDocumento52 páginasPresented By: Bhawna Joshi Msc. Nursing 1 YearBhawna JoshiAún no hay calificaciones

- VEINDOCANOL English PresentationDocumento9 páginasVEINDOCANOL English PresentationSOLOSCOPE MEDICALAún no hay calificaciones

- Concurrence of Big Data Analytics and HealthcareDocumento10 páginasConcurrence of Big Data Analytics and HealthcareShubham KimtaniAún no hay calificaciones