Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Perrys Tabsssz

Cargado por

eugenio jackz100%(1)100% encontró este documento útil (1 voto)

136 vistas5 páginasperry perry tabs

Título original

Perrys tabsssz

Derechos de autor

© © All Rights Reserved

Formatos disponibles

DOC, PDF, TXT o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoperry perry tabs

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como DOC, PDF, TXT o lea en línea desde Scribd

100%(1)100% encontró este documento útil (1 voto)

136 vistas5 páginasPerrys Tabsssz

Cargado por

eugenio jackzperry perry tabs

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como DOC, PDF, TXT o lea en línea desde Scribd

Está en la página 1de 5

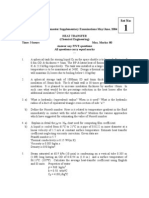

Drag Diameter Equations Compressib Solubilitie Surface

Affinity Bed of Lost Cubic Capillary MIchaelis

Coeff/ Hyd- of ility s of Inorg Roughnes

Laws Solids Work EOS Rise Menten

Force equiv Balance Factor (Z) Comp s

10-36 6-39 4-39 4-11 10-8 6-51 7-16 6-12 4-15 2-468 2-125 6-10

Arrheniu

Terminal Dust Clapeyro Metals

s Fans’ Henry’s Friction Nusselt Half-Life Antoine V-P Partial

Settling Controlle n Props

Equatio Power Law Losses Number (nth order) Constants Pressures

V rs Equation (Pipes)

n

7-6 6-51 10-51 14-8 6-16 17-24 4-13 5-8 7-36 13-14 10-101 2-81

Antoine Pitot Activity Fenske- W Constants: Tube Pitch

Power Orifice Phase Heat

Equatio NPSHA Tube Coefficien Underwo Compresso Lee Kesler (tube

Number Flow Rule Capacity

n (velocity) t od r & COS layout)

6-35 6-22 2-477 10-27 4-27 10-11 13-68 13-25 10-45 2-502 11-7 2-183

Flashpoin Petro & Physi

Relative Radius

Rayleigh Radiatio Liquid Accentric Fourier’s t Diffusivity Petro props: Critical

Volatilit of

Number n Fuels Factor Law Calculatio Calc. Eqns Product INORG Constants

y Gyration

n Charac. COMP

13-7 5-8 5-15 24-7 2-475 2-473 5-3 4-32 5-50 13-99 2-7 2-138

Faraday’ Particle Cavitatio Viscosity Densities

Diffusio Filtratio Beds of Bernoulli Packed Humidificati Gibbs Free

s Dynamic n (Org. & of Aq.

n n Solids Eqn Columns on Energy

Law s Number Inorg) Solns

7-32 6-53 5-49 18-82 6-39 6-7 6-45 14-53 2-427 12-3 2-104 4-21

Membran

Physi Process Pipes Mat:

Convecti Enzyme Froude Reboiler Solid e Heats of

Drying Mixing props: Measureme Cost

on Kinetics Number s Fuels Separatio Fusion

ORGCOMP nt Ranking

n

5-7 12-25 7-18 6-29 11-13 24-4 18-6 20-36 2-28 8-54 10-136 2-145

Vapor Thermal

Corrosio Gaseous Nature of Fluidized Centrifug Supercritica Func. Grp. Head

Work Reactors Pressur Conductivi

n Fuel Fluids Bed es l Fluid Sepa Polarities Volume

e ty

25-3 4-39 7-10 2-477 24-10 6-4 17-2 18-114 2-439 20-14 13-93 10-145

Henry’s Parameter Thermo Heat Capa Typical

Therm Diffusiviti Condense Manometer

Constant s Cubic Bearings HAPS prop (Pure Heattra Coeff

Expans Coeff es rs s

s EOS Relations Subst) in HE

2-130 10-116 4-11 10-65 2-455 22-11 4-6 2-156 11-11 11-25 10-9

Steel

Random Valves Heats of Batch McCabe-

Pipe Evaporator Leachin Viscosit Compressib Dew and

Packings Dimensio Vaporizati Distillatio Thiele

Propertie s g y ility Factors Bubble Pt.

Char. ns on n Method

s

10-78 14-61 11-110 18-59 10-95 2-504 2-143 2-150 13-109 13-18 4-29

Tray

Heats of Pumps & Pvap in

Fluid Sat’d Air Pvap of Surface Conducti Chromatogra Column,

Vessels Formatio Compressor terms of

Mixing Thermoprop Pure Subst Tension on phy Disti. &

n s °C

Abs.

6-34 12-11 2-48 10-140 2-185 2-513 10-24 2-56 5-3 16-38 14-26

Frictional

Particle Chemical Enthalpy Flashpoin Dry & Wastewater Controllers

Heats of Cooling Loss Crystalliza

Size Family: and Gibbs t Autoigni Wet Bulb Characteristi &

Solution Towers (Fitting tion

Analysis Sorted EF (T) Temp cs Regulators

&Valve)

21-8 2-49 2-196 2-203 2-446 12-17 6-18 7-5 10-7 22-60 8-71

Thermal Densities Principal Newton’s Thermal Flange Size

Steam Unit Ops Raoult’s Multiphas

Props. of Pure Pollutant Law Conductivi Fittings Enlargeme

Table Control Law e Flow

of Var. Mat. Subst s of Cooling ty Dimensions nt

2-413 11-28 2-96 8-39 22-29 4-28 5-7 2-509 6-26 10-91 21-117

H-bonding Air Velocity Kremser-

Adsorben Tube Charact Prandtl Solid Refrigerati Flowmete Heat

Classificati Propertie Measureme Souders

ts TEMA Number Wastes on rs Exchangers

on s nt Brown

16-8 11-42 13-92 2-451 2-211 22-81 10-11 11-78 10-15 11-33

Insulatio Total Process Fans Size Antoine Overall Gen.

Prandtl Dimensionles Particulate

n Emissivity Plant and Reductio Coeff (Air- Masstra Cubic

Number s Groups Emissions

Thickness of Surfaces Piping Blowers n Water) Eqn EOS

11-71 5-21 10-73 10-49 21-45 5-8 12-5 5-49 4-11 6-50 22-53

Thermal con Pumps:

Kremser

Insulating Series and

Eqn

Mat Parallel

2-459 10-33

Fanning

Friction

Factor

6-16

Specific

Growth Rate

(Monod)

7-18

También podría gustarte

- Bagpipe LV 1-5Documento228 páginasBagpipe LV 1-5Sathia Kdms100% (2)

- Kaged Muscle Magazine Issue 1Documento41 páginasKaged Muscle Magazine Issue 1hashimhafiz1100% (1)

- Reynold A. Nicholson - The Mystics of IslamDocumento65 páginasReynold A. Nicholson - The Mystics of IslamLuminon SamanAún no hay calificaciones

- Indiabix SummaryDocumento6 páginasIndiabix SummaryMayAún no hay calificaciones

- Name of Students: Rucha Lokhande, Rucha Dhavale, Prajakta Kulal, Isha Meshram Under Guidance of DR - Tanushree BhattacharjeeDocumento41 páginasName of Students: Rucha Lokhande, Rucha Dhavale, Prajakta Kulal, Isha Meshram Under Guidance of DR - Tanushree BhattacharjeeIsha MeshramAún no hay calificaciones

- Theoretical CyclesDocumento49 páginasTheoretical CyclesMariaEzzaSyUyAún no hay calificaciones

- Critical Analysis of W.H Auden Poems The PDFDocumento8 páginasCritical Analysis of W.H Auden Poems The PDFMöĤämmĔd äĹ-ŚäÁdï100% (1)

- GX Operating Manual v0.4 EDocumento38 páginasGX Operating Manual v0.4 EBadmaarag JlssAún no hay calificaciones

- Tutorial Group 1Documento6 páginasTutorial Group 1Sanjeev NehruAún no hay calificaciones

- Evaluation of Michaelis-Menten ParametersDocumento109 páginasEvaluation of Michaelis-Menten ParametersAnonymous 0zrCNQ100% (1)

- Carinthia Katalog DownloadDocumento16 páginasCarinthia Katalog DownloadOperator_010100% (2)

- Specific Heat Capacity and CalorimetryDocumento12 páginasSpecific Heat Capacity and CalorimetryAndreaMarkhamAún no hay calificaciones

- Types of Loads Considered For Design of BridgeDocumento45 páginasTypes of Loads Considered For Design of BridgeAbhishek100% (1)

- BIochem AssDocumento5 páginasBIochem AssCheng PasionAún no hay calificaciones

- Experiment 2-2 - CalorimetryDocumento6 páginasExperiment 2-2 - CalorimetryAndrew Stephen LimAún no hay calificaciones

- Sample Problem ThermoDocumento25 páginasSample Problem ThermoJonnah Faye Mojares0% (1)

- Refresher Day 1 Part 3Documento3 páginasRefresher Day 1 Part 3Robert DelfinAún no hay calificaciones

- Tugas 2 - Kelompok 1 - Problem 2.1 - RevisiDocumento3 páginasTugas 2 - Kelompok 1 - Problem 2.1 - RevisiDelyana RatnasariAún no hay calificaciones

- Review Questions: LeachingDocumento1 páginaReview Questions: LeachingJohn P. BandoquilloAún no hay calificaciones

- Perrys TabsDocumento4 páginasPerrys TabsJose Daniel AsuncionAún no hay calificaciones

- Blank Sticker Tabs TemplateDocumento3 páginasBlank Sticker Tabs TemplateHina OdaAún no hay calificaciones

- Tabs PDFDocumento2 páginasTabs PDFJana MagpayoAún no hay calificaciones

- OG OG Local Mass Transfer Coeff, Kya: Material Thermal ConductivityDocumento2 páginasOG OG Local Mass Transfer Coeff, Kya: Material Thermal ConductivityJenny LlanesAún no hay calificaciones

- Tabs (From Zee)Documento4 páginasTabs (From Zee)Stefani Ann CabalzaAún no hay calificaciones

- Inbound 532829914Documento64 páginasInbound 532829914angellene.lucky18Aún no hay calificaciones

- Chap 1 Workshop HandoutDocumento2 páginasChap 1 Workshop HandoutHenry RodriguezAún no hay calificaciones

- AsdfghjklDocumento4 páginasAsdfghjklJV CustodioAún no hay calificaciones

- Activity 2 Thermo 1 & 2 PDFDocumento4 páginasActivity 2 Thermo 1 & 2 PDFonyxAún no hay calificaciones

- Corr 2018 SRC Analytical Chemistry Module 5 JGDocumento5 páginasCorr 2018 SRC Analytical Chemistry Module 5 JGpaula lunaAún no hay calificaciones

- Adsorption Review Questions and ProblemsDocumento4 páginasAdsorption Review Questions and ProblemsJohn Bryan Aldovino0% (2)

- 3.ionic Equilibria and Biochemical ReactionsDocumento4 páginas3.ionic Equilibria and Biochemical ReactionsbackseeAún no hay calificaciones

- Problem 1.1ADocumento23 páginasProblem 1.1AJohnathan Ortega MenesesAún no hay calificaciones

- 04 Oxygen DemandDocumento19 páginas04 Oxygen DemandCharisma SubaAún no hay calificaciones

- Lec 7-1Documento37 páginasLec 7-1Caterina BarrettaAún no hay calificaciones

- (Differential Calculus, Integral Calculus, Differential Equations, Probability and StatisticsDocumento7 páginas(Differential Calculus, Integral Calculus, Differential Equations, Probability and Statisticskimuel demesaAún no hay calificaciones

- Lecture 2 - Particle Characterization & Size Reduction v2Documento32 páginasLecture 2 - Particle Characterization & Size Reduction v2roxette100% (1)

- Penguapan Pengembunan 5 2Documento18 páginasPenguapan Pengembunan 5 2Dhiyaul IhsantiAún no hay calificaciones

- Problem Set Flip CrystallizationDocumento2 páginasProblem Set Flip CrystallizationSam Denielle TugaoenAún no hay calificaciones

- Biochemical Engineering Enzyme KineticsDocumento5 páginasBiochemical Engineering Enzyme KineticsLin Xian Xing33% (3)

- Ps1-Che171 Chemical Reaction Engineering 1Documento2 páginasPs1-Che171 Chemical Reaction Engineering 1Cha CanceranAún no hay calificaciones

- Exam Weekly Exam5Documento4 páginasExam Weekly Exam5Gab LibetarioAún no hay calificaciones

- Sample Problem 2Documento2 páginasSample Problem 2Sata AjjamAún no hay calificaciones

- Chemical Reaction PDFDocumento4 páginasChemical Reaction PDFonyxAún no hay calificaciones

- AssigDocumento2 páginasAssigZakwan0% (1)

- Air Sterilization PDFDocumento6 páginasAir Sterilization PDFEzekielAún no hay calificaciones

- CHE 412 CHE Thermodynamics IIDocumento4 páginasCHE 412 CHE Thermodynamics IIMaria Cecille Sarmiento GarciaAún no hay calificaciones

- Gibbs TotexDocumento5 páginasGibbs TotexWahid AliAún no hay calificaciones

- ChE - Laws and EthicsDocumento5 páginasChE - Laws and EthicsChosel LawagonAún no hay calificaciones

- Experiment No. 7 Measurement of Reaction ConversionDocumento8 páginasExperiment No. 7 Measurement of Reaction ConversionHoneylet Recaña TayactacAún no hay calificaciones

- LoveresLabExercise04Group06CAECHE51S1 PDFDocumento34 páginasLoveresLabExercise04Group06CAECHE51S1 PDFShania LoveresAún no hay calificaciones

- Handling A: 3-Day Board ExamDocumento32 páginasHandling A: 3-Day Board ExamAna Lorraine DalilisAún no hay calificaciones

- ChE 135 HQRUV Laboratory Manual v2Documento52 páginasChE 135 HQRUV Laboratory Manual v2gol12345Aún no hay calificaciones

- Check BoardDocumento5 páginasCheck BoardExelsis LeanoAún no hay calificaciones

- University Life Purpose: VisionDocumento7 páginasUniversity Life Purpose: VisionMaria Cecille Sarmiento GarciaAún no hay calificaciones

- Problem Set 3Documento2 páginasProblem Set 3Nigel Kow0% (1)

- Heat Transfer May2004 NR 310803Documento8 páginasHeat Transfer May2004 NR 310803Nizam Institute of Engineering and Technology LibraryAún no hay calificaciones

- Generalized Correlations For GasesDocumento3 páginasGeneralized Correlations For GasesAllen DimayugaAún no hay calificaciones

- CHE 311 CHE Calculations IDocumento4 páginasCHE 311 CHE Calculations IMikho SaligueAún no hay calificaciones

- MECHANICAL SEPARATIONS Transport Phenomena and Unit Operations A Combined Approach-Richard G. GriskeyDocumento43 páginasMECHANICAL SEPARATIONS Transport Phenomena and Unit Operations A Combined Approach-Richard G. GriskeyMarco Antonio FeriaAún no hay calificaciones

- 2 Cell Kinetics and Fermenter Design Part 2 DiscussionDocumento4 páginas2 Cell Kinetics and Fermenter Design Part 2 DiscussionEzekielAún no hay calificaciones

- CHEM 1221: Neutralization Titration Problem SetDocumento2 páginasCHEM 1221: Neutralization Titration Problem SetJohn Kristoffer RoblezaAún no hay calificaciones

- Che Day1Documento22 páginasChe Day1Janrey DohinogAún no hay calificaciones

- Cell Maintenance and Endogenous MetabolismDocumento5 páginasCell Maintenance and Endogenous MetabolismBenePicarAún no hay calificaciones

- Prayer For The Succes of Chemical Engineering Board ExamDocumento1 páginaPrayer For The Succes of Chemical Engineering Board Examjeamnard balitaanAún no hay calificaciones

- Sterilization Examples and ProblemsDocumento4 páginasSterilization Examples and ProblemsRooth AdajetAún no hay calificaciones

- Orange/TopDocumento6 páginasOrange/TopMaria Mikaela PelagioAún no hay calificaciones

- With Page No.1Documento5 páginasWith Page No.1Maria Cecille Sarmiento GarciaAún no hay calificaciones

- T.A.T.U. - Waste Management - Digital BookletDocumento14 páginasT.A.T.U. - Waste Management - Digital BookletMarieBLAún no hay calificaciones

- MC MATH 01 Syllabus SJCCDocumento11 páginasMC MATH 01 Syllabus SJCCAcire NonacAún no hay calificaciones

- A Study On Traditional Medicinal Herbs Used by The Ethnic People of Goalpara District of Assam, North East IndiaDocumento6 páginasA Study On Traditional Medicinal Herbs Used by The Ethnic People of Goalpara District of Assam, North East IndiaDr. Krishna N. SharmaAún no hay calificaciones

- Maintenance Páginas-509-580Documento72 páginasMaintenance Páginas-509-580Alexandra Gabriela Pacheco PrietoAún no hay calificaciones

- Hashimoto's Thyroiditis: Veena RedkarDocumento10 páginasHashimoto's Thyroiditis: Veena RedkarSan RedkarAún no hay calificaciones

- Haldex-Barnes 2-Stage Pump For Log SplittersDocumento2 páginasHaldex-Barnes 2-Stage Pump For Log SplittersPer Akkamaan AgessonAún no hay calificaciones

- Clocks (New) PDFDocumento5 páginasClocks (New) PDFAbhay DabhadeAún no hay calificaciones

- SR No Service CodeDocumento30 páginasSR No Service CodeShiva KrishnaAún no hay calificaciones

- BIO 201 Chapter 11 LectureDocumento34 páginasBIO 201 Chapter 11 LectureDrPearcyAún no hay calificaciones

- DP November 2017 Examination Schedule en PDFDocumento4 páginasDP November 2017 Examination Schedule en PDFSuperlucidoAún no hay calificaciones

- Resume: Satyam KumarDocumento3 páginasResume: Satyam KumarEr Satyam Kumar KrantiAún no hay calificaciones

- 2017 Classification of Periodontal and Peri-Implant Diseases and Conditions. Decision Making Algorithms For Clinical PracticeDocumento40 páginas2017 Classification of Periodontal and Peri-Implant Diseases and Conditions. Decision Making Algorithms For Clinical PracticebbAún no hay calificaciones

- Asme Code Sec Ix Ma Appe 2004Documento3 páginasAsme Code Sec Ix Ma Appe 2004Guillermo CamachoAún no hay calificaciones

- Integration ConceptDocumento34 páginasIntegration ConceptJANELLA ALVAREZAún no hay calificaciones

- Document List - Eni Progetti - Algeria BRN-MLE - 2019-06-10Documento18 páginasDocument List - Eni Progetti - Algeria BRN-MLE - 2019-06-10Naceri Mohamed RedhaAún no hay calificaciones

- TheBasicsofBrainWaves - RS PDFDocumento4 páginasTheBasicsofBrainWaves - RS PDFOnutu Adriana-LilianaAún no hay calificaciones

- Water Filling MachineDocumento15 páginasWater Filling Machinepallab D RozarioAún no hay calificaciones

- Contoh CV / Daftar Riwayat HidupDocumento2 páginasContoh CV / Daftar Riwayat HiduprusmansyahAún no hay calificaciones

- Pharmalytica Exhibitor List 2023Documento3 páginasPharmalytica Exhibitor List 2023Suchita PoojaryAún no hay calificaciones

- Parameters Identification of Induction Motor Model BasedDocumento10 páginasParameters Identification of Induction Motor Model Basedretrueke1170Aún no hay calificaciones

- Statics: Vector Mechanics For EngineersDocumento39 páginasStatics: Vector Mechanics For EngineersVijay KumarAún no hay calificaciones

- Psle Science Keywords !Documento12 páginasPsle Science Keywords !Aftertea CarousellAún no hay calificaciones

- Danika Cristoal 18aDocumento4 páginasDanika Cristoal 18aapi-462148990Aún no hay calificaciones