Documentos de Académico

Documentos de Profesional

Documentos de Cultura

MaritimeStateUniversity TDR RS18

Cargado por

fhsdhfuehfDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

MaritimeStateUniversity TDR RS18

Cargado por

fhsdhfuehfCopyright:

Formatos disponibles

Maritime State University AUV TEAM 1 of 5

Maritime State University AUV TEAM

Autonomous underwater vehicle for RoboSUB

2018

Aleksandr Esin, Petr Gorelov, Vladislav Bolotov, Oleg Shevchenko and Tatiana Cheremnykh

Abstract — MSU AUV team was founded in 2015 with the aim One of the challenges for navigation system

to improve students’ skills in electronics, programming, designers is reducing impact on the navigation units.

mechanics, and construction. The team consists of one mechanic,

It is necessary to reduce interference on navigation as

one electronics engineers, three programmers, and two advisors.

The vehicle was especially for the RoboSUB competition. MSU much as possible.

AUV sensor suite includes hand-made hydrophones, an Analog Vehicle should be capable of operating in remote

Devices IMU – ADIS16480, two color GiGE cameras by iDS control mode. It will allow to debug it easily.

imaging, a depth sensor. The software was rewritten from

scratch this year. The team switched away from using Qt Fig 1. and Table 1 below show final rendering of the

framework on the vehicle to Boost libraries. However, Qt is still

used for GUI apps. vehicle and specification.

I. INTRODUCTION

The Maritime State University AUV TEAM was founded in

2015 with the aim to design and build autonomous underwater

vehicles for the RoboSub competition, to increase the level of

students' professional skills, and the popularization of robotics

in the Far East of Russia. In three past years, the team took

prizes in the RoboSub competition. Thanks to this Maritime

State University retains its position as the leading university in

Russia on training of specialists in robotics.

At the beginning of the study year, the team recruits new Fig 1. A SolidWorks render of MSU AUV.

members, so everyone in team has a different level of

preparedness. Each team member is involved in one of the Table I

following areas: mechanics, electronics, and programming. MSU AUV SPECIFICATION

Specification Dimension

II. DESIGN STRATEGY

Mission/Vision Intel NUC: Intel Core i5, 128 Gb SSD, 4 GB

Before constructing the vehicle, the team searched for computer DDR3 RAM

technical reports from previous years. After studying different Weight 36 kg

teams practice in building such vehicles MSU AUV Team Navigation controller STM32F373

developed requirements for their sub: Hydroacoustic boards Marsohod2, Custom amplification and filtering

board

The vehicle should be as light as possible, preferably Hydrophones Custom

less than 28kg. This would bring extra bonus points. Navigation Analog Devices ADIS16480, Д0,1Т-4

Vision Sensors 2x GiGE cameras iDS UI-5260CP-C-HQ

The structure of vehicle should be modular. This Power Supply 23V 10Ah Li-Po

allows to replace battery easily and to have easy Connectors RMG, RMGD

access to the electronics if it is necessary. Software Boost (ASIO, MSM), Qt, Websocketpp,

To accomplish most missions, it is required to work C++/Chai Script, Ubuntu 16.04

with images. To process video successfully it is

necessary to deploy high-quality machine vision

cameras which will not break objects geometry and III. MECHANICAL SYSTEMS

colors of images. A. Frame and housings

An important requirement is easy maneuverability of The frame of vehicle is made of polyethylene, which has

the vehicle. To accomplish a number of tasks it is neutral buoyancy. The housings are acrylic and aluminum.

necessary to be capable of moving sideways. Also The usage of these materials reduces need for additional

AUV should have strong stabilization system. buoyancy and helps to minimize apparatus weight. The battery

Maritime State University AUV TEAM 2 of 5

is located in a separate housing and can be easily replaced by potential difference (voltage) is applied, it is opened and the

the charged one. It allows to train without breaks for charging. air immediately with great speed goes through the tube, and

There are magnetic compass and LED indication on the top of simultaneously pushes the torpedo. An important element of

the vehicle. Such location of the compass reduces interference the device is a tube, the length of which was chosen

on it. LED shows status of apparatus. empirically taking into account the initial torpedo rate and its

The vehicle consists of six housings: electronic acrylic accuracy. Also the team paid much attention to the

housing, battery housing, front camera housing, bottom development and creation of the torpedo. Correct form and

camera housing, IMU acrylic housing, and pressure sensor proper ballasting of it allowed to achieve the required results.

housing. Connections between units are made with transparent Before each start it is necessary to make pumping and

pneumatic cable. recharge device.

The team replaced cameras’ acrylic housings by aluminum, The team uses 2 torpedoes launchers. The weight of each of

because acrylic housings were damaged by pressure them is 0.8 kg, the shooting distance is 3 m.

compensation system during previous RoboSub competition.

B. Thrusters

Thruster Control Unit (TCU) is located in a separate

housing. This solution allowed to save space in the autopilot

and to save sensitive electronics of the vehicle from

superfluous electrical interference. This year thrusters were

provided by the Center for Robotics Development.

MSU AUV team uses five thrusters (one of them is shown

КЕ И ИКИ

in Fig 2.) to increase mobility, which is important for some

missions. Two thrusters are used for moving forward or

backward and yaw stabilization. One thruster is used for Fig 3. Render of torpedo launcher.

moving sideways and 2 vertical thrusters are used for

surfacing or diving and vehicle stabilizing by depth.

D. Marker Dropper

Marker Dropper, shown in Fig 4, is the device consisting of

- a plastic hollow cylinder and marker (a golf ball) which is

located inside of it. Latch, which is placed in the lower inner

part of the cylinder, fixes the marker. Due to the fact that the

latch is pressed, marker does not fall out. Reset is carried out

using an electromagnet, which controls the position of latch.

When the electromagnet starts to work, it attracts the latch and

А ball falls out of the cylinder. The simplicity and reliability of

the design prevents from unintentionally falling out of the

marker.

The MSU AUV has 2 marker droppers with weight 0.25 kg.

Fig 2. Thruster.

Ш Thrusters spec is shown in the table II below.

Table II

THRUSTER SPECIFICATION

Specification Dimension

Sizes (W/H/L) 0.097/0.081/0.068m

Weight 0.206 kg

Thrust 1.5kg/f

Mac. current 2A

Voltage 12-24V Fig 4. Render of marker dropper.

Control PWM

Driver External

IV. ELECTRICAL SYSTEM

C. Torpedo launcher A. Battery

The torpedo launcher, shown in Fig 3, is a construction AUV power supply based on 23V, 10Ah Li-Po battery.

consisting of a plastic tube with a torpedo inside of it, capacity The capacity of battery is enough for 2-3 hours of the

of compressed air and solenoid valve which was installed vehicle’s work. Battery’s switch is based on BTS555 high

between them. The solenoid valve is locked and keeps current power switch. The switch is controlled by an outer

excessive pressure in the capacity before launch. When waterproof magnetic button. The kill switch is big and bright

Maritime State University AUV TEAM 3 of 5

and located on top of the vehicle. That allows Sir. Diver to 2. Orientation sensors.

turn off AUV immediately. Required power supply voltage for The vehicle is equipped with IMU and the depth sensor.

all on-board devices and systems is converted by the power The team uses ADIS16480. It is a complete inertial system

supply board, consisting of DC-DC converters and filters. that includes a triaxial gyroscope, a triaxial accelerometer,

triaxial magnetometer, pressure sensor, and an extended

B. Computer system Kalman filter (EKF) for dynamic orientation sensing. It makes

The team subdivides data processing between two it possible to determine roll, pitch, magnetic heading, and rate

computers: the main computer and the navigation controller. of angular motion of the vehicle.

The main computer is Intel NUC based on Intel Core i5 Magnetic heading is subject to interferences generated by

processor with 4 gigabytes of random access memory and 128 thrusters and electronic systems. In order to reduce their

gigabytes solid state drive. It is performing high-load data impact, the team did the best to locate inertial system as far

processing: missions planning and image processing. This from the interference sources as possible and placed it on a

computer has compact size and has enough performance to separate housing on top of the vehicle.

accomplish tasks allotted to it.

3. Depth sensor

In order to determine the depth, the team uses

piezoconverter Д0,1Т-4. MSU AUV team designed and built a

separate board based on STM32F373. The depth sensor board,

shown in Fig 7, is used l data from this board are transmitting

via CAN Bus on to navigation controller.

Fig 5. On board electronics inside housing.

The navigation controller is based on STM32F407

Fig 7. Disassembled depth sensor.

microcontroller. It is used for real time tasks: receiving and

processing data from sensors, controlling magnets, controlling

Due to the use of a separate controller with 16-bit Delta-

thrusters, calculating PID regulators, as well as monitoring the

Sigma analog-to-digital converter, and minimizing the length

vehicle for leaks and other emergency subsystems. The team

of wire between controller and piezoconverter, the team

chooses STM32F407 for its good processing speed, energy-

receives the depth data with sufficiently high accuracy.

saving and peripherals, needed to handle sensors and thrusters.

4. Hydrophone Array

C. Sensors

Hydrophone system is needed for acoustic pinger detection.

1. Cameras It is based on three hydrophones and signal processing board.

MSU AUV team switched from using Allied Vision Tech Hydrophones are handmade. For better identification of the

Prosilica GC1380C cameras on the vehicle on to iDS UI- ping hydrophones are located at the bottom of the vehicle.

5260CP-C-HQ. New cameras, shown in Fig 6, have a wider Signal processing boards are used for signal amplification,

angle of view and better color sensitivity. analog filtration, analog-to-digital converting of the signal,

and mathematical processing. This year the team switched

from using board based on STM32 to Russian board

Marsohod2 based on Altera Cyclone III FPGA. New

hydroacoustic electronics and software allow to separate sonar

waves by frequencies.

Fig 6. Old and new cameras.

Maritime State University AUV TEAM 4 of 5

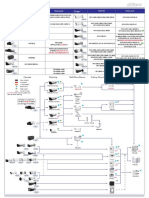

D. Communication

For the purposes of device interaction and data transmission

there are two networks deployed in the vehicle: Ethernet and

CAN Bus. Bandwidth-greedy devices are connected into

Ethernet (main computer, navigation controller, video

cameras, Wi-Fi router). In remote control mode

communication with a surface is also effected via Ethernet.

Thrusters and sensors are connected via CAN Bus (navigation

controller, thrusters, pressure sensor, LED indication), as seen

in Fig 8.

Fig 10. Photo of the MUR robot.

Table III

MUR SPECIFICATION

Specification Dimension

Mission/Vision Intel EDISON

computer

Weight 5.5 kg

Navigation controller TI TM4C123G

Navigation Invensense MPU-9250

Vision Sensors USB Camera

Fig 8. AUV networks. Power Supply 6x 18650 Batteries

Software Boost (ASIO, MSM), Qt, Websocketpp,

C++, Yocto Linux

V. SOFTWARE

The detection software was rewritten from scratch this year.

The team switched away from using binarization to YOLO B. Intervehicle communication

DNN. Thanks to this detection accuracy was increased. To communicate between two subs MSUAUV team are

Example of dice detection shown in Fig 9. Also the team using low frequency radio transmitter with a custom amplifier.

rewrite mission description subsystem, which based on Chai Electromagnetic waves propagate badly under water due to

Script – scripting language. skin effect but we are able to communicate at distance about

10 - 12 meters with reasonable speed ~50 kbps. RF transmitter

a located in a separate housing, shown Fig 11.

Fig 9. AUV detection software (Dice detector running).

VI. TWO VEHICLES Fig. 11 Radio modem.

A. Micro underwater robot VII. EXPERIMENTAL RESULTS

This year the team are going to use two subs. The second Vehicle functionality test is one of the most important

one was kindle provided by the Center for Robotics stages in preparations for competitions which helps to identify

Development. It’s a modified version of AUV educational kit unexpected errors in vehicle’s hardware and software.

– MUR.

Fig 10. and Table III. below show photo of the vehicle and

specification.

Maritime State University AUV TEAM 5 of 5

Fig 12. MSU AUV in the university pool.

While testing the team checked the vehicle for being

waterproof, ballasted and software have correct settings. It is

an important feature of the vehicle that it is capable of

operating in remote control mode which ensures easier getting

the vehicle ready for missions.

VIII. ACKNOWLEDGMENTS

The Maritime State University AUV Team is grateful to

advisors: Sergei Mun and Andrei Kushnerik. The team

was created thanks to support of the Maritime State University

and Center for Robotics Development.

And special thanks to the sponsors: Intel, Abtronics, and

DNS.

También podría gustarte

- RADIATION SAFETY FUNDAMENTALSDocumento69 páginasRADIATION SAFETY FUNDAMENTALSJay Lawson100% (1)

- Stabilization of A Model Rocket PDFDocumento5 páginasStabilization of A Model Rocket PDFRiddhijit ChattopadhyayAún no hay calificaciones

- Earthing Substation Earthing Guide Central NetworksDocumento12 páginasEarthing Substation Earthing Guide Central Networksshahkhan552000100% (1)

- G 26 Building Using ETABS 1673077361Documento68 páginasG 26 Building Using ETABS 1673077361md hussainAún no hay calificaciones

- Tennis BiomechanicsDocumento14 páginasTennis BiomechanicsΒασίλης Παπατσάς100% (1)

- Drone Project: Physics 118 - Final ReportDocumento13 páginasDrone Project: Physics 118 - Final ReportMahdi MiriAún no hay calificaciones

- Design and Development of A Robotic Drone A Drover.Documento14 páginasDesign and Development of A Robotic Drone A Drover.IJRASETPublicationsAún no hay calificaciones

- Design and Development of Unmanned Ground and Aerial Vehicle With The Concept of Integration of Drone and RoverDocumento10 páginasDesign and Development of Unmanned Ground and Aerial Vehicle With The Concept of Integration of Drone and RoverkoftamAún no hay calificaciones

- ADDC Construction QuestionairesDocumento19 páginasADDC Construction QuestionairesUsman Arif100% (1)

- GSM Based Arial Photography Using Remote Flying RobotDocumento4 páginasGSM Based Arial Photography Using Remote Flying RobotseventhsensegroupAún no hay calificaciones

- Water Trash CollectorDocumento3 páginasWater Trash CollectorInternational Journal of Innovative Science and Research TechnologyAún no hay calificaciones

- System Design and Implementation of Autonomous Underwater Vehicle "Matsya"Documento9 páginasSystem Design and Implementation of Autonomous Underwater Vehicle "Matsya"RAVI KATTAKWALAún no hay calificaciones

- Rutgers IEEE Student Branch 2011 IGVC team reportDocumento15 páginasRutgers IEEE Student Branch 2011 IGVC team reportKenDaniswaraAún no hay calificaciones

- Design and Implementation of An Autonomous Underwater Vehicle Kauro'Documento5 páginasDesign and Implementation of An Autonomous Underwater Vehicle Kauro'Ghazal IraniAún no hay calificaciones

- RaDMI 2014Documento17 páginasRaDMI 2014Shin Han NxtAún no hay calificaciones

- Team Nirma AUV, Unmanned Underwater Systems.docxDocumento10 páginasTeam Nirma AUV, Unmanned Underwater Systems.docxsameersam18600Aún no hay calificaciones

- Robosub Design Document Matsya2.0Documento8 páginasRobosub Design Document Matsya2.0pi194043Aún no hay calificaciones

- Iit Kanpur AuvDocumento20 páginasIit Kanpur AuvKoushik Ch 19BME1186100% (1)

- Brochure DTU-AUV - 230607 - 230138Documento26 páginasBrochure DTU-AUV - 230607 - 230138Ishpreet SinghAún no hay calificaciones

- Design Report For The White Russian Unmanned Ground Vehicle: York College of PennsylvaniaDocumento17 páginasDesign Report For The White Russian Unmanned Ground Vehicle: York College of Pennsylvaniasteve4ovenAún no hay calificaciones

- UTD Autonomous Underwater Vehicle: Michael Giambalvo, Ed Paradis, Eric SumnerDocumento7 páginasUTD Autonomous Underwater Vehicle: Michael Giambalvo, Ed Paradis, Eric SumnernntoolAún no hay calificaciones

- RF Controlled Solar Panel Based Robotic VehicleDocumento6 páginasRF Controlled Solar Panel Based Robotic VehicleMohan Babu AAún no hay calificaciones

- Maze Solving Quad Rotor PDFDocumento18 páginasMaze Solving Quad Rotor PDFVartolomeiDumitruAún no hay calificaciones

- RaDMI 2014Documento10 páginasRaDMI 2014Shin Han NxtAún no hay calificaciones

- Design and Static Structural Analysis of A QuadcopterDocumento4 páginasDesign and Static Structural Analysis of A QuadcopterMohammed Ali Al-shaleliAún no hay calificaciones

- BEARCAT Cub Design ReportDocumento16 páginasBEARCAT Cub Design ReportMohd Sazli SaadAún no hay calificaciones

- Bearcat Cub Robot: Design ReportDocumento16 páginasBearcat Cub Robot: Design ReportMohd Sazli SaadAún no hay calificaciones

- Ultra-Lightweight Autonomous Solar Airplane for Continuous FlightDocumento12 páginasUltra-Lightweight Autonomous Solar Airplane for Continuous FlightAndrei BadulescuAún no hay calificaciones

- Android Based Advanced Car Lifting System Using Bluetooth: August 2017Documento6 páginasAndroid Based Advanced Car Lifting System Using Bluetooth: August 2017Just4 FuntechAún no hay calificaciones

- Developing A Quadcopter Frame and Its Structural AnalysisDocumento6 páginasDeveloping A Quadcopter Frame and Its Structural AnalysisInternational Journal of Innovative Science and Research TechnologyAún no hay calificaciones

- CPS & Chasis DynoDocumento8 páginasCPS & Chasis Dynothomason mikeAún no hay calificaciones

- Design and construction of a drone with GPS tracking, collision avoidance and object trackingDocumento4 páginasDesign and construction of a drone with GPS tracking, collision avoidance and object trackingLarry Nelson BorbaAún no hay calificaciones

- ORCA-2: Old Dog, New TricksDocumento10 páginasORCA-2: Old Dog, New TricksMaciek OlszowskiAún no hay calificaciones

- Unmanned Ground Vehicle With NI LabVIEW Using myRIODocumento6 páginasUnmanned Ground Vehicle With NI LabVIEW Using myRIOGRD JournalsAún no hay calificaciones

- A Complete Survey On Onborad Computers Microcontroller Selection For Icube2 CUBESATDocumento5 páginasA Complete Survey On Onborad Computers Microcontroller Selection For Icube2 CUBESATZammad AhmadAún no hay calificaciones

- Abstracts / JSAE Review 18 (1997) 185-209Documento1 páginaAbstracts / JSAE Review 18 (1997) 185-209Dhawadi MahdiAún no hay calificaciones

- Practical Development of An Experimental PDFDocumento9 páginasPractical Development of An Experimental PDFharold medina martinezAún no hay calificaciones

- Design and Implementation of Cartesian RobotDocumento6 páginasDesign and Implementation of Cartesian RobotSang VũAún no hay calificaciones

- Art:10.1007/s00170 007 1024 XDocumento7 páginasArt:10.1007/s00170 007 1024 XMichael WareAún no hay calificaciones

- Indication of Brake Failure by Using IR SensorDocumento3 páginasIndication of Brake Failure by Using IR SensormahendranAún no hay calificaciones

- PayloadDocumento4 páginasPayloadXabi AdinAún no hay calificaciones

- Eco Friendly Electric Scooter For Energy Consumption: G. Priya, M.TechDocumento12 páginasEco Friendly Electric Scooter For Energy Consumption: G. Priya, M.TechGautham NAún no hay calificaciones

- Design of Controller Board For A Lunar Rover: Electronic Basic ThesisDocumento24 páginasDesign of Controller Board For A Lunar Rover: Electronic Basic ThesisMuhammad AhsanAún no hay calificaciones

- Design and Fabrication of Self Balancing Bike Using Gyroscopic EffectDocumento6 páginasDesign and Fabrication of Self Balancing Bike Using Gyroscopic EffectRoshan BahadurAún no hay calificaciones

- Designing a Solar-Powered Pond Cleaning BoatDocumento13 páginasDesigning a Solar-Powered Pond Cleaning BoatAVINASH KUMARAún no hay calificaciones

- Gujarat Technological University: Ac Motor ControllerDocumento17 páginasGujarat Technological University: Ac Motor ControllerEngineers worldAún no hay calificaciones

- CCTV Camera Controller Simulation Using Arduino Uno and JoystickDocumento10 páginasCCTV Camera Controller Simulation Using Arduino Uno and JoystickEnache AlinAún no hay calificaciones

- Cargo Delivery System With Drone: Gazi University Engineering Faculty Electrical-Electronics Engineering DepartmentDocumento44 páginasCargo Delivery System With Drone: Gazi University Engineering Faculty Electrical-Electronics Engineering DepartmentGöktuğ AlbayrakAún no hay calificaciones

- Design and fabrication of AGVDocumento6 páginasDesign and fabrication of AGVMICHEL RAJ MechAún no hay calificaciones

- EC P73 Seminar Report on Autonomous VehiclesDocumento30 páginasEC P73 Seminar Report on Autonomous VehiclesUdhayakumar GAún no hay calificaciones

- Quadcopter Design, Construction and Testing ExplainedDocumento8 páginasQuadcopter Design, Construction and Testing ExplainedashokkumarAún no hay calificaciones

- Esda 2010 M DogruDocumento7 páginasEsda 2010 M DogruVăn Hiếu NguyễnAún no hay calificaciones

- 12V DC Electric Car JackDocumento4 páginas12V DC Electric Car Jack2349 Rohit Ramesh GorivaleAún no hay calificaciones

- ConferencePaper PDFDocumento8 páginasConferencePaper PDFPrayitno FidiantoroAún no hay calificaciones

- Effi CycleDocumento6 páginasEffi CycleHar ShaAún no hay calificaciones

- Electric Skateboard Incorporating Foot Operated Ackerman Steering SystemDocumento7 páginasElectric Skateboard Incorporating Foot Operated Ackerman Steering SystemInternational Journal of Innovative Science and Research TechnologyAún no hay calificaciones

- Image Processing Safety Assessment Ferrer2013Documento6 páginasImage Processing Safety Assessment Ferrer2013Utsa RashiqueAún no hay calificaciones

- Design of ATV PartsDocumento20 páginasDesign of ATV PartsAkash HiremathAún no hay calificaciones

- 12.solar Power Based Optimal Battery Charging Mechanism Using Microcontroller in Robotic VehicleDocumento5 páginas12.solar Power Based Optimal Battery Charging Mechanism Using Microcontroller in Robotic VehicleSanthosh KumarAún no hay calificaciones

- Design and Construction of An Underwater Robot: September 2017Documento5 páginasDesign and Construction of An Underwater Robot: September 2017Kenneth UtiAún no hay calificaciones

- Using A High-Speed Mini-PC To Control An Autonomous Underwater VehicleDocumento13 páginasUsing A High-Speed Mini-PC To Control An Autonomous Underwater VehicleLu PatyAún no hay calificaciones

- Automated Guided Vehicle For Phsically HDocumento8 páginasAutomated Guided Vehicle For Phsically HDanil KhardniAún no hay calificaciones

- ReportDocumento5 páginasReportapi-281316772Aún no hay calificaciones

- Effortless Personal TransporterDocumento6 páginasEffortless Personal TransporterIJRASETPublicationsAún no hay calificaciones

- Gain-Cell Embedded DRAMs for Low-Power VLSI Systems-on-ChipDe EverandGain-Cell Embedded DRAMs for Low-Power VLSI Systems-on-ChipAún no hay calificaciones

- POLIOMYELITISDocumento26 páginasPOLIOMYELITISIzhra Margate100% (1)

- AMYLOIDOSISDocumento22 páginasAMYLOIDOSISMohan ChoudharyAún no hay calificaciones

- Kingspan Spectrum™: Premium Organic Coating SystemDocumento4 páginasKingspan Spectrum™: Premium Organic Coating SystemNikolaAún no hay calificaciones

- Manual Del GVMapper v3 3 PDFDocumento102 páginasManual Del GVMapper v3 3 PDFguanatosAún no hay calificaciones

- PC Poles: DescriptionDocumento2 páginasPC Poles: DescriptionSantoso SantAún no hay calificaciones

- SC Earthquake GuideDocumento8 páginasSC Earthquake GuideNevin SmithAún no hay calificaciones

- TP5 W9 S9 R0Documento2 páginasTP5 W9 S9 R0DickiEffendy0% (1)

- 4 Ideal Models of Engine CyclesDocumento23 páginas4 Ideal Models of Engine CyclesSyedAún no hay calificaciones

- Gerovital anti-aging skin care product guideDocumento10 páginasGerovital anti-aging skin care product guideכרמן גאורגיהAún no hay calificaciones

- Is Revalida ExamDocumento11 páginasIs Revalida ExamRodriguez, Jhe-ann M.Aún no hay calificaciones

- Dahua Pfa130 e Korisnicko Uputstvo EngleskiDocumento5 páginasDahua Pfa130 e Korisnicko Uputstvo EngleskiSaša CucakAún no hay calificaciones

- Cdd153167-Samsung Un32d6500vf Un32 40 46 55d6400uf 6420uf 6450uf 6500vf 6900wf Chassis U63a SM PDFDocumento87 páginasCdd153167-Samsung Un32d6500vf Un32 40 46 55d6400uf 6420uf 6450uf 6500vf 6900wf Chassis U63a SM PDFMilciades MurilloAún no hay calificaciones

- Poultry DiseasesDocumento5 páginasPoultry DiseasesAnjum IslamAún no hay calificaciones

- Pump Course Material Chapter 2Documento16 páginasPump Course Material Chapter 2engr victorAún no hay calificaciones

- Surface Hardening enDocumento20 páginasSurface Hardening engtm1207Aún no hay calificaciones

- DGPS Sensor JLR-4331W Instruction ManualDocumento42 páginasDGPS Sensor JLR-4331W Instruction ManualantonioAún no hay calificaciones

- 2290 PDFDocumento222 páginas2290 PDFmittupatel190785Aún no hay calificaciones

- Hedging Techniques in Academic WritingDocumento11 páginasHedging Techniques in Academic WritingÛbř ÖňAún no hay calificaciones

- Mycbseguide: Cbse Class 10 Social Science Sample Paper - 08 (MCQ Based)Documento10 páginasMycbseguide: Cbse Class 10 Social Science Sample Paper - 08 (MCQ Based)Abdul MuqsitAún no hay calificaciones

- SAMMAJIVA - VOLUME 1, NO. 3, September 2023 Hal 235-250Documento16 páginasSAMMAJIVA - VOLUME 1, NO. 3, September 2023 Hal 235-250Nur Zein IzdiharAún no hay calificaciones

- Mfz-Odv065r15j DS 1-0-0 PDFDocumento1 páginaMfz-Odv065r15j DS 1-0-0 PDFelxsoonAún no hay calificaciones

- 10risk Assessment and ComahDocumento25 páginas10risk Assessment and ComahHansraj RahulAún no hay calificaciones

- The Creators College of Science & Commerce: 1 TermDocumento2 páginasThe Creators College of Science & Commerce: 1 TermJhangir Awan33% (3)

- EiaDocumento14 páginasEiaRamir FamorcanAún no hay calificaciones

- LogiquidsDocumento2 páginasLogiquidsAloma FonsecaAún no hay calificaciones