Documentos de Académico

Documentos de Profesional

Documentos de Cultura

LWS Series 2015-10 PDF

Cargado por

Julio TovarTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

LWS Series 2015-10 PDF

Cargado por

Julio TovarCopyright:

Formatos disponibles

“Designed, Tested and Approved for Shipment

by LWT Engineering Staff”

INDUSTRIAL FILTRATION EQUIPMENT

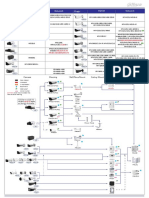

LWS Filter Series

(Single, Twin, Triple or Quadruple Demand Systems)

LWS Series Phone: 414.365.0787

1|Page eMail:info@lakesidewater.com

“Designed, Tested and Approved for Shipment

by LWT Engineering Staff”

LWS Series filtration equipment can be engineered to solve complex commercial and industrial water

treatment problems. Our catalog filtration equipment comes standard with a 2001 electronic cycle

controller. Multiple tank systems often utilize the pressure differential package to trigger regeneration.

An Optional 3214 Microprocessor provides single, twin, triple or quadruple

system capabilities. The controller features single, twin alternating,

progressive demand or parallel application options. Multiple tank applications

with sequential regeneration and user friendly programming are the premiere

features of this controller. Five programmable cycle adjustments are standard

for those problem water applications.

Optional Allen Bradley PLC control packages come with HMI EZ color

touch screen and are extremely user friendly. Lakeside PLC solenoid

system features a hold, advance, resume, termination or close of all

valves function, for fast, easy field service. The main screen can be

programmed to display a variety of parameters such as current flow

rates, online tank status and remaining gallons of each vessel. The AB

10/100 IP Ethernet Network Connection port is standard for building

management capabilities. Custom Programming and alternate

communication protocols are available.

Pressure Differential Systems are a frequently requested design for the Multi-Media Systems removing

turbidity and suspended particles down to nominal 10 microns. This feature has two pressure

connections, one on the inlet pipe and one connected on the outlet pipe. When operator selected or a

10-15 lb. differential in operating pressure occurs, the indicating pressure switch sends a signal to the

controller for immediate or delayed regeneration to clean the media bed. The correct backwash

duration is critical to prevent premature bed failure. This can be accomplished by observing the

backwash water at the end of the cycle and verifying the water is clear, ensuring a clean media bed for

peak performance.

Carbon Steel Pressure Vessels Standard working pressure options are 100PSI. Higher pressures are

available with custom engineered systems. A standard epoxy lining of 10-12 DFT mil is applied internally

and 6-8 mils DFT safety blue finish coating applied over the exterior of the vessel. The vessels can be

fabricated in non-code or ASME certified. Stainless steel or fiberglass vessels are available.

LWS Series Phone: 414.365.0787

2|Page eMail:info@lakesidewater.com

“Designed, Tested and Approved for Shipment

by LWT Engineering Staff”

Underdrain The radial hub underdrain uses high quality PVC pipe and fittings,

delivering high performance standards. The .010” PVC slotted laterals are installed

to utilize the entire bed area minimizing channeling during low flow. This design

provides high flow rates, reliability and quality assurance. Lakeside’s four point

header inlet baffle on 48” and larger vessels increases even flow distribution.

Cast Iron diaphragm valve nest design allows each valve to be exactly

designed and sized for the required functions, providing the most cost

effective, efficient and serviceable system in the market. These valves can be

hydraulically or pneumatically operated for your operational requirements.

Numerous piping and valve configurations such as Copper, PVC or Stainless

steel are available. Boiler drain valves and rack style pressure gauge

packages are standard for fast and easy diagnostics.

Filter Media

Carbon Filtration - Chlorine, chloramine and dissolved organic material removal is accomplished by

using a carbon media matched to your application. Contact time and bed depth are very critical in the

adsorption process and has a direct impact on the effectiveness of the equipment. To achieve the

proper contact time, correct equipment sizing and an outlet flow control is critical. The water supply

should be tested with complete water analysis for proper application and engineering. Elevated

concentrations of oil, turbidity or iron can foul and prevent optimal performance of the equipment. Pre-

treatment equipment would be a recommended solution.

Greensand Filtration - Iron, manganese and hydrogen sulfide problems require the pH between the 6.8 -

8.0 ranges for optimum filtration. The manganese greensand media has an oxide coating that oxidizes

the iron, manganese and hydrogen sulfide and precipitates on contact. The precipitates are filtered

down to nominal 30 microns by the media bed and then expelled during the regeneration process. The

media can be regenerated using a continuous feed of chlorine or potassium permanganate or both. The

correct backwash duration is critical to prevent premature bed failure. This can be accomplished by

observing the backwash water at the end of the cycle and verifying the water is clear, ensuring a clean

media bed.

LWS Series Phone: 414.365.0787

3|Page eMail:info@lakesidewater.com

“Designed, Tested and Approved for Shipment

by LWT Engineering Staff”

Multi-Media Filtration provides filtration down to nominal 10 microns utilizing quartz sand, garnet and

anthracite combinations designed to increase service flow rates per square foot of bed area, compared

to traditional sand filtration systems. Restratification of the media layer automatically occurs and is

based on their density and particle size, which reduces rinse time and water costs.

Operating Parameters Pressure 30-100psi. Temperature range 35F-100F Electrical: 120vac, 60Hz Electrical

enclosures rated NEMA 12/4x Drain piping limits: 10ft vertical and discharged to an atmospheric floor

drain sized to handle the backwash rate of the system (Max proven length is 25ft).

OPTIONS AVAILABLE:

• Skid mounted, pre-piped, pre-wired for faster and cost effective installations

• PVC, Copper and Stainless Steel Piping Options

• Non-code and ASME code vessels with custom linings available

• Separate source back wash systems

• Sanitized hot water or steam systems available

• Chemical injection (pre-treatment)

• Custom controls, programming, pre-engineered and custom engineered systems available

LWS Series Phone: 414.365.0787

4|Page eMail:info@lakesidewater.com

“Designed, Tested and Approved for Shipment

by LWT Engineering Staff”

MODEL NO. MEDIA TANK L1 L2 L3 L4

LxWxH LxWxH LxWxH LxWxH

LWS-X-20 20" x 54" 25" x 30" x 69" 57" x 30" x 69" 89" x 30" x 69" 57" x 30" x 69"

LWS-X-24 24" x 54" 27" x 36" x 70" 63" x 36" x 70" 99" x 36" x 70" 63" x 36" x 70"

LWS-X-30 30" x 60" 34" x 42" x 81" 76" x 42" x 81" 118" x 42" x 81" 76" x 42" x 81"

LWS-X-36 36" x 60" 40" x 48" x 89" 88" x 48" x 89" 136" x 48" x 89" 88" x 48" x 89"

LWS-X-42 42" x 60" 44" x 54" x 90" 98" x 54" x 90" 152" x 54" x 90" 98" x 54" x 90"

LWS-X-48 48" x 60" 52" x 61" x 103" 116" x 61" x 103" 180" x 61" x 103" 116" x 61" x103"

LWS-X-54 54" x 60" 58" x 66" x 100" 128" x 66" x 100" 198" x 66" x 100" 128" x 66" x 100"

LWS-X-60 60" x 60" 64" x 72" x 102" 140" x 72" x 102" 216" x 72" x 102" 140" x 72" x 102"

LWS-X-66 66" x 60" 70" x 79" x 104" 152" x 79" x 104" 234" x 79" x 104" 152" x 79" x 104"

LWS-X-72 72" x 60" 76" x 86" x 106" 164" x 86" x 106" 252" x 86" x 106" 164" x 86" x 106"

LWS Series Phone: 414.365.0787

5|Page eMail:info@lakesidewater.com

“Designed, Tested and Approved for Shipment

by LWT Engineering Staff”

LWS Multi-Media Filter Model Specifications

MODEL MINERAL IN/OUT BACKWASH SERVICE PSI-D PEAK PSI-D BWF MINERAL

TANK SIZE PIPE SIZE PIPE SIZE GPM GPM RATE

(Diameter (inches) IN /OUT GPM QTY.

& height) CU.FT.

LWS-ML-20 20 x 54 1 1 20 1 30 5 30 7

LWS-ML-24 24 x 54 1¼ 1¼ 30 1 45 8 45 10

LWS-ML-30 30 x 54 1½ 1½ 50 2 65 9 75 16

LWS-ML-36 36 x 60 2 2 70 2 105 9 105 22

LWS-ML-42 42 X 60 2½ 2½ 95 2 140 12 150 30

LWS-ML-48 48 X 60 2½ 2½ 120 1 170 6 180 40

LWS-ML-54 54 x 60 3 3 160 2 230 8 240 52

LWS-ML-60 60 x 60 3 3 200 2 260 10 300 63

LWS-ML-66 66 x 60 4 4 235 2 350 15 350 75

LWS-ML-72 72 x 60 4 4 275 3 415 7 415 91

LWS Manganese Greensand Filter Model Specifications

MODEL MINERAL IN/OUT BACKWASH SERVIC PSI-D PEAK PSI-D BWF MINERAL

TANK SIZE PIPE SIZE PIPE E GPM GPM RATE

IN /OUT QTY.

CU.FT.

LWS-MG-20 20 x 54 ¾ 1 8 3 3 6 25 6

LWS-MG-24 24 x 54 ¾ 1¼ 10 4 17 6 40 9

LWS-MG-30 30 x 54 1 1¼ 15 3 25 5 60 14

LWS-MG-36 36 x 60 1¼ 2 21 2 35 3 85 22

LWS-MG-42 42 X 60 1¼ 2 29 3 48 7 110 30

LWS-MG-48 48 X 60 1½ 2 40 2 63 4 140 40

LWS-MG-54 54 x 60 2 2½ 55 3 80 5 190 51

LWS-MG-60 60 x 60 2 3 69 3 99 5 235 62

LWS-MG-66 66 x 60 2½ 3 90 3 130 7 285 75

LWS-MG-72 72 x 60 2½ 4 100 3 141 7 340 90

LWS Carbon Filter Model Specifications

MODEL MINERAL IN/OUT BACKWASH SERVIC PSI-D PEAK PSI-D BWF MINERAL

TANK SIZE PIPE SIZE PIPE E GPM GPM RATE

IN /OUT QTY.

CU.FT.

LWS-AC-20 20 x 54 1 1 8 1 22 5 20 5

LWS-AC-24 24 x 54 1 1 10 1 22 5 30 5

LWS-AC-30 30 x 54 1¼ 1¼ 15 2 49 9 45 12

LWS-AC-36 36 x 60 1½ 1½ 21 2 65 9 70 18

LWS-AC-42 42 X 60 1½ 2 29 2 96 12 90 24

LWS-AC-48 48 X 60 2 2 40 1 120 6 110 32

LWS-AC-54 54 x 60 2 2½ 55 2 159 8 150 40

LWS-AC-60 60 x 60 2½ 2½ 69 2 175 10 190 50

LWS-AC-66 66 x 60 3 3 90 2 210 15 245 60

LWS-AC-72 72 x 60 3 3 100 3 250 7 270 75

LWS Series Phone: 414.365.0787

6|Page eMail:info@lakesidewater.com

También podría gustarte

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2099)

- Surgical InstrumentsDocumento4 páginasSurgical InstrumentsWafa L. AbdulrahmanAún no hay calificaciones

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (73)

- Allen Bradley Power Monitor 3000 Manual PDFDocumento356 páginasAllen Bradley Power Monitor 3000 Manual PDFAndrewcaesar100% (1)

- G 26 Building Using ETABS 1673077361Documento68 páginasG 26 Building Using ETABS 1673077361md hussainAún no hay calificaciones

- Revised fire drill performance standardsDocumento47 páginasRevised fire drill performance standardsKartikeya GuptaAún no hay calificaciones

- UNIT-2 Design of Spur GearDocumento56 páginasUNIT-2 Design of Spur GearMarthandeAún no hay calificaciones

- Regenerative Medicine Manual ISSCA 2020 EnglishDocumento21 páginasRegenerative Medicine Manual ISSCA 2020 EnglishDana MihutAún no hay calificaciones

- AOAC 2012.11 Vitamin DDocumento3 páginasAOAC 2012.11 Vitamin DPankaj BudhlakotiAún no hay calificaciones

- Aldec G2 PDFDocumento2 páginasAldec G2 PDFJulio TovarAún no hay calificaciones

- Products Typically Used Within Water Power Stations and Level Control SystemsDocumento6 páginasProducts Typically Used Within Water Power Stations and Level Control SystemsJulio TovarAún no hay calificaciones

- Aeration LoresDocumento2 páginasAeration LoresJulio TovarAún no hay calificaciones

- ME Circular Clarifiers PDFDocumento5 páginasME Circular Clarifiers PDFJulio TovarAún no hay calificaciones

- T90 TurquiaDocumento7 páginasT90 TurquiaJulio TovarAún no hay calificaciones

- Bio-Plus 2010 Brochure Emailable PDFDocumento3 páginasBio-Plus 2010 Brochure Emailable PDFJulio TovarAún no hay calificaciones

- Bio-Plus 2010 Brochure Emailable PDFDocumento3 páginasBio-Plus 2010 Brochure Emailable PDFJulio TovarAún no hay calificaciones

- Bio-Plus 2010 Brochure Emailable PDFDocumento3 páginasBio-Plus 2010 Brochure Emailable PDFJulio TovarAún no hay calificaciones

- Rotamat® Mini Complete Plant MinicopDocumento2 páginasRotamat® Mini Complete Plant MinicopJulio TovarAún no hay calificaciones

- Waste Water Industry Waste Water IndustryDocumento2 páginasWaste Water Industry Waste Water IndustryJulio TovarAún no hay calificaciones

- Waste Water Industry Waste Water IndustryDocumento2 páginasWaste Water Industry Waste Water IndustryJulio TovarAún no hay calificaciones

- Sedimentador Specs PDFDocumento5 páginasSedimentador Specs PDFJulio TovarAún no hay calificaciones

- Zinc Slag - IC.20090206.NL.0037 - Cranendonck PDFDocumento1 páginaZinc Slag - IC.20090206.NL.0037 - Cranendonck PDFJulio TovarAún no hay calificaciones

- 5 - Rayo - Dredging in South America Mining Industry PDFDocumento6 páginas5 - Rayo - Dredging in South America Mining Industry PDFJulio TovarAún no hay calificaciones

- BIOWIN 3.0 Simulator FeaturesDocumento2 páginasBIOWIN 3.0 Simulator FeaturesJulio TovarAún no hay calificaciones

- BIOWIN 3.0 Simulator FeaturesDocumento2 páginasBIOWIN 3.0 Simulator FeaturesJulio TovarAún no hay calificaciones

- Argos SBR: A Compact SBR System Offering Process Flexibility and Major Capital SavingsDocumento2 páginasArgos SBR: A Compact SBR System Offering Process Flexibility and Major Capital SavingsJulio TovarAún no hay calificaciones

- HarmscoUpflowfilters PDFDocumento2 páginasHarmscoUpflowfilters PDFJulio TovarAún no hay calificaciones

- Advjuly2009 PDFDocumento2 páginasAdvjuly2009 PDFJulio TovarAún no hay calificaciones

- Inclined Plate Settler PDFDocumento6 páginasInclined Plate Settler PDFJulio TovarAún no hay calificaciones

- Inclined Plate Settler PDFDocumento6 páginasInclined Plate Settler PDFJulio TovarAún no hay calificaciones

- LSM 80 (Lamella Settler Module 80 MM) : DesignDocumento2 páginasLSM 80 (Lamella Settler Module 80 MM) : DesignJulio TovarAún no hay calificaciones

- 20-Tee Intake Drawing Assembly PDFDocumento1 página20-Tee Intake Drawing Assembly PDFJulio TovarAún no hay calificaciones

- 21-Biological Fouling Solutions PDFDocumento1 página21-Biological Fouling Solutions PDFJulio TovarAún no hay calificaciones

- ME Circular Clarifiers PDFDocumento5 páginasME Circular Clarifiers PDFJulio TovarAún no hay calificaciones

- Alkaline Stabilization PDFDocumento9 páginasAlkaline Stabilization PDFJulio TovarAún no hay calificaciones

- Pueblo Viejo Environment Water Fact Sheet PDFDocumento3 páginasPueblo Viejo Environment Water Fact Sheet PDFJulio TovarAún no hay calificaciones

- 20-Tee Intake Drawing Assembly PDFDocumento1 página20-Tee Intake Drawing Assembly PDFJulio TovarAún no hay calificaciones

- 20-Tee Intake Drawing Assembly PDFDocumento1 página20-Tee Intake Drawing Assembly PDFJulio TovarAún no hay calificaciones

- 21-Biological Fouling Solutions PDFDocumento1 página21-Biological Fouling Solutions PDFJulio TovarAún no hay calificaciones

- Wirkungen FlechtenstoffeDocumento21 páginasWirkungen FlechtenstoffeLogge UliAún no hay calificaciones

- H. Bateman, A. Erdélyi Et Al. - Higher Transcendental Functions 3 (1955, McGraw-Hill)Documento310 páginasH. Bateman, A. Erdélyi Et Al. - Higher Transcendental Functions 3 (1955, McGraw-Hill)ITALO HERRERA MOYAAún no hay calificaciones

- Surface Hardening enDocumento20 páginasSurface Hardening engtm1207Aún no hay calificaciones

- SmartRunway SmartLandingDocumento39 páginasSmartRunway SmartLandingMikeAún no hay calificaciones

- Fendering For Tugs: Mike Harrison, Trelleborg Marine Systems, UKDocumento5 páginasFendering For Tugs: Mike Harrison, Trelleborg Marine Systems, UKRizal RachmanAún no hay calificaciones

- Pentecostal Ecclesiology: Simon K.H. Chan - 978-90-04-39714-9 Via Free AccessDocumento156 páginasPentecostal Ecclesiology: Simon K.H. Chan - 978-90-04-39714-9 Via Free AccessStanley JohnsonAún no hay calificaciones

- Fajar Secondary Sec 3 E Math EOY 2021Documento16 páginasFajar Secondary Sec 3 E Math EOY 2021Jayden ChuaAún no hay calificaciones

- Guidelines On Dissolution Profile Comparison: Udrun ReitagDocumento10 páginasGuidelines On Dissolution Profile Comparison: Udrun ReitagRaju GawadeAún no hay calificaciones

- Philip Rance EAH Philo of ByzantiumDocumento3 páginasPhilip Rance EAH Philo of ByzantiumstoliAún no hay calificaciones

- 9701 s12 QP 11 PDFDocumento16 páginas9701 s12 QP 11 PDFHubbak KhanAún no hay calificaciones

- Dahua Pfa130 e Korisnicko Uputstvo EngleskiDocumento5 páginasDahua Pfa130 e Korisnicko Uputstvo EngleskiSaša CucakAún no hay calificaciones

- The Creators College of Science & Commerce: 1 TermDocumento2 páginasThe Creators College of Science & Commerce: 1 TermJhangir Awan33% (3)

- The Quill Vol. LVIII Issue 1 1-12Documento12 páginasThe Quill Vol. LVIII Issue 1 1-12Yves Lawrence Ivan OardeAún no hay calificaciones

- GSM Modernization Poster2Documento1 páginaGSM Modernization Poster2leonardomarinAún no hay calificaciones

- Sample Field Trip ReportDocumento6 páginasSample Field Trip ReportBILAL JTTCAún no hay calificaciones

- Mahle KFWA MAIN Data SheetDocumento4 páginasMahle KFWA MAIN Data SheetRudnikAún no hay calificaciones

- Sensor Controlled Animatronic Hand: Graduation Project PresentationDocumento24 páginasSensor Controlled Animatronic Hand: Graduation Project PresentationAnonymous D2FmKSxuuAún no hay calificaciones

- Desiderata: by Max EhrmannDocumento6 páginasDesiderata: by Max EhrmannTanay AshwathAún no hay calificaciones

- Thank You For Taking The Week 3: Assignment 3. Week 3: Assignment 3Documento3 páginasThank You For Taking The Week 3: Assignment 3. Week 3: Assignment 3DhivyaAún no hay calificaciones

- Workload Assessment in Railway ControlDocumento8 páginasWorkload Assessment in Railway ControlbbeeAún no hay calificaciones

- Abb 60 PVS-TLDocumento4 páginasAbb 60 PVS-TLNelson Jesus Calva HernandezAún no hay calificaciones

- NarendraVani KallubaluVKV 2010-11Documento144 páginasNarendraVani KallubaluVKV 2010-11Vivekananda Kendra100% (1)

- LogiquidsDocumento2 páginasLogiquidsAloma FonsecaAún no hay calificaciones