Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Poison Test Procedure

Cargado por

prashanthDescripción original:

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Poison Test Procedure

Cargado por

prashanthCopyright:

Formatos disponibles

Format # PI.QS.

P001

Procedure for Poison Test Revision 01

Rev. Date 16-Apr-19

Scope:

Scope of this procedure is to ensure inspectors at all stage meets the specification &

required standards are defined.

Incoming Inspection stage

In process inspection stage

Final inspection stage

Input:

Drawing specification

Measuring Instruments

Ok Samples

NG Samples

Purpose:

To test if inspectors are able to identify all defective parts mixed with ok parts.

Hence, it is a periodic test for inspector’s qualification.

Process Steps:

Arrange 20 parts with 15 ok and 5 parts NG and mix with both Ok and NG parts or mix 5%

parts in any lot.

Give these 20 parts to visual / Dimensional checking inspectors to segregate the defected

part ( He should be unaware of the process)

Observe appraiser segregating parts.

Verify the parts after his segregation and record in poison test report.

If appraiser doesn’t finds all 5 defective parts then give him training and again test him on

next day.

Do poison test for all visual & Dimensional inspectors every month / for a new inspectors

before deputing them to inspection stage.

Process Owner:

Process owner for the definition of this process is QA/QC-In-charge & MR.

Issue No / Date Sheet No. Prepared By Approved By

01-16-Apr-19 01 of 03

Format # PI.QS.P001

Procedure for Poison Test Revision 01

Rev. Date 16-Apr-19

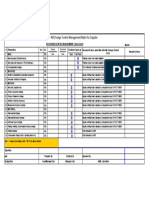

Records:

Record # Description Retention Time

PI.QA.F007 Incoming inspection report Metal parts

Till Project in use

PI.QA.F020 Incoming Inspection Report Plastic Raw Material

Till Project in use

Records:

Change Creation Date Valid from

Issue- Sup.-

No. No. Keyword Short change description

1 1 New Procedure New release 14-Nov-18 14-Nov-18

Issue No / Date Sheet No. Prepared By Approved By

01-16-Apr-19 01 of 03

También podría gustarte

- 2.procedures Initial Supply Control UpdatedDocumento3 páginas2.procedures Initial Supply Control UpdatedKapil Karhana100% (1)

- Poison Cake Test: Standard Operating ProcedureDocumento1 páginaPoison Cake Test: Standard Operating ProcedureGirdhar Sahu100% (3)

- Poison Test Sheet: Inspector Name: DateDocumento2 páginasPoison Test Sheet: Inspector Name: DateDinesh Kumar100% (4)

- Meenakshi Polymers Pvt. LTD.: Poison Test SheetDocumento2 páginasMeenakshi Polymers Pvt. LTD.: Poison Test SheetKaran Malhi100% (2)

- Red Bin Analysis ProcedureDocumento4 páginasRed Bin Analysis ProcedureVenkatesan92% (12)

- Operator Observance SheetDocumento5 páginasOperator Observance SheetEr Avinash Kumar100% (2)

- 4M Change MatrixDocumento1 página4M Change MatrixAnkit SainiAún no hay calificaciones

- Abnormality Handling - R2Documento4 páginasAbnormality Handling - R2Sagar Daund100% (4)

- Operator Observation SheetDocumento1 páginaOperator Observation Sheet25aprilAún no hay calificaciones

- Mini DOJO ConceptDocumento24 páginasMini DOJO ConceptMukesh Sharma Akshu100% (3)

- T2 VSA With RequirementDocumento8 páginasT2 VSA With RequirementSandeep K Malhotra100% (3)

- Mini Dojo Guidance Handbook: Maruti Suzuki India LimitedDocumento126 páginasMini Dojo Guidance Handbook: Maruti Suzuki India LimitedRakesh Chauhan100% (3)

- MSIL Training On VSA Check SheetDocumento145 páginasMSIL Training On VSA Check Sheetsumit_saraf_550% (16)

- 16.work Instruction For VMCDocumento1 página16.work Instruction For VMCSAKTHIVEL A33% (3)

- W.I - Abnormal SituationDocumento1 páginaW.I - Abnormal Situation25april100% (2)

- Tier-2 Audit ChecksheetDocumento17 páginasTier-2 Audit ChecksheetSilambarasan KAún no hay calificaciones

- Inital Flow Management Productivity ProcedureDocumento4 páginasInital Flow Management Productivity Procedureshaggyrahul100% (3)

- Plastic & Rubber DOJO Examples PDFDocumento65 páginasPlastic & Rubber DOJO Examples PDFUday Sharma100% (2)

- 3.6 Initial SupplyDocumento2 páginas3.6 Initial SupplySunil Kumar92% (12)

- 4M Change RequestDocumento5 páginas4M Change RequestNJMU LAB67% (3)

- Abnormal Handling Module (English Version)Documento15 páginasAbnormal Handling Module (English Version)Mukesh Sharma Akshu67% (3)

- Red Bin Analysis FormatDocumento1 páginaRed Bin Analysis FormatPRABHAT RANJAN100% (1)

- Acceptence Criteria - IMTEDocumento15 páginasAcceptence Criteria - IMTEnedunchi83% (6)

- 4M Change Tracking SheetDocumento1 página4M Change Tracking SheetKanaiya Jha100% (5)

- MSIL Audit Cheklist 16Documento22 páginasMSIL Audit Cheklist 16Pravin Balasaheb GunjalAún no hay calificaciones

- 1 2 3 - 4M Change Part TagDocumento4 páginas1 2 3 - 4M Change Part TagIt's me DJAún no hay calificaciones

- Training On VSA Check Sheet PDFDocumento151 páginasTraining On VSA Check Sheet PDFSwapnil Bachhav100% (2)

- 4M Change Management For Supplier - TennecoDocumento1 página4M Change Management For Supplier - TennecoOBSC PerfectionAún no hay calificaciones

- Work Instruction For Handling Abnormal Situations: Impact On Product Impact-ProcessDocumento1 páginaWork Instruction For Handling Abnormal Situations: Impact On Product Impact-Processhow2belive100% (2)

- 4 M Change ProcedureDocumento2 páginas4 M Change ProcedureManasi shindeAún no hay calificaciones

- Guideline 4M Change MatrixDocumento3 páginasGuideline 4M Change MatrixAman JasujaAún no hay calificaciones

- Red Bin Analysis-MaceDocumento51 páginasRed Bin Analysis-MaceAtul Sharma100% (7)

- Control Plan & FmeaDocumento9 páginasControl Plan & FmeaManu SharmaAún no hay calificaciones

- .013-00-Checking AidsDocumento3 páginas.013-00-Checking Aidsdaniel_sasikumarAún no hay calificaciones

- Dojo Establishment in DNHADocumento16 páginasDojo Establishment in DNHAanamika tripathi100% (1)

- 4M Change Procedure - PED 02Documento2 páginas4M Change Procedure - PED 02sathyabalaraman87% (23)

- 4M Change Control Management Matrix For Supplier: MonthDocumento1 página4M Change Control Management Matrix For Supplier: Monthsuresh kumar100% (4)

- Rework & Repair ProcedureDocumento1 páginaRework & Repair ProcedureManu Sharma100% (4)

- APQP ProcedureDocumento9 páginasAPQP ProcedurePk Nimiwal100% (4)

- Operator Observance SheetDocumento2 páginasOperator Observance Sheetrajesh sharma100% (1)

- 4M Change Management Matrix-Rane NSK-signedDocumento1 página4M Change Management Matrix-Rane NSK-signednitin rathoreAún no hay calificaciones

- WI For DFT MeterDocumento4 páginasWI For DFT MeterRahul PoriyaAún no hay calificaciones

- Initial Supply ControlDocumento3 páginasInitial Supply ControlKuldeep Chauhan100% (2)

- MACE Green Activity Timing PlanDocumento1 páginaMACE Green Activity Timing PlanshinuAún no hay calificaciones

- Instrument History CardDocumento1 páginaInstrument History CardDurairaj TAún no hay calificaciones

- P13-Process For APQPDocumento6 páginasP13-Process For APQPBangali Singh100% (1)

- 4M Change Management FormatDocumento1 página4M Change Management FormatSUBODHH100% (2)

- IATF 16949 2016 Mandatory ProcedureDocumento1 páginaIATF 16949 2016 Mandatory Procedureshivendrakumar100% (3)

- 4M Sheet FormatDocumento2 páginas4M Sheet FormatJetesh Devgun87% (38)

- Acceptance CriteriaDocumento2 páginasAcceptance Criteriasajithv7890% (41)

- NPD Check SheetDocumento6 páginasNPD Check Sheets.charlie0% (1)

- List of Documents IATF 16949 Documentation Toolkit EN PDFDocumento4 páginasList of Documents IATF 16949 Documentation Toolkit EN PDFRahul SharmaAún no hay calificaciones

- Skill Required Skill Required Skill Required Skill Required Skill Required Skill RequiredDocumento2 páginasSkill Required Skill Required Skill Required Skill Required Skill Required Skill RequiredRavi YadavAún no hay calificaciones

- Process & Product Audit Check SheetDocumento6 páginasProcess & Product Audit Check SheetPrakashRai100% (7)

- Supplier 4M Change Request FormatDocumento1 páginaSupplier 4M Change Request FormatManoj KumarAún no hay calificaciones

- Kova Fasteners (P) LTD: Sampling PlanDocumento1 páginaKova Fasteners (P) LTD: Sampling PlanAmandeep SinghAún no hay calificaciones

- Imv-Qp-Pvd-06 (Ppap)Documento5 páginasImv-Qp-Pvd-06 (Ppap)ori wahyuniAún no hay calificaciones

- Click To Go To IndexDocumento16 páginasClick To Go To Indexrty2Aún no hay calificaciones

- Title: Inspection & Test PlanDocumento3 páginasTitle: Inspection & Test PlanNova CastyAún no hay calificaciones

- P3-Process For Control of Non-ConformanceDocumento3 páginasP3-Process For Control of Non-ConformanceBangali SinghAún no hay calificaciones

- AGE Verification: Protection For Unregistered Children From Child LabourDocumento20 páginasAGE Verification: Protection For Unregistered Children From Child LabourprashanthAún no hay calificaciones

- Purpose: Scope: Responsibility: Details:: Personal Protective Equipment (PPE)Documento5 páginasPurpose: Scope: Responsibility: Details:: Personal Protective Equipment (PPE)prashanthAún no hay calificaciones

- Child Labour Guidance: Ilo Better Factories CambodiaDocumento19 páginasChild Labour Guidance: Ilo Better Factories CambodiaprashanthAún no hay calificaciones

- QMS Development Check List: Previous Audit ScoresDocumento4 páginasQMS Development Check List: Previous Audit ScoresprashanthAún no hay calificaciones

- QSV 2 Product Release Procedure EN 01 PDFDocumento6 páginasQSV 2 Product Release Procedure EN 01 PDFprashanthAún no hay calificaciones

- QSV 2 Product Release Procedure EN 01Documento6 páginasQSV 2 Product Release Procedure EN 01prashanthAún no hay calificaciones

- Example Call CentreDocumento2 páginasExample Call CentreprashanthAún no hay calificaciones

- PFMEA (Process Failure Mode Effect Analysis)Documento77 páginasPFMEA (Process Failure Mode Effect Analysis)prashanthAún no hay calificaciones

- PoisonTest PPTDocumento33 páginasPoisonTest PPTprashanthAún no hay calificaciones

- Induction ProgramDocumento15 páginasInduction ProgramprashanthAún no hay calificaciones

- MR 2 PortionsDocumento2 páginasMR 2 PortionsprashanthAún no hay calificaciones

- Project Name: Project Manager: R - Person Responsible For The Task A - Person Accountable For The Task C - Consulted. I - Kept InformedDocumento3 páginasProject Name: Project Manager: R - Person Responsible For The Task A - Person Accountable For The Task C - Consulted. I - Kept InformedprashanthAún no hay calificaciones

- Please Fill The Form in English: Basic InformationDocumento1 páginaPlease Fill The Form in English: Basic InformationprashanthAún no hay calificaciones

- Donation CircularDocumento2 páginasDonation CircularprashanthAún no hay calificaciones

- Rapid Problem Solving (RPS) /8D: IS: Is NotDocumento2 páginasRapid Problem Solving (RPS) /8D: IS: Is NotprashanthAún no hay calificaciones

- Kts From HSEDocumento3 páginasKts From HSEprashanthAún no hay calificaciones

- Employee Name Employee No. Vehicle No Test Date Exp. Date Emission Report (Yes/ No)Documento3 páginasEmployee Name Employee No. Vehicle No Test Date Exp. Date Emission Report (Yes/ No)prashanthAún no hay calificaciones

- Safety in Manufacturing: Ergonomics: Awkward PosturesDocumento2 páginasSafety in Manufacturing: Ergonomics: Awkward PosturesprashanthAún no hay calificaciones

- Competency MappingDocumento38 páginasCompetency MappingprashanthAún no hay calificaciones

- Run@RateDocumento10 páginasRun@RateprashanthAún no hay calificaciones

- Re Work MatrixDocumento20 páginasRe Work MatrixprashanthAún no hay calificaciones

- PCPA Checklist (Process Control Plan Audit Format) : Audit Final Score and DispositionDocumento21 páginasPCPA Checklist (Process Control Plan Audit Format) : Audit Final Score and DispositionNeumar NeumannAún no hay calificaciones

- Bloomberg - Transport - SecurityDocumento13 páginasBloomberg - Transport - SecurityFernandoAún no hay calificaciones

- Wrights Mushroom ColumnDocumento33 páginasWrights Mushroom ColumnKeithy GandhiAún no hay calificaciones

- 3 3 1 Material Sorter Design ChallengeDocumento3 páginas3 3 1 Material Sorter Design Challengeapi-343534512Aún no hay calificaciones

- SAP Hybris Thinking Outside The Box. PART 1Documento18 páginasSAP Hybris Thinking Outside The Box. PART 1Rauf AlievAún no hay calificaciones

- Constraints in DBMS - Types of Constraints in DBMS - Gate VidyalayDocumento5 páginasConstraints in DBMS - Types of Constraints in DBMS - Gate VidyalayBivek Man SinghAún no hay calificaciones

- Computer SoftwareDocumento3 páginasComputer SoftwareCyrine CalagosAún no hay calificaciones

- Standard Costing ExercisesDocumento3 páginasStandard Costing ExercisesNikki Garcia0% (2)

- Kaltreparatur-Textil WT2332 enDocumento20 páginasKaltreparatur-Textil WT2332 enFerAK47aAún no hay calificaciones

- Features: 833H - 1A - F - CDocumento3 páginasFeatures: 833H - 1A - F - CDaniboy1994Aún no hay calificaciones

- Cadence Short CommandsDocumento1 páginaCadence Short Commandsgetme_samAún no hay calificaciones

- 4 MPM Scope - OutputDocumento45 páginas4 MPM Scope - OutputSajid Ali MaariAún no hay calificaciones

- Wear Study On SS316L, Ti-6Al-4V, PEEK, Polyurethane and Alumina Used As Bio-MaterialDocumento5 páginasWear Study On SS316L, Ti-6Al-4V, PEEK, Polyurethane and Alumina Used As Bio-MaterialRing MasterAún no hay calificaciones

- Molinos VerticalesDocumento172 páginasMolinos VerticalesLeonardo RodriguezAún no hay calificaciones

- VX-1700 Owners ManualDocumento32 páginasVX-1700 Owners ManualVan ThaoAún no hay calificaciones

- SA Flight Instructors Training ProceduresDocumento371 páginasSA Flight Instructors Training ProceduresGuilioAún no hay calificaciones

- V1 V2 Cal PRCDocumento5 páginasV1 V2 Cal PRCCyril J PadiyathAún no hay calificaciones

- QBDC - Season 5-RulebookDocumento50 páginasQBDC - Season 5-RulebookHggvgAún no hay calificaciones

- Parth Valves and Hoses LLP.: Test & Guarantee CertificateDocumento1 páginaParth Valves and Hoses LLP.: Test & Guarantee CertificateSURYAKANTAún no hay calificaciones

- PDK Repair Aftersales TrainingDocumento22 páginasPDK Repair Aftersales TrainingEderson BJJAún no hay calificaciones

- M Block PDFDocumento45 páginasM Block PDFKristina ViskovićAún no hay calificaciones

- tt130 Ultrasonic Wall Thickness Material Thickness Gauge Instruction Manual PDFDocumento20 páginastt130 Ultrasonic Wall Thickness Material Thickness Gauge Instruction Manual PDFelmek jayaAún no hay calificaciones

- Alloc 150 DMDocumento301 páginasAlloc 150 DMSheik Mohamed ImranAún no hay calificaciones

- Student Manual of Damped & Un DampedDocumento3 páginasStudent Manual of Damped & Un DampedaqibAún no hay calificaciones

- Construction of Rajive Gandhi Urja Bhawan, Ongc Energy Center & Corporate OfficeDocumento23 páginasConstruction of Rajive Gandhi Urja Bhawan, Ongc Energy Center & Corporate OfficeDevendra SharmaAún no hay calificaciones

- Meitrack Gprs Protocol v1.6Documento45 páginasMeitrack Gprs Protocol v1.6monillo123Aún no hay calificaciones

- 200 Series Service Manual FLX200 & SCR200Documento39 páginas200 Series Service Manual FLX200 & SCR200Carlos Gomez100% (3)

- Seafastening Calculations Transit ModifiedDocumento380 páginasSeafastening Calculations Transit ModifiedUtkarsh RamayanAún no hay calificaciones

- Deepwater Horizon Accident Investigation Report Appendices ABFGHDocumento37 páginasDeepwater Horizon Accident Investigation Report Appendices ABFGHBren-RAún no hay calificaciones

- Hyundai Robex 220LC-9A SpecificationsDocumento14 páginasHyundai Robex 220LC-9A SpecificationsKundan DhurveAún no hay calificaciones

- Transfer Action in Sap HRDocumento3 páginasTransfer Action in Sap HRKarthi MrvkAún no hay calificaciones