Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Co PDF

Cargado por

Moheb MakarTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Co PDF

Cargado por

Moheb MakarCopyright:

Formatos disponibles

B ENGINE

ENGINE COOLING SYSTEM

SECTION CO CO

E

CONTENTS

PRECAUTIONS .......................................................... 2 Components (Models Without A/C) ........................ 15 F

Precautions for Supplemental Restraint System Removal and Installation ........................................ 16

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN- REMOVAL ........................................................... 16

SIONER” .................................................................. 2 INSTALLATION ................................................... 16 G

Precautions Necessary for Steering Wheel Rotation DISASSEMBLY AND ASSEMBLY .......................... 16

After Battery Disconnect .......................................... 2 DISASSEMBLY ................................................... 16

OPERATION PROCEDURE ................................. 2 INSPECTION AFTER DISASSEMBLY ............... 16

H

Precautions for Liquid Gasket .................................. 2 ASSEMBLY ......................................................... 16

REMOVAL OF LIQUID GASKET SEALING .......... 2 WATER PUMP .......................................................... 17

LIQUID GASKET APPLICATION PROCEDURE..... 3 Components ........................................................... 17

PREPARATION ........................................................... 4 Removal and Installation ........................................ 17 I

Special Service Tools ............................................... 4 REMOVAL ........................................................... 17

Commercial Service Tools ........................................ 4 INSPECTION AFTER REMOVAL ....................... 17

OVERHEATING CAUSE ANALYSIS .......................... 5 INSTALLATION ................................................... 17 J

Troubleshooting Chart .............................................. 5 INSPECTION AFTER INSTALLATION ................ 17

COOLING SYSTEM .................................................... 7 THERMOSTAT .......................................................... 18

Cooling Circuit .......................................................... 7 Components ........................................................... 18

K

ENGINE COOLANT .................................................... 8 Removal and Installation ........................................ 18

Inspection ................................................................. 8 REMOVAL ........................................................... 18

LEVEL CHECK ..................................................... 8 INSPECTION AFTER REMOVAL ....................... 18

CHECKING COOLING SYSTEM FOR LEAKS ..... 8 INSTALLATION ................................................... 19 L

Changing Engine Coolant ........................................ 8 INSPECTION AFTER INSTALLATION ................ 19

DRAINING ENGINE COOLANT ........................... 8 WATER OUTLET AND WATER CONTROL VALVE... 20

REFILLING ENGINE COOLANT .......................... 8 Components ........................................................... 20 M

FLUSHING COOLING SYSTEM ........................... 9 Removal and Installation ........................................ 20

RADIATOR .................................................................11 REMOVAL ........................................................... 20

Components ............................................................11 INSPECTION AFTER REMOVAL ....................... 21

Removal and Installation ........................................ 12 INSTALLATION ................................................... 21

REMOVAL ........................................................... 12 INSPECTION AFTER INSTALLATION ................ 22

INSTALLATION ................................................... 12 SERVICE DATA AND SPECIFICATIONS (SDS) ...... 23

INSPECTION AFTER INSTALLATION ............... 12 Standard and Limit .................................................. 23

Checking Radiator Cap .......................................... 13 CAPACITY ........................................................... 23

Checking Radiator .................................................. 13 THERMOSTAT .................................................... 23

COOLING FAN ......................................................... 15 WATER CONTROL VALVE ................................. 23

Components (Models With A/C) ............................. 15 RADIATOR .......................................................... 23

Revision: June 2006 CO-1 2007 Versa

PRECAUTIONS

PRECAUTIONS PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER” EBS00U8A

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

● To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

● Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

● Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions Necessary for Steering Wheel Rotation After Battery Disconnect

EBS00U8C

NOTE:

● This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT

SYSTEM).

● Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK″ position.

● Always use CONSULT-II to perform self-diagnosis as a part of each function inspection after finishing

work. If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the ″LOCK″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of all control units using CONSULT-II.

Precautions for Liquid Gasket EBS00U8B

REMOVAL OF LIQUID GASKET SEALING

● After removing nuts and bolts, separate the mating surface, using Tool and remove old liquid gasket seal-

ing.

Revision: June 2006 CO-2 2007 Versa

PRECAUTIONS

Tool number : KV10111100 (J-37228)

A

CAUTION:

Be careful not to damage the mating surfaces.

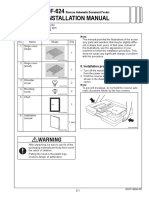

● Tap Tool to insert it (1), and then slide it by tapping on the side CO

(2) as shown.

● In areas where Tool is difficult to use, use plastic hammer to

lightly tap the parts, to remove it.

C

CAUTION:

If for some unavoidable reason suitable tool such as screw-

driver is used, be careful not to damage the mating sur- WBIA0566E

faces. D

LIQUID GASKET APPLICATION PROCEDURE

1. Remove old liquid gasket adhering to the liquid gasket applica- E

tion surface and the mating surface, using scraper.

● Remove liquid gasket completely from the groove of the liquid

gasket application surface, bolts, and bolt holes.

F

2. Thoroughly clean the mating surfaces and remove adhering

moisture, grease and foreign materials.

3. Attach liquid gasket tube to Tool.

G

Tool number : WS39930000 ( — )

PBIC0003E

H

K

WBIA0567E

Use Genuine RTV Silicone Sealant or equivalent. Refer to GI-46, "Recommended Chemical Prod-

ucts and Sealants" . L

4. Apply liquid gasket without breaks to the specified location with the specified dimensions.

● If there is a groove for the liquid gasket application, apply liquid gasket to the groove.

M

● As for the bolt holes, normally apply liquid gasket inside the

holes. Occasionally, it should be applied outside the holes.

Make sure to read the text of service manual.

● Within five minutes of liquid gasket application, install the mat-

ing component.

● If liquid gasket protrudes, wipe it off immediately.

● Do not retighten nuts or bolts after the installation.

● After 30 minutes or more have passed from the installation, fill

engine oil and engine coolant.

CAUTION: SEM159F

If there are specific instructions in this manual, observe them.

Revision: June 2006 CO-3 2007 Versa

PREPARATION

PREPARATION PFP:00002

Special Service Tools EBS00U8D

The actual shapes of Kent-Moore tools may from those of special service tools illustrated here.

Tool number Description

(Kent-Moore No.)

Tool name

WS39930000 Pressing the tube of liquid gasket

( — )

Tube pressure

S-NT052

EG17650301 Adapting radiator cap tester to radiator cap

(J-33984-A) and radiator filler neck

Radiator cap tester adapter a: 28 (1.10) dia.

b: 31.4 (1.236) dia.

c: 41.3 (1.626) dia.

Unit: mm (in)

S-NT564

KV10111100 Removing chain tensioner cover and water

(J-37228) pump cover

Seal cutter

NT046

— Checking concentration of ethylene glycol in

(J-23688) engine coolant

Engine coolant refractometer

WBIA0539E

Commercial Service Tools EBS00T77

Tool name Description

Radiator cap tester Checking radiator and radiator cap

PBIC1982E

Revision: June 2006 CO-4 2007 Versa

OVERHEATING CAUSE ANALYSIS

OVERHEATING CAUSE ANALYSIS PFP:00012

A

Troubleshooting Chart EBS00T78

Symptom Check items

Water pump malfunction Worn or loose drive belt CO

Thermostat stuck closed Thermostat

Dust contamination or

C

Poor heat transfer Damaged fins paper clogging —

Physical damage

Clogged radiator cooling Excess foreign material D

tube (rust, dirt, sand, etc.)

Cooling fan does not oper-

ate

E

Reduced air flow High resistance to fan rota- —

tion Fan assembly

Damaged fan blades

F

Damaged radiator shroud — —

Improper engine coolant

Cooling sys- — — —

mixture ratio G

tem parts Engine coolant viscosity

malfunction Poor engine coolant quality — —

Loose clamp

Cooling hose H

Cracked hose

Water pump Poor sealing

Loose

Radiator cap I

Poor sealing

Engine coolant leaks

O-ring for damage, deterio-

Insufficient engine coolant ration or improper fitting J

Radiator

Cracked radiator tank

Cracked radiator core

Reservoir tank Cracked reservoir tank K

Cylinder head deterioration

Exhaust gas leaks into

Overflowing reservoir tank Cylinder head gasket dete-

cooling system L

rioration

Revision: June 2006 CO-5 2007 Versa

OVERHEATING CAUSE ANALYSIS

Symptom Check items

High engine rpm under no

load

Driving in low gear for

Abusive driving

extended time

Driving at extremely high

speed

— Overload on engine

Power train system mal-

function

Installed improper size

Except cool- wheels and tires —

ing system

parts mal- Dragging brakes

function Improper ignition timing

Blocked bumper —

Installed front bumper fas-

cia cover

Blocked radiator grille

Mud contamination or

Blocked or restricted air

paper clogging —

flow

Blocked radiator

—

Blocked condenser

Blocked air flow

Installed large fog lamp

Revision: June 2006 CO-6 2007 Versa

COOLING SYSTEM

COOLING SYSTEM PFP:21020

A

Cooling Circuit EBS00U89

CO

PBIC4719E

Revision: June 2006 CO-7 2007 Versa

ENGINE COOLANT

ENGINE COOLANT PFP:KQ100

Inspection EBS00T7A

LEVEL CHECK

● Check if the reservoir tank engine coolant level is within the

“MIN” to “MAX” range when engine is cool.

● Adjust the engine coolant level as necessary.

SMA412B

CHECKING COOLING SYSTEM FOR LEAKS

To check for leaks, apply pressure to the cooling system using Tool.

Tool number : EG17650301 (J-33984-A)

Testing pressure : 157 kPa (1.6 kg/cm2 , 23 psi)

WARNING:

Never remove the radiator cap when the engine is hot. Serious

burns could occur from high pressure coolant escaping from

the radiator.

CAUTION:

Higher pressure than specified may cause radiator damage. WBIA0568E

Changing Engine Coolant EBS00T7B

WARNING:

● To avoid being scalded, do not change engine coolant when engine is hot.

● Wrap a thick cloth around radiator cap and carefully remove the cap. First, turn the cap a quarter

of a turn to release built-up pressure. Then turn the cap all the way.

● Be careful not to allow engine coolant to contact drive belt.

DRAINING ENGINE COOLANT

1. Open radiator drain plug (1) at the bottom of radiator, and then

remove radiator cap.

● Front

When drain all of engine coolant in the system, open water

drain plug on cylinder block. Refer to EM-77, "CYLINDER

BLOCK" .

CAUTION:

● Perform this step when engine is cold.

● Do not spill engine coolant on drive belt.

PBIC3799E

2. Remove reservoir tank as necessary, and drain engine coolant and clean reservoir tank before installing.

Refer to CO-11, "RADIATOR" .

3. Check drained engine coolant for contaminants such as rust, corrosion or discoloration.

If contaminated, flush the engine cooling system. Refer to CO-9, "FLUSHING COOLING SYSTEM" .

REFILLING ENGINE COOLANT

1. Install reservoir tank if removed. Refer to CO-11, "RADIATOR" .

2. Install radiator drain plug.

Revision: June 2006 CO-8 2007 Versa

ENGINE COOLANT

● If water drain plug on cylinder block is removed, close and tighten it. Refer to EM-77, "CYLIN-

DER BLOCK" . A

CAUTION:

Be sure to clean radiator drain plug and install with new O-ring. Refer to CO-11, "Components" .

3. Make sure that each hose clamp has been firmly tightened. CO

4. Remove air duct assembly. Refer to EM-16, "AIR CLEANER AND AIR DUCT" .

5. Disconnect heater hose (1) at position ( ) as shown.

C

● Front

● Reposition heater hose as high as possible.

D

PBIC3802E

F

6. Fill radiator and reservoir tank to specified level.

● Pour engine coolant through engine coolant filler neck

slowly of less than 2 (2 1/8 US qt, 1-3/4 lmp qt) a minute G

to allow air in system to escape.

● Use NISSAN Genuine Engine Coolant or equivalent

mixed with water (distilled or demineralized). Fill cooling H

system to specification. Refer to MA-11, "RECOM-

MENDED FLUIDS AND LUBRICANTS".

● When engine coolant overflows disconnected heater hose, I

connect heater hose, and continue filling the engine coolant, if

SMA182B

heater hose is disconnected.

7. Install radiator cap. J

8. Install air duct assembly. Refer to EM-16, "AIR CLEANER AND AIR DUCT" .

9. Warm up until opening thermostat. Standard for warming-up time is approximately 10 minutes at 3,000

rpm. K

● Make sure thermostat opening condition by touching radiator hose (lower) to see a flow of warm water.

CAUTION:

Watch water temperature gauge so as not to overheat the engine. L

10. Stop engine and cool down to less than approximately 50°C (122°F).

● Cool down using fan to reduce the time.

● If necessary, refill radiator up to filler neck with engine coolant. M

11. Refill reservoir tank to “MAX” level line with engine coolant.

12. Repeat steps 6 through 11 two or more times with radiator cap installed until engine coolant level no

longer drops.

13. Check cooling system for leaks with engine running.

14. Warm up engine, and check for sound of engine coolant flow while running engine from idle up to 3,000

rpm with heater temperature controller set at several position between “COOL” and “WARM”.

● Sound may be noticeable at heater unit.

15. Repeat step 14 three times.

16. If sound is heard, bleed air from cooling system by repeating steps 6 through 11 until engine coolant level

no longer drops.

FLUSHING COOLING SYSTEM

1. Install reservoir tank if removed. Refer to CO-11, "RADIATOR" .

2. Install radiator drain plug.

Revision: June 2006 CO-9 2007 Versa

ENGINE COOLANT

● If water drain plug on cylinder block is removed, close and tighten it. Refer to EM-77, "CYLIN-

DER BLOCK" .

CAUTION:

Be sure to clean radiator drain plug and install with new O-ring. Refer to CO-11, "Components" .

3. Fill radiator and reservoir tank with water and reinstall radiator cap.

4. Run engine and warm it up to normal operating temperature.

5. Rev engine two or three times under no-load.

6. Stop engine and wait until it cools down.

7. Drain water from the cooling system. Refer to CO-8, "DRAINING ENGINE COOLANT" .

8. Repeat steps 1 through 7 until clear water begins to drain from radiator.

Revision: June 2006 CO-10 2007 Versa

RADIATOR

RADIATOR PFP:21400

A

Components EBS00T7C

CO

PBIC4720E

1. Reservoir tank cap 2. Reservoir tank 3. Radiator hose (upper)

4. Mounting rubber (upper) 5. Radiator cap 6. Reservoir tank hose

7. Radiator 8. A/T fluid cooler hose 9. Mounting rubber (lower)

10. O-ring 11. Radiator drain plug 12. A/T fluid cooler hose

13. Radiator hose (lower) 14. Cooling fan assembly 15. CVT fluid cooler hose

16. CVT fluid cooler hose A. To water outlet B. To A/T

C. To water inlet D. M/T models E. CVT models

F. Models with A/C G. To CVT

Revision: June 2006 CO-11 2007 Versa

RADIATOR

Removal and Installation EBS00T7D

WARNING:

Do not remove radiator cap when the engine is hot. Serious burns could occur from high-pressure

engine coolant escaping from radiator. Wrap a thick cloth around the cap. Slowly turn it a quarter of a

turn to release built-up pressure. Carefully remove radiator cap by turning it all the way.

REMOVAL

1. Drain engine coolant from radiator. Refer to CO-8, "Changing Engine Coolant" .

CAUTION:

● Perform this step when engine is cold.

● Do not spill engine coolant on drive belt.

2. Remove air duct (inlet). Refer to EM-16, "AIR CLEANER AND AIR DUCT" .

3. Remove reservoir tank as follows:

a. Disconnect reservoir tank hose.

b. Release the tab (A) in the direction shown by the arrow ( ).

c. Lift up while removing the reservoir tank hose, and remove it.

PBIC3800E

4. Disconnect harness connector from fan motors, and move harness to aside.

5. Disconnect CVT or A/T fluid cooler hoses if equipped.

● Install plug to avoid leakage of CVT or A/T fluid if equipped.

6. Remove radiator hoses (upper and lower).

7. Remove radiator core support cover. Refer toBL-20, "RADIATOR CORE SUPPORT" .

8. Remove radiator core support (upper) bolts, bolts of stationary

part on the radiator core support side and clip. Lift radiator from

radiator (upper) mount part of radiator core support (upper) (2).

9. Move radiator assembly (1) to the rearward direction of vehicle,

and then lift it upward to remove.

CAUTION:

Do not damage or scratch A/C condenser if equipped and

radiator core when removing.

PBIC3805E

INSTALLATION

Installation is the reverse order of removal.

CAUTION:

Do not damage or scratch A/C condenser if equipped and radiator core when removing.

INSPECTION AFTER INSTALLATION

● Check for leaks of engine coolant. Refer to CO-8, "LEVEL CHECK" .

● Start and warm up engine. Visually check if there is no leaks of engine coolant and CVT or A/T fluid if

equipped. Refer to CVT-16, "CVT FLUID" or AT-16, "A/T FLUID" .

Revision: June 2006 CO-12 2007 Versa

RADIATOR

Checking Radiator Cap EBS00T7E

A

● Check valve seat of radiator cap.

– Check if valve seat is swollen to the extent that the edge of the

plunger cannot be seen when watching it vertically from the top.

CO

– Check if valve seat has no soil and damage.

D

PBIC2816E

● Pull negative-pressure valve to open it, and make sure that it is E

completely closed when released.

– Make sure that there is no dirt or damage on the valve seat of

radiator cap negative-pressure valve.

F

– Make sure that the valve operates properly in the opening and

closing conditions.

SMA967B

H

● Check radiator cap relief pressure using Tool.

Tool number : EG17650301 (J-33984-A) I

Standard: 78 – 98 kPa (0.78 - 0.98 bar, 0.8 – 1.0 kg/cm2 ,

11 – 14 psi) J

Limit: 59 kPa (0.59 bar, 0.6 kg/cm2 , 9 psi)

– When connecting the radiator cap to the tester, apply water or K

coolant to the cap seal surface.

– Replace the radiator cap if there is an abnormality in the nega- WBIA0570E

tive-pressure valve, or if the open-valve pressure is outside of L

the standard values.

● Replace radiator cap if there it does not comply to specifications to the above three checks.

M

CAUTION:

When installing radiator cap, thoroughly wipe out the radiator filler neck to remove any waxy residue

or foreign material.

Checking Radiator EBS00T7F

Check radiator for mud or clogging. If necessary, clean radiator as follows.

● Be careful not to bend or damage radiator fins.

● When radiator is cleaned without removal, remove all surrounding parts such as cooling fan, radiator

shroud and horns. Then tape harness and connectors to prevent water from entering.

1. Apply water by hose to the back side of the radiator core vertically downward.

2. Apply water again to all radiator core surface once per minute.

3. Stop washing if any stains no longer flow out from radiator.

4. Blow air into the back side of radiator core vertically downward.

● Use compressed air lower than 490 kPa (4.9 bar, 5 kg/cm2 , 71 psi) and keep distance more than 30 cm

(11.8 in).

Revision: June 2006 CO-13 2007 Versa

RADIATOR

5. Blow air again into all the radiator core surfaces once per minute until no water sprays out.

Revision: June 2006 CO-14 2007 Versa

COOLING FAN

COOLING FAN PFP:21140

A

Components (Models With A/C) EBS00U81

CO

PBIC4538E

1. Fan motor cover 2. Fan motor 3. Cooling fan control module J

4. Washer 5. Fan shroud 6. Washer

7. Cooling fan A. Apply on fan motor shaft Front

K

Components (Models Without A/C) EBS00U82

WBIA0786E

1. Fan motor 2. Fan shroud 3. Cooling fan

A. Apply on fan motor shaft Front

Revision: June 2006 CO-15 2007 Versa

COOLING FAN

Removal and Installation EBS00U83

REMOVAL

1. Drain engine coolant from radiator. Refer to CO-8, "DRAINING ENGINE COOLANT" .

CAUTION:

● Perform this step when engine is cold.

● Do not spill engine coolant on drive belt.

2. Remove air duct (inlet). Refer to EM-16, "Components" .

3. Remove reservoir tank. Refer to CO-11, "Components" .

4. Disconnect radiator hose (upper) at radiator side. Refer to CO-11, "Components" .

5. Disconnect harness connectors from fan motor, and move harness to aside.

6. Remove cooling fan assembly.

CAUTION:

Be careful not to damage or scratch the radiator core.

INSTALLATION

Installation is the reverse order of removal.

● Cooling fans are controlled by ECM. For details, refer to EC-443, "DTC P1217 ENGINE OVER TEMPER-

ATURE" .

CAUTION:

Be careful not to damage or scratch the radiator core.

DISASSEMBLY AND ASSEMBLY EBS00V62

DISASSEMBLY

1. Remove cooling fan from fan motor.

2. Remove fan motor from fan shroud.

INSPECTION AFTER DISASSEMBLY

Inspect cooling fan for crack or unusual bend.

● If anything is found, replace cooling fan.

ASSEMBLY

Assembly is the reverse order of disassembly.

Revision: June 2006 CO-16 2007 Versa

WATER PUMP

WATER PUMP PFP:21020

A

Components EBS00U84

CO

G

PBIC3921E

1. Gasket 2. Water pump

Removal and Installation EBS00U85

H

REMOVAL

1. Drain engine coolant. Refer to CO-8, "DRAINING ENGINE COOLANT" .

CAUTION: I

Perform this step when the engine is cold.

2. Remove drive belt auto-tensioner. Refer to EM-37, "TIMING CHAIN" .

3. Remove water pump. J

CAUTION:

● Handle water pump vane so that it does not contact any other parts.

K

● Water pump cannot be disassembled and should be replaced as a unit.

INSPECTION AFTER REMOVAL

● Visually check that there is no significant dirt or rusting on water L

pump body and vane (A).

● Make sure that there is no looseness in vane shaft, and that it

turns smoothly when rotated by hand. M

● Replace water pump, if necessary.

PBIC3313J

INSTALLATION

Installation is in the reverse order of removal.

INSPECTION AFTER INSTALLATION

● Check for leaks of engine coolant. Refer to CO-8, "Inspection" .

● Start and warm up the engine. Visually check if there is no leaks of engine coolant.

Revision: June 2006 CO-17 2007 Versa

THERMOSTAT

THERMOSTAT PFP:21200

Components EBS00U6H

PBIC4485E

1. Thermostat housing 2. Water hose (models with oil cooler) 3. Radiator hose (lower)

4. Water inlet 5. Thermostat 6. Rubber ring

7. Gasket A. To oil cooler B. To radiator

Engine front

Removal and Installation EBS00U6I

REMOVAL

1. Drain engine coolant. Refer to CO-8, "DRAINING ENGINE COOLANT" .

2. Remove water inlet.

3. Remove thermostat.

4. Remove water pump. Refer to CO-17, "WATER PUMP" .

5. Remove thermostat housing.

INSPECTION AFTER REMOVAL

● Place a thread (A) so that it is caught in the valves of thermostat

(1). Immerse fully in a container (B) filled with water. Heat while

stirring.

● The valve opening temperature is the temperature at which the

valve opens and falls from the thread.

● Continue heating. Check the full open valve lift amount.

● After checking the maximum valve lift amount, lower the water

temperature and check the valve closing temperature.

PBIC3314J

Revision: June 2006 CO-18 2007 Versa

THERMOSTAT

Items Thermostat

A

Valve opening temperature 80.5 - 83.5°C (177 - 182°F)

Maximum valve lift 8 mm/ 95°C (0.315 in/ 203°F)

Valve closing temperature 77°C (171°F) CO

● If out of the specification, replace thermostat.

INSTALLATION C

Installation is in the reverse order of removal.

Thermostat

CAUTION: D

Replace the rubber ring with a new one.

● Install thermostat while making rubber ring (1) groove fit to ther-

mostat flange (A) around the whole circumference. E

PBIC3315J

H

● Install thermostat (1) into the thermostat housing (2) with jiggle

valve (A) facing upwards.

I

K

PBIC3548J

Thermostat Housing

L

CAUTION:

Replace the rubber ring with a new one.

● Securely insert the rubber ring into the mating groove of thermostat housing and install it.

M

● Install the thermostat housing to the cylinder block without displacing the gasket from the gasket position.

INSPECTION AFTER INSTALLATION

● Check for leaks of engine coolant. Refer to CO-8, "CHECKING COOLING SYSTEM FOR LEAKS" .

● Start and warm up the engine. Visually check for engine coolant leaks.

Revision: June 2006 CO-19 2007 Versa

WATER OUTLET AND WATER CONTROL VALVE

WATER OUTLET AND WATER CONTROL VALVE PFP:11060

Components EBS00U86

PBIC4699E

1. Engine coolant temperature sensor 2. Rubber ring 3. Water control valve

4. Gasket 5. Water hose 6. Gasket

7. Water hose 8. Water outlet 9. Heater hose

10. Heater hose 11. Radiator hose (upper) Front

A. To heater B. To electric throttle control actuator C. To radiator

Removal and Installation EBS00U87

REMOVAL

1. Drain engine coolant. Refer to CO-8, "DRAINING ENGINE COOLANT" .

CAUTION:

Perform this step when the engine is cold.

2. Remove air duct. Refer to EM-16, "Components" .

3. Remove radiator hose (upper). Refer to CO-11, "Components" .

4. Remove heater hoses and water hoses.

5. Remove water outlet.

6. Remove water control valve.

7. Remove engine coolant temperature sensor, if necessary.

CAUTION:

● Handle carefully to avoid any shock to engine coolant temperature sensor.

● Replace the gasket with a new one.

Revision: June 2006 CO-20 2007 Versa

WATER OUTLET AND WATER CONTROL VALVE

INSPECTION AFTER REMOVAL

● Place a thread (A) so that it is caught in the valves of water con- A

trol valve (1). Immerse fully in a container (B) filled with water.

Heat while stirring.

● The valve opening temperature is the temperature at which the CO

valve opens and falls from the thread.

● Continue heating. Check the full open valve lift amount.

NOTE: C

The maximum valve lift amount standard temperature for water

control valve is the reference value.

● After checking the maximum valve lift amount, lower the water PBIC3314J

D

temperature and check the valve closing temperature.

Valve opening temperature 93.5 - 96.5°C (200 - 206°F)

E

Maximum valve lift 8 mm/ 108°C (0.315 in/ 226°F)

Valve closing temperature 90°C (194°F)

● If out of the specification, replace water control valve. F

INSTALLATION

Installation is in the reverse order of removal.

G

Water Control Valve

CAUTION:

Replace the rubber ring with a new one. H

● Install water control valve while making rubber ring (1) groove fit

to water control valve flange (A) around the whole circumfer-

ence.

I

K

PBIC3317J

● While the mark (A) points to up, install water control valve (2)

L

with frame center (B) facing straight upward into water outlet (1).

PBIC4700E

Water Outlet

Install the water control valve to the cylinder head without displacing the valve from the valve position.

Revision: June 2006 CO-21 2007 Versa

WATER OUTLET AND WATER CONTROL VALVE

Water Hoses

Install water hoses (3),(5) as shown.

● Electric throttle control actuator (1)

● Clamp (2)

● Water outlet (4)

● Paint mark (A)

● Clamp shall not interfere with the bulged area (B)

PBIC4703E

INSPECTION AFTER INSTALLATION

● Check for leaks of engine coolant. Refer to CO-8, "Inspection" .

● Start and warm up the engine. Visually check if there is no leaks of engine coolant.

Revision: June 2006 CO-22 2007 Versa

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS) PFP:00030

A

Standard and Limit EBS00T7Q

CAPACITY

Unit: (US qt, lmp qt)

CO

Engine coolant capacity (with reservoir tank at “MAX” level) Approx. 6.8 (7 1/4, 6.0)

THERMOSTAT

C

Valve opening temperature 80.5 - 83.5°C (177 - 182°F)

Maximum valve lift 8 mm/ 95°C (0.315 in/ 203°F)

Valve closing temperature 77°C (171°F) D

WATER CONTROL VALVE

Valve opening temperature 93.5 - 96.5°C (200 - 206°F)

E

Maximum valve lift 8 mm/ 108°C (0.315 in/ 226°F)

Valve closing temperature 90°C (194°F)

RADIATOR F

2

Unit: kPa (bar, kg/cm , psi)

Standard 78 - 98 (0.78 - 0.98, 0.8 - 1.0, 11- 14)

Cap relief pressure G

Limit 59 (0.59, 0.6, 9)

Leakage test pressure 157 (1.57, 1.6, 23)

H

Revision: June 2006 CO-23 2007 Versa

SERVICE DATA AND SPECIFICATIONS (SDS)

Revision: June 2006 CO-24 2007 Versa

También podría gustarte

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- FS 534Documento13 páginasFS 534Moheb Makar100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- DF 624 PDFDocumento9 páginasDF 624 PDFMoheb MakarAún no hay calificaciones

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (895)

- DF 624 PDFDocumento9 páginasDF 624 PDFMoheb Makar100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- DF 701Documento13 páginasDF 701Moheb MakarAún no hay calificaciones

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (588)

- DF 624Documento9 páginasDF 624Moheb MakarAún no hay calificaciones

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (400)

- Stage 1 Professional Engineer SummaryDocumento6 páginasStage 1 Professional Engineer SummaryMoheb MakarAún no hay calificaciones

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- Bibliotheca AlexandrinaDocumento7 páginasBibliotheca AlexandrinaMoheb MakarAún no hay calificaciones

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Ir5000 6000smDocumento839 páginasIr5000 6000smoleg-spb85% (13)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2259)

- Orascom CE2.1 Orascom Construction Industrial (OCI) One of The Prominent ConstructionDocumento3 páginasOrascom CE2.1 Orascom Construction Industrial (OCI) One of The Prominent ConstructionMoheb MakarAún no hay calificaciones

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (74)

- Rexnord Product Catalogue 2013 PDFDocumento6 páginasRexnord Product Catalogue 2013 PDFMahasweta MitraAún no hay calificaciones

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- Cooling Tower DesignDocumento11 páginasCooling Tower DesignSmrutiAún no hay calificaciones

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- S.K.M Air Conditioning LLC: Spare Parts CatalogueDocumento20 páginasS.K.M Air Conditioning LLC: Spare Parts Catalogueomar farukAún no hay calificaciones

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Installation Instructions: WarningDocumento20 páginasInstallation Instructions: WarningAlfredo CórdobaAún no hay calificaciones

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (266)

- Packaged Air Conditioner Rooftop B Series: Technical ManualDocumento93 páginasPackaged Air Conditioner Rooftop B Series: Technical ManualJf OngAún no hay calificaciones

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (345)

- Types of Fans and Their FunctionDocumento1 páginaTypes of Fans and Their FunctionZakir MunirAún no hay calificaciones

- 201511ERACS.C Air-Cooled ChillerDocumento16 páginas201511ERACS.C Air-Cooled ChillerZaw Moe KhineAún no hay calificaciones

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- Fini Cat K-Max 45-90 enDocumento16 páginasFini Cat K-Max 45-90 enbujin.gym.essenAún no hay calificaciones

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- BE EngGuide RooftopSeries12R ZXZYDocumento147 páginasBE EngGuide RooftopSeries12R ZXZYjosebolisAún no hay calificaciones

- HVAC Brochure PDFDocumento16 páginasHVAC Brochure PDFCarlos Benavides AlvarezAún no hay calificaciones

- Ata Chapters DetailsDocumento21 páginasAta Chapters Detailsanandshankar05100% (5)

- FTKG 1117 ADocumento5 páginasFTKG 1117 AyugenAún no hay calificaciones

- Amana Amvc95Documento12 páginasAmana Amvc95Veljko MilasinovicAún no hay calificaciones

- HVAC - Handbook Commercial Kitchen Ventilation - Best Practice PDFDocumento39 páginasHVAC - Handbook Commercial Kitchen Ventilation - Best Practice PDFOliver HermosaAún no hay calificaciones

- SD310 enDocumento2 páginasSD310 enBhagoo HatheyAún no hay calificaciones

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- SkyDiving Simulator PDFDocumento26 páginasSkyDiving Simulator PDFAbubu30Aún no hay calificaciones

- Ceiling Concealed DuctsDocumento2 páginasCeiling Concealed Ductsvishal vananiAún no hay calificaciones

- Fan FundamentalsDocumento24 páginasFan Fundamentalsstevenly15100% (4)

- Chapter 6XDocumento70 páginasChapter 6XvinidesoAún no hay calificaciones

- ME Laboratory 2: "Test of Centrifugal Fan and Rotary Blower"Documento17 páginasME Laboratory 2: "Test of Centrifugal Fan and Rotary Blower"Jay Mark BalaneAún no hay calificaciones

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (121)

- A406 - Manuale Cappa e BruciatoriDocumento478 páginasA406 - Manuale Cappa e BruciatoriLuis Cruz100% (1)

- Dojo Establishment in DNHADocumento16 páginasDojo Establishment in DNHAanamika tripathi100% (1)

- Handbook On WDP4 WDG4 Locomotives For Maintenance Staff PDFDocumento125 páginasHandbook On WDP4 WDG4 Locomotives For Maintenance Staff PDFabhinav lohia100% (2)

- Hand Book For Dual Cab (WDP4D) Locomotives Siemens MakeDocumento82 páginasHand Book For Dual Cab (WDP4D) Locomotives Siemens MakeSumit dharaAún no hay calificaciones

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2104)

- Coolermaster Fans 2Documento4 páginasCoolermaster Fans 2api-3767836Aún no hay calificaciones

- Brochure ECblue High Efficiency MotorsDocumento14 páginasBrochure ECblue High Efficiency MotorsCiprian BalcanAún no hay calificaciones

- Ibiza Climatronic ControlDocumento32 páginasIbiza Climatronic ControlBoris Lokas100% (3)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- Ventilation Horse Barns and Stable DesignDocumento50 páginasVentilation Horse Barns and Stable DesignQOBIT100% (2)

- Voltas VRF Variable Refrigerant Flow PDFDocumento36 páginasVoltas VRF Variable Refrigerant Flow PDFYogesh0% (1)