Documentos de Académico

Documentos de Profesional

Documentos de Cultura

NL-WI-236-04 Nozzle Loads Equipment

Cargado por

Chirag ShahTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

NL-WI-236-04 Nozzle Loads Equipment

Cargado por

Chirag ShahCopyright:

Formatos disponibles

Document No: Page:

Work Instruction NL-WI-236-04 1 of 3

Revision & Effective Date:

Nozzle Loads Equipment Revision 0, 01 Sep 2012

Issuing Department: Previous Revision & Effective Date:

Mechanical NL-LEI-WI-236-14

Copyright 2012 by Jacobs Engineering Group, Inc. All rights reserved. The contents of this document are proprietary and produced for the

exclusive benefit of Jacobs Engineering Group, Inc. and its affiliated companies. No part of this document may be reproduced, stored in a retrieval

system, or transmitted, in any form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written

approval of Jacobs Engineering Group, Inc.

The applicable version of this document resides in the Business Practices section of http://JNet.jacobs.com. All copies are considered to be

uncontrolled.

File name: 434805737.doc

1 PURPOSE OF WORK INSTRUCTION

This Work Instruction describes the standard approach, criteria and working

methods for piping loads on equipment.

At start of a Project the allowable loads on equipment have to be verified and

agreed upon with piping department, client requirements and/or other special

project applications and confirmed in a job specific document.

2 PROCEDURE

Piping Loads shall be agreed upfront at start of project between disciplines piping

and mechanical.

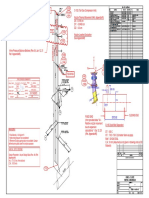

Attachment I shows the template to be used. This document shall be made

“project specific” by the LE-Mechanical, after agreement with the Pipe stress

engineer.

The Mechanical Engineer shall include the agreed nozzle loads into the

equipment requisitions.

For vendor designed equipment it could be possible that the selected vendor can

not adhere to the agreed nozzle loads as indicated in Attachment I.

The Pipe Stress Engineer will be informed for values which deviate to the agreed

nozzle loads.

The values in this work instruction shall be read by the Mechanical Engineer as

minimum required and by the Pipe Stress Engineer as maximum allowable.

The Pipe Stress Engineer must ascertain that the loads acting on the nozzles are

within the load values given in this work instruction. No further approval is

required in case the listed values are not exceeded. For cases where it is

impossible or impractical to keep the actual loads below these values, the

calculated loads have to be issued to the Mechanical Engineer for his perusal

and approval.

Special attention:

- Revamp activities;

For revamp, actual applied loads and “as is” situation loads shall be verified

this to avoid current specified load is above original design.

- Nozzle sizes < 8” and operating temp of > -50 ºC and < 100 ºC.

See limitations as covered in note 7 of the ES 22700 series nozzle loading

standard.

- Reinforcing;

Allowance of reinforcing shall be agreed and verified that this is correctly

addressed in the requisition and clearly communicated with the bidders

during enquiry stage. By default vendors are calculating with reinforcing and

when reinforcing is not allowed this might lead to calculating with too little

thickness and thus incorrect bid.

- Cyclic loading;

Perform a fatigue analysis for cycling loading.

To check if the nozzle is suitable the peak and through values of pressure or

Copyright 2012 by Jacobs Engineering Group, Inc. All rights reserved. The contents of this document are proprietary and produced for the

exclusive benefit of Jacobs Engineering Group, Inc. and its affiliated companies. No part of this document may be reproduced, stored in a retrieval

system, or transmitted, in any form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written

approval of Jacobs Engineering Group, Inc.

The applicable version of this document resides in the Business Practices section of http://JNet.jacobs.com. All copies are considered to be

uncontrolled.

File name: 434805737.doc

temperature loading and the required number of cycles shall be necessary for

each loading case.

Reinforcing plates are not permitted for:

- Carbon and low alloy steel apparatus with wall thickness >= 38 mm

- Stainless steel apparatus with wall thickness >= 25 mm

- Nozzles <= 2”

- Design temperatures > 400 ºC and < -50 ºC

- Shell side nozzles of shell and tube heat exchangers

- HIC service (Sour service)

3 EQUIPMENT

Reference is made to attachment I.

4 RELATED DOCUMENTATION (REFERENCES)

Document Required Suggested Sample

NL-WI-236-04-f1 Nozzle Loads X

Equipment

Required – Use of this document is mandatory.

Suggested – This document shows required content and a suggested format,

although it may be modified at the discretion of the Project Manager (e.g., the

Project Manager may elect to combine the Project Execution Plan and Project

Procedures Manual in a single document).

Sample – The document is included as an example of one way to implement the

intent of the Work Instruction.

Related Regulations and Jacobs Procedures

Allowable Nozzle Loadings on Cylindrical and Spherical

ES-22701

Shell ASME

Allowable Nozzle Loadings on Cylindrical and Spherical

ES 22702

Shell PD 5500

Allowable Nozzle Loadings on Cylindrical and Spherical

ES 22703

Shell RTOD

Allowable Nozzle Loadings on Cylindrical and Spherical

ES 22704

Shell CODAP

Copyright 2012 by Jacobs Engineering Group, Inc.

File name: 434805737.doc

También podría gustarte

- MOUNDED BULLETS FOR LPG STORAGEDocumento41 páginasMOUNDED BULLETS FOR LPG STORAGEMarco Dos Santos NevesAún no hay calificaciones

- OISD Tank Farm Rules The Piping Engineering WorldDocumento1 páginaOISD Tank Farm Rules The Piping Engineering Worldrenger20150303Aún no hay calificaciones

- Process Industry Practices Structural: PIP STE01100 Constructability Design GuideDocumento22 páginasProcess Industry Practices Structural: PIP STE01100 Constructability Design Guideeng laythAún no hay calificaciones

- STD PIP VECQ1001 2009 Vessel Shop Qualification ProcedureDocumento27 páginasSTD PIP VECQ1001 2009 Vessel Shop Qualification ProcedureNikunj KAún no hay calificaciones

- ELT-01-EP-TS-0005 - Specification For Manual Valve - R0Documento20 páginasELT-01-EP-TS-0005 - Specification For Manual Valve - R0jorgekarlosprAún no hay calificaciones

- OISD Standard on Process Design and Operating Philosophy for Fired Process FurnacesDocumento25 páginasOISD Standard on Process Design and Operating Philosophy for Fired Process FurnacesSanjay Patel0% (1)

- Astm c1086Documento4 páginasAstm c1086mezaro84Aún no hay calificaciones

- Pip PNSM0105Documento6 páginasPip PNSM0105romerobernaAún no hay calificaciones

- Petrofac Pipeline Documents TransmittalDocumento2 páginasPetrofac Pipeline Documents TransmittalbelhaskaAún no hay calificaciones

- Dhamra LNG Terminal Pvt. Ltd. (DLTPL)Documento11 páginasDhamra LNG Terminal Pvt. Ltd. (DLTPL)balajikrishnanAún no hay calificaciones

- ITP F TK-4101 & TK-4201 A/B: Persian Gulf Star Gas Condensate Refinery-Kal Station Booster PumpDocumento20 páginasITP F TK-4101 & TK-4201 A/B: Persian Gulf Star Gas Condensate Refinery-Kal Station Booster PumpHamid MansouriAún no hay calificaciones

- Load Case Explanation in PV EliteDocumento2 páginasLoad Case Explanation in PV ElitekuselanmlAún no hay calificaciones

- Datahseet For Strainer With Air EliminatorDocumento4 páginasDatahseet For Strainer With Air Eliminatorvinoj chandranAún no hay calificaciones

- No.: HURL-G-ED-C00-STA-SPC-000-D102 Engineering Specification For Pressure VesselsDocumento38 páginasNo.: HURL-G-ED-C00-STA-SPC-000-D102 Engineering Specification For Pressure VesselsDarshan PanchalAún no hay calificaciones

- 32 Samss 006Documento22 páginas32 Samss 006Vajid MadathilAún no hay calificaciones

- Nozzle Calculation - Primary Reformer Stack-R0Documento22 páginasNozzle Calculation - Primary Reformer Stack-R0Aditya Jain100% (1)

- SPE 76-002 (2006) Flange MaterialsDocumento6 páginasSPE 76-002 (2006) Flange Materials김창배Aún no hay calificaciones

- 26071-100-M0-M000-00100-002 Standard Drawing For Mechanical Stationary Equipment (Amendment)Documento121 páginas26071-100-M0-M000-00100-002 Standard Drawing For Mechanical Stationary Equipment (Amendment)Ade FaruroziAún no hay calificaciones

- Pipe Support ProcedureDocumento21 páginasPipe Support ProcedureEfrain PonseAún no hay calificaciones

- Process Safety Check List 2Documento2 páginasProcess Safety Check List 2renjithv_4Aún no hay calificaciones

- Sa 672Documento7 páginasSa 672lalitaliAún no hay calificaciones

- Nozzle Movement Calculation ModuleDocumento23 páginasNozzle Movement Calculation Moduledjole112Aún no hay calificaciones

- H-652 Ecc Specification For Piping Design - 01Documento17 páginasH-652 Ecc Specification For Piping Design - 01vermaakash22100% (1)

- Air Cooled Heat ExchangerDocumento24 páginasAir Cooled Heat Exchangeriaft100% (2)

- Jacketed Piping Interview QuestionsDocumento4 páginasJacketed Piping Interview Questionsbinukumar100Aún no hay calificaciones

- Piping Design Requirements PDFDocumento6 páginasPiping Design Requirements PDFkarunaAún no hay calificaciones

- A-1-10-Specification For FRP Vessels and TanksDocumento17 páginasA-1-10-Specification For FRP Vessels and TanksbecemAún no hay calificaciones

- Piping Material Specifications for Gasco PlantDocumento217 páginasPiping Material Specifications for Gasco PlantMaffone Numerouno100% (1)

- Training Manual-Piping: Piping Study Underground PipingDocumento30 páginasTraining Manual-Piping: Piping Study Underground Pipingrams789100% (2)

- IOGP S-619D Pressure Vessel Datasheet (Ver 1.0)Documento24 páginasIOGP S-619D Pressure Vessel Datasheet (Ver 1.0)CrAún no hay calificaciones

- Pipe Rack Loading Data - 2 PDFDocumento55 páginasPipe Rack Loading Data - 2 PDFGalih PrianggodoAún no hay calificaciones

- PVM Su 1322 H.1 PDFDocumento22 páginasPVM Su 1322 H.1 PDFJEEVITHAAún no hay calificaciones

- Pressure Testing of Unfired Pressure Vessels: ScopeDocumento9 páginasPressure Testing of Unfired Pressure Vessels: Scopebenedicto soto mestanzaAún no hay calificaciones

- Design and Analysis of Above-Ground Full Containment LNG Storage TanksDocumento6 páginasDesign and Analysis of Above-Ground Full Containment LNG Storage TanksrodrigoperezsimoneAún no hay calificaciones

- TEMA Standard PDFDocumento302 páginasTEMA Standard PDFlubangjarumAún no hay calificaciones

- ADocumento55 páginasAdon bowo'sAún no hay calificaciones

- Cross Country Piping Stress AnalysisDocumento8 páginasCross Country Piping Stress Analysisprabu2001Aún no hay calificaciones

- Mechanical Data Sheet For Centrifugal Pumps (P-1203A/B) : Poly Butadiene II (35000 TPY)Documento7 páginasMechanical Data Sheet For Centrifugal Pumps (P-1203A/B) : Poly Butadiene II (35000 TPY)you kackAún no hay calificaciones

- MR ValvesDocumento56 páginasMR ValvesIdris SiddiquiAún no hay calificaciones

- Reconstruction Airport Expansion JointsDocumento5 páginasReconstruction Airport Expansion JointsaltipatlarAún no hay calificaciones

- Mechanical Engineer CVDocumento4 páginasMechanical Engineer CVLe Thanh HaiAún no hay calificaciones

- Surge Analysis: Mostafa Ajjawi, Jr. Engineer 16230 Mr. Barry Howe, Head of Piping StressDocumento17 páginasSurge Analysis: Mostafa Ajjawi, Jr. Engineer 16230 Mr. Barry Howe, Head of Piping StressprashantAún no hay calificaciones

- Equipment SizingDocumento5 páginasEquipment SizingPandu RockingAún no hay calificaciones

- A869-6-44-0005 PMS For RevampDocumento950 páginasA869-6-44-0005 PMS For RevampMastram HatheshAún no hay calificaciones

- Oxygen Pipeline Code of Practice for Steel IndustryDocumento17 páginasOxygen Pipeline Code of Practice for Steel Industrysiddhesh_guessAún no hay calificaciones

- Assembly Instructions For Taper JointsDocumento12 páginasAssembly Instructions For Taper JointsmohdAún no hay calificaciones

- Tubesheet As Per ASME Sec. VIII-Div.1 UHXDocumento1 páginaTubesheet As Per ASME Sec. VIII-Div.1 UHXruponline1Aún no hay calificaciones

- NSC Piping Supt ChecklistDocumento3 páginasNSC Piping Supt ChecklistzahoorAún no hay calificaciones

- 202517C-0000-JSD-1300-008-B - Piping Stres CalculationDocumento32 páginas202517C-0000-JSD-1300-008-B - Piping Stres CalculationHasan arif KısaalioğluAún no hay calificaciones

- Valve Material ApplicationDocumento16 páginasValve Material Applicationswapneel_kulkarniAún no hay calificaciones

- Iocl Tank Spec F-601 Rev 0Documento18 páginasIocl Tank Spec F-601 Rev 0Rama Krishna Reddy Donthireddy100% (1)

- Mechanical Design Basics of Tall ColumnsDocumento45 páginasMechanical Design Basics of Tall Columnshardik5818Aún no hay calificaciones

- NRC - Bulletin 79-02 - Pipe Support Base Plate Designs Using Concrete Expansion Anchor BoltsDocumento4 páginasNRC - Bulletin 79-02 - Pipe Support Base Plate Designs Using Concrete Expansion Anchor BoltsdavidgmarksAún no hay calificaciones

- Nozzle Loads As Per Shell DEPDocumento4 páginasNozzle Loads As Per Shell DEPSarfaraz KhanAún no hay calificaciones

- Gen 253 Dep 31.38.01.11-Gen., Section 3.5Documento5 páginasGen 253 Dep 31.38.01.11-Gen., Section 3.5vermaakash220% (1)

- Ludwigs's Applied Process Design For Chemical and Petrochemical Plants, Agitación, 4ta Ed. Vol. 1Documento79 páginasLudwigs's Applied Process Design For Chemical and Petrochemical Plants, Agitación, 4ta Ed. Vol. 1Luis Joel Ramos RamosAún no hay calificaciones

- Checklist of Support DesignDocumento2 páginasChecklist of Support DesignSakshi AgrawalAún no hay calificaciones

- (Offer PDF) - Numerical Index of SHELL DEP Piping Classes Feb. 2012-NEW Standards - Powered by Discuz!Documento11 páginas(Offer PDF) - Numerical Index of SHELL DEP Piping Classes Feb. 2012-NEW Standards - Powered by Discuz!Mathias OnosemuodeAún no hay calificaciones

- Hot Box Design PDFDocumento8 páginasHot Box Design PDFAbu Anas M.SalaheldinAún no hay calificaciones

- Proceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988De EverandProceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988R. G. ScurlockAún no hay calificaciones

- Ph4 Si 1004 Var r2 Stress IsometricsDocumento106 páginasPh4 Si 1004 Var r2 Stress IsometricsChirag ShahAún no hay calificaciones

- Ph4-Si-1004-Var-R2 - Stress Input ReportDocumento217 páginasPh4-Si-1004-Var-R2 - Stress Input ReportChirag ShahAún no hay calificaciones

- Piping Engineering Piping Engineering Piping Engineering Piping EngineeringDocumento12 páginasPiping Engineering Piping Engineering Piping Engineering Piping EngineeringChirag ShahAún no hay calificaciones

- C2Documento16 páginasC2Chirag ShahAún no hay calificaciones

- PH4-SI-1004-VAR-R2 - Trunnion at Node151Documento10 páginasPH4-SI-1004-VAR-R2 - Trunnion at Node151Chirag ShahAún no hay calificaciones

- GID Engineering Feedback SummaryDocumento4 páginasGID Engineering Feedback SummaryChirag ShahAún no hay calificaciones

- PH4-SI-1004-VAR-R2 - Trunnion at Node 3801Documento12 páginasPH4-SI-1004-VAR-R2 - Trunnion at Node 3801Chirag ShahAún no hay calificaciones

- Sketch Skirt Data: Vessel Skirt Average Temperature Calculation Calculations and SketchesDocumento2 páginasSketch Skirt Data: Vessel Skirt Average Temperature Calculation Calculations and SketchesChirag ShahAún no hay calificaciones

- PH4-SI-1004-VAR-R2 - Trunnion at Node 3801Documento12 páginasPH4-SI-1004-VAR-R2 - Trunnion at Node 3801Chirag ShahAún no hay calificaciones

- PH4-SI-1004-VAR-R2 - Trunnion at Node 3801Documento12 páginasPH4-SI-1004-VAR-R2 - Trunnion at Node 3801Chirag ShahAún no hay calificaciones

- PH4-SI-1004-VAR-R2 - Nozzle N5 1 To N5 12 of Equipment 25-2501Documento10 páginasPH4-SI-1004-VAR-R2 - Nozzle N5 1 To N5 12 of Equipment 25-2501Chirag ShahAún no hay calificaciones

- R2Documento12 páginasR2Chirag ShahAún no hay calificaciones

- C-102 Stress Sketches (RevB - Jan 30 - 21)Documento6 páginasC-102 Stress Sketches (RevB - Jan 30 - 21)Chirag ShahAún no hay calificaciones

- Write XDocumento1 páginaWrite XChirag ShahAún no hay calificaciones

- Application DomicileDocumento1 páginaApplication DomicileAbhinav JhaAún no hay calificaciones

- SafeNet MobilePASS+ Setup Guide For AndroidDocumento12 páginasSafeNet MobilePASS+ Setup Guide For AndroidChirag ShahAún no hay calificaciones

- Trade Notice 36 Particulars of Mundra LPG Terminal PVT LTD MLTPLDocumento2 páginasTrade Notice 36 Particulars of Mundra LPG Terminal PVT LTD MLTPLChirag ShahAún no hay calificaciones

- Jacobs - Positive Mental Health Programme - Health and Wellbeing Initiative of The YearDocumento9 páginasJacobs - Positive Mental Health Programme - Health and Wellbeing Initiative of The YearChirag ShahAún no hay calificaciones

- New Ration Card Form 64Documento3 páginasNew Ration Card Form 64Chirag ShahAún no hay calificaciones

- Piping Stress AnalysisDocumento52 páginasPiping Stress Analysispatdumont100% (6)

- 2562 10968 1 PBDocumento21 páginas2562 10968 1 PBFaiz AizAún no hay calificaciones

- WBeDistrict Domicile Certificate Application FormDocumento4 páginasWBeDistrict Domicile Certificate Application FormHimaniAún no hay calificaciones

- Geothermal Pipe Line DesignDocumento15 páginasGeothermal Pipe Line DesignjohnjuantamadAún no hay calificaciones

- Calculation of Strut StiffnessDocumento1 páginaCalculation of Strut Stiffnesskeroro18Aún no hay calificaciones

- Behringer IndustrialDocumento36 páginasBehringer IndustrialChirag ShahAún no hay calificaciones

- Two Step Verification FAQDocumento8 páginasTwo Step Verification FAQChirag ShahAún no hay calificaciones

- Spans 3 FT Rise - Steel - SCH 40and160Documento1 páginaSpans 3 FT Rise - Steel - SCH 40and160Chirag ShahAún no hay calificaciones

- Rubber Expansion Joints Engineering GuideDocumento12 páginasRubber Expansion Joints Engineering GuideChirag ShahAún no hay calificaciones

- Worley quiz questions and answersDocumento2 páginasWorley quiz questions and answersChirag ShahAún no hay calificaciones

- Marketing Policy: 1. PurposeDocumento3 páginasMarketing Policy: 1. PurposeJenny Amante-BesasAún no hay calificaciones

- Fancyvrb PDFDocumento73 páginasFancyvrb PDFdart13Aún no hay calificaciones

- Manitowoc 111 80 Product GuideDocumento24 páginasManitowoc 111 80 Product GuideZian HennAún no hay calificaciones

- Conversor Mecanico 1808Documento8 páginasConversor Mecanico 1808ALBERTOAún no hay calificaciones

- .AnomDocumento2 páginas.AnomMC CondéAún no hay calificaciones

- Z1 ManualDocumento6 páginasZ1 ManualIvana JazidzijaAún no hay calificaciones

- As 5100.6-2017 Steel and Composite ConstructionDocumento337 páginasAs 5100.6-2017 Steel and Composite ConstructiontracyhopyAún no hay calificaciones

- Burndy Grounding CountermatDocumento1 páginaBurndy Grounding CountermatwilmanzitoAún no hay calificaciones

- YD Series Three Phase Asynchro Conveyor MotorDocumento18 páginasYD Series Three Phase Asynchro Conveyor MotorAditya SafarudinAún no hay calificaciones

- Madvac LR50e - ExprolinkDocumento4 páginasMadvac LR50e - ExprolinkpppopAún no hay calificaciones

- Commentary and Worked Examples To en 1993-1-5-Plated StructuresDocumento230 páginasCommentary and Worked Examples To en 1993-1-5-Plated Structuresda_116107118Aún no hay calificaciones

- Laf 631 1001 1251 1601 enDocumento2 páginasLaf 631 1001 1251 1601 enCarlos PadillaAún no hay calificaciones

- OM DefaultingDocumento6 páginasOM DefaultingAshvini VijayendraAún no hay calificaciones

- GE Carescape V100 Monitor - Service ManualDocumento178 páginasGE Carescape V100 Monitor - Service ManualGIGAún no hay calificaciones

- Common Mikrotik Ospf Mistakes: and How To Avoid ThemDocumento95 páginasCommon Mikrotik Ospf Mistakes: and How To Avoid ThemfabeltranmAún no hay calificaciones

- Configure DHCP Option 43Documento15 páginasConfigure DHCP Option 43Herbert Leon PascualAún no hay calificaciones

- Interfacing The MCP215X To A Host Controller: Author: Mark Palmer Microchip Technology, IncDocumento38 páginasInterfacing The MCP215X To A Host Controller: Author: Mark Palmer Microchip Technology, IncglizAún no hay calificaciones

- WPS - 018Documento12 páginasWPS - 018MAT-LIONAún no hay calificaciones

- Boiler Safety and Pressure Vessel HazardsDocumento72 páginasBoiler Safety and Pressure Vessel HazardsKabiAún no hay calificaciones

- Tuv India Private Limited: Inspection Visit ReportDocumento5 páginasTuv India Private Limited: Inspection Visit ReportAkhtar aliAún no hay calificaciones

- BOM Interfaces - White PaperDocumento23 páginasBOM Interfaces - White PapersreeharireddylAún no hay calificaciones

- BZS - D - 16-601 Hilti HIT-RE 500 V3 Shock Approval ENDocumento2 páginasBZS - D - 16-601 Hilti HIT-RE 500 V3 Shock Approval ENfdfazfzAún no hay calificaciones

- Substations PDFDocumento16 páginasSubstations PDFsorry2qaz100% (1)

- Letter For Manufacturer To Send To SuppliersDocumento2 páginasLetter For Manufacturer To Send To SuppliersTrọng Đức HoàngAún no hay calificaciones

- Coventry UniversityDocumento104 páginasCoventry Universitymz-documentsAún no hay calificaciones

- BBC TVP What Is IptvDocumento32 páginasBBC TVP What Is IptvMukhlis YuliantoAún no hay calificaciones

- Cisco - VPC ConceptsDocumento90 páginasCisco - VPC ConceptsausmitchAún no hay calificaciones

- 3GPP TS 22.101Documento33 páginas3GPP TS 22.101santanameroAún no hay calificaciones

- CR 6Documento672 páginasCR 6Francisco José Fontelles ObelenisAún no hay calificaciones

- ISO 19100 Geographic Information StandardsDocumento12 páginasISO 19100 Geographic Information StandardsHermenegildo LuisAún no hay calificaciones