Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Delomatic 3, Multi-Function Systems For Marine Plants 4921410011 UK PDF

Cargado por

adi merTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Delomatic 3, Multi-Function Systems For Marine Plants 4921410011 UK PDF

Cargado por

adi merCopyright:

Formatos disponibles

Delomatic multi-function systems for marine plants

Basic applications Ref.: 4921410011E

PREFACE

This document is a brief description of the 5 basic Delomatic Power Management Systems for marine

plants. Each basic system can easily be extended with 7 optional add-on functions.

Each basic system works as a complete system but can also be used as a platform for more complex

applications containing more bus tie breakers, special heavy consumers and/or a customer’s specific

running modes etc.

If you cannot find a technical solution to your application please send your inquiry and we will prepare a

technical solution.

CONTENT

No Description Page

I Delomatic for 2 diesel gen-sets (DG1+DG2) ............................................................... 2

incl. supervision of shore connection breaker

II Delomatic for 2 diesel gen-sets (DG1+DG2+SC) ........................................................ 5

incl. sync. of shore connection breaker

III Delomatic for 2 diesel gen-sets and 1 shaft generator (DG1+DG2+SG)................... 8

incl. supervision of shore connection breaker

IV Delomatic for 2 diesel gen-sets (DG1+DG2+TB) ........................................................ 11

incl. sync. of tie breaker and supervision of shore connection breaker

VII Delomatic for 2 diesel gen-sets and 1 shaft generator (DG1+DG2+SG+TB) ............ 15

incl. sync. of tie breaker and supervision of shore connection breaker

Optional ADD-ON functions ........................................................................................................... 19

1 Delomatic system for 1 additional diesel gen-set (DGn) (2 < n <=8)

2 External communication (1 per plant)

3 Additional control panel (CP)

4 Short circuit protection

5 Differential protection

6 Analogue outputs

7 Additional 3 heavy consumers

Additional documentation.............................................................................................................. 20

4040000003D

Date: 010919 Page 1 of 19

Delomatic multi-function systems for marine plants

Basic applications Ref.: 4921410011E

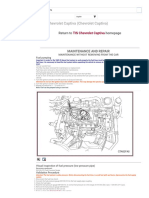

I Delomatic system for 2 diesel gen-sets (DG1 + DG2)

incl. supervision of shore connection breaker

configuration according to the below principle block diagram

The system is inclusive of the following common and gen-set functions:

Common functions (total plant)

• Plant modes: - SEMI-AUTO

- AUTOMATIC

- SECURED

• User-programmable start priority

• Automatically start priority control with regards to running hours

• Load dependent start/stop function incl.:

- transmission of PMS start/stop commands

- safety start of stand-by generator sets due to expected stop of a running

generator set

- transfer of PMS start command in case of failed engagement of the generator set

• Common black-out detection and subsequently black-out start of two generator sets

• Load sharing:

- symmetrical load sharing

- asymmetrical load sharing

• Conditional connection of 3 heavy consumers with fixed or variable load

• Supervision of the shore connection position

4040000003D

Date: 010919 Page 2 of 19

Delomatic multi-function systems for marine plants

Basic applications Ref.: 4921410011E

Gen-set functions (for each gen-set)

• Internal system supervision comprising:

- I/O error; supervision of hardware configuration

- breaker position feedback supervision

- supervision of ARC-network communication

- supervision of the power supply

- cable supervision

• Selection of local control for each generator set

- PMS control; the generator set is included in the PMS functions

- SWBD control, the generator set is excluded from all automatic functions and can

only be controlled manually (protection functions are still active)

• Automatically start sequence

- programmable start prepare output

- programmable number of start attempts

- programmable pause stop during the start sequence

- programmable priming output

• Automatically stop sequence

- programmable cooling down time

- programmable stop time

• GB ON sequence; dynamical synchronization of the generator set to the busbar

- programmable dynamical synchronization parameters

(concerning voltage and frequency)

- supervision of positive sequential order of phase before synchronization

- supervision of generator voltage and frequency before synchronization

- programmable closing time for the breaker

• GB OFF sequence:

- deloading the generator set before opening the generator breaker

• Generator set load control

- load share supervision

• Generator protection:

- supervision of generator voltage and frequency

- over-current, I> (two step protection)

- overload, P> (both protection and supervision)

- reverse power, -P> (protection)

• Busbar supervision and protection:

- undervoltage, UBB< (both protection and supervision)

- overvoltage, UBB> (both protection and supervision)

- under-frequency, fBB< (both protection and supervision)

- over-frequency, fBB> (both protection and supervision)

• 5 different alarm sequences

- DG warning (only information for operator)

- DG blocked (inhibit of automatic functions of the DG)

- Safety stop (expected stop when DG has been replaced by another unit)

4040000003D

Date: 010919 Page 3 of 19

Delomatic multi-function systems for marine plants

Basic applications Ref.: 4921410011E

- Trip of the generator breaker (immediately opening of CB)

- Shutdown of entire gen-set

-

• Trip of two non-essential loads groups in case of:

- trip of the generator breaker

- high load at the generator set

- low frequency at the busbar

· User setup of all relevant parameters of the DG and the entire plant from the control panel

· User scalable instrument outputs from the control panel

· Cable supervision for digital and analogue inputs

· Alarm test function of all implemented alarms

· “Test mode” function indicates when a timer is running.

· Operator programmable binary alarm input function (machine interface):

- programmable selection of designated alarm sequence

- programmable alarm delay

- programmable status for alarm detection

- programmable connection to the alarm inhibit function

· Relay- or Analogue output for the speed governor

· Running hour indication on display of the Control Panel

· Indication of rpm on the Control Panel in case of analogue running feedback

User’s Manual Part 1 of 2 ”BASIC 01” (DG1 + DG2)

Chapter No. Description Document No.

1. Introduction In The Present System 4189230101

2. The Present Power Management 4189230102

3. Alarm List 4189230103

4. System Setup 4189230104

5. I/O List 4189230105

6. Fat Report 4189230106

7. Present Serial Communication (STD) 4189230107

8. The Present Menu System 4189230108

9. - -

10. - -

4040000003D

Date: 010919 Page 4 of 19

Delomatic multi-function systems for marine plants

Basic applications Ref.: 4921410011E

II Delomatic system for 2 diesel gen-sets (DG1+DG2+SC)

incl. sync. of shore connection breaker

configuration according to the below principle block diagram

The system is inclusive of the following common and gen-set functions:

Common functions (total plant)

• Plant modes: - SEMI-AUTO

- AUTOMATIC

- SECURED

- SHORE

• User-programmable start priority

• Automatically start priority control with regards to running hours

• Load dependent start/stop function incl.:

- transmission of PMS start/stop commands

- safety start of stand-by generator sets due to expected stop of a running

- generator set

- transfer of PMS start command in case of failed engagement of the generator

set

• Common black-out detection and subsequently black-out start of two generator sets

• Load sharing

- symmetrical load sharing

- asymmetrical load sharing

4040000003D

Date: 010919 Page 5 of 19

Delomatic multi-function systems for marine plants

Basic applications Ref.: 4921410011E

• Conditional connection of 2 heavy consumers with fixed or variable load

• Control and supervision of a shore connection offering:

- dynamical synchronization of shore connection breaker

- load transfer from diesel generator set(s) to the shore connection and back

- shore connection protection

- supervision of shore busbar

"Gen-set" functions

• Internal system supervision comprising:

- I/O error; supervision of hardware configuration

- breaker position feedback supervision

- supervision of ARC-network communication

- supervision of the power supply

- cable supervision

• Selection of local control for each generator set

- PMS control; the generator set is included in the PMS functions

- SWBD control, the generator set is excluded from all automatic functions and can

only be controlled manually (protection functions are still active)

• Automatically start sequence

- programmable start prepare output

- programmable number of start attempts

- programmable pause stop during the start sequence

- programmable priming output

• Automatically stop sequence

- programmable cooling down time

- programmable stop time

• GB ON sequence; dynamical synchronization of the generator set to the busbar

- programmable dynamical synchronization parameters (concerning voltage and

- frequency)

- supervision of positive sequential order of phase before synchronization

- supervision of generator voltage and frequency before synchronization

- programmable closing time for the breaker

• GB OFF sequence:

- deloading the generator set before opening the generator breaker

• Generator set load control

- load share supervision

• Generator protection:

- supervision of generator voltage and frequency

- over-current, I> (two step protection)

- overload, P> (both protection and supervision)

- reverse power, -P> (protection)

• Busbar supervision and protection:

4040000003D

Date: 010919 Page 6 of 19

Delomatic multi-function systems for marine plants

Basic applications Ref.: 4921410011E

- undervoltage, UBB< (both protection and supervision)

- overvoltage, UBB> (both protection and supervision)

- under-frequency, fBB< (both protection and supervision)

- over-frequency, fBB> (both protection and supervision)

• 8 different alarm sequences

- DG warning (only information for operator)

- DG blocked (inhibit of automatic functions of the DG)

- Safety stop (expected stop when DG has been replaced by another unit)

- Trip of the generator breaker (immediately opening of CB)

- Shutdown of entire gen-set

- SC warning (only information for operator)

- SC blocked (inhibit of automatic functions of the SC)

- Trip of the shore connection breaker (immediately opening of CB)

• Trip of two non-essential loads groups in case of:

- trip of the generator breaker

- high load at the generator set

- low frequency at the busbar

• User setup of all relevant parameters of the DG, SG and the entire plant from the control

panel

• User scalable instrument outputs from the control panel

• Cable supervision for digital and analogue inputs

• Alarm test function of all implemented alarms

• “Test mode” function indicates when a timer is running

• Operator programmable binary alarm input function (machine interface):

- programmable selection of designated alarm sequence

- programmable alarm delay

- programmable status for alarm detection

- programmable connection to the alarm inhibit function

• Relay- or Analogue output for the speed governor

• Running hour indication on display of the Control Panel

• Indication of rpm on the Control Panel in case of analogue running feedback

User’s Manual Part 1 of 2 ”Basic 02” (DG1 + DG2 + SC)

Chapter No. Description Document No.

1. Introduction In The Present System 4189230201

2. The Present Power Management 4189230202

3. Alarm List 4189230203

4. System Setup 4189230204

5. I/O List 4189230205

6. Fat Report 4189230206

7. Present Serial Communication (STD) 4189230207

8. The Present Menu System 4189230208

9. - -

10. - -

4040000003D

Date: 010919 Page 7 of 19

Delomatic multi-function systems for marine plants

Basic applications Ref.: 4921410011E

III Delomatic system for 2 diesel gen-sets and 1 shaft generator (DG1+DG2+SG)

Incl. supervision of shore connection breaker

configuration according to the below block diagram

The system is inclusive of the following common and gen-set functions:

Common functions (total plant)

• Plant modes: - SEMI-AUTO

- AUTOMATIC

- SECURED

- SG

• User-programmable start priority

• Automatically start priority control with regards to running hours

• Load dependent start/stop function incl.:

- transmission of PMS start/stop commands

- safety start of stand-by generator sets due to expected stop of a running

generator set

• Common black-out detection and subsequently black-out start of two generator sets

• Load sharing:

- symmetrical load sharing

- asymmetrical load sharing

• Conditional connection of 3 heavy consumers with fixed or variable load

• Supervision of the shore connection position

4040000003D

Date: 010919 Page 8 of 19

Delomatic multi-function systems for marine plants

Basic applications Ref.: 4921410011E

• Control and supervision of a shaft generator offering:

- dynamical synchronization of shaft generator breaker

- load transfer from diesel generator set(s) to the shaft generator(s) and back

- shaft generator protection

- supervision of shaft generator busbar

- trip of non-essential load groups due to the shaft generator conditions

"Gen-set" functions

• Internal system supervision comprising:

- I/O error; supervision of hardware configuration

- breaker position feedback supervision

- supervision of ARC-network communication

- supervision of the power supply

- cable supervision

• Selection of local control for each generator set

- PMS control; the generator set is included in the PMS functions

- SWBD control, the generator set is excluded from all automatic functions and can

only be controlled manually (protection functions are still active)

• Automatically start sequence

- programmable start prepare output

- programmable number of start attempts

- programmable pause stop during the start sequence

- programmable priming output

• Automatically stop sequence

- programmable cooling down time

- programmable stop time

• GB ON sequence; dynamical synchronization of the generator set to the busbar

- programmable dynamical synchronization parameters (concerning voltage and

- frequency)

- supervision of positive sequential order of phase before synchronization

- supervision of generator voltage and frequency before synchronization

- programmable closing time for the breaker

• GB OFF sequence:

- deloading the generator set before opening the generator breaker

• Generator set load control

- load share supervision

• Generator protection:

- supervision of generator voltage and frequency

- over-current, I> (two step protection)

- overload, P> (both protection and supervision)

- reverse power, -P> (protection)

4040000003D

Date: 010919 Page 9 of 19

Delomatic multi-function systems for marine plants

Basic applications Ref.: 4921410011E

• Busbar supervision and protection:

- undervoltage, UBB< (both protection and supervision)

- overvoltage, UBB> (both protection and supervision)

- under-frequency, fBB< (both protection and supervision)

- over-frequency, fBB> (both protection and supervision)

• 8 different alarm sequences

- DG warning (only information for operator)

- DG blocked (inhibit of automatic functions of the DG)

- Safety stop (expected stop when DG has been replaced by another unit)

- Trip of the generator breaker (immediately opening of CB)

- Shutdown of entire gen-set

- SG warning (only information for operator)

- SG blocked (inhibit of automatic functions of the SG)

- Trip of the shaft generator breaker (immediately opening of CB)

• Trip of two non-essential loads groups in case of:

- trip of the generator breaker

- high load at the generator set

- low frequency at the busbar

• User setup of all relevant parameters of the DG, SG and the entire plant from the control

panel

• User scalable instrument outputs from the control panel

• Cable supervision for digital and analogue inputs

• Alarm test function of all implemented alarms

• “Test mode” function indicates when a timer is running

• Operator programmable binary alarm input function (machine interface):

- programmable selection of designated alarm sequence

- programmable alarm delay

- programmable status for alarm detection

- programmable connection to the alarm inhibit function

• Relay- or Analogue output for the speed governor

• Running hour indication on display of the Control Panel

• Indication of rpm on the Control Panel in case of analogue running feedback

User’s Manual Part 1 of 2 ”Basic 03” (DG1 + DG2 + SG)

Chapter No. Description Document No.

1. Introduction In The Present System 4189230301

2. The Present Power Management 4189230302

3. Alarm List 4189230303

4. System Setup 4189230304

5. I/O List 4189230305

6. Fat Report 4189230306

7. Present Serial Communication (STD) 4189230307

8. The Present Menu System 4189230308

9. - -

10. - -

4040000003D

Date: 010919 Page 10 of 19

Delomatic multi-function systems for marine plants

Basic applications Ref.: 4921410011E

IV Delomatic system for 2 diesel gen-sets (DG1+DG2+TB)

incl. sync of tie breaker and supervision of shore connection breaker

configuration according to the below principle block diagram

The system is inclusive of the following common and gen-set functions:

Common functions (total plant)

• Plant modes: - SEMI-AUTO

- AUTOMATIC

- SECURED

• User-programmable start priority

• Automatically start priority control with regards to running hours

• Load dependent start/stop function incl.:

- transmission of PMS start/stop commands

- safety start of stand-by generator sets due to expected stop of a running

generator set

• Common black-out detection and subsequently black-out start of two generator sets

(with split busbar, black-out start on each side)

• Load sharing:

- symmetrical load sharing

- asymmetrical load sharing

4040000003D

Date: 010919 Page 11 of 19

Delomatic multi-function systems for marine plants

Basic applications Ref.: 4921410011E

• Conditional connection of 3 heavy consumers with fixed or variable load

• Supervision of the shore connection position

• Control and supervision of bus tie breaker offering:

- dynamical synchronization of bus tie breaker

- tie breaker protection

- supervision of both sides of the tie breaker busbar

"Gen-set" functions

• Internal system supervision comprising:

- I/O error; supervision of hardware configuration

- breaker position feedback supervision

- supervision of ARC-network communication

- supervision of the power supply

- cable supervision

• Selection of local control for each generator set

- PMS control; the generator set is included in the PMS functions

- SWBD control, the generator set is excluded from all automatic functions and can

only be controlled manually (protection functions are still active)

• Automatically start sequence

- programmable start prepare output

- programmable number of start attempts

- programmable pause stop during the start sequence

- programmable priming output

• Automatically stop sequence

- programmable cooling down time

- programmable stop time

• GB ON sequence; dynamical synchronization of the generator set to the busbar

- programmable dynamical synchronization parameters (concerning voltage and

frequency)

- supervision of positive sequential order of phase before synchronization

- supervision of generator voltage and frequency before synchronization

- programmable closing time for the breaker

• GB OFF sequence:

- deloading the generator set before opening the generator breaker

• Generator set load control

- load share supervision

• Generator protection:

- supervision of generator voltage and frequency

- over-current, I> (two step protection)

- overload, P> (both protection and supervision)

- reverse power, -P> (protection)

4040000003D

Date: 010919 Page 12 of 19

Delomatic multi-function systems for marine plants

Basic applications Ref.: 4921410011E

• Busbar supervision and protection:

- undervoltage, UBB< (both protection and supervision)

- overvoltage, UBB> (both protection and supervision)

- under-frequency, fBB< (both protection and supervision)

- over-frequency, fBB> (both protection and supervision)

• 8 different alarm sequences

- DG warning (only information for operator)

- DG blocked (inhibit of automatic functions of the DG)

- Safety stop (expected stop when DG has been replaced by another unit)

- Trip of the generator breaker (immediately opening of CB)

- Shutdown of entire gen-set

- TB warning (only information for operator)

- TB blocked (inhibit of automatic functions of the TB)

- Trip of the bus tie breaker (immediately opening of TB)

• Trip of two non-essential loads groups in case of:

- trip of the generator breaker

- high load at the generator set

- low frequency at the busbar

• User setup of all relevant parameters of the DG, SG and the entire plant from the control

panel

• User scalable instrument outputs from the control panel

• Cable supervision for digital and analogue inputs

• Alarm test function of all implemented alarms

• “Test mode” function indicates when a timer is running

• Operator programmable binary alarm input function (machine interface):

- programmable selection of designated alarm sequence

- programmable alarm delay

- programmable status for alarm detection

- programmable connection to the alarm inhibit function

• Relay- or Analogue output for the speed governor

• Running hour indication on display of the Control Panel

• Indication of rpm on the Control Panel in case of analogue running feedback

User’s Manual Part 1 of 2 ”Basic 04” (DG1 + DG2 + TB)

Chapter No. Description Document No.

1. Introduction In The Present System 4189230401

2. The Present Power Management 4189230402

3. Alarm List 4189230403

4. System Setup 4189230404

5. I/O List 4189230405

6. Fat Report 4189230406

7. Present Serial Communication (STD) 4189230407

8. The Present Menu System 4189230408

9. - -

10. - -

4040000003D

Date: 010919 Page 13 of 19

Delomatic multi-function systems for marine plants

Basic applications Ref.: 4921410011E

VII Delomatic system for 2 diesel gen-sets (DG1+DG2+SG+TB)

incl. sync of tie breaker and supervision of shore connection breaker

configuration according to the below principle block diagram

The system is inclusive of the following common and gen-set functions:

Common functions (total plant)

• Plant modes: - SEMI-AUTO

- AUTOMATIC

- SPLIT BUSBAR

- SG

NOTE ! It is only possible to select SPLIT BUSBAR or SG (Shaft

Generator) mode when the shaft generator is selected to be in PMS

control and AUTO mode.

• User-programmable start priority

• Automatically start priority control with regards to running hours

• Load dependent start/stop function incl.:

- transmission of PMS start/stop commands

- safety start of stand-by generator sets due to expected stop of a running

generator set

• Common black-out detection and subsequently black-out start of two generator sets

4040000003D

Date: 010919 Page 14 of 19

Delomatic multi-function systems for marine plants

Basic applications Ref.: 4921410011E

• Load sharing:

- symmetrical load sharing

- asymmetrical load sharing

• Conditional connection of 3 heavy consumers with fixed or variable load

• Supervision of the shore connection position

• Control and supervision of a shaft generator offering:

- dynamical synchronization of shaft generator breaker

- load transfer from diesel generator set(s) to the shaft generator(s) and back

- shaft generator protection

- supervision of shaft generator busbar

- trip of non-essential load groups due to the shaft generator conditions

• Control and supervision of bus tie breaker offering:

- dynamical synchronization of bus tie breaker

- tie breaker protection

- supervision of both sides of the tie breaker busbar

"Gen-set" functions

• Internal system supervision comprising:

- I/O error; supervision of hardware configuration

- breaker position feedback supervision

- supervision of ARC-network communication

- supervision of the power supply

- cable supervision

• Selection of local control for each generator set

- PMS control; the generator set is included in the PMS functions

- SWBD control, the generator set is excluded from all automatic functions and can

only be controlled manually (protection functions are still active)

• Automatically start sequence

- programmable start prepare output

- programmable number of start attempts

- programmable pause stop during the start sequence

- programmable priming output

• Automatically stop sequence

- programmable cooling down time

- programmable stop time

• GB ON sequence; dynamical synchronization of the generator set to the busbar

- programmable dynamical synchronization parameters (concerning voltage and

frequency)

- supervision of positive sequential order of phase before synchronization

- supervision of generator voltage and frequency before synchronization

- programmable closing time for the breaker

• GB OFF sequence:

4040000003D

Date: 010919 Page 15 of 19

Delomatic multi-function systems for marine plants

Basic applications Ref.: 4921410011E

- deloading the generator set before opening the generator breaker

• Generator set load control

- load share supervision

• Generator protection:

- supervision of generator voltage and frequency

- over-current, I> (two step protection)

- overload, P> (both protection and supervision)

- reverse power, -P> (protection)

• Busbar supervision and protection:

- undervoltage, UBB< (both protection and supervision)

- overvoltage, UBB> (both protection and supervision)

- under-frequency, fBB< (both protection and supervision)

- over-frequency, fBB> (both protection and supervision)

• 11 different alarm sequences

- DG warning (only information for operator)

- DG blocked (inhibit of automatic functions of the DG)

- Safety stop (expected stop when DG has been replaced by another unit)

- Trip of the generator breaker (immediately opening of CB)

- Shutdown of entire gen-set

- TB warning (only information for operator)

- TB blocked (inhibit of automatic functions of the TB)

- Trip of the bus tie breaker (immediately opening of TB)

- SG warning (only information for operator)

- SG blocked (inhibit of automatic functions of the SG)

- Trip of the shaft generator breaker (immediately opening of CB)

• Trip of two non-essential loads groups in case of:

- trip of the generator breaker

- high load at the generator set

- low frequency at the busbar

• User setup of all relevant parameters of the DG, SG and the entire plant from the control

panel

• User scalable instrument outputs from the control panel

• Cable supervision for digital and analogue inputs

• Alarm test function of all implemented alarms

• “Test mode” function indicates when a timer is running

• Operator programmable binary alarm input function (machine interface):

- programmable selection of designated alarm sequence

- programmable alarm delay

- programmable status for alarm detection

- programmable connection to the alarm inhibit function

• Relay- or Analogue output for the speedgovernor

• Running hour indication on display of the Control Panel

• Indication of rpm on the Control Panel in case of analogue running feedback

4040000003D

Date: 010919 Page 16 of 19

Delomatic multi-function systems for marine plants

Basic applications Ref.: 4921410011E

User’s Manual Part 1 of 2 ”Basic 07” (DG1 + DG2 + SG + TB)

Chapter No. Description Document No.

1. Introduction In The Present System 4189230701

2. The Present Power Management 4189230702

3. Alarm List 4189230703

4. System Setup 4189230704

5. I/O List 4189230705

6. Fat Report 4189230706

7. Present Serial Communication (STD) 4189230707

8. The Present Menu System 4189230708

9. - -

10. - -

4040000003D

Date: 010919 Page 17 of 19

Delomatic multi-function systems for marine plants

Basic applications Ref.: 4921410011E

Optional ADD-ON functions

1 Delomatic system for 1 additional diesel gen-set (DGn)

inclusive of all common and gen-set functions described in the basic system.

Max. 8 DGs (DGUs) totally in one system.

2 External communication (1 per plant)

"The Delomatic system operates indepently but may easily work in conjunction with an alarm,

monitoring and control system connected through a bi-directional serial interface RS485

(modbus) providing access to:

- system control commands

- set-points and timers

- measure and calculated values

- system status

- ”alarm status"

3 Additional control panel (CP)

Extra control panels, CPn, for example to be installed on the bridge or in the control desk.

Max. 3 control panels can be installed for each diesel gen-set.

4 Short-circuit protection

Short circuit protection (I>>) by

one current relay module, CRM-1, to be mounted in the relevant DGU.

5 Differential protection (non compensated)

Differential protection by (Id>) by

one current relay module, CRM-1, diff, to be installed in the relevant DGU.

6 Analogue outputs

Analogue outputs (current or voltage with or without offset) for measured data by

one1 analogue output module, AOM-1, to be installed in the relevant DGU.

7 Additional 3 heavy consumers

Conditional and sequential connection of 1…3 additional heavy consumers (HC4…HC6)

with constant or variable power consumption.

4040000003D

Date: 010919 Page 18 of 19

Delomatic multi-function systems for marine plants

Basic applications Ref.: 4921410011E

Additional Documentation

User’s Manual Part 2 of 2 ”Generel Description”

Chapter No. Description Document No.

11. Generel Introduction 4189230111

12. - -

13. Alarm Handling 4189230113

14. - -

15. The Generel Menu System 4189230115

16. Power Management Unit 4189230116

17. Generator Set Control 4189230117

18. Generator Set Protection 4189230118

19. Shaft Generator 4189230119

20. Shore Connection 4189230120

21. Tie Breaker 4189230121

22. Generel Serial Communication (STD) 4189230122

23. Service Guide 4189230123

24. MODBUS Communication 4189230124

25. Installation Instruction 4189230125

26. - -

27. Commissioning Guide 4189230127

28. - -

29. Data Sheets 4189230129

30. - -

4040000003D

Date: 010919 Page 19 of 19

También podría gustarte

- Chevrolet Captiva Service Manual. MAINTENANCE AND REPAIR.Documento57 páginasChevrolet Captiva Service Manual. MAINTENANCE AND REPAIR.krisdiarto@gmail.com96% (23)

- Manual G36 O2 Analyzer - V.2.04 July 2017Documento46 páginasManual G36 O2 Analyzer - V.2.04 July 2017Isidoros100% (3)

- User Manual For E-R Alarm Monitoring SystemDocumento124 páginasUser Manual For E-R Alarm Monitoring SystemTomislav Korencic100% (1)

- Electronic Governor System: Main BenefitsDocumento2 páginasElectronic Governor System: Main Benefitsredchaoz0% (1)

- Advanced Micro Controller 2: 1. PurposeDocumento3 páginasAdvanced Micro Controller 2: 1. PurposeAdi VAún no hay calificaciones

- Auxitrol Mannual 759197-FDocumento255 páginasAuxitrol Mannual 759197-FGumaMohamed25% (4)

- InstructionManual BookDocumento62 páginasInstructionManual Bookankit100% (1)

- Delomatic 3, SCM-1, Synchronising-Measuring Module 4921240056 UKDocumento3 páginasDelomatic 3, SCM-1, Synchronising-Measuring Module 4921240056 UKВупсень ПупсеньAún no hay calificaciones

- 4-2953 - 55 Final Manual - Eng 05-08-11 PDFDocumento225 páginas4-2953 - 55 Final Manual - Eng 05-08-11 PDFVladimirAún no hay calificaciones

- 03Documento47 páginas03LekembauerAún no hay calificaciones

- VSP-12Way - Is Rev.03Documento55 páginasVSP-12Way - Is Rev.03Marcelo AlmeidaAún no hay calificaciones

- Gensys Marine Technical Documentation PDFDocumento128 páginasGensys Marine Technical Documentation PDFRic RioAún no hay calificaciones

- Salwico Cargo Addressable Installation Manual EDocumento74 páginasSalwico Cargo Addressable Installation Manual EAshish DharjiyaAún no hay calificaciones

- Digital Indicating Controller SDC 31: DigitronikDocumento12 páginasDigital Indicating Controller SDC 31: Digitronikshakir sarvaiya100% (1)

- Refrigerator: Service ManualDocumento44 páginasRefrigerator: Service ManualBetileno QuadAlexAún no hay calificaciones

- Kill Sheet Calculation Steps, Formulas & Calculators - Drilling ManualDocumento7 páginasKill Sheet Calculation Steps, Formulas & Calculators - Drilling ManualGourav RanaAún no hay calificaciones

- Yahama Golf Cart G2e Parts ManualDocumento50 páginasYahama Golf Cart G2e Parts Manualtl3883100% (1)

- Delomatic - Multi-Function System System Data: DEIF Generator Unit Control PanelDocumento4 páginasDelomatic - Multi-Function System System Data: DEIF Generator Unit Control Panellukasberg100% (1)

- Delomatic 3, Replacement Instruction, Flash Prom, 4189340245 UK PDFDocumento1 páginaDelomatic 3, Replacement Instruction, Flash Prom, 4189340245 UK PDFadi merAún no hay calificaciones

- Manual Usuario Alarma Incendio DECKMA, 815.8-6Documento12 páginasManual Usuario Alarma Incendio DECKMA, 815.8-6pevalpevalAún no hay calificaciones

- Navigation Light Control Panel PDF Download PandeltaDocumento3 páginasNavigation Light Control Panel PDF Download Pandeltaricky100% (1)

- FJ4000A4-21 MonitorDocumento8 páginasFJ4000A4-21 Monitorgunawan100% (1)

- MAS2600 Installation User Manual v10-UKDocumento27 páginasMAS2600 Installation User Manual v10-UKJohn LockAún no hay calificaciones

- Servomex 1800 1900 Manual PDFDocumento122 páginasServomex 1800 1900 Manual PDFbrunolacerdajrAún no hay calificaciones

- Jowa OdmeDocumento2 páginasJowa OdmeFaisal anwarAún no hay calificaciones

- Technical Description: Type: 810.001.420Documento8 páginasTechnical Description: Type: 810.001.420Radu VasilacheAún no hay calificaciones

- 801AP MX Service ToolDocumento10 páginas801AP MX Service ToolDiones CristianAún no hay calificaciones

- BF10 T1000 CV SysDocumento16 páginasBF10 T1000 CV SysNguyen Phuoc HoAún no hay calificaciones

- KTMS 2500Documento127 páginasKTMS 2500etchegarayfAún no hay calificaciones

- Mackay Service VAF Oilcon Annual Inspection Checklist MK6Documento5 páginasMackay Service VAF Oilcon Annual Inspection Checklist MK6Cleverson SchmidtAún no hay calificaciones

- Part1 Sound Power Tele. LC-800Documento17 páginasPart1 Sound Power Tele. LC-800Tammy Jim Tanjutco100% (1)

- 3264 - 01 - 02 - FU Steering Control Unit Handwheel, Type 105-106Documento20 páginas3264 - 01 - 02 - FU Steering Control Unit Handwheel, Type 105-106MariosAún no hay calificaciones

- Electronic Fuel Viscosity Controller New Model English Tib 771 GB 0215Documento50 páginasElectronic Fuel Viscosity Controller New Model English Tib 771 GB 0215irfanWPK100% (2)

- OMC-138-139 Manual en v1.10 PDFDocumento21 páginasOMC-138-139 Manual en v1.10 PDFCarlos CoelhoAún no hay calificaciones

- Bilgmon488 Instruction Manual VCDocumento23 páginasBilgmon488 Instruction Manual VCLwin PhyoAún no hay calificaciones

- Technical Description: Type: 810.001.230Documento8 páginasTechnical Description: Type: 810.001.230Radu VasilacheAún no hay calificaciones

- MC Rap1Documento33 páginasMC Rap1nitin9860Aún no hay calificaciones

- Tyco T1000Documento4 páginasTyco T1000Beni Saputra0% (1)

- BTS 4000 PDFDocumento43 páginasBTS 4000 PDFBf Ipanema100% (1)

- Cleantrack1000 Manual en 20060906Documento195 páginasCleantrack1000 Manual en 20060906CRIS SEDANTOAún no hay calificaciones

- CS3000 Service v6 E5 09 1 EDocumento83 páginasCS3000 Service v6 E5 09 1 EHarman SandhuAún no hay calificaciones

- DARLAS SERES ODME S 300 2 PCBs Removal Instructions For MK3 Hengstler Printer UpgradeDocumento8 páginasDARLAS SERES ODME S 300 2 PCBs Removal Instructions For MK3 Hengstler Printer UpgradeDen CakraAún no hay calificaciones

- UmsDocumento0 páginasUmsrolley5909Aún no hay calificaciones

- E-050 Engine Control ConsoleDocumento535 páginasE-050 Engine Control ConsoleВасиль ГудзьAún no hay calificaciones

- Salwico 2020 Manual-130524Documento141 páginasSalwico 2020 Manual-130524Mayan De la CruzAún no hay calificaciones

- Hyundai UAN Cradle Retrofit ManualDocumento11 páginasHyundai UAN Cradle Retrofit Manualauto etrustAún no hay calificaciones

- MG 800Documento7 páginasMG 800fotiniAún no hay calificaciones

- TemPower ACBsDocumento56 páginasTemPower ACBsABDUL GHAFOORAún no hay calificaciones

- NOHMI BOSAI Marine Fire DetectorDocumento2 páginasNOHMI BOSAI Marine Fire Detectorryan azzaamAún no hay calificaciones

- ACC20 Digital Governor UnitDocumento2 páginasACC20 Digital Governor Unitsike_99100% (1)

- Rse-P Ii Short Manual: W X +12.0 Bar +12.0 BarDocumento81 páginasRse-P Ii Short Manual: W X +12.0 Bar +12.0 Bar徐玉坤100% (2)

- VMP 430Documento2 páginasVMP 430Rodrigo BohrerAún no hay calificaciones

- Service Manual Damcos Local Power Unit en 60632 1 PDFDocumento144 páginasService Manual Damcos Local Power Unit en 60632 1 PDFpapaki2100% (1)

- Control/Repeater Panel M 4.3: General Description DataDocumento28 páginasControl/Repeater Panel M 4.3: General Description DatadangthutqmAún no hay calificaciones

- Control-Repeater Panel M 4.3 M en 2018 HDocumento5 páginasControl-Repeater Panel M 4.3 M en 2018 HTURARAMA100% (1)

- How To Recovery ACONIS ServerDocumento16 páginasHow To Recovery ACONIS ServerAdrian VasilacheAún no hay calificaciones

- Engine Order Telegraph SystemsDocumento17 páginasEngine Order Telegraph SystemslusifadilahAún no hay calificaciones

- Rivertrace Manual 2015 - SseDocumento44 páginasRivertrace Manual 2015 - SseRomankoAún no hay calificaciones

- K-Chief 600 - Alarm History Report - 20201215092129 - ROS3Documento5 páginasK-Chief 600 - Alarm History Report - 20201215092129 - ROS3Marcus Vinicius Ribeiro GomesAún no hay calificaciones

- Salwico cs3004Documento108 páginasSalwico cs3004завир мансуров100% (1)

- Yantai BKJ2 Marine Master-Slave ClockDocumento7 páginasYantai BKJ2 Marine Master-Slave ClockFront Crown100% (1)

- Delomatic 3 Data Sheet 4921240164 UkDocumento2 páginasDelomatic 3 Data Sheet 4921240164 Ukdali.marouenAún no hay calificaciones

- Vdocuments - MX Seg Nb2Documento34 páginasVdocuments - MX Seg Nb2KrzysztofAún no hay calificaciones

- SEPARATION THEORY - From Basic Separation To ALCAP SystemDocumento42 páginasSEPARATION THEORY - From Basic Separation To ALCAP SystemmgbouneAún no hay calificaciones

- Bearing Detail PDFDocumento1152 páginasBearing Detail PDFJayesh MachhiAún no hay calificaciones

- Código BoogaDocumento138 páginasCódigo BoogaJazmin SeguelAún no hay calificaciones

- Spirent TestCenter Automation Obj RefDocumento3210 páginasSpirent TestCenter Automation Obj Refokie11Aún no hay calificaciones

- Sidewall Framing Elevation @GL.K: Gutter DetailDocumento1 páginaSidewall Framing Elevation @GL.K: Gutter DetailLUUVANDONG48XFAún no hay calificaciones

- 03 Transformers CT VTDocumento10 páginas03 Transformers CT VTEnrique G.Aún no hay calificaciones

- Literature ReviewDocumento2 páginasLiterature ReviewkhairulAún no hay calificaciones

- Se MeterDataProcessingDocumento83 páginasSe MeterDataProcessingbzkxtAún no hay calificaciones

- VSSUT (EEE) SyllabusDocumento47 páginasVSSUT (EEE) SyllabusAshutosh GuptaAún no hay calificaciones

- A35 Ostetricia Ginecologia PDFDocumento8 páginasA35 Ostetricia Ginecologia PDFAarthiAún no hay calificaciones

- ICE Annex A Methodologies For RecyclingDocumento17 páginasICE Annex A Methodologies For RecyclingChai Lin NyokAún no hay calificaciones

- Potsdam Village Police Dept. Blotter April 12, 2018Documento2 páginasPotsdam Village Police Dept. Blotter April 12, 2018NewzjunkyAún no hay calificaciones

- EVI DC Inverter Technical Manual 2 Capacity TableDocumento67 páginasEVI DC Inverter Technical Manual 2 Capacity TableMouyed Al QasemAún no hay calificaciones

- 2013 OSPE Salary Survey PDFDocumento20 páginas2013 OSPE Salary Survey PDFdarinscottjohnsonAún no hay calificaciones

- Guinness Case StudyDocumento3 páginasGuinness Case StudyMunyaradzi T HotoAún no hay calificaciones

- CH 19Documento147 páginasCH 19Kathy YellaAún no hay calificaciones

- A Simulation of Attempts To Influence Crowd Dynamics'Documento6 páginasA Simulation of Attempts To Influence Crowd Dynamics'KhairulAún no hay calificaciones

- Survey MODULE 4Documento16 páginasSurvey MODULE 4InsurrectionAún no hay calificaciones

- Centum VPDocumento101 páginasCentum VPgopalAún no hay calificaciones

- ABB I RWEDocumento1 páginaABB I RWEPredrag VucinicAún no hay calificaciones

- NextCloud OnlyOffice PDFDocumento89 páginasNextCloud OnlyOffice PDFOmar Gallegos Vazquez100% (1)

- Croatia: Approved Port Facilities in CroatiaDocumento1 páginaCroatia: Approved Port Facilities in CroatiaАлександрAún no hay calificaciones

- Hydrocracking Reactor Temperature Control For Increased Safety, Reliability and PerformanceDocumento8 páginasHydrocracking Reactor Temperature Control For Increased Safety, Reliability and Performancekirandevi1981Aún no hay calificaciones

- A Study of Chemical Structure of Soft and Hardwood andDocumento7 páginasA Study of Chemical Structure of Soft and Hardwood andBruna BarraAún no hay calificaciones

- MSM Carbon FibreDocumento35 páginasMSM Carbon FibrelokeshkrkushwahaAún no hay calificaciones

- NEOCLASSICAL CITY PlanningDocumento10 páginasNEOCLASSICAL CITY PlanningAfrahAún no hay calificaciones