Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Slump Test

Cargado por

Joan EmarDescripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Slump Test

Cargado por

Joan EmarCopyright:

Formatos disponibles

PS•3000 Installation Manual

WE’RE BUILDING A BETTER WORLD

Tips & Techniques

D.14 CONCRETE SLUMP TEST

Testing the slump of the concrete that arrives on your job site is the only way you can assure

that the concrete you ordered is the concrete you received, and that it is ready to place through

the pump. Accordingly, we recommend that you slump test every truck that arrives on the job

site and notify your supplier that you will be doing so. This practice will go a long way

towards ensuring that your project is successful.

Slump Test Procedures

PURPOSE OF TEST: To determine the consistency of fresh concrete and to check its uniformity from batch to batch.

This test is based on ASTM C 143-74: Standard Test Method for Slump of Portland Cement Concrete. Also refer to ASTM

172-71 Standard Method Sampling Fresh Concrete.

Take two or more representative samples—at regularly spaced intervals—from the middle of the mixer discharge; do

not take samples from beginning or end of discharge. Obtain samples within 15 minutes or less.

Important: Slump test must be made within 5 minutes after taking samples.

Combine samples in a wheelbarrow or appropriate container and remix before making test.

Dampen slump cone with water and place it on a flat, level, smooth, moist, nonabsorbent, firm surface.

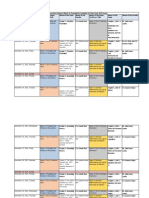

1. Stand on the two foot pieces of cone to 2. Fill cone 2/3 full by volume (half the 3. Fill cone to overflowing and again rod

hold it firmly in place during steps 1 height) and again rod 25 times with ro d 25 times with rod just penetrating into,

through 4. Fill cone mold 1/3 by volume just penetrating into, but not through, but not through, the second layer. Again,

[2-5/8” (67mm) high] with the concrete the first layer. Distribute strokes evenly distribute strokes evenly.

sample and rod it with 25 strokes using a as described in Step 1.

round, straight steel rod of 5/8” (16mm)

diameter x 24” (600mm) long. Distribute

rodding strokes evenly over entire cross

section of the concrete by using

approximately half the strokes near the

perimeter (outer edge) and then

progressing spirally toward the center.

4. Strike off excess concrete from top of 5. Immediately after completion of Step 6. Place the steel rod horizontally across

cone with the steel rod so the cone is 4, the operation of raising the mold shall the inverted mold so the rod extends

exactly level full. Clean the overflow be performed in 5 + 2 sec. by a steady over the slumped concrete. Immediately

away from the base of the cone mold. upward lift with no lateral or torsional measure the distance from bottom of the

motion being imparted to the concrete. steel rod to the original center of the top

The entire operation from the start of the of the specimen. This distance, to the

filling through removal of the mold nearest 1/4” (6mm), is the slump of the

shall be carried out without interruption concrete. If a decided falling away or

and shall be completed within the shearing off of concrete from one side or

elapsed time of 2-1/2 minutes. portion of the mass occurs, disregard the

test and make a new test on another

portion of the sample.

© American PolySteel, LLC Version 4.0

(800) 977-3676 • www.polysteel.com 141 May 2005

También podría gustarte

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- RRC Igc1Documento6 páginasRRC Igc1kabirAún no hay calificaciones

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (587)

- CHECK LIST FOR HIGH RISE BUILDING NOCDocumento15 páginasCHECK LIST FOR HIGH RISE BUILDING NOCNedunuri.Madhav Murthy100% (2)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (890)

- PPPoE Packet Format - HCNADocumento6 páginasPPPoE Packet Format - HCNARobert Sanchez OchochoqueAún no hay calificaciones

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- V Bhebhe PDFDocumento63 páginasV Bhebhe PDFVusi BhebheAún no hay calificaciones

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (399)

- Mobile-Friendly Cooperative WebDocumento7 páginasMobile-Friendly Cooperative WebWahyu PAún no hay calificaciones

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (73)

- Facelift at Your Fingertips - An Aromatherapy Massage Program For Healthy Skin and A Younger FaceDocumento136 páginasFacelift at Your Fingertips - An Aromatherapy Massage Program For Healthy Skin and A Younger Faceugur gebologluAún no hay calificaciones

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- Year 2 - Push and Pull FPDDocumento18 páginasYear 2 - Push and Pull FPDRebecca LAún no hay calificaciones

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- MATH 8 QUARTER 3 WEEK 1 & 2 MODULEDocumento10 páginasMATH 8 QUARTER 3 WEEK 1 & 2 MODULECandy CastroAún no hay calificaciones

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- Chapter 12Documento52 páginasChapter 12Mr SaemAún no hay calificaciones

- Paper23 PGDMM Public Procurement MCQ Sept2021Documento25 páginasPaper23 PGDMM Public Procurement MCQ Sept2021Gagan VermaAún no hay calificaciones

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Chapter 1-The Indian Contract Act, 1872, Unit 1-Nature of ContractsDocumento10 páginasChapter 1-The Indian Contract Act, 1872, Unit 1-Nature of ContractsALANKRIT TRIPATHIAún no hay calificaciones

- Sequence TransformationDocumento2 páginasSequence Transformationbrown222Aún no hay calificaciones

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- Gender and Other Cross Cutting Issues Mental HealthDocumento6 páginasGender and Other Cross Cutting Issues Mental HealthJamira Inoc SoboAún no hay calificaciones

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- Armitage Tutorial for Cyber Attack ManagementDocumento54 páginasArmitage Tutorial for Cyber Attack Managementworkmumbai3870Aún no hay calificaciones

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2219)

- 1st ClassDocumento18 páginas1st Classchitl.23bi14075Aún no hay calificaciones

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Camp ApplianceDocumento1 páginaCamp ApplianceflyzalAún no hay calificaciones

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- Lect 1.2 Principles of Food Process DesignDocumento43 páginasLect 1.2 Principles of Food Process Designmahmoud hassanAún no hay calificaciones

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (265)

- Localized Commercial LeafletDocumento14 páginasLocalized Commercial LeafletJohn Kim CarandangAún no hay calificaciones

- Lecturer No 1 - Transformer BasicDocumento1 páginaLecturer No 1 - Transformer Basiclvb123Aún no hay calificaciones

- AESCSF Framework Overview 2020-21Documento30 páginasAESCSF Framework Overview 2020-21Sandeep SinghAún no hay calificaciones

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- Class 9 - Half Yearly Examination - 2023 - Portions and BlueprintDocumento16 páginasClass 9 - Half Yearly Examination - 2023 - Portions and BlueprintSUBRAMANI MANOHARANAún no hay calificaciones

- Synetek Controls Inc.: Ds1-S: Installation InstructionsDocumento2 páginasSynetek Controls Inc.: Ds1-S: Installation Instructionsdgd_electromecAún no hay calificaciones

- NCERT Solutions For Class 12 Flamingo English Lost SpringDocumento20 páginasNCERT Solutions For Class 12 Flamingo English Lost SpringHarsh solutions100% (1)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- Sankalp Sanjeevani NEET: PhysicsDocumento11 páginasSankalp Sanjeevani NEET: PhysicsKey RavenAún no hay calificaciones

- Black BeautyDocumento70 páginasBlack BeautyMeryem DevirgenAún no hay calificaciones

- Atlanta Pipes and FittingsDocumento2 páginasAtlanta Pipes and Fittingsotadoyreychie31Aún no hay calificaciones

- Citi Global College Inc 12STEM3G72Documento9 páginasCiti Global College Inc 12STEM3G72yanna villarealAún no hay calificaciones

- Douglas Frayne Sargonic and Gutian Periods, 2334-2113 BCDocumento182 páginasDouglas Frayne Sargonic and Gutian Periods, 2334-2113 BClibrary364100% (3)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2099)

- MechanismDocumento17 páginasMechanismm_er100Aún no hay calificaciones

- Bioav 3Documento264 páginasBioav 3Sabiruddin Mirza DipuAún no hay calificaciones

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (119)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)