Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Medicion Flujo Con Pitot

Cargado por

alfredopinillos0 calificaciones0% encontró este documento útil (0 votos)

39 vistas7 páginasInstrucciones (en inglés) para medir flujo de gases con tubo pitot

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoInstrucciones (en inglés) para medir flujo de gases con tubo pitot

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

39 vistas7 páginasMedicion Flujo Con Pitot

Cargado por

alfredopinillosInstrucciones (en inglés) para medir flujo de gases con tubo pitot

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

Está en la página 1de 7

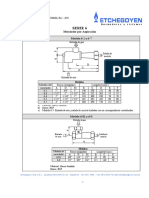

9-14 Industrial Ventilation

F 2m 69 7

' oe | eres mo

sal | i '

: = SEILER Sn | 9

i = Son '

| } RQ

WY ' | 8

2 MOLES = 0.08 W. ole

EQUALLY Spaced

FREE FROM BURRS

NOSE SHALL BE FREE

ot

a secnow Acs

j Suten Wwe Simin snot Wot Sew pauere® pesenees

Baz IN e.0. x 21 BRS GUAGE

O12 m OD. x APPROX. 12 GAS GUAGE

TOTAL PRESSURE

FIGURE 6-9, Standard Pot tubes

ddue to insufficient conveying velocities, condensation

of oil or water vapors on duet walls, adhesive charac-

teristics of material exhausted, or leakage losses

caused by loose clean-out doors, broken joints, holes

wom in duct (most frequently in elbows), poor eon-

nection to exhauster inlet, accumulations in ducts or

con fan blades.

3. Reduced air low rate also can be charged t additional

exhaust duct openings added the system (sometimes

systems are designed for future connections and more

air than required is handled by present branches until

future connections are made) or change of setting of

blast gates in branch lines. Blast gates adjust the air

distribution beoween the various branches. Tampering

with the blast gates can seriously affect such distribu-

tion and therefore they should be locked in place

immediately ater the system has been installed and its

effectiveness verified. Fan volume control dampers

also should be checked,

4. Reduced volumetric flow may be caused by increased

pressure loss through the dust collector due to lack of

maintenance, improper operation, wear, ete. These

effects will vary with the collector design. Refer to

‘operation and maintenance instructions furnished with

the collector or consult the equipment manufacturer

9.44 Velocity Pressure: For measuring velocity pressure

to determine air velocity, a standard Pitot tube may be used,

A large volume of research and many applications have been

devoted to the subject of flow measurements by this instru

iment, which was developed by Henry Pitot in 1734 while a

student in Paris, France. A standard Pitot tube (see Figure 9-9)

needs no calibration if carefully made and the accuracy of

velocity pressure readings obtained are considered to be ac~

crate at velocities above 600 fpm (see Table 9-1). For more

details concerning specifications and application of the Pitot

tube, see the "Standard Test Code" published by the American

Society of Heating, Refrigerating and Air Conditioning Engi

neers and the Air Moving and Conditioning Association.° ©

‘The device consists of two concentric tubes — one meas-

tures the otal or impact pressure existing in the airstream; the

other measures the static pressure only. When the annular

space and the center tube are connected across a manometer,

the difference between the total pressure and the static pres-

sure is indicated on the manometer. This difference is the

\ : J

i

10 POINT PITOT TRAVERSE

IN A CIRCULAR DUCT.

(GREATER THAN 6" DIAM.)

10 OR 20 LOCATIONS IN’ CENTERS

OF EQUAL ANGULAR AREA,

FIGURE 9-108, 10point Pitot traverse na cular dct

velocity pressure.

‘The velocity pressure can be used to compute the velocity

of the air stream if the density of the air is known, The

following equation can be used

v=1o96 |<. ps

>

where:

VP = velocity pressure, "we

p= actual gas density, Ib/mift

Where air is at standard conditions (p = 0.075 Ibim/f?),

Equation 9.9 becomes:

v= 4005 /VP pag)

For example, ifthe temperature of the air stream varies more

than 30 from standard air (70 F and 29.92 "He)orthealtitude

‘of the site is more than 1,000 feet above or below sea level or

the moisture content ofthe a is 0.02 Ib/b of dry airor greater,

the actual gas density (p) must be used.

‘Velocity pressure versus velocity tables for standard air can

be found in Chapter 5 (Tables 5-7A and 5-7B). These tables

‘can be used for air at densities other than standard conditions

by determining an equivalent velocity pressure.

ne Ne

vn a1

"== peat)

6 POINT PITOT TRAVERSE

INA CIRCULAR DUCT.

(DIM. 98 LESS)

| OR 12 LOCATIONS IN

| ore

NTERS

UAL ANGULAR’ ARE)

FIGURE 9-108, 6 point Pol ravorsein a irula dct

where:

VP, = equivalent velocity pressure,

VP, = measured velocity pressure, "wu

d

‘The equivalent VP then can be used in the velocity pressure

versus velocity table selected to give the actual velocity at

duct conditions.

density factor coefficient

‘A number of techniques can be used to determine the

volumetric flow rate at hood openings and at other points in

an exhaust system using the uid flow principles previously

described. The method selected will depend on the degree of

accuracy required, time available for testing, and the type of

test data required. tis extremely important that measurements

taken atthe time of the tests include all necessary information

to determine the gas density to permit the calculation of the

actual velocity and volumetric flow rate.

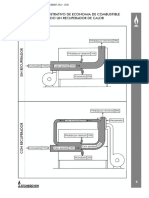

9.5 PITOT TRAVERSE METHOD

Because the air low in the cross-section of a duct is not

uniform, it isnecessary to obtain an average by measuring VP.

at points in a number of equal arcas in the cross-section. The

usual method is to make two traverses across the diameter of|

the duct at right angles to each other. Readings are taken at

the center of annular rings of equal area (see Figures 9-104

and 9-10B), Whenever possible, the traverse should be made

7 ¥6 duet diameters or more downstream from any major air

9-16 Industrial Ventilation

3

‘A: FULLY DEVELOPED VP DISTRIBUTION

B: GOOD VP DISTRIBUTION. (ALSO SATISFACTORY FOR

FLOW INTO FAN INLETS, BUT MAY BE UNSATIS~

FACTORY FOR FLOW INTO INLET BOXES ~ MAY

PRODUCE SWIRL IN BOXES.)

VP Max. tt wry

4

(

i: {

1

: SATISFACTORY VP DISTRIBUTION

MORE THAN

75% OF VP READINGS. Gf

EATER THAN YP_UAK

1D: D0_NOT USE!_UNSATISFACTORY YP DISTRIBUTION ~

LESS THAN 75% OF VP READINGS GREATER THAN

E: DO NOT USE! UNSATISFACTORY VP DISTRIBUTION ~

LESS THAN’ 75% OF VP REAGINGS GREATER THAN

we MAX.

70

AMERICAN CONFERENCE

OF GOVERNMENTAL.

INDUSTRIAL HYGIENISTS

F: DO NOT USE! UNSATISFACTORY VP O'STRIBUTION —

LESS THAN 75% OF VP READINGS GREATER THAN

Ve _MAX.

70

VELOCITY PRESSURE

DISTRIBUTIONS

ETO

PITOT TRAVERSE POINTS INA RECTANGULAR

DUCT. CENTERS OF 16 TO 64 EQUAL AREAS.

LOCATIONS NOT MORE THAN 6" APART }

FIGURE $12, Pitt ravers paints ina rectanguar duct

disturbance such as an elbow, hood, branch entry, ete. Where

‘measurements ate made closer to disturbances, the results

_must be considered subject to some doubt and checked against

a second location. If agreement within 10% of the two tr

verses is obtained, reasonable accuracy can be assumed and

the average of the two readings used. Where the variation

exceeds 10%, a third location should be selected and two air

flows in the best agreement averaged and used. The use of a

single centerline reading for obtaining average velocity is a

very coarse approximation and is NOT recommended.

‘The reason for the uncertainty and vatiation in measure-

‘ments is the non-uniformity of air flow after a disturbance.

Figure 9-11 shows some airflow patterns that could develop

after a disturbance and the resulting difficulties in obtaining

good reliable measures are evident.

For round ducts 6” and smaller, at least 6 traverse points

should be used, For round ducts larger than 6" diameter, at

least 10 traverse points should be employed, The number of

traverse locations on each diameter and the number of tra-

TABLE 8-5, Distance from Wal of Round Pipe to Pont Reading

(nearest 18 inch) for €-Point Traverse

Duct | oR | oR | | OR | Re | OR

ia_{.043 1A) 146 D1A| 296 Dia | 704 DIA| 84 DIA 957 IA

3 | | 1 | te | ew | ore | one

we ff [em] 3 | as6

«fe [se [ane [278 | sxe | 37m

wz | iw | se | 198 | ate | ame [ai

Fa

sia [tm [au | tee | orm | ase | om

1m [a | sie [sae

verse diameters required are determined by the need for

accuracy and the symmetry of the measured values. Where

uniform velocity pressure profiles exist, a single traverse

along one diameter may be adequate. Where the values are

moderately skewed, the use of two diameters is recom-

mended. For greater accuracy, a third diameter should be

used. Six, ten, and twenty point traverse points for various

duct diameters are given in Tables 9-5, 9-6, and 9-7. To

‘minimize errors, a Pitot tube smaller than the standard 5/16"

©.D. should be used in ducts less than 12" in diameter.

For square or rectangular ducts, the procedure isto divide

the cross-section intoa number ofequal rectangular areas and

measure the velocity pressure at the center of each. The

number of readings should not be less than 16. However,

enough readings should be made so the greatest distance

between centers is approximately 6" (see Figure 9-12).

‘The following data are essential and more detailed data may

be taken if desired:

+ Thearea of the duct atthe traverse location,

‘+ Velocity pressure at each point in the traverse.

+ Temperature of the air stream at the time and location

of the traverse,

‘The velocity pressure readings obtained are converted to

velocities and the velocities, not the velocity pressures, are

averaged. Where mote convenient, the square root ofeach of

the velocity pressures may be averaged and this value then

converted to velocity (average). The measured ar flow is then

the average velocity multiplied by the cross-sectional area of

the duct (Q = VA), Where conditions are not standard, see

"Corrections for Non-Standard Conditions.”

The Pitot tube cannot be used for measuring velocities less

‘than 600 fpm inthe field, It is susceptible to plugging in air

streams with heavy dust and/or moisture loadings. A vibration

free mounting is necessary if using a liquid manometer. See

Reference 9.10 for special instrumentation which can be used

to measure low velocities

Modified Pitot Tubes: Modified Pitot tubes have been

‘made in an effort to reduce plugging dificultes encountered

in heavy dust streams orto increase manometer differentials

enabling the measurement of lower velocities in the field

“These are refered to as "S-type (Staubscheide) tubes. They

usually take the form of two relatively large impact openings,

‘one facing upstream and the otier facing downstream. Such

tubes are useful when thick-walled ducts, such as boiler

stacks, make it dificult or impossible to insert a conventional

Pitot tube through any reasonably’ sized port opening. They

require only inital calibration forall conditions

Measurements made with an "S"- type Pitot tube cannot be

used directly. The tube first must be calibrated against a

standard Pitot tube and the velocity pressure measured cor-

rected to the actual velocity pressure.

9-18 Industrial Ventilation

TABLE 9-6. Distance from Wall of Round Pipe to Point of Reaing (nearest 118i

R R Ry Ry Ry R R Ry ip

oucToia | oo2soa | oos2nia | ov4sow | azo | 03201 | ossebia | a7 | ossioa | osreb | osrbA

4 1% 8 oe | 7e | ix | 258 | a18 | sae | 358 | 376

wa | 3 | se 4 am _| 2 | 3 | 370 | sw | ae

5 8 8 wa | 1 | isa | 3m | a7e | am | 458 | are

sia | wa | me | 1m | ime | 300 | am | 4m 5 538

é ie | 7 | 138 2 4 asa | sie | 512 | one

7 18 38 +_[ 158 [7238 [ase [san |e sae | 678

a a se | te | 1x4 | 2a4 | saa | ou | ore | rae | 74

Q ‘a | 2 aie | sme | 7 | 7m | am | om

0 im me | tie | 2 | 308 | 698 | rae | 12 | ow | om

4 ‘a 7m | 198 | 2m | saa | 7m | om | 930 | 101 | 10m

2 28 1 tm [2m | sve | 770 | om | ow | 1 | 156

ee at |e im ene |e ie omer eon ee

“ ae | 116 2 ave | eu | 9m | wre | 2 | wre | 1350

a ae | tm | 2m | sae | swe | ove | nse | ize | i994 | use

6 ae | 14 | 228 | ase | sia | wom | ae | ee | uaa | 1558

v va_|_13e | 2m [ ze | a4 | nm | 1308 | tae | rose | weir |

8 va _| 11 | 258 | 4 | ove | nze | 7 | tae | wie | iin

@ ve | ie | 2a4 | 4m | 6 | rm | wae | som | rie | wie

2 ve | 198 | 276 | «im | o7e | pe | tm | vie | wae | 1912

2 | tx4 [38 [5 ra_| win | 7 | tae | mom | 2130

a 58 2 sw_| sin | oi | tu | wim | mm | 2 | 238

6 36 | 26 | saa | 576 | o7e | trie | ww | zim | a7 | 2530

28 au | 2m | aw | eae | ose | tox | arse | ave | ose | cm

0 34 | 2 | 30 | 636 | wr | 1934 | zu | ase | aie | ave

2 7e_ | ase | ase | 7m | a a | usa | ase | mse | 3118

a 7 | 24 | 5 7a | nse | zoe | 2m | ao | one | a0

% 1 3 si | eve | wae | ose | ae | wom | x S

8 1 sve [ sa | ose | 13 3 | ox | 2m | are | x

4 4 sie | 578 9 | se [a8 | 1 | owe | oe |

2 | 1 | 28 | ow | 91 | wae | zoe | sew | wre | we | 70

4 | 1 | 368 | 638 | 10 5 2 u | ase | wae | 278

«| 1m | sae | xe | wae | woe | som | ose | som | aie | ae

8 11 4 7 so7e_[ 1636 [ aise | ave | a | a3

‘Testing of Ventilation Systems 9-19

‘TABLE 9-7. Distance from Wall of Round Pipe fo Point of Reading (nearest 18 inch for 20 Point Traverse

De Ro | fe | | Ry | | Re | | | he

1| 0080 | 0.0390 | a06ro | aosro | 0.1290 | 01650 | a2040| a2500 | 0.3060

jaa | Fy Re Rs Rs Rs fs fy Ra Ry

esizo_| a6s¢0 | a7500 | a7960 | 28350 | aa7i0 | 9030 | 09330 | ase

wo] we] rae] ase] smal sae] 6 af eae [ao ws

ee ara | a7 srk | 50 si iva | 33 sre | su ave | 35 ave | 37 aye | 3a 172

wa] we] vere] ame | wael ss sre [© ve |e sye [a0 a2 | a2 78

as 3/4 | 29 178 | at 72 | 3 v0 | 35 ave | 36 Sra | 37 ava | 33 ave | eo S70

wl u2{ ase s wus] sss | ran] o nn 33172

a6 78 | 30472 | 33 38 sé 574 | 36 37a | 38 au | ar Bin

wl sel 1am] suel vals se] sae fara favs [ar ve

ae iva | st ava | se 172 | 56576 | 5a sve | 00 abaya fanaa | meta | AS 57e

wel sve] ama] san] «sel care | ave] sare fae ae sve [ae se

zo 57a | 3370 | 6 sae | ub 76 | ot svt | us ave | ak ave | Ae ava | 07 378

sul sve| 2 sel ars] saz | vars [rose [az azz [as sve | as 378

go 57a | sk sea | si iva | sa Sy | at 3a | ud a2 | as ave | ae 57a | oo ao 578

sz] srl 2 sats eosre | 8 ay2 | a0 sve | as 15 7/8 | 20 178

si 7/8 | sb ave | 38 siosva [8072 | asad | ata | 50 St Sa

se [ sva[ zaye] 3 sea | sam] 7 puefa 13.172 | a6 72 | 21

3 sha | ua iva | a3 aS ass | ur ae ssa | 50 578 | 31 aa | 53 ave

sel ae] zare] 330] 5578] 2 uy noe | be aye [ar sie

su the | 38778 | a2 ab 308 | a8 5M BO B/E | SE ar | 55 aha | 35 ae

se] ae | zare| sre] ssa] 7 are avs [aware [ar aye [a2 aye

g5172 | wo ie | a5 172 | 06 Ie | ab 272 | 50472 | $2 570 | su avd | 55 yu | 57 178

col av sue{ 7s | ova | 12 aye | 25 ve 578 | 25478

36578 vi 5 | so tra | sz ae | 5u ave | 56 5) 574 | $8 174

oz] 3m{ 23| sal 6 + ao ave | a2 578 | 15 472 | 29 2 1/8

37478 | as ue 172 | 08 50 | st sve | 5h 5B Sr 1/8 | 39 sya | 51a”

eo { am | zaz| sam | oa] eave [aoe | sare | as aa s/e | 20 77/8

soya | ak 378 | at sora | 55172 | 55 374 | 37 37u | $3 aya | ot av? | 63 7

eel val 2 sre] ssa | 6 sre] ease [a0 ve | as ave | as ave | 20 ae | 2s sre

so 37a | 45 370 | uo iva | 52 ive | 55 ave | 57 are | 50 578 | or 578 | 63 ava | 65 17a

eel wal zsre| wae] 6 sre] sae [ans [as re [ar 20 7/8 | 26 3/8

aise | arava | sit st iva | se su | 53 ire | 61 578 | 83 ase | 65 Sve | €) ive

wl vel zany | sae] eae [3 aa ava [aware [ay aya | 22 aye | 27 78

az 178 | a8 372 | 52472 | $5 370 | sae | 6h es aye | a5 ae | 67 ak | 83 ve

nl wel 2s sae] 7 are [ar qa | au sve [ae 22 a

“ 5b st stam | oo tes | Oz 38 | 65 Bo aye | 65 aye | hve

ml vl eve | os pays | ov uz [az va | sare | ae ave | 22 aye | ae ary

as ine | st 37a | 55 asa | 98 78 | ot 178 | ot 172 | 66 778 | 8 Han | ie

wt 3 sel rove] ome [az ue | is az | a9 ain faa

e612 | 52 370 | 57 60 172 | 3 1/2 | 66 ive | 68 57a | 20 va | 33 5

mi] a 3 sare] or arz | ao are [az ays | as re | a9 a2 | 25 278 | 30 are

ab syu | st ase | 58472 | 02 176 | 6S a78 | bo 78 | ro a2 | 72 ark | 95 2

wo] a sass] sae] 7 sya | 10 se [1s va | ae sve | 20 ze aye | 3

a 55172 | 60 63 376 | os ru | os 378 | re are | M4 seu | 70 78 | 8

9.20 Industrial Ventilation

6 5

5 4

4 a

3 2

< oe ‘

vil 2" 0

o yt 1

2

3

4

5

2-072" 1/22"

FIGURE 9-13, Utube manometer

Other modified forms of the Pitot tube are the air foil

pitometer, the Pitot venturi and the air speed nozzle, toname

afew.079

Pressure Sensors: Pressure sensorscan be usedinconjune-

with the pitot tube to measure pressures existing within

‘entiation systems. These devices are described below.

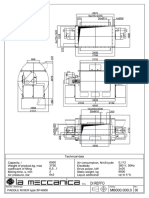

U-Tube Manometer: The vertical U-tube (see Figure 9-13)

is the simplest type of pressure gauge. Usually calibrated in

inches water gauge, itis used with various fluid media such

asalcohol, mercury,cil, water, kerosene and special manome-

{er fluids, The Utube may be used for either portable or

stationary applications. Available commercial units offer a

‘ide latitude in range, number of columns, and styles. Tubes

are usually of all-plastic construction to minimize breakage.

One leg may be replaced by a reservoir or well (well-type

‘manometer) with the advantage of easier manometer reading.

Well

FIGURE 9-14, nctined manometer

10

9

8

7

Fas} Cer

a 5 || 2"

eey ay—t

3

2

1

0

6-4=2"

Inclined Manometer (Figure 9-14) Increased sensitivity

‘and scale magnification is realized by tilting one leg of the

U-tube to form an inclined manometer or draft gauge. The

inclined manometer gives increased accuracy and permits

lower readings. In commercial versions, only one tube of the

small bore is used and the other leg is replaced by a reservoir,

‘The accuracy of the gauge is dependent on the slope of the

tubes. Consequently, the base of the gauge must be leveled

carefully and the mounting must be firm enough to permit

accurate leveling. The better draft gauges are equipped with

built-in level, leveling adjustment and, in addition, a means

‘of adjusting the scale to zero. Some models include over-pres-

sure safety trapsto prevent oss of fluid in the event of pressure

surges beyond the manometer range.

‘A modification of the inclined manometer is the inclined

vertical gauge in which the indicator leg is bent or shaped to

give both a vertical and inclined portion — the advantage is

También podría gustarte

- Avisa No SiDocumento2 páginasAvisa No SialfredopinillosAún no hay calificaciones

- TesisDocumento4 páginasTesisalfredopinillosAún no hay calificaciones

- Mag 3Documento3 páginasMag 3alfredopinillosAún no hay calificaciones

- Catalogo Aspiradores Serie 6 EtchegoyenDocumento1 páginaCatalogo Aspiradores Serie 6 EtchegoyenalfredopinillosAún no hay calificaciones

- AntaresDocumento3 páginasAntaresalfredopinillosAún no hay calificaciones

- Catalogo Aspiradores Serie 6 EtchegoyenDocumento1 páginaCatalogo Aspiradores Serie 6 EtchegoyenalfredopinillosAún no hay calificaciones

- Figura Con Idea de Perdidas de Calor Sin Recuperacion EtchegoyenDocumento1 páginaFigura Con Idea de Perdidas de Calor Sin Recuperacion EtchegoyenalfredopinillosAún no hay calificaciones

- Molino de Martillos Móviles La Meccanica Modelo M180-2PDocumento2 páginasMolino de Martillos Móviles La Meccanica Modelo M180-2PalfredopinillosAún no hay calificaciones

- Catálogo de Molino de Martillos Móviles La Meccanica Modelo MM150-2P-2016Documento2 páginasCatálogo de Molino de Martillos Móviles La Meccanica Modelo MM150-2P-2016alfredopinillosAún no hay calificaciones

- Figura Con Idea de Perdidas de Calor Sin y Con Recuperacion EtchegoyenDocumento1 páginaFigura Con Idea de Perdidas de Calor Sin y Con Recuperacion EtchegoyenalfredopinillosAún no hay calificaciones

- Flujo 5U 500SSUDocumento1 páginaFlujo 5U 500SSUalfredopinillosAún no hay calificaciones

- Flujo Bomba Haigth Tamaño 8Documento1 páginaFlujo Bomba Haigth Tamaño 8alfredopinillosAún no hay calificaciones

- BFM Global Booklet Spanish PDFDocumento4 páginasBFM Global Booklet Spanish PDFalfredopinillosAún no hay calificaciones

- Nomograma Ahorro de Energia Por Uso de Aire Precalentado EtchegoyenDocumento1 páginaNomograma Ahorro de Energia Por Uso de Aire Precalentado EtchegoyenalfredopinillosAún no hay calificaciones

- Accesorios para Almacenaje y Secado de GranosDocumento10 páginasAccesorios para Almacenaje y Secado de GranosalfredopinillosAún no hay calificaciones

- Sensor de Humedad Hydronix Guía de Instalación Mecánica hd0766sp - 1 - 1 - 0Documento33 páginasSensor de Humedad Hydronix Guía de Instalación Mecánica hd0766sp - 1 - 1 - 0alfredopinillosAún no hay calificaciones

- 3515 Scheda VB 1 06 13Documento2 páginas3515 Scheda VB 1 06 13alfredopinillosAún no hay calificaciones

- BFM Global Booklet Spanish PDFDocumento4 páginasBFM Global Booklet Spanish PDFalfredopinillosAún no hay calificaciones

- Enfriador de Contraflujo RCC-28x28 La MeccanicaDocumento2 páginasEnfriador de Contraflujo RCC-28x28 La MeccanicaalfredopinillosAún no hay calificaciones

- Catálogo de Molino MM100-2P-2016Documento2 páginasCatálogo de Molino MM100-2P-2016alfredopinillosAún no hay calificaciones

- Catalogo BESADocumento4 páginasCatalogo BESAalfredopinillosAún no hay calificaciones

- Molino de Martillos Móviles La Meccanica Modelo M180-2PDocumento2 páginasMolino de Martillos Móviles La Meccanica Modelo M180-2PalfredopinillosAún no hay calificaciones

- Enfriador de Contraflujo RCC-28x28 La MeccanicaDocumento2 páginasEnfriador de Contraflujo RCC-28x28 La MeccanicaalfredopinillosAún no hay calificaciones

- Enfriador de Contraflujo RCC-28x28 La MeccanicaDocumento2 páginasEnfriador de Contraflujo RCC-28x28 La MeccanicaalfredopinillosAún no hay calificaciones

- SP 6000 Rev00Documento1 páginaSP 6000 Rev00alfredopinillosAún no hay calificaciones

- Di Reffo: Macchina - Machine Type S.R.L. Drawing: Rev.Documento1 páginaDi Reffo: Macchina - Machine Type S.R.L. Drawing: Rev.alfredopinillosAún no hay calificaciones

- Enfriador de Contraflujo RCC-28x28 La MeccanicaDocumento2 páginasEnfriador de Contraflujo RCC-28x28 La MeccanicaalfredopinillosAún no hay calificaciones

- Enfriador de Contraflujo RCC-28x28 La MeccanicaDocumento2 páginasEnfriador de Contraflujo RCC-28x28 La MeccanicaalfredopinillosAún no hay calificaciones