Documentos de Académico

Documentos de Profesional

Documentos de Cultura

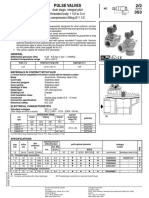

WAREX - Dependable butterfly valves for over 35 years

Cargado por

Saâd Eddine AtifTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

WAREX - Dependable butterfly valves for over 35 years

Cargado por

Saâd Eddine AtifCopyright:

Formatos disponibles

We introduce ourselves

WAREX – Armatures have been the embodiment of depend-

Problem-free design and various changeable A design that encourages trust:

able and inexpensive butterfly valves for more than 35 years.

WAREX – Butterfly Valves are employed in the most diverse drive elements such as:

process plants worldwide and have become an indisputable

term of quality. Whether in the chemical, food or pharma-

ceutical industries, the construction of plant or containers, or ( )

Ratchet hand lever Self – locking Electric Pneumatic actuator ( )

in water- and air technology, WAREX – Butterfly Valves have

proved to be the best even in the roughest operational times 2 / worm gear actuator

( )

times 7 ratchet

( )

conditions and the most problematic cases of employment.

Even in the case of aggressive fluids or gases, including abrasive

bulk-materials and, last but not least, in the case of solid

substances in plant with the danger of dust-explosions,

the WAREX – Butterfly Valves are preferred as being

particularly safe shutoff devices. Production Plant in Senden/Westphalia

Dependability and user-specific, detailed constructions have represented our butterfly valves for many years. A continuous control

of the functions and the quality of our products are as much a standard procedure as employing the experience of decades in the

selection of the material combinations and the technical design of the armatures – that being equally valid in the case of the:

Connection according to the standard DIN / ISO 5211

DKZ 110

Tightly sealing ring butterfly valve for clamping between the flanges, according to

DIN 2501/ANSI 150 lb. Light product series for pressure differences up to 10 bar – pressure-

tight in line with DIN 3230 B0; Leakage rate 1.

D

PC

Special Features:

These butterfly valves are equipped with the respective pc

■ designed to be maintenance-free d

drive elements according to the operating conditions.

The activation field ranges over the simple manual

■ casing with a high self lifting capacity activation of servo levers, through raster levers with

2 or 7 fixed points for dosing functions, and electrical

■ centrally located disc that is servo and regulation actuators, to pneumatic actuator

favourable for the flow with intelligent control units for automatic process

plants, dosing or filling systems, and Double Flap

■ shaft or disk connection dependent on Valves (Sluices).

the form by having multiple edges

The butterfly valve can be used for solid and liquid as

■ seals can be replaced; with a protrusion well as gaseous media and in temperature areas from

DKZ 110 R on both sides, including the seal DKZ 110 H

– 40° C to + 200° C. For hot gases or solid substances

supports, they guarantee a complete of more than 200° C, this product series is produced

and therefore safe sealing of the as a choke valve in a metal casing model.

armature between the flanges without ANSI

ND 6 ND 10 ND 16 150lb/sq.in

additional flange seals

flange connection hole hole hole hole

■ universal field of application Can also be delivered as a shockproof,

DKZ 110

PCD

PCD

PCD

PCD

PC

PC

PC

Ød

Ød

Ød

Ød

PC

■ practical and inexpensive design

ignition proof model with the DMT DN A B h (R) (T) L L1 (Ød2xS) (ØE) pcd d1 SW

certificate 50 110 70 38 98 13 39 41 35 x 3 14 50 6.5 11 110 4 14 125 4 18 125 4 18 120.6 4 19

65 118 78 38 118 13 39 41 35 x 3 14 50 6.5 11 130 4 14 145 4 18 145 4 18 139.7 4 19

80 125 85 38 134 13 39 41 35 x 3 14 50 6.5 11 150 4 18 160 8 18 160 8 18 152.4 4 19

100 135 95 38 154 13 39 41 35 x 3 14 50 6.5 11 170 4 18 180 8 18 180 8 18 190.5 8 19

Materials Table Standard Model 125 163 124 53 183 19 44 46 55 x 3 20 70 8.5 17 200 8 18 210 8 18 210 8 18 215.9 8 22.2

150 175 136 53 209 19 44 46 55 x 3 20 70 8.5 17 225 8 18 240 8 22 240 8 22 241.3 8 22.2

Casing : G-A15i 10 Mg / GG 25 / GGG 40 200 200 161 53 263 19 54 56 55 x 3 20 70 8.5 17 280 8 18 295 8 22 295 12 22 298.4 8 22.2

250 249 206 15 315 24 68 70 70 x 3 28 102 10.5 22 335 12 18 350 12 22 355 12 26 361.9 12 25.4

Disk : Stainless Steel / GG 40 / Steel

DN 50 – DN 400 Sealing : NBR / Perbunan / Silicon / Viton etc.

300

350

274

304

229

266

15

15

372

423

24

28

78

67

80

69

70 x 3

85 x 3

28

36

102

125

10.5

12.5

22

27

395

445

12

12

22

22

400

460

12

16

22

22

410

470

12

16

26

26

431.8

476.2

12

12

25.4

28.6

Shafts : Stainless Steel 400 330 301 15 473 28 67 69 85 x 3 36 125 12.5 27 495 16 22 515 16 26 525 16 30 539.7 16 28.6

PN 6 – PN 10 Shaft bearing : Brass / Bronze / Polyamide / Teflon 450 400 337 15 537 28 102 104 85 x 3 36 125 12.5 27 550 16 22 565 20 26 585 20 30 577.8 16 31.7

500 433 360 15 578 28 77 78 85 x 3 36 125 12.5 27 600 20 22 620 20 26 650 20 33 635 20 31.7

Shaft Sealing : Perbunan / Silicon / Viton

DKZ 110 DZ DKZ 110 E ANSi 150 lb More material options for special models on request Special model on demand ( ) – Variations are possible Right to make technical changes reserved.

También podría gustarte

- Variable-Speed, Water-Cooled Chillers and Heat Pumps: 30XW-V/30XWHVDocumento8 páginasVariable-Speed, Water-Cooled Chillers and Heat Pumps: 30XW-V/30XWHVdavid hAún no hay calificaciones

- Valve Solutions For Drilling BRDocumento8 páginasValve Solutions For Drilling BRshamekhalmaamariAún no hay calificaciones

- Daps enDocumento73 páginasDaps enPutri ChairanyAún no hay calificaciones

- ASCO Series 353 2-2 Pules Valves Dual StageDocumento2 páginasASCO Series 353 2-2 Pules Valves Dual StageAdnan AliAún no hay calificaciones

- European Catalog Single Stage Pulse Valves Series 353 Asco en 7028704Documento2 páginasEuropean Catalog Single Stage Pulse Valves Series 353 Asco en 7028704AirteamAún no hay calificaciones

- En Cat RVDocumento122 páginasEn Cat RVMurat CanAún no hay calificaciones

- 0120 CSS Subsea Diver Installed ConnectorsDocumento2 páginas0120 CSS Subsea Diver Installed ConnectorsThamer KhatibAún no hay calificaciones

- Le Plasma Range EngDocumento12 páginasLe Plasma Range EngBertho Quisoccala LlampiAún no hay calificaciones

- Oil and Gas Shapes enDocumento5 páginasOil and Gas Shapes enCarlosIkedaAún no hay calificaciones

- Smartpack H SeriesDocumento2 páginasSmartpack H Seriesmarcelo espinozaAún no hay calificaciones

- Solenoid Valves-Dust Collector-353-CAT-60059GBDocumento2 páginasSolenoid Valves-Dust Collector-353-CAT-60059GBangelosAún no hay calificaciones

- SCG238 Series PDFDocumento2 páginasSCG238 Series PDFrika monikaAún no hay calificaciones

- E TechNews SBO Full-PTFE-diaphragm 200227Documento1 páginaE TechNews SBO Full-PTFE-diaphragm 200227Nicolas AguilarAún no hay calificaciones

- B 81417 EfaDocumento2 páginasB 81417 EfaIshak EnginerAún no hay calificaciones

- Asco Series 238 ASCO Pilot Operated Solenoid Valves (Floating Diaphragm) PDFDocumento2 páginasAsco Series 238 ASCO Pilot Operated Solenoid Valves (Floating Diaphragm) PDFKhyle Laurenz DuroAún no hay calificaciones

- Solenoid Valves Pilot Operated 2/2 Series NCDocumento2 páginasSolenoid Valves Pilot Operated 2/2 Series NCKhyle Laurenz DuroAún no hay calificaciones

- The Air Admittance Valve Designed Specially For Commercial ApplicationsDocumento2 páginasThe Air Admittance Valve Designed Specially For Commercial ApplicationsSenn OdrapmasdAún no hay calificaciones

- Iwk 219019 Esm HarnessDocumento1 páginaIwk 219019 Esm HarnessJoão Pedro MoreiraAún no hay calificaciones

- Rotex: Torsionally Flexible CouplingsDocumento30 páginasRotex: Torsionally Flexible CouplingsFreddy AyalaAún no hay calificaciones

- European Catalog Solenoid Valves 2 2 Pilot Operated Built in Pilot Floating Diaphragm Series 238 Asco en 5080052Documento2 páginasEuropean Catalog Solenoid Valves 2 2 Pilot Operated Built in Pilot Floating Diaphragm Series 238 Asco en 5080052Farhan HirsanAún no hay calificaciones

- European Catalog Pulse Valve Dust Collector Remote Pilot 353 Asco en 5084840Documento2 páginasEuropean Catalog Pulse Valve Dust Collector Remote Pilot 353 Asco en 5084840Julio César Herrera MontoyaAún no hay calificaciones

- Precision Reduction Gear RV: AF SeriesDocumento44 páginasPrecision Reduction Gear RV: AF SeriesManoj KumarAún no hay calificaciones

- Seco-DC-Drives Catalog en-US Rev2005Documento40 páginasSeco-DC-Drives Catalog en-US Rev2005milacronAún no hay calificaciones

- Red Jacket pump specifications and environmental protectionDocumento2 páginasRed Jacket pump specifications and environmental protectionDario FloresAún no hay calificaciones

- Brochure o Pumps Deepwell Gas CarriersDocumento4 páginasBrochure o Pumps Deepwell Gas CarriersJohn MarxisAún no hay calificaciones

- Rotary Vane Vs Liquid Ring CompessorsDocumento2 páginasRotary Vane Vs Liquid Ring Compessorsmember1000Aún no hay calificaciones

- Cs5864 02 SH GadusfamilypstrDocumento1 páginaCs5864 02 SH GadusfamilypstrMitesh SinghAún no hay calificaciones

- 920-01-520 FGDAgitators EN 12.14Documento2 páginas920-01-520 FGDAgitators EN 12.14FelySaezAún no hay calificaciones

- Distributor Valves P-1247 enDocumento2 páginasDistributor Valves P-1247 enKrishna KumarAún no hay calificaciones

- Precision Reduction Gear RV: Turntable GearheadDocumento40 páginasPrecision Reduction Gear RV: Turntable GearheadManoj KumarAún no hay calificaciones

- Single Stage, Integral Pilot Threaded Body or Compression Fitting 3/4 To 1Documento2 páginasSingle Stage, Integral Pilot Threaded Body or Compression Fitting 3/4 To 1VM ExportAún no hay calificaciones

- Pres VacDocumento6 páginasPres VacSandro AraújoAún no hay calificaciones

- ASCO Series 353-2-2 Pulse Valves Single Stage 4Documento2 páginasASCO Series 353-2-2 Pulse Valves Single Stage 4Peter UhuleAún no hay calificaciones

- Anti Static Protective Wrap: Aec FlexguardDocumento3 páginasAnti Static Protective Wrap: Aec Flexguardpichet33Aún no hay calificaciones

- Diagram & Circuit Boards Edition: © 2013-4 Printed in Ja Pan RQ005 (Y) 195 (B53-7038-00)Documento54 páginasDiagram & Circuit Boards Edition: © 2013-4 Printed in Ja Pan RQ005 (Y) 195 (B53-7038-00)NickEglezosAún no hay calificaciones

- Válvulas de SeguridadDocumento12 páginasVálvulas de Seguridadjohn jimenezAún no hay calificaciones

- BW30 365Documento2 páginasBW30 365cristian gaete essedinAún no hay calificaciones

- RV-N Rev.9 EN No DRW Nabtesco PDFDocumento50 páginasRV-N Rev.9 EN No DRW Nabtesco PDFEdy HeadbangerAún no hay calificaciones

- Amarex KRT submersible pumps guideDocumento96 páginasAmarex KRT submersible pumps guidemohammad ziad khatibAún no hay calificaciones

- Ups12-475 Ups12-475 Ups12-475 Ups12-475 Ups12-475Documento2 páginasUps12-475 Ups12-475 Ups12-475 Ups12-475 Ups12-475CARLOS SARMIENTOAún no hay calificaciones

- Rexroth Servo Valves Start-Up & Maintenance Re07700 - 2006-08Documento4 páginasRexroth Servo Valves Start-Up & Maintenance Re07700 - 2006-08buddhivasuAún no hay calificaciones

- AquaJet BrochureDocumento8 páginasAquaJet BrochureViorel HarceagAún no hay calificaciones

- Desicorr Vpci Pouches/ Desicorr NW Vpci: CorporationDocumento2 páginasDesicorr Vpci Pouches/ Desicorr NW Vpci: CorporationSefa ZumbulAún no hay calificaciones

- Shell Omala Product Family BrochureDocumento3 páginasShell Omala Product Family BrochurenghiaAún no hay calificaciones

- Shell Omala Product Family Brochure PDFDocumento3 páginasShell Omala Product Family Brochure PDFjuanAún no hay calificaciones

- RS Series Product Catalog FullDocumento40 páginasRS Series Product Catalog Fullmikel.hernandezAún no hay calificaciones

- NEMO-CPro 0313 ENDocumento4 páginasNEMO-CPro 0313 ENrosario medinaAún no hay calificaciones

- Distillation Tray SelectionDocumento4 páginasDistillation Tray Selectionchemsac2Aún no hay calificaciones

- DM200 ManualDocumento2 páginasDM200 ManualSamuelAún no hay calificaciones

- Power Pulse Valves PDFDocumento12 páginasPower Pulse Valves PDFUrip S. SetyadjiAún no hay calificaciones

- Integral Pilot (External Exhaust) Threaded or Quick Mount Connection 3/4 To 1 1/2Documento16 páginasIntegral Pilot (External Exhaust) Threaded or Quick Mount Connection 3/4 To 1 1/2Kishor JadhavAún no hay calificaciones

- DPI Transom Shield InstallationDocumento2 páginasDPI Transom Shield InstallationSONAún no hay calificaciones

- Gas Liquid Separation TechnologyDocumento26 páginasGas Liquid Separation TechnologyCSAún no hay calificaciones

- Screw CompressorsDocumento21 páginasScrew CompressorsAiman DadoushAún no hay calificaciones

- Bluetruckmaster Diesel Exhaust Fluid (Def) Storage & Dispensing Solutions Product CatalogDocumento3 páginasBluetruckmaster Diesel Exhaust Fluid (Def) Storage & Dispensing Solutions Product CatalogRazi A. RahimAún no hay calificaciones

- Valeoscope CV Clutch 2020Documento39 páginasValeoscope CV Clutch 2020Mickael HespelAún no hay calificaciones

- HE Loops 9 - 20Documento4 páginasHE Loops 9 - 20mkkb mk3Aún no hay calificaciones

- Dynatorque Gears and Automated Valve Accessories Ps PDFDocumento2 páginasDynatorque Gears and Automated Valve Accessories Ps PDFzahraAún no hay calificaciones

- Assembly Lines enDocumento14 páginasAssembly Lines enYassine SlimiAún no hay calificaciones

- Geotextiles and Geomembranes HandbookDe EverandGeotextiles and Geomembranes HandbookT.S. IngoldCalificación: 5 de 5 estrellas5/5 (1)

- PB3906 - Raymond Bowl Mill Coal & Pet Coke App PDFDocumento2 páginasPB3906 - Raymond Bowl Mill Coal & Pet Coke App PDFSaâd Eddine AtifAún no hay calificaciones

- Installation Operation & Maintenance ManualDocumento13 páginasInstallation Operation & Maintenance ManualGustavo PaezAún no hay calificaciones

- Bowl Mill Coal & Pet Coke AppDocumento2 páginasBowl Mill Coal & Pet Coke AppSaâd Eddine AtifAún no hay calificaciones

- Presentation Weibull Analysis English PDFDocumento20 páginasPresentation Weibull Analysis English PDFSaâd Eddine AtifAún no hay calificaciones

- 15 Lidonnici Cous&EuvesselDocumento15 páginas15 Lidonnici Cous&EuvesselkanchanabalajiAún no hay calificaciones

- Guide To ASME Code VIII Division 1 Pressure VesselsDocumento16 páginasGuide To ASME Code VIII Division 1 Pressure VesselsSaâd Eddine Atif0% (1)

- 15 Lidonnici Cous&EuvesselDocumento15 páginas15 Lidonnici Cous&EuvesselkanchanabalajiAún no hay calificaciones

- Montecarlosimulations: Software By: Barringer & Associates, IncDocumento19 páginasMontecarlosimulations: Software By: Barringer & Associates, IncSaâd Eddine Atif100% (1)

- 15 Lidonnici Cous&EuvesselDocumento15 páginas15 Lidonnici Cous&EuvesselkanchanabalajiAún no hay calificaciones

- Alcoholic BeveragesDocumento15 páginasAlcoholic BeveragesArlyn Jane GregorioAún no hay calificaciones

- Perfume Industry Final PaperDocumento15 páginasPerfume Industry Final Paperleo besaAún no hay calificaciones

- Jurema-Preta (Mimosa Tenuiflora) - A Review of Its Traditional Use, Phytochemistry and PharmacologyDocumento11 páginasJurema-Preta (Mimosa Tenuiflora) - A Review of Its Traditional Use, Phytochemistry and PharmacologyPedro S ReisAún no hay calificaciones

- (Encyclopedia of Plant Physiology 17) H. F. Linskens, J. Heslop-Harrison (Auth.), Professor Dr. Hans F. Linskens, Professor Dr. John Heslop-Harrison (Eds.)-Cellular Interactions-Springer-Verlag BerlinDocumento760 páginas(Encyclopedia of Plant Physiology 17) H. F. Linskens, J. Heslop-Harrison (Auth.), Professor Dr. Hans F. Linskens, Professor Dr. John Heslop-Harrison (Eds.)-Cellular Interactions-Springer-Verlag BerlinvitaAún no hay calificaciones

- Understanding Exergy Efficiencies and Value DiagramsDocumento13 páginasUnderstanding Exergy Efficiencies and Value DiagramsElzimar FreitasAún no hay calificaciones

- Notes Science Modes in Reproduction PLANTSDocumento3 páginasNotes Science Modes in Reproduction PLANTSmary-ann escalaAún no hay calificaciones

- Soal Pas B Inggris Kelas 6Documento8 páginasSoal Pas B Inggris Kelas 6Aizen nyatirAún no hay calificaciones

- 2nd CotDocumento15 páginas2nd CotKatherine Castro SolatorioAún no hay calificaciones

- Refrigeration Experiment ComponentsDocumento40 páginasRefrigeration Experiment Componentsflorenz rubricoAún no hay calificaciones

- Pharmacognosy Lec ReviewerDocumento53 páginasPharmacognosy Lec Reviewerprinz1mendezAún no hay calificaciones

- Training Text Gas TurbineDocumento87 páginasTraining Text Gas Turbinebmw316100% (1)

- 21 Species Booklet 2004Documento38 páginas21 Species Booklet 2004Abdullah ZakiAún no hay calificaciones

- Production of Organic Vegetable SeedsDocumento99 páginasProduction of Organic Vegetable SeedsSchool Vegetable GardeningAún no hay calificaciones

- Cell StructureDocumento15 páginasCell StructureLavanya KalapalaAún no hay calificaciones

- Traditional Knowledge On Chiuri and Its Potentiality For CommercializationDocumento3 páginasTraditional Knowledge On Chiuri and Its Potentiality For Commercializationkhilendra gurungAún no hay calificaciones

- Ed135942 PDFDocumento372 páginasEd135942 PDFMohammad Al-SalemAún no hay calificaciones

- Parts of The Flower and Seed IIIDocumento8 páginasParts of The Flower and Seed IIISydney UyAún no hay calificaciones

- John Josselyn - New Englands Rarities Discovered in Birds Beasts Fishes Serpents and Plants of That CountryDocumento188 páginasJohn Josselyn - New Englands Rarities Discovered in Birds Beasts Fishes Serpents and Plants of That Countrymiguelkg65Aún no hay calificaciones

- Jathroper Charcoal As Alternative Heat Source. Clyde2Documento29 páginasJathroper Charcoal As Alternative Heat Source. Clyde2Charles Jebb Belonio JuanitasAún no hay calificaciones

- Kenyan RecipesDocumento5 páginasKenyan Recipesammodero100% (1)

- The Lion and The MouseDocumento10 páginasThe Lion and The MouseSiti Zainab MazlanAún no hay calificaciones

- Koreksi Per 31032020Documento3922 páginasKoreksi Per 31032020Surya MojorotoAún no hay calificaciones

- Diversity in The Plant KingdomDocumento14 páginasDiversity in The Plant KingdomJimmy Serendip100% (1)

- WHLP Grade 6 Q1 W3Documento2 páginasWHLP Grade 6 Q1 W3Maicah Alcantara MarquezAún no hay calificaciones

- SEED TREATMENT WITH BOTANICAL EXTRACTSDocumento18 páginasSEED TREATMENT WITH BOTANICAL EXTRACTSRohitAún no hay calificaciones

- Evaluatinging Capital Cost Estimation Programs PDFDocumento8 páginasEvaluatinging Capital Cost Estimation Programs PDFAnonymous RJkpep7D0rAún no hay calificaciones

- Tukutuku Tuturu Maori - Auckland MuseumDocumento20 páginasTukutuku Tuturu Maori - Auckland MuseumMichael NorrisAún no hay calificaciones

- Green Spring Sale PosterDocumento1 páginaGreen Spring Sale Posterkhayra umairahAún no hay calificaciones

- K P GroupDocumento13 páginasK P GroupMihrak SafirAún no hay calificaciones

- Cicind Lidos Neotropicales PDFDocumento23 páginasCicind Lidos Neotropicales PDFMyrian Resquin100% (2)