Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Wifpl Qap 2019-20-058 Rev 00 Konecranes 18crnimo7 6 Signed

Cargado por

Deepak HoleDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Wifpl Qap 2019-20-058 Rev 00 Konecranes 18crnimo7 6 Signed

Cargado por

Deepak HoleCopyright:

Formatos disponibles

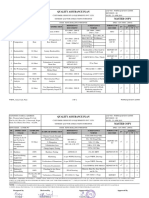

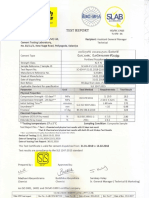

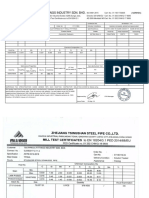

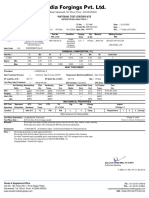

VENDOR'S NAME & ADDRESS QAP NO : WIFPL/QAP/2019-20/058

M/s. Western India Forgings Pvt. Ltd.

QUALITY ASSURANCE PLAN REVISION : 00

CUSTOMER: KONECRANES FINLAND OY DATE : 09-FEB-2019

Gat No 163, Hissa No 1, Sanaswadi, Nagar MATERIAL AND TEST REQUIREMENTS FOR GEAR WHEELS

Road, Tal. Shirur, Dist. Pune - 412208; MATERIAL GRADE -18CrNiMo7-6 AS PER DIN EN 10084 : 2008

MASTER COPY

ITEM : GEAR WHEELS DRAWING NO : 55027836-DRW1 REV-4; 55027869-DRW1-REV-4; 53838910-DRW1 REV-5 SPEC : EN 10084 & ISO 6336-5

SR INSPECTION SAMPLING REFERENCE ACEEPTANCE FORMAT OF AGENCY

SCOPE OF INSPECTION D*

NO STAGE PLAN DOCUMENT NORMS RECORD P W V

Steel

ISO 6336-5 : MQ

1 Manufacturing 100% Verification of MTC

DIN EN 10084 : 2008

EF/EAF-LRF-VD-ING / CC MTC P 2 - 1

Process

Raw Material ISO 6336-5 : MQ ISO 6336-5 : MQ

2

Procurment

100% Verification of MTC

DIN EN 10084 : 2008 DIN EN 10084 : 2008

MTC P 2 - 1

C=0.15-0.21 Cr=1.50-1.80

Mn=0.50-0.90 Ni=1.40-1.70

Chemical 01 Sample per Chemical Compositon of ISO 6336-5 : MQ

3

Composition Heat Raw Material DIN EN 10084 : 2008

P=0.025 Max Mo= 0.25-0.35 - P 2 - 1

S=0.035 Max Fe=Balance

Si= 0.40 Max

As per DIN EN 10084

ISO 6336-5 : MQ

4 Hardenability 01 / Heat Hardenability of Steel

DIN EN 10084 : 2008

2008 E - P 2 - 1

Grade 18CrNiMo7-6 +H

Estimation of Austenitic

5 Grain Size 01/ Heat

Grain Size

ISO 643 Latest Edition ASTM No 5 of Finer - P 2 - 1

ASTM E45 Method A / As per MQ Quality

6 Degree of Purity 01 / Heat Inclusion Rating

ISO 4967 Method B Plate II Specified in ISO 6336-5

- P 2 - 1

Final Reduction Ratio ISO 6336-5 : MQ Final Reduction Ratio

7 Forging 100%

including RM Reduction DIN EN 10084 : 2008 3 : 1 Min

- P 2 - 1

1 No at the time

Macro Etch Test of Grain flow will be inline with the

8

Forging

of die Grain Flow ASTM E381

patern of forging. no break allows

REPORT P 2 - 1

development

WIFPL, Sanaswadi, Pune 1 OF 2 WIFPL/QAP/2019-20/058

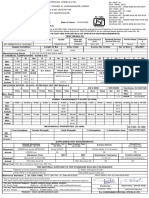

VENDOR'S NAME & ADDRESS QAP NO : WIFPL/QAP/2019-20/058

M/s. Western India Forgings Pvt. Ltd.

QUALITY ASSURANCE PLAN REVISION : 00

CUSTOMER: KONECRANES FINLAND OY DATE : 09-FEB-2019

Gat No 163, Hissa No 1, Sanaswadi, Nagar MATERIAL AND TEST REQUIREMENTS FOR GEAR WHEELS

Road, Tal. Shirur, Dist. Pune - 412208; MATERIAL GRADE -18CrNiMo7-6 AS PER DIN EN 10084 : 2008

MASTER COPY

ITEM : GEAR WHEELS DRAWING NO : 55027836-DRW1 REV-4; 55027869-DRW1-REV-4; 53838910-DRW1 REV-5 SPEC : EN 10084 & ISO 6336-5

SR INSPECTION SAMPLING REFERENCE ACEEPTANCE FORMAT OF AGENCY

SCOPE OF INSPECTION D*

NO STAGE PLAN DOCUMENT NORMS RECORD P W V

Austenitizing Temp 920°C-950°C

ISO 6336-5 : MQ

9 Heat Treatment 100% Iso Thermal Annealing

DIN EN 10084 : 2008

Transformation Temp 620°C-650°C HT Graph P 2 - 1

Soaking 30 Minutes Min / Inch

Micro Structure 01/ Heat / HT ISO 6336-5 : MQ ISO 6336-5 : MQ

10

Analysis Batch

Phase Analysis

DIN EN 10084 : 2008 DIN EN 10084 : 2008

REPORT P 2 - 1

Material Shall be free from

11 Shot Blasting 100% Shot Blasting - - - 2 - 1

Scale

12 Hardness 100% Hardness Testing ASTM E110 159-207 HBW - P 2 1 -

Dimensional

13

Inspection

100% Verification of Dimensions As per Drawing As per Drawing REPORT P 2 1 -

Free from Surface & Subsurface

14 Surface NDE 100% Magnetic Particle Exam. ASTM E709 relevant indications.

- P 2 1 -

ISO 6336-5 : MQ

15 Volumetric NDE 100% Ultrasonic Examination

ASTM A388

As per ISO 6336-5 : MQ - P 2 1 -

Marking & Punching by low Stress

16 100% PO & Drawing PO & Drawing - - 2 - 1

Treaceability Punch

per Heat Per HT ISO 6336-5 : MQ ISO 6336-5 : MQ

17 Certification

Batch

Verfication of Documents

DIN EN 10084 : 2008 DIN EN 10084 : 2008

REPORT P 2 - 1

LEGEND: P: PERFORM, W:WITNESS, V: VERIFICATION, INDICATE 1 FOR M/S. KONECRANES FINLAND OY QA ( OR M/s. KONECRANES FINLAND OY NOMINATED THIRD PARTY) & 2 FOR WIFPL OR SUB VENDORS

OF WIFPL/ NABL LAB * FOR ITEMS MARKED BY 'P' ( TICK) IN COLUMN 'D' ;TEST CERTIFICATES SHALL BE SUBMITTED TO M/S.KONECRANES FINLAND OY

NOTE : 1) MECHANICAL TESTING SHALL BE CARRIED OUT ON THE SAMPLES OBTAINED FROM THE TEST BAR OF DIA 30 MM DULY BLANK HARDENED WHICH IS DULY TURNED FROM

THE SAME MATERIAL BATCH AND HAVE TO MEET THE REQUIREMENTS OF DEFORMATION, HEAT TREAT STATE AND HARDENABILITY.

Prepared by Reviewed by Approved by Approved By

H. Dipak Shrikant Bhirud Vinod Sawale

Sr.MQC Engineer Asst Manager, MQC DGM, MQC & HT M/s. KONECRANES FINLAND OY

WIFPL, Sanaswadi, Pune 2 OF 2 WIFPL/QAP/2019-20/058

También podría gustarte

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDe EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsAún no hay calificaciones

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsDe EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsCalificación: 5 de 5 estrellas5/5 (1)

- Wifpl-Qap-2019!20!008 Rev-00 Hindustan Equipment PVT Ltd-SignedDocumento2 páginasWifpl-Qap-2019!20!008 Rev-00 Hindustan Equipment PVT Ltd-SignedDeipak HoleAún no hay calificaciones

- Inspection certificate for spiral wound gaskets and reducersDocumento3 páginasInspection certificate for spiral wound gaskets and reducersRaul Esteban Jaimes GalvisAún no hay calificaciones

- Material Verification Report: Elongation in 50 MM, Min % (Gauge Length 4D 50 MM)Documento2 páginasMaterial Verification Report: Elongation in 50 MM, Min % (Gauge Length 4D 50 MM)shrikant mishraAún no hay calificaciones

- PO SR - No.8, HEL REPORT 120004Documento4 páginasPO SR - No.8, HEL REPORT 120004Agni DuttaAún no hay calificaciones

- Test Certificate: Highway Industries Ltd. (Sahnewal)Documento1 páginaTest Certificate: Highway Industries Ltd. (Sahnewal)Deepak MehtaAún no hay calificaciones

- Letter For Feild Compressive Strength Test 1Documento2 páginasLetter For Feild Compressive Strength Test 1Pja Shantha100% (1)

- 84518-56 MM RevisedDocumento1 página84518-56 MM RevisedDeepak MehtaAún no hay calificaciones

- Annexure-I For Gem Bid No:Gem/2021/B/1451378 Dated: 19-08-2021Documento15 páginasAnnexure-I For Gem Bid No:Gem/2021/B/1451378 Dated: 19-08-2021Sravan DasariAún no hay calificaciones

- Sample FET To ISO 15848-1 PDFDocumento4 páginasSample FET To ISO 15848-1 PDFVivi Oktavianti100% (1)

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 344, - , - : Heat-Resistant Cast Steel, Cr-Ni-AlloyedDocumento3 páginasMCGB - Data Sheet For Suppliers Old MAT Nos.: 344, - , - : Heat-Resistant Cast Steel, Cr-Ni-AlloyedgraduateAún no hay calificaciones

- Wifpl Qap 2019-20-015 Rev 00 Mdns 40ni6cr4mo3 SignedDocumento3 páginasWifpl Qap 2019-20-015 Rev 00 Mdns 40ni6cr4mo3 SignedDeipak HoleAún no hay calificaciones

- VENDOR ITP - BALL VALVE (LOT-2Documento3 páginasVENDOR ITP - BALL VALVE (LOT-2VIVEK TIWARIAún no hay calificaciones

- 90mm 316l Peeled and PolishedDocumento1 página90mm 316l Peeled and PolishedB.M Industrial WorksAún no hay calificaciones

- Werkszeugnis Altena Blech Vom 17.06.PDF 1Documento2 páginasWerkszeugnis Altena Blech Vom 17.06.PDF 1MuzammilAún no hay calificaciones

- 26-05-2022 13-15-03-465 PDFDocumento1 página26-05-2022 13-15-03-465 PDFQualityAún no hay calificaciones

- Inspection Checklist for Suction Bell CastingsDocumento8 páginasInspection Checklist for Suction Bell CastingsCheeragAún no hay calificaciones

- KN-10069-CP-101-EL-MT-00009 OilDocumento3 páginasKN-10069-CP-101-EL-MT-00009 Oilahffg nnffAún no hay calificaciones

- Tubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)Documento2 páginasTubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)alexis garciaAún no hay calificaciones

- Bright Steel Data SheetDocumento3 páginasBright Steel Data Sheetbaskaran ayyapparajAún no hay calificaciones

- TMT Fe-550D, 500DDocumento9 páginasTMT Fe-550D, 500DRAJKUMAR CHATTERJEE. (RAJA.)Aún no hay calificaciones

- Indcon Projects Electrode Qualification Procedure IOCL Gas PipelineDocumento11 páginasIndcon Projects Electrode Qualification Procedure IOCL Gas PipelineAkhilesh Kumar67% (3)

- MCGB - Data Sheet For Suppliers Old MAT Nos.: - , - , - : Bright Steel Unalloyed, MachinedDocumento3 páginasMCGB - Data Sheet For Suppliers Old MAT Nos.: - , - , - : Bright Steel Unalloyed, Machinedbaskaran ayyapparajAún no hay calificaciones

- nITP For Suspenion Hanger Pin Alt 2Documento4 páginasnITP For Suspenion Hanger Pin Alt 2ABHISHEK KUMARAún no hay calificaciones

- Cold Drawn Steel Data SheetDocumento3 páginasCold Drawn Steel Data Sheetengfaridmalk100% (1)

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 203, - , - : Heat-Treatable Steel, Carbon SteelDocumento3 páginasMCGB - Data Sheet For Suppliers Old MAT Nos.: 203, - , - : Heat-Treatable Steel, Carbon Steelbaskaran ayyapparaj100% (1)

- TJ2404018-05 Cement(Physical) ReportDocumento2 páginasTJ2404018-05 Cement(Physical) ReportFalcon LabAún no hay calificaciones

- Magnetic Particle Examination: Ies-Industrial Engineering ServicesDocumento2 páginasMagnetic Particle Examination: Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanAún no hay calificaciones

- MAT 2002 MCGB - Data Sheet For Suppliers Old MAT Nos.Documento3 páginasMAT 2002 MCGB - Data Sheet For Suppliers Old MAT Nos.engfaridmalkAún no hay calificaciones

- Reporte Element T 47Documento3 páginasReporte Element T 47Edson AragaAún no hay calificaciones

- SUMMARY PQT PT PERTAMINA (PERSERO) 15 February 2017Documento15 páginasSUMMARY PQT PT PERTAMINA (PERSERO) 15 February 2017YuwantoniAl100% (1)

- MAT 2130 - Heat-treatable Carbon Steel Data SheetDocumento3 páginasMAT 2130 - Heat-treatable Carbon Steel Data Sheetbaskaran ayyapparajAún no hay calificaciones

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 142, - , - : Bright Steel, Unalloyed, Cold DrawnDocumento3 páginasMCGB - Data Sheet For Suppliers Old MAT Nos.: 142, - , - : Bright Steel, Unalloyed, Cold Drawnbaskaran ayyapparajAún no hay calificaciones

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 202, - , - : Heat-Treatable Steel, Carbon SteelDocumento3 páginasMCGB - Data Sheet For Suppliers Old MAT Nos.: 202, - , - : Heat-Treatable Steel, Carbon Steelbaskaran ayyapparajAún no hay calificaciones

- Offshore Testing Services Lab ReportDocumento3 páginasOffshore Testing Services Lab ReportKandula RajuAún no hay calificaciones

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 143, - , - : Bright Steel Unalloyed, Cold DrawnDocumento3 páginasMCGB - Data Sheet For Suppliers Old MAT Nos.: 143, - , - : Bright Steel Unalloyed, Cold Drawnbaskaran ayyapparajAún no hay calificaciones

- Magnetic Particle Examination: Ies-Industrial Engineering ServicesDocumento2 páginasMagnetic Particle Examination: Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanAún no hay calificaciones

- IES-MPI ReportDocumento2 páginasIES-MPI ReportMD Shadikul Huq ShezanAún no hay calificaciones

- Test Report PDFDocumento4 páginasTest Report PDFHarshad ArondkarAún no hay calificaciones

- Icpo NG En590 2704231111Documento3 páginasIcpo NG En590 2704231111Nikita NovikovAún no hay calificaciones

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 282, - , - : Carbon Steel For Large ForgingsDocumento3 páginasMCGB - Data Sheet For Suppliers Old MAT Nos.: 282, - , - : Carbon Steel For Large Forgingsbaskaran ayyapparajAún no hay calificaciones

- Certificado EsparragosDocumento8 páginasCertificado EsparragosJesus CondoriAún no hay calificaciones

- IES-MPI Report AcceptedDocumento2 páginasIES-MPI Report AcceptedMD Shadikul Huq ShezanAún no hay calificaciones

- Reliable Pipes and TubesDocumento4 páginasReliable Pipes and TubesretrogradesAún no hay calificaciones

- Perno GR2 Unc HDG 5-8 X 1 1-2 (Tkr+hy7129220)Documento1 páginaPerno GR2 Unc HDG 5-8 X 1 1-2 (Tkr+hy7129220)Naomi Mascco VilchezAún no hay calificaciones

- 3685 Mir 006 PDFDocumento1 página3685 Mir 006 PDFashishpearlAún no hay calificaciones

- 3685 Mir 006 PDFDocumento1 página3685 Mir 006 PDFashishpearlAún no hay calificaciones

- 3685 Mir 006Documento1 página3685 Mir 006ashishpearlAún no hay calificaciones

- Page 2 Tsi MTC 150x4 (MTC - 247)Documento2 páginasPage 2 Tsi MTC 150x4 (MTC - 247)trayojam.rilAún no hay calificaciones

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 211, - , - : Heat-Treatable Steel, Low Alloy Steel, Cr-MoDocumento3 páginasMCGB - Data Sheet For Suppliers Old MAT Nos.: 211, - , - : Heat-Treatable Steel, Low Alloy Steel, Cr-Mobaskaran ayyapparajAún no hay calificaciones

- TDC For Pipes - Sa 106 GR.BDocumento2 páginasTDC For Pipes - Sa 106 GR.BRenny DevassyAún no hay calificaciones

- HIC & SSC Test ProcedureDocumento32 páginasHIC & SSC Test ProcedureMohamed FarisAún no hay calificaciones

- Transformer: Quality Assurance PlanDocumento9 páginasTransformer: Quality Assurance PlanRadhakrishnan VAún no hay calificaciones

- Din933 A4l 8 X 80 MMDocumento1 páginaDin933 A4l 8 X 80 MMM K ANBUDURAIAún no hay calificaciones

- EPCC-03 TS-GEN-L-6405-0468 Date 22.02.2023Documento9 páginasEPCC-03 TS-GEN-L-6405-0468 Date 22.02.2023ISGECFAB YARD2Aún no hay calificaciones

- MGT-FF-007 - Master List of External OriginDocumento6 páginasMGT-FF-007 - Master List of External OriginGourav SharmaAún no hay calificaciones

- CC - Cot 90g S-S (Cotss) 73.03x7.01 304 Tras LRDocumento2 páginasCC - Cot 90g S-S (Cotss) 73.03x7.01 304 Tras LRNarcis NarteaAún no hay calificaciones

- AMBICA 36mm Rod SS316L MTCDocumento2 páginasAMBICA 36mm Rod SS316L MTCmetalexinAún no hay calificaciones

- 4555 70 03 Ec2125 1111Documento4 páginas4555 70 03 Ec2125 1111Deepak HoleAún no hay calificaciones

- 4555 70 03 Ec2125 1111Documento4 páginas4555 70 03 Ec2125 1111Deepak HoleAún no hay calificaciones

- 1300 EC2192 SignedDocumento4 páginas1300 EC2192 SignedDeepak HoleAún no hay calificaciones

- 1299 EC2153 SignedDocumento5 páginas1299 EC2153 SignedDeepak HoleAún no hay calificaciones

- 1485 - EC2172-signedDocumento4 páginas1485 - EC2172-signedDeepak HoleAún no hay calificaciones

- Deepak Dattatray HoleDocumento2 páginasDeepak Dattatray HoleDeepak HoleAún no hay calificaciones

- 1300 EC2192 SignedDocumento4 páginas1300 EC2192 SignedDeepak HoleAún no hay calificaciones

- 4555 70 03 Ec2125 1111Documento4 páginas4555 70 03 Ec2125 1111Deepak HoleAún no hay calificaciones

- 4555 70 03 Ec2125 1111Documento4 páginas4555 70 03 Ec2125 1111Deepak HoleAún no hay calificaciones

- 1485 - EC2172-signedDocumento4 páginas1485 - EC2172-signedDeepak HoleAún no hay calificaciones

- 1300 EC1986 SignedDocumento4 páginas1300 EC1986 SignedDeepak HoleAún no hay calificaciones

- 1300 EC1986 SignedDocumento4 páginas1300 EC1986 SignedDeepak HoleAún no hay calificaciones

- Htytdjhfjgk LJ K JKFTDRGBNDocumento45 páginasHtytdjhfjgk LJ K JKFTDRGBNDeepak HoleAún no hay calificaciones

- 1299 EC2153 SignedDocumento5 páginas1299 EC2153 SignedDeepak HoleAún no hay calificaciones

- Repayment-Deepak As On Date 07.12.2022Documento2 páginasRepayment-Deepak As On Date 07.12.2022Deepak HoleAún no hay calificaciones

- F-HRA-05 On Job Training Record R04Documento3 páginasF-HRA-05 On Job Training Record R04Deepak HoleAún no hay calificaciones

- Adwo PedDocumento1 páginaAdwo PedDeepak HoleAún no hay calificaciones

- 4340/ BS EN10083 817M40, 140 KSI (965 MPA), FORGINGS AND BAR Stock, Restricted Use SubseaDocumento3 páginas4340/ BS EN10083 817M40, 140 KSI (965 MPA), FORGINGS AND BAR Stock, Restricted Use SubseaDeepak HoleAún no hay calificaciones

- PD Nomenclature PDFDocumento1 páginaPD Nomenclature PDFDeepak HoleAún no hay calificaciones

- Quality Assurance PlanDocumento3 páginasQuality Assurance PlanDeepak HoleAún no hay calificaciones

- Deviation Request - Raltech 10 10 2020Documento1 páginaDeviation Request - Raltech 10 10 2020Deepak HoleAún no hay calificaciones

- Addition To Forging Requirements QuestioniareDocumento1 páginaAddition To Forging Requirements QuestioniareDeepak HoleAún no hay calificaciones

- Corrective and Preventive Action (8D) Report: Cust. Complaint Serial Number Cust. Complaint Ref. No. & DateDocumento1 páginaCorrective and Preventive Action (8D) Report: Cust. Complaint Serial Number Cust. Complaint Ref. No. & DateDeepak HoleAún no hay calificaciones

- Test ReportDocumento1 páginaTest ReportDeepak HoleAún no hay calificaciones

- Customer Complaint Summery Sheet Updated 23.10.20 18.22Documento1 páginaCustomer Complaint Summery Sheet Updated 23.10.20 18.22Deepak HoleAún no hay calificaciones

- STK/WIF/1920/1691 Bar No.: C CR MN Mo Ni P S Si VDocumento32 páginasSTK/WIF/1920/1691 Bar No.: C CR MN Mo Ni P S Si VDeepak HoleAún no hay calificaciones

- STK/WIF/20-21/283 Bar No.: QTC With DespatchDocumento58 páginasSTK/WIF/20-21/283 Bar No.: QTC With DespatchDeepak HoleAún no hay calificaciones

- Material Test Certificate: M/s Alstom Projects India LimitedDocumento1 páginaMaterial Test Certificate: M/s Alstom Projects India LimitedDeepak HoleAún no hay calificaciones

- Corrective and Preventive Action (8D) Report: Cust. Complaint Serial Number Cust. Complaint Ref. No. & DateDocumento1 páginaCorrective and Preventive Action (8D) Report: Cust. Complaint Serial Number Cust. Complaint Ref. No. & DateDeepak HoleAún no hay calificaciones

- Bar No - 5763: Test CertificateDocumento2 páginasBar No - 5763: Test CertificateDeepak HoleAún no hay calificaciones

- Check For Palindrome: Compute GCD and LCMDocumento3 páginasCheck For Palindrome: Compute GCD and LCMAadhi JAún no hay calificaciones

- The Champion Legal Ads: 11-02-23Documento58 páginasThe Champion Legal Ads: 11-02-23Donna S. SeayAún no hay calificaciones

- Lead Funnels On Funnel Swipe File - TrelloDocumento5 páginasLead Funnels On Funnel Swipe File - TrelloKatherie BriersAún no hay calificaciones

- DodupukegakobemavasevuDocumento3 páginasDodupukegakobemavasevuMartian SamaanAún no hay calificaciones

- Sensor Guide: Standard Triaxial Geophones Specialty Triaxial Geophones Standard Overpressure MicrophonesDocumento1 páginaSensor Guide: Standard Triaxial Geophones Specialty Triaxial Geophones Standard Overpressure MicrophonesDennis Elias TaipeAún no hay calificaciones

- CA 1 - Đề thi AV5 - CLC - Made - efDocumento5 páginasCA 1 - Đề thi AV5 - CLC - Made - efQuang NguyenAún no hay calificaciones

- ZXJ 10 SPCDocumento7 páginasZXJ 10 SPCMuhammad Yaseen100% (1)

- Private Void BtnDeleteActionPerformedDocumento12 páginasPrivate Void BtnDeleteActionPerformedDDDAún no hay calificaciones

- Katja Kruckeberg, Wolfgang Amann, Mike Green-Leadership and Personal Development - A Toolbox For The 21st Century Professional-Information Age Publishing (2011)Documento383 páginasKatja Kruckeberg, Wolfgang Amann, Mike Green-Leadership and Personal Development - A Toolbox For The 21st Century Professional-Information Age Publishing (2011)MariaIoanaTelecan100% (1)

- The Arcane Formulas or Mental AlchemyDocumento121 páginasThe Arcane Formulas or Mental AlchemyTim Boire100% (1)

- Low rank tensor product smooths for GAMMsDocumento24 páginasLow rank tensor product smooths for GAMMsDiego SotoAún no hay calificaciones

- 6907 6 52 0040Documento35 páginas6907 6 52 0040amitkumar8946Aún no hay calificaciones

- Department of Education Region IV-A Business Plan GuideDocumento4 páginasDepartment of Education Region IV-A Business Plan GuideSEAN DANIEL AGUARESAún no hay calificaciones

- CA Ashish Dewani - Resume-1Documento2 páginasCA Ashish Dewani - Resume-1Payal JainAún no hay calificaciones

- Green Screen Background Remover Using CV SystemDocumento20 páginasGreen Screen Background Remover Using CV SystemSubhamAún no hay calificaciones

- Bashir Ahmad NewDocumento3 páginasBashir Ahmad NewBashir AhmadAún no hay calificaciones

- Sigmund Freud and His Main TheoriesDocumento5 páginasSigmund Freud and His Main TheoriesNguyen HarryAún no hay calificaciones

- Assembly Transmission Volvo A40GDocumento52 páginasAssembly Transmission Volvo A40GNanang SetiawanAún no hay calificaciones

- Academic Transition To Senior High SchoolDocumento30 páginasAcademic Transition To Senior High SchoolGabriel ExalaAún no hay calificaciones

- Exoskeleton Power Requirements Based on Human BiomechanicsDocumento54 páginasExoskeleton Power Requirements Based on Human Biomechanicsja2ja1Aún no hay calificaciones

- Effective-Plant-Course Brochure NovDocumento8 páginasEffective-Plant-Course Brochure NovAzri HafiziAún no hay calificaciones

- Texas Final LeadsDocumento36 páginasTexas Final Leadsabdullahmohammed4460Aún no hay calificaciones

- The historical evolution of organizational behavior and how it shaped modern managementDocumento3 páginasThe historical evolution of organizational behavior and how it shaped modern managementSaravanan Swagger100% (1)

- 10 ExtSpringsDocumento27 páginas10 ExtSpringsresh27Aún no hay calificaciones

- Ethics in ResearchDocumento21 páginasEthics in Researchmukku_raviAún no hay calificaciones

- Risk Assissment 1Documento12 páginasRisk Assissment 1Ibrahim BouzinaAún no hay calificaciones

- Evolution of The Fire SprinklerDocumento11 páginasEvolution of The Fire SprinklerPedro DudesonAún no hay calificaciones

- Theories of SelfDocumento5 páginasTheories of SelfTd Devi AmmacayangAún no hay calificaciones

- Methanol Technical Data Sheet FactsDocumento1 páginaMethanol Technical Data Sheet FactsmkgmotleyAún no hay calificaciones