Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Spray Dryer Design UPDATED3

Cargado por

victorTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Spray Dryer Design UPDATED3

Cargado por

victorCopyright:

Formatos disponibles

Pamantasan ng Lungsod ng Maynila

College of Engineering and Technology

Chemical Engineering Department

SPRAY DRYER

DESIGN DESCRIPTION

Spray drying is a method of producing a dry powder from a liquid or slurry by rapidly

drying with a hot gas. In a spray dryer a liquid or slurry solution is sprayed into a hot gas

stream in the form of mist of fine droplets. This is achieved with the use of special nozzles

called atomizers. The atomization of the feed creates very large surface area, followed by

intense contact with hot air. Due to this, rapid evaporation occurs from the surface of each

particle or droplet in the spray. (Perry, 2008). The water is rapidly vaporized from the

droplets, leaving particles of dry solid which are separated from the gas stream.

(Genkoplis, 2012)

Depending on the process needs, drop sizes from 10 to 500 µm can be achieved with

spray dying. The most common applications are in the 100 to 200 µm diameter range. The

dry powder is free-flowing. (Mujumdar, 2007).

DESIGN SELECTION

Spray Dryer is selected because the fine powders generated from it have uniform

particle size. The major and most successful applications of spray dryers are for slurries

which cannot be dewatered mechanically. It is ideal for heat-sensitive materials and

cannot be exposed to high temperature atmospheres short drying periods. Among the

types of spray dryers, centrifugal-disk dryer is used which is particularly advantageous

for atomizing suspensions and pastes that erode and plug nozzles. The FS1.5 rotary

atomizer was selected (Table12-41, Pg. 12-92 of Perry, 8th ed.).

Acid Hydrolysis and Catalytic Condensation of Coconut Coir Dust Technical 1

for Diphenolic Acid Production Study

Pamantasan ng Lungsod ng Maynila

College of Engineering and Technology

Chemical Engineering Department

DESIGN PARTS AND ACCESSORIES

Figure 1. Isometric View of Spray Dryer, Parts and Accessories

Figure 2. Schematic Diagram of Spray Dryer, Parts and Accessories

Acid Hydrolysis and Catalytic Condensation of Coconut Coir Dust Technical 2

for Diphenolic Acid Production Study

Pamantasan ng Lungsod ng Maynila

College of Engineering and Technology

Chemical Engineering Department

Centrifugal Fan

The centrifugal fan along with its electrical motor drive assembly, is the one that

provides the required drying air for the spray dryer.

Heating Coils

The heating coils provides the heat to increase the temperature of the drying air

which is required to vaporize the feed droplets in the spray dryer. The heating coils are

heated by steam which passes inside the coils.

Feed Inlet

The slurry feed is pumped from the evaporator through a pipeline that is directly

connected to the feed inlet of the spray dryer. The slurry feed enters from to the spray

dryer via the feed inlet and passes through the atomizer.

Atomizer

The wet slurry feed is pumped to an atomizer which disperses the feed into smaller

droplets/particles creating a large surface area resulting to rapid drying time. This is also

the main feature that distinguishes the spray dryer from other types of dryer.

Motor Drive for Atomizer

The atomizer is powered by a motor drive which is placed on top section of the

spray dryer.

Drying Air Inlet

The hot drying air enters the drying chamber through the drying air inlet. The hot

air is supplied by a centrifugal fan which passes to a series of steam heated coils to impart

heat to the air.

Drying Chamber

This is the section of the spray dryer where the atomization of the feed and the

intense contact of the droplets to the hot drying gas occurs. The drying chamber must

provide enough space for the drying air to circulate and induce drying of the droplets.

Product Outlet: Ball Valve

The product is discharged in the bottom of the spray dryer through the product

outlet, which is controlled by a ball valve.

Drying Air Outlet

This is where the drying air containing the moisture removed from the droplets

escapes outside the drying chamber. The air goes to a bag filter prior to its discharge to

the atmosphere, to further purify the air to be discharged.

Bag Filter

Acid Hydrolysis and Catalytic Condensation of Coconut Coir Dust Technical 3

for Diphenolic Acid Production Study

Pamantasan ng Lungsod ng Maynila

College of Engineering and Technology

Chemical Engineering Department

This is an emission control accessory incorporated to the spray dryer. Its main

function is to purify the air prior to its release to the environment.

DATA AND ASSUMPTIONS

1. The mass of the entering feed is 467 kg/batch (From material balance, Pg. 215).

2. Diphenolic acid leaving the dryer is 355 kg/batch (From material balance, Pg. 215)

3. Initial moisture content of feed is 32% w/w.

4. Final moisture of diphenolic acid leaving the spray dryer is assumed to be 10%.

5. The density of the feed slurry is 1226 kg/m3.

6. Drying air enters at 150OC (423 K) and leaves at 81OC (354 K). (Initial temp from

material balance, Pg 210; Final Temp. calculated by interpolation of values given

from Table 12-43, Pg. 12-96 of Perry 8th ed.).

7. The densities of air at 150ºC and 81 ºC are 0.867 kg/m3 and 1.024 kg/m3 respectively.

(From Geankoplis, Table A.3-3, Pg. 971).

8. The kinematic viscosity of air at 150ºC is 1.495x10-5m2/s (From Geankoplis, Table A.3-

3, Pg. 971).

DESIGN CONSIDERATIONS

1. Drying air is concurrent to the feed, to prevent degradation of product due to high

temperature and provide product with low final temperature.

2. The material to be handled is diphenolic acid slurry from the evaporator.

3. The material of construction is stainless steel.

4. The insulation material is calcium silicate.

5. For FS1.5 Rotary Atomizer: (From Table 12-41, Pg. 12-92 of Perry 8th ed.)

The speed range is 10,000 rpm to 30,000 rpm. Taking the average; 20,000 rpm,

shall be used in the design.

Atomizer wheel diameter is 90 mm ≈ 0.3 ft.

Maximum feed rate is 0.52 t/hr.

6. The mean particle size produced after drying is 100μm. (From Mass Transfer

Operations by Alapati Suryanarayana, Page 572).

7. The drying air is driven by a centrifugal fan:

Suction Pressure = 741.7 mmHg (Geankoplis, Pg. 150)

Acid Hydrolysis and Catalytic Condensation of Coconut Coir Dust Technical 4

for Diphenolic Acid Production Study

Pamantasan ng Lungsod ng Maynila

College of Engineering and Technology

Chemical Engineering Department

The pressure increase induced by the fan is 1.2% (From Chemical Process

Equipment: Selection and Design 3rd Ed., Pg. 130)

The efficiency of the fan is 80% (Geankoplis, Pg. 150)

DESIGN REQUIREMENTS

1. Spraying Time d. Height of the Drying Chamber

2. Mass Flow Rate 6. Wall thickness

3. Drying Air Requirement 7. Insulation Thickness

4. Operating Air Velocity 8. Power Consumption of Rotary

5. Chamber Dimension Atomizer

a. Column Area 9. Power Consumption of Centrifugal

b. Column Diameter Fan

c. Volume of the Drying Chamber

DESIGN CALCULATIONS

1. Spraying Time

The total spraying (feeding) time of the feed depends on the maximum feed rate that the

atomizer can handle. In case of the FS1.5 rotary atomizer, the maximum feed rate is

0.52 t/hr. To calculate for the spraying time:

𝑚𝑎𝑠𝑠 𝑜𝑓 𝑓𝑒𝑒𝑑 𝑟𝑒𝑞′𝑑 1

𝑇𝑠 = ×

𝑏𝑎𝑡𝑐ℎ 𝑓𝑒𝑒𝑑 𝑟𝑎𝑡𝑒

467 𝑘𝑔 ℎ𝑟 1𝑡 2.2046 𝑙𝑏 60 𝑚𝑖𝑛

𝑇𝑠 = × × × ×

𝑏𝑎𝑡𝑐ℎ 0.52 𝑡 2000 𝑙𝑏 1 𝑘𝑔 1 ℎ𝑟

𝑇𝑠 = 59.4 𝑚𝑖𝑛⁄𝑏𝑎𝑡𝑐ℎ ≈ 60 𝑚𝑖𝑛⁄𝑏𝑎𝑡𝑐ℎ

Use 60 min/batch spraying time.

2. Mass Flow Rate

To determine the actual mass flow rate (mf):

𝑚𝑎𝑠𝑠 𝑜𝑓 𝑓𝑒𝑒𝑑 𝑟𝑒𝑞′𝑑

𝑚𝑓 =

𝑠𝑝𝑟𝑎𝑦𝑖𝑛𝑔 𝑡𝑖𝑚𝑒

Acid Hydrolysis and Catalytic Condensation of Coconut Coir Dust Technical 5

for Diphenolic Acid Production Study

Pamantasan ng Lungsod ng Maynila

College of Engineering and Technology

Chemical Engineering Department

𝑘𝑔

467 ⁄𝑏𝑎𝑡𝑐ℎ

𝑚𝑓 =

60 𝑚𝑖𝑛⁄𝑏𝑎𝑡𝑐ℎ

𝑘𝑔 𝑘𝑔

𝑚𝑓 = 7.78 ≈ 7.8

𝑚𝑖𝑛 𝑚𝑖𝑛

The actual mass flow rate is 7.8 kg/min.

3. Drying Air Requirement (DAR)

The drying air required is dependent on the evaporation rate of water and the moisture

removed per unit mass of air which is determined using the equation below (From Mass

Transfer Operations by Alapati Suryanarayana, Page 574):

𝑒𝑣𝑎𝑝𝑜𝑟𝑎𝑡𝑖𝑜𝑛 𝑟𝑎𝑡𝑒 𝑜𝑓 𝑤𝑎𝑡𝑒𝑟

𝐷𝐴𝑅 =

𝑚𝑜𝑖𝑠𝑡𝑢𝑟𝑒 𝑟𝑒𝑚𝑜𝑣𝑒𝑑 𝑝𝑒𝑟 𝑘𝑔 𝑑𝑟𝑦 𝑎𝑖𝑟

𝑒𝑣𝑎𝑝𝑜𝑟𝑎𝑡𝑖𝑜𝑛 𝑟𝑎𝑡𝑒 𝑜𝑓 𝑤𝑎𝑡𝑒𝑟 = (𝑖𝑛𝑖𝑡𝑖𝑎𝑙 𝑚. 𝑐. −𝑓𝑖𝑛𝑎𝑙 𝑚. 𝑐𝑚. ) ∗ 𝑐𝑎𝑝𝑎𝑐𝑖𝑡𝑦

𝑘𝑔 𝑘𝑔 𝑤𝑎𝑡𝑒𝑟

𝑒𝑣𝑎𝑝𝑜𝑟𝑎𝑡𝑖𝑜𝑛 𝑟𝑎𝑡𝑒 𝑜𝑓 𝑤𝑎𝑡𝑒𝑟 = (0.32 − 0.1) ∗ 7.8 = 1.716

𝑚𝑖𝑛 𝑚𝑖𝑛

𝑚𝑜𝑖𝑠𝑡𝑢𝑟𝑒 𝑟𝑒𝑚𝑜𝑣𝑒𝑑 𝑝𝑒𝑟 𝑘𝑔 𝑑𝑟𝑦 𝑎𝑖𝑟 = (ℎ𝑢𝑚𝑖𝑑𝑖𝑡𝑦 𝑎𝑡 𝑇2 − ℎ𝑢𝑚𝑖𝑑𝑖𝑡𝑦 𝑎𝑡 𝑇1 )

The data for humidity with respect to the temperature of air was gathered from the

humidity chart of Perry, pg. 12-7

At T1 = 150OC, H1 = 0.01 kg water / kg d.a.

At T2 = 81OC, H2 = 0.0305 kg water/ kg d.a.

𝑘𝑔 𝑤𝑎𝑡𝑒𝑟

𝑚𝑜𝑖𝑠𝑡𝑢𝑟𝑒 𝑟𝑒𝑚𝑜𝑣𝑒𝑑 𝑝𝑒𝑟 𝑘𝑔 𝑑𝑟𝑦 𝑎𝑖𝑟 = (0.0305 − 0.01) = 0.0205

𝑘𝑔 𝑑. 𝑎.

1.716 𝑘𝑔 𝑑. 𝑎. 𝑘𝑔 𝑑. 𝑎. 𝑘𝑔 𝑑. 𝑎.

𝐷𝐴𝑅 = = 83.71 = 5,022.44 ≈ 5,023

0.0205 𝑚𝑖𝑛 ℎ ℎ

Drying air requirement is 5,023 kg d.a./h.

4. Operating Air Velocity

The operating air velocity (va) is estimated based on the settling velocity of the droplets

from the atomized feed inside the drying chamber. From Geankoplis, eq. 14.3-9 Page 921:

𝐷𝑝 2 (𝜌𝑃 − 𝜌𝐹 )𝑔

𝑣𝑠 =

18µ

Acid Hydrolysis and Catalytic Condensation of Coconut Coir Dust Technical 6

for Diphenolic Acid Production Study

Pamantasan ng Lungsod ng Maynila

College of Engineering and Technology

Chemical Engineering Department

Where:

Dp = Drop Diameter µ = Viscosity of air at average temperature

ρp = Density of droplet vs = Settling velocity

ρF = Density of air at average temperature g = Acceleration due to gravity

1226 𝑘𝑔 0.867𝑘𝑔 9.81𝑚

(100𝑥10−6 𝑓𝑡)2 ( − )∗

𝑚3 𝑚3 𝑠2

𝑣𝑠 = −5 2

1.495𝑥10 𝑚

18 ∗ ( 𝑠 )

𝑚

𝑣𝑠 = 0.45

𝑠

The operating velocity would be twice the settling velocity to provide turbulence and

maximum contact time between droplets and air:

𝑣𝑎 = 2𝑣𝑠

𝑚

𝑣𝑎 = 2(0.45 )

𝑠

𝑚

𝑣𝑎 = 0.9

𝑠

𝒎

𝒗𝒂 ≈ 𝟏. 𝟎

𝒔

Use operating velocity of 1.0 m/s.

5. Chamber Dimensions

The calculations for chamber dimensions are based on Mass Transfer Operations by

Suryanarayana, Pages 575-576.

a. Column Area

The column area is based on the mass flow rate of the drying air and its operating

velocity. The column must provide enough space for a given mass flow rate of drying air

to circulate and remove most moisture from the droplets as possible. Thus, the equation

given below is used:

𝑚 ∗ Ṽ𝑑𝑎

𝐴𝑐 =

𝑣𝑎

Where:

Ac = Column area

Acid Hydrolysis and Catalytic Condensation of Coconut Coir Dust Technical 7

for Diphenolic Acid Production Study

Pamantasan ng Lungsod ng Maynila

College of Engineering and Technology

Chemical Engineering Department

m = mass flowrate of d.a.

Ṽ𝑑𝑎 = Specific Volume of dry air

𝑣𝑎 = Operating velocity

5,023 𝑘𝑔 1 ℎ𝑟 1.1587𝑚3

∗

ℎ𝑟 3,600 𝑠 𝑘𝑔

𝐴𝑐 =

1𝑚

𝑠

𝐴𝑐 = 1.62 𝑚2

For safety purposes, we assume 15% safety,

𝐴𝑐 = 1.15 ∗ 1.62 𝑚2

𝐴𝑐 = 1.86 𝑚2

𝑨𝒄 = 𝟐 𝒎𝟐

Use Column Area of 2 m2.

b. Column Diameter

The cylindrical column diameter (Dc) is based on the computed column area which is

computed using the equation:

4𝐴𝑐

𝐷𝑐 = √

𝜋

4 ∗ 2 𝑚2

𝐷𝑐 = √

𝜋

𝐷𝑐 = 1.60 𝑚

𝑫𝒄 ≈ 𝟐 𝒎

Use Column Diameter of 2 m.

c. Volume of Drying Chamber

The total volume of the drying chamber, like the column area is based on the mass flow

rate of the entering drying air along with the specific volume of the air; which indicates the

volume of air that can be occupied by the moisture removed, and the air residence time

(T) in the chamber. The chamber volume must provide enough residence time for the air

to be scattered around the chamber providing efficient drying of the droplets. The volume

is computed using the equation:

Acid Hydrolysis and Catalytic Condensation of Coconut Coir Dust Technical 8

for Diphenolic Acid Production Study

Pamantasan ng Lungsod ng Maynila

College of Engineering and Technology

Chemical Engineering Department

𝑉𝑇 = 𝑚 ∗ Ṽ𝑑𝑎 ∗ 𝑇

To compute for the volume of the drying chamber, we need first to determine the residence

time of the drying air needed to complete the drying. The residence time of the air is

calculated based on Mass Transfer Operations by Suryanarayana, Page 576:

𝑇 = 20√𝑥

Where:

T = residence time of drying air in seconds

x = initial moisture content

x = 0.32 (from material balance, p.215)

𝑇 = 20√0.32

𝑇 = 11.31 𝑠𝑒𝑐

𝑻 ≈ 𝟏𝟐 𝒔𝒆𝒄

Computing for the volume of the chamber:

5,023 𝑘𝑔 1 ℎ𝑟 1.1587𝑚3

𝑉𝑇 = ∗ ∗ ∗ 12 𝑠𝑒𝑐

ℎ𝑟 3,600 𝑠 𝑘𝑔

𝑉𝑇 = 19.40 𝑚3

𝑽𝑻 ≈ 𝟐𝟎 𝒎𝟑

Use Volume of 20 m3.

d. Height of the Drying Chamber

The height of the drying chamber is determined by calculating the height of the cylindrical

and the conical section of the chamber. For the height of the cylindrical portion, we’ll be

using a ratio of H=2D:

𝐻𝑐𝑦𝑙 = 2𝐷𝑐

𝐻𝑐𝑦𝑙 = 2 ∗ 2 𝑚

𝑯𝒄𝒚𝒍 = 𝟒 𝒎

Acid Hydrolysis and Catalytic Condensation of Coconut Coir Dust Technical 9

for Diphenolic Acid Production Study

Pamantasan ng Lungsod ng Maynila

College of Engineering and Technology

Chemical Engineering Department

For the height of the conical portion, the conical volume is first determined by subtracting

the chamber total volume to the volume of the cylindrical portion of the drying chamber

which is translated into this equation:

𝜋𝐷𝑐 2 𝐻𝑐𝑦𝑙

𝑉𝑐𝑜𝑛𝑒 = 𝑉𝑇 −

4

𝜋 ∗ (2 𝑚)2 ∗ 4 𝑚

𝑉𝑐𝑜𝑛𝑒 = 20 𝑚3 −

4

𝑽𝒄𝒐𝒏𝒆 = 𝟕. 𝟒𝟑 𝒎𝟑

The height of the conical portion is then computed using the equation:

3𝑉𝑐𝑜𝑛𝑒

𝐻𝑐𝑜𝑛𝑒 =

𝜋𝐷𝑐 2

3 ∗ 7.43 𝑚3

𝐻𝑐𝑜𝑛𝑒 =

𝜋 ∗ (2 𝑚)2

𝐻𝑐𝑜𝑛𝑒 = 1.77 𝑚

𝑯𝒄𝒐𝒏𝒆 ≈ 𝟐 𝒎

For the angle of the conical section (α):

𝛼 𝑅𝑎𝑑𝑖𝑢𝑠 𝑜𝑓 𝑡ℎ𝑒 𝐶ℎ𝑎𝑚𝑏𝑒𝑟

tan ( ) =

2 𝐶𝑜𝑛𝑖𝑐𝑎𝑙 𝐻𝑒𝑖𝑔ℎ𝑡

2

𝛼 𝑚

tan ( ) = 2

2 2𝑚

𝛼 = 53.130

The height of the drying chamber is:

𝐻𝑇 = 𝐻𝑐𝑦𝑙 + 𝐻𝑐𝑜𝑛𝑒

𝐻𝑇 = 4 𝑚 + 2 𝑚

𝑯𝑻 = 𝟔 𝒎

Height of the drying chamber is 6 m.

6. Wall Thickness

Wall thickness can be estimated using the formula:

𝐷𝑐 + 100

𝑡𝑚𝑖𝑛 =

1000

Acid Hydrolysis and Catalytic Condensation of Coconut Coir Dust Technical 10

for Diphenolic Acid Production Study

Pamantasan ng Lungsod ng Maynila

College of Engineering and Technology

Chemical Engineering Department

3.2808 𝑓𝑡 12𝑖𝑛

(2 𝑚 ∗ 1𝑚 ∗ ) + 100

1𝑓𝑡

𝑡𝑚𝑖𝑛 =

1000

𝑡𝑚𝑖𝑛 = 0.18 𝑖𝑛 ≈ 4.54 𝑚𝑚

Use 4.6 mm thickness.

7. Insulation Thickness

From energy balance,

Q = 13,729.8 kJ/batch = 13,013.3 BTU/batch

The operating temperature of the steam at the boiler is 200°C and the temperature of the

surrounding is assumed to be at 25 °C,

ΔT = 175°C = 347°F

Using Equation 10.8 from page 294 Unit Operation of Chemical Engineering, 6th ed, by

McCabe, Smith, and Harriott,

𝑄 ∆𝑇

=𝑘

𝐴 𝑥

Arranging the equation,

∆𝑇

𝑄 = (2𝜋𝑟𝐿)𝑘

𝑥

Where x is the thickness of layer of insulation,

6.56𝑓𝑡 𝐵𝑇𝑈

𝐵𝑇𝑈 𝑏𝑎𝑡𝑐ℎ 3600 𝑠𝑒𝑐 2𝜋(19.69 𝑓𝑡) ( 2 ) (0.35 )(347)

𝑓𝑡 − ℎ𝑟 − 𝐹

13,013.3 𝑥 𝑥 =

𝑏𝑎𝑡𝑐ℎ 12 𝑠𝑒𝑐 1ℎ𝑟 𝑥

𝑥 = 0.013 𝑓𝑡 = 0.15 𝑖𝑛 = 3.9 𝑚𝑚

Use 4 mm insulation thickness.

8. Power Consumption of Rotary Atomizer

The power consumption of the atomizer is computed based on the feed rate of the solution

that is atomized, the rotational speed of the atomizer and the atomizer size in terms of

radius, which is expressed using this equation:

𝑃 = 1.02𝑥10−8 ∗ 𝐹 ∗ (𝑁 ∗ 𝑟𝑑 )2

Where:

F = Feed rate of solution in lb/min

Acid Hydrolysis and Catalytic Condensation of Coconut Coir Dust Technical 11

for Diphenolic Acid Production Study

Pamantasan ng Lungsod ng Maynila

College of Engineering and Technology

Chemical Engineering Department

N = Rotational speed in rpm

rd= Radius of rotary atomizer in ft

P=power in hp

17.2 𝑙𝑏 20000 𝑟𝑒𝑣 0.3 𝑓𝑡 2

𝑃 = 1.02𝑥10−8 ∗ ∗( ∗ )

𝑚𝑖𝑛 𝑚𝑖𝑛 2

𝑃 = 1.58 ℎ𝑝

𝑷 ≈ 𝟏. 𝟔 𝒉𝒑

The power requirement of the atomizer is 1.6 hp, use a standard 2 hp motor (Silla,

pg. 240).

9. Power Consumption of Centrifugal Fan

The power consumption of the centrifugal fan is computed using the mechanical-energy-

balance equation (Geankoplis, Pg. 150). This equation was used since it gives the power

consumption with respect to the pressure head, velocity head, and mass flowrate of the

drying air. To solve for the power consumption, we first assume that the flow is

incompressible. The average density of the flowing gas will be used in the mechanical-

energy-balance equation. The density at the suction of the fan (Point 1), is:

𝑘𝑔 𝑎𝑖𝑟 1 𝑘𝑔 𝑚𝑜𝑙 273.2 741.7

𝜌1 = (29 )( )( )( )

𝑘𝑔 𝑚𝑜𝑙 22.414 𝑚3 366 760

𝜌1 = 0.940 𝑘𝑔⁄𝑚3

The molecular weight of 29 for air, the volume of 22.414 m3/kg mol at 101.3 kPa, and

273.2 K were obtained from Appendix A.1. The other densities are:

𝜌2 = 0.867 𝑘𝑔⁄𝑚3 at 150℃

𝜌3 = 1.024 𝑘𝑔⁄𝑚3 at 81℃

Getting the average density:

0.940 + 0.867 + 1.024

𝜌𝑎𝑣 =

3

𝜌𝑎𝑣 = 0.944 𝑘𝑔⁄𝑚3

Since the centrifugal fan has a suction pressure of 741.7 mmHg and a pressure increase

of 3%, then the developed pressure head is:

Acid Hydrolysis and Catalytic Condensation of Coconut Coir Dust Technical 12

for Diphenolic Acid Production Study

Pamantasan ng Lungsod ng Maynila

College of Engineering and Technology

Chemical Engineering Department

𝑁⁄

𝑝2 − 𝑝1 [(1.012)(741.7) − 741.7]𝑚𝑚𝐻𝑔 2 1

= (1.01325 × 105 𝑚 ) ( )

𝜌𝑎𝑣 760 𝑚𝑚𝐻𝑔⁄𝑎𝑡𝑚 𝑎𝑡𝑚 0.944 𝑘𝑔⁄𝑚3

𝑝2 − 𝑝1

= 1,257.02 𝐽⁄𝑘𝑔

𝜌𝑎𝑣

The developed velocity head for v1 = 0, and operating velocity of 1 m/s is:

𝑣22 (1)2

=

2 2

𝑣22

= 0.5 𝐽⁄𝑘𝑔

2

Writing the mechanical-energy-balance equation:

𝑣12 𝑝1 𝑣22 𝑝2

𝑧1 𝑔 + + − 𝑊𝑠 = 𝑧2 𝑔 + + + ∑𝐹

2 𝜌 2 𝜌

Setting z1=0, v1=0, and ∑F=0, and solving for Ws:

𝑝2 − 𝑝1 𝑣22

−𝑊𝑠 = + = 1,257.02 − 0.5 = 1,256.52 𝐽⁄𝑘𝑔

𝜌𝑎𝑣 2

Substituting into eq. 3.3-2 of Geankoplis, Pg. 145, and with an efficiency of 80% for the

fan, we compute for the brake kW:

−𝑊𝑠 𝑚

𝑏𝑟𝑎𝑘𝑒 𝑘𝑊 =

𝜂 × 1000

(1,256.52 𝐽⁄𝑘𝑔) (1.40 𝑘𝑔⁄𝑠)

𝑏𝑟𝑎𝑘𝑒 𝑘𝑊 =

0.8 × 1000

𝑏𝑟𝑎𝑘𝑒 𝑘𝑊 = 1.57 𝑘𝑊

Solving now for the electric power input, using 90% efficiency of electric motor,

substituting into eq. 3.3-5 of Geankoplis, Pg. 145:

𝑏𝑟𝑎𝑘𝑒 𝑘𝑊 7.33 𝑘𝑊

𝑒𝑙𝑒𝑐𝑡𝑟𝑖𝑐 𝑝𝑜𝑤𝑒𝑟 𝑖𝑛𝑝𝑢𝑡 (𝑘𝑊) = = = 1.75 𝑘𝑊 ≈ 2.34 ℎ𝑝

𝜂𝑒 0.90

The power requirement of the centrifugal fan is 2.34 hp, use a standard 2.5 hp

motor (Silla, pg. 240).

Acid Hydrolysis and Catalytic Condensation of Coconut Coir Dust Technical 13

for Diphenolic Acid Production Study

Pamantasan ng Lungsod ng Maynila

College of Engineering and Technology

Chemical Engineering Department

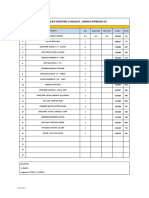

DESIGN SPECIFICATION

SPRAY DRYER DATA SHEET

Operating Data

Mode of Operation Batch

Number of Units 1

Total Drying Time 60 min/ batch

Compound Moist Diphenolic Acid

Inlet Temperature 130°C

Outlet Temperature 50°C

Feed Initial Moisture Content 32 % w/w

Final Moisture Content 10 % w/w

Final Particle Mean

100μm

Diameter

Inlet temperature 150°C

Outlet Temperature 80.9°C

Drying Air

Inlet Humidity 0.01 kg water/ kg d.a.

Outlet Humidity 0.0305 kg water/ kg d.a.

Technical Data

Atomizer

Proposed Existing

High speed centrifugal

Atomizer Type FS1.5 rotary atomizer

atomizer

Maximum Feed Rate 0.52 t/hr -

Rotational Speed 20,000 rpm 18,000 rpm

Diameter 90 mm 120mm

Drying Chamber

Capacity 7.8 kg/min -

Drying Air Requirement 5,023 kg d. a. /hr -

Operating Air Velocity 1.0 m/s -

Column Area 2 m2 -

Column Diameter 2m 3m

Column Total Volume 20 m3 -

Column Total Height 6m 3.2 m

Cylinder Height 4m -

Conical Bottom Height 2m -

Conical Bottom Angle 53.13O 55O

Wall Thickness 4.6 mm -

Miscellaneous

Insulation Type and -

Calcium silicate – 4 mm

Thickness

Power Requirement of

2 hp 2.95 hp

Atomizer

Power Requirement of

2.5 hp 2.1 hp

Centrifugal Fan

Acid Hydrolysis and Catalytic Condensation of Coconut Coir Dust Technical 14

for Diphenolic Acid Production Study

Pamantasan ng Lungsod ng Maynila

College of Engineering and Technology

Chemical Engineering Department

Materials of Construction Stainless Steel 304 Stainless Steel

Existing Equipment

Supplier TOPTION GROUP CO., LIMITED

5-21501 ROOM, Hecheng, Taibai South Road, Yanta

Supplier Address

District, Xi'an, China

Cost Php 3,200,000

Auxiliaries

Fan Centrifugal Fan

Dryer Exhaust Control Bag Filter

Air Heater Steam-heated Coils

Acid Hydrolysis and Catalytic Condensation of Coconut Coir Dust Technical 15

for Diphenolic Acid Production Study

También podría gustarte

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (894)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2099)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (73)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- Chemical Engineering Design of The Spray DryerDocumento6 páginasChemical Engineering Design of The Spray Dryervictor100% (1)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Tomorrow Man Initiative OverviewDocumento1 páginaThe Tomorrow Man Initiative OverviewvictorAún no hay calificaciones

- Software DeveloperDocumento21 páginasSoftware DevelopervictorAún no hay calificaciones

- Fibonacci Chheet SheetDocumento1 páginaFibonacci Chheet SheetvictorAún no hay calificaciones

- What Is Technical AnalysisDocumento2 páginasWhat Is Technical AnalysisvictorAún no hay calificaciones

- Bullish ContinuationDocumento1 páginaBullish ContinuationvictorAún no hay calificaciones

- LCA Product Sustainability Analysis Mathematical ModelingDocumento13 páginasLCA Product Sustainability Analysis Mathematical ModelingvictorAún no hay calificaciones

- Knight-Hennessy Scholars Welcome PacketDocumento26 páginasKnight-Hennessy Scholars Welcome PacketvictorAún no hay calificaciones

- The Building Blocks For Succeeding With Binary Options TradingDocumento26 páginasThe Building Blocks For Succeeding With Binary Options TradingKonie LappinAún no hay calificaciones

- Docsity Coplanar Forces Mechanics ExamDocumento5 páginasDocsity Coplanar Forces Mechanics ExamvictorAún no hay calificaciones

- Optimization of Chemical Processes: Course Code: 13CH1136 L TPC 4 1 0 3Documento2 páginasOptimization of Chemical Processes: Course Code: 13CH1136 L TPC 4 1 0 3victorAún no hay calificaciones

- Withdrawal From The Course (2013-2014)Documento3 páginasWithdrawal From The Course (2013-2014)victorAún no hay calificaciones

- Spectroscopic analysis of compoundsDocumento4 páginasSpectroscopic analysis of compoundsvictorAún no hay calificaciones

- PE I Paper 1 CMA SM PDFDocumento4 páginasPE I Paper 1 CMA SM PDFvictorAún no hay calificaciones

- PE I Paper 3 DMQADocumento3 páginasPE I Paper 3 DMQAvictorAún no hay calificaciones

- CHG 509 Chem Eng Exam 2019 - Sheet2Documento15 páginasCHG 509 Chem Eng Exam 2019 - Sheet2victorAún no hay calificaciones

- WasteDocumento40 páginasWastevictorAún no hay calificaciones

- Huang 2008Documento8 páginasHuang 2008victorAún no hay calificaciones

- Drying Technology: An International Journal: Click For UpdatesDocumento37 páginasDrying Technology: An International Journal: Click For UpdatesvictorAún no hay calificaciones

- PIPE SIZING CALCULATIONSDocumento17 páginasPIPE SIZING CALCULATIONSJaykumar100% (6)

- IHC 2014 Published Tomato Paper SiddickDocumento5 páginasIHC 2014 Published Tomato Paper SiddickvictorAún no hay calificaciones

- 5. Colomn Diameter The cross-sectional area of the column is a circle: 𝐴 = πd² 4 d = diameter of column √4A π² 𝑑 = √4 × 105 π² 𝑑 = 11.56mDocumento1 página5. Colomn Diameter The cross-sectional area of the column is a circle: 𝐴 = πd² 4 d = diameter of column √4A π² 𝑑 = √4 × 105 π² 𝑑 = 11.56mvictorAún no hay calificaciones

- Shavandi 2018Documento68 páginasShavandi 2018victorAún no hay calificaciones

- Design of A Cyclone SeparatorDocumento17 páginasDesign of A Cyclone SeparatorIvan Ivanovski100% (2)

- CHG 509 Chem Eng Exam 2019 - Sheet2Documento15 páginasCHG 509 Chem Eng Exam 2019 - Sheet2victorAún no hay calificaciones

- Cyclone Design and SpecificationDocumento7 páginasCyclone Design and SpecificationvictorAún no hay calificaciones

- Laboratory Spray Dryer Performance for Tomato PowderDocumento17 páginasLaboratory Spray Dryer Performance for Tomato PowdervictorAún no hay calificaciones

- Spray Dryer DesignDocumento24 páginasSpray Dryer DesignJan Benner83% (12)

- SSS 3Documento3 páginasSSS 3victorAún no hay calificaciones

- Outdoor Cabinet Type2Documento2 páginasOutdoor Cabinet Type2Ольга КолчинаAún no hay calificaciones

- CHAPTER 2 Excel IntroductionDocumento21 páginasCHAPTER 2 Excel Introductionnatasha thaiAún no hay calificaciones

- 01.4TB.076 Bus Duct Enclosure MaterialDocumento1 página01.4TB.076 Bus Duct Enclosure MaterialJonathan FerueloAún no hay calificaciones

- Turbine Gland Steam CondenserDocumento4 páginasTurbine Gland Steam CondenserSai Swaroop100% (1)

- EN Operating Instructions VEGABAR 82 Two Wire 4 20 MaDocumento84 páginasEN Operating Instructions VEGABAR 82 Two Wire 4 20 MaHerick MoscardiniAún no hay calificaciones

- Rapid Urban Growth TriadDocumento18 páginasRapid Urban Growth TriadDiana Sophia KanAún no hay calificaciones

- Jis-Astm SpecDocumento1 páginaJis-Astm SpecRizki AhmadAún no hay calificaciones

- P34x EN MD M96 V35+V70 Incl P341Documento163 páginasP34x EN MD M96 V35+V70 Incl P341tandin.t6393Aún no hay calificaciones

- Gas Turbine Trip System 2.2.5.3 Trip MatrixDocumento1 páginaGas Turbine Trip System 2.2.5.3 Trip MatrixMohammad Jahangir AlamAún no hay calificaciones

- Week 9 Lab - Configuring and Modifying Standard IPv4 ACLs - ILMDocumento10 páginasWeek 9 Lab - Configuring and Modifying Standard IPv4 ACLs - ILMAhmedAún no hay calificaciones

- Ampacity of 230kV Taungoo-Loikaw LineDocumento6 páginasAmpacity of 230kV Taungoo-Loikaw Line정상진Aún no hay calificaciones

- Releasenotes FR FRDocumento9 páginasReleasenotes FR FRdadjudadju11Aún no hay calificaciones

- 2 Drillstring DesignDocumento34 páginas2 Drillstring DesignAdel Ahmed AlkhaligyAún no hay calificaciones

- Orifice Catalogue EnglishDocumento11 páginasOrifice Catalogue Englishrahman ariwibowoAún no hay calificaciones

- Application of Transportation Problem in Operational ResearchDocumento17 páginasApplication of Transportation Problem in Operational ResearchTina JinaAún no hay calificaciones

- Technical Blogs on Compiling Qualcomm MSM8909 Chipset FirmwareDocumento4 páginasTechnical Blogs on Compiling Qualcomm MSM8909 Chipset FirmwareSaurabh GuptaAún no hay calificaciones

- Terminology Introduction 1Documento18 páginasTerminology Introduction 1Paula ChenaAún no hay calificaciones

- Manual Apex Thermal SightsDocumento56 páginasManual Apex Thermal SightsGuido Catello0% (1)

- LN 2.1 IBS - Issues and ChallengesDocumento29 páginasLN 2.1 IBS - Issues and ChallengesthamilAún no hay calificaciones

- QAF5180 Rev0 First Aid Kit Inventory Sheet - ARAMCO TYPEDocumento1 páginaQAF5180 Rev0 First Aid Kit Inventory Sheet - ARAMCO TYPEMohamed El-SawahAún no hay calificaciones

- Hyundai Part Catalogue D6ACDocumento157 páginasHyundai Part Catalogue D6ACHammim Hamzhahh100% (1)

- SPE 26515 Overbalance Perforating and Stimulation Method For WellsDocumento10 páginasSPE 26515 Overbalance Perforating and Stimulation Method For WellsSebastián PavónAún no hay calificaciones

- Isb PTCL Bill March 2020Documento1 páginaIsb PTCL Bill March 2020Umar FarooqAún no hay calificaciones

- Hydraulic Winch Operation ManualDocumento11 páginasHydraulic Winch Operation ManualMohammed MostafaAún no hay calificaciones

- Chapter 2. The Evolution of Management ThinkingDocumento5 páginasChapter 2. The Evolution of Management ThinkingBùi Thị Minh YếnAún no hay calificaciones

- Mounted Disc Plough Operator ManualDocumento14 páginasMounted Disc Plough Operator ManualJunior KachikhoAún no hay calificaciones

- ATT - 1443630574733 - ENSA Agadir Hassane Bouzahir Chapter 1 - GraphsDocumento17 páginasATT - 1443630574733 - ENSA Agadir Hassane Bouzahir Chapter 1 - GraphsNouhaila BabaAún no hay calificaciones

- Semi-Automatic Twister: The Way To Make ItDocumento1 páginaSemi-Automatic Twister: The Way To Make ItSidharthAún no hay calificaciones

- Advanced e-Voting Project ReportDocumento7 páginasAdvanced e-Voting Project ReportEducation Tech PoolAún no hay calificaciones

- Techniques and Tools For Software Analysis: Freescale SemiconductorDocumento7 páginasTechniques and Tools For Software Analysis: Freescale SemiconductorjohnAún no hay calificaciones