Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Structural Steel

Cargado por

rize1159Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Structural Steel

Cargado por

rize1159Copyright:

Formatos disponibles

LOWE’S OF QUINCY MA 02/2010

SECTION 05120 - STRUCTURAL STEEL

PART 1 - GENERAL

1.01 RELATED DOCUMENTS

A. Drawings and general provisions of the Contract, including General and Supplementary Conditions and

Division 1 Specification Sections, apply to this Section.

1.02 SUMMARY

A. This Section includes structural steel. All steel framing shall be of type, size, and spacing as shown in the

drawings, and shall comply with the provisions of the codes and standards as indicated in the drawings

and/or below.

1.03 PERFORMANCE REQUIREMENTS

A. Structural Performance: Engineer structural-steel connections required by the Contract Documents to be

selected or completed by fabricator to withstand design loadings indicated.

1.04 SUBMITTALS

A. Product Data: For each product indicated.

B. Shop Drawings: Submit drawings (3 sets) for Structural Engineer of Record’s review and (1 set) for

Owner’s approval, including complete details/schedules for fabrication/shop assembly of members, details,

schedules, procedures and diagrams showing sequence of erection. Include details of cuts, connections,

camber, holes and other pertinent data. Indicate welds by standard AWS symbols and show

size/length/type each weld. Provide setting drawings, templates and directions for installation of anchor

bolts and other anchorages to be installed by others, to include guard rails. (These shall be sent directly to

project architect.)

1. Reproducible copies of contract documents shall not be used as erection drawings.

2. Owner and Structural Engineer of Record’s review of shop drawings will be for general consideration

only. Compliance with requirements for materials fabrication/erection of structural steel is

Contractor’s responsibility.

3. Fabrication shall not commence until approval is received from Owner.

C. Affidavit: If requested, furnish an affidavit from manufacturer or fabricator certifying that materials or

produce delivered to job meet requirements specified. However, such certification shall not relieve

Contractor from responsibility of complying with any requirements specified herein.

D. Mill certificates.

E. Welding certificates.

1.05 QUALITY ASSURANCE

A. Fabricator shall comply with the applicable provisions, unless otherwise indicated on drawings.

1. AISC “Code of Standard Practice for Steel Buildings and Bridges”.

2. AISC “Specifications for Design, Fabrication, and Erection of Structural Steel for Buildings”, Latest

Edition.

3. AISC “Specifications for Structural Joints Using ASTM A-325 or A-490 Bolts”.

4. AWS D1.1 “Structural Welding Code”, latest edition.

5. Appropriate specifications of American Society for Testing and Materials.

6. Appropriate specifications of the Society for Protective Coatings (SSPC).

7. ASTM A6/A6M-93B “General Requirements for Delivery of Rolled Steel Plates, Shapes, Sheet Piling

and Bars for Structural Use”.

8. Work in this section shall be subject to all applicable provisions of State and Local building codes.

9. Occupational Safety and Health Act of 1970 (OSHA) as amended to date.

1.06 STORAGE AND PROTECTION

A. Store steel members off ground and protect steel members and packaged materials from corrosion and

deterioration.

B. Store fasteners in a protected place. Clean and relubricate bolts and nuts that become dry or rusty before

use.

STRUCTURAL STEEL 05120 - 1

LOWE’S OF QUINCY MA 02/2010

C. Deliver material to site at such intervals to insure uninterrupted progress of work. Deliver anchor bolts and

anchorage devices to be embedded in cast-in-place concrete or masonry, in ample time to not delay work.

PART 2 - PRODUCTS

2.01 MATERIALS

A. Structural-Steel Shapes, Plates, and Bars: ASTM A 36/A 36M, carbon steel with Fy = 36 ksi, or if indicated

on drawings, ASTM A 992, Grade 50, high-strength, low-alloy columbium-vanadium steel.

B. Cold-Formed Structural-Steel Tubing: ASTM A 500, Grade B.

C. Anchor Rods, Bolts, Nuts: ASTM A 307, hex carbon-steel nuts. Anchor bolts requiring bent hooks shall

be fabricated from steel rod stock with a minimum Fy = 36 ksi. These items shall be provided by the

structural steel fabricator.

D. High-Strength Bolts, Nuts, and Washers: ASTM A 325, Type 1, heavy hex steel structural bolts, heavy hex

carbon-steel nuts, and hardened carbon-steel washers, uncoated. These items shall be provided by the

structural steel fabricator.

E. Primer: Gray alkyd primer. Primer: SSPC – Paint 25 Alkyd Primer.

F. Nonmetallic, Shrinkage-Resistant Grout: Premixed, ASTM C 1107, of consistency suitable for application.

Also see Section 03300.

2.02 FABRICATION

A. Fabricate and assemble structural steel in shop to greatest extent possible. Fabricate structural steel

according to AISC specifications referenced in this Section and in Shop Drawings.

1. Comply with fabrication tolerance limits in AISC's "Code of Standard Practice for Steel Buildings and

Bridges" for structural steel and architectural exposed structural steel.

2. Shop install and tighten high-strength bolts, except where high-strength bolts are indicated.

3. Shop install and tighten high-strength bolts according to RCSC's "Specification for Structural Joints

Using ASTM A 325 or A 490 Bolts."

a. Connection Type: Snug tightened, unless indicated as slip-critical, direct-tension, or tensioned

shear/bearing connections.

4. Weld Connections: Comply with AWS D1.1 for procedures, appearance and quality of welds, and

methods used in correcting welding work.

B. All members shall be fabricated in strict accordance with the Drawings.

C. Properly mark and match-mark materials for field assembly. Fabricate for delivery sequence which will

expedite erection to greatest extent possible and minimize field handling of materials.

D. Provide finish surfaces of members exposed in final structure free of markings, burrs and other defects. Do

not splice any columns lower than 12’-0” above finish floor elevation.

E. Shop Priming: Shop prime steel, except surfaces embedded in concrete or mortar, surfaces to be field

welded, surfaces to be high-strength bolted with slip-critical connections, and surfaces to receive sprayed-

on fireproofing.

1. Surface Preparation: SSPC-SP 2, "Hand Tool Cleaning."

2. Primer coat shall be gray primer per Federal Specification TT-P-636.

3. Priming: Immediately after surface preparation, apply primer according to manufacturer's written

instructions and at rate recommended by SSPC to provide a dry film thickness of not less than 1.5 mils

(0.038 mm). Use priming methods that result in full coverage of joints, corners, edges, and exposed

surfaces.

2.03 SOURCE QUALITY CONTROL

A. At Owner’s discretion, Owner will engage an independent testing and inspecting agency to perform shop

tests, inspections and to prepare test reports. Comply with Part 3 "Field Quality Control" Article.

PART 3 - EXECUTION

3.01 ERECTION

A. Examination:

1. Check elevations of concrete and masonry bearing surfaces, and locations of anchor bolts and other

points of tie-in, before erection work proceeds, and report discrepancies to Owner. Do not proceed

STRUCTURAL STEEL 05120 - 2

LOWE’S OF QUINCY MA 02/2010

with erection until corrections have been made, or until compensating adjustments have been agreed

upon with Owner.

2. Verify member dimensions at site where possible without causing delay in work. Promptly notify

Owner when design of members for any portion of structure is not clearly indicated.

B. Erect structural steel accurately in locations and to elevations indicated and according to AISC

specifications referenced in this Section.

C. Install anchor bolts/other connections required for securing structural steel to foundations and other in-

place work.

D. Base and Bearing Plates: Clean concrete and masonry bearing surfaces of bond-reducing materials and

roughen surfaces before setting base and bearing plates. Clean bottom surface of base and bearing plates

and set on wedges, shims, or setting nuts as required.

1. Tighten anchor bolts after supported members have been positioned/plumbed. Do not remove wedges

or shims, but if protruding cut off flush with edge of base or bearing plate prior to packing with grout.

2. Pack grout solidly between bearing surfaces/bases or plates to insure that no voids remain. Finish

exposed surfaces, protect installed materials and allow to cure.

E. Maintain erection tolerances of structural steel and architecturally exposed structural steel within AISC's

"Code of Standard Practice for Steel Buildings and Bridges."

F. Install and tighten high-strength bolts, except where high-strength bolts are indicated.

G. Install and tighten high-strength bolts according to RCSC's "Specification for Structural Joints Using

ASTM A 325 or A 490 Bolts."

1. Connection Type: Snug tightened, unless indicated as slip-critical, direct-tension, or tensioned

shear/bearing connections.

H. Weld Connections: Comply with AWS D1.1 for procedures, appearance and quality of welds, and methods

used in correcting welding work.

I. The steel erector shall be responsible for installing the structural curbs for the Light Transmitting Roof

Panel System as described in Section 13123. This work shall be completed prior to installing roof decking.

J. The steel erector shall be responsible for installing the structural curbs for all RTU’s and skylights, if

shown on plans. This work shall be completed prior to installing roof decking.

3.02 FIELD QUALITY CONTROL

A. Contractor is responsible for quality control of all materials/workmanship, including workmanship/material

furnished by subcontractors and suppliers.

B. Refer to Division 0 for payment responsibility of testing. As part of quality assurance program will not

relieve Contractor of his responsibility to provide material/workmanship in compliance with specified

requirements.

C. Contractor shall be responsible for correction of work which does not conform to specified requirements

including, but not limited to, strength of material, fit up, conformance to tolerance requirements,

conformance to welding requirements, conformance to connection requirements, painting, etc.

D. Additional testing, at Contractor's expense, will be performed to determine compliance of corrected Work

with specified requirements.

E. Field Assembly: Set structural frames accurately to lines/elevations indicated. Align and adjust various

members forming part of complete frame or structure before permanently fastening. Clean bearing

surfaces/other surfaces in permanent contract before assembly. Perform necessary adjustments to

compensate for discrepancies in elevations and alignment. Level/plumb individual members of structure

within specified AISC tolerances. Splice members only where indicated and accepted on shop drawings.

F. Temporary Shoring and Bracing: Provide temporary shoring/bracing members with connections of

sufficient strength to bear imposed loads. Remove temporary members/connections when permanent

members are in place and final connections are made. Provide temporary guy lines to achieve proper

alignment of structures as erection proceeds.

END OF SECTION 05120

STRUCTURAL STEEL 05120 - 3

LOWE’S OF QUINCY MA 02/2010

This Page Left Intentionally Blank

STRUCTURAL STEEL 05120 - 4

También podría gustarte

- Division 5Documento15 páginasDivision 5hari banggaAún no hay calificaciones

- FL - Ta1056Documento10 páginasFL - Ta1056ery achjariAún no hay calificaciones

- Sec 05520 - Handrails and RailingsDocumento5 páginasSec 05520 - Handrails and Railingstiju2005hereAún no hay calificaciones

- NU - Division 05 - MetalsDocumento18 páginasNU - Division 05 - Metalsyamanta_rajAún no hay calificaciones

- Section 05120 Structural Steel Part 1Documento43 páginasSection 05120 Structural Steel Part 1jacksondcplAún no hay calificaciones

- GratingsDocumento6 páginasGratingsHusen ZahranAún no hay calificaciones

- Section051200 StructuralsteelDocumento5 páginasSection051200 StructuralsteelZeljko VasicAún no hay calificaciones

- Part 1 GeneralDocumento6 páginasPart 1 GeneralCamilo Eduardo Celis MeloAún no hay calificaciones

- PCI Hollowcore Specifications 4-8-11Documento8 páginasPCI Hollowcore Specifications 4-8-11Roberto Pérez LeónAún no hay calificaciones

- Concrete Reinforcing SpecsDocumento3 páginasConcrete Reinforcing Specsطه حلمىAún no hay calificaciones

- STRUCTURAL STEEL Rev.1Documento11 páginasSTRUCTURAL STEEL Rev.1mohdAún no hay calificaciones

- Pipe and Tube Railing SystemsDocumento8 páginasPipe and Tube Railing Systemsery achjariAún no hay calificaciones

- Steel Joist Specification for Libyan Infrastructure ProjectDocumento7 páginasSteel Joist Specification for Libyan Infrastructure Projectwafikmh4Aún no hay calificaciones

- 05120-Structural SteelDocumento10 páginas05120-Structural SteelHusen ZahranAún no hay calificaciones

- SECTION 03200 Concrete ReinforcementDocumento8 páginasSECTION 03200 Concrete ReinforcementSuranga ManuAún no hay calificaciones

- Pre-Fabricated Bridge - MSTDocumento12 páginasPre-Fabricated Bridge - MSTwafikmh4Aún no hay calificaciones

- 1.5 Sample BRB Specification - bw2sDocumento7 páginas1.5 Sample BRB Specification - bw2sKen SuAún no hay calificaciones

- Concrete ReinforcementDocumento5 páginasConcrete Reinforcementsethu1091Aún no hay calificaciones

- SECTION 05 12 00 Structural Steel FramingDocumento6 páginasSECTION 05 12 00 Structural Steel FramingmiteshsuneriyaAún no hay calificaciones

- SharonStairsSpecs PDFDocumento7 páginasSharonStairsSpecs PDFJohn TreffAún no hay calificaciones

- Building No. SC#Documento7 páginasBuilding No. SC#ephremAún no hay calificaciones

- Guide Specifications For NUTRUSS Cold-Formed Steel FramingDocumento6 páginasGuide Specifications For NUTRUSS Cold-Formed Steel FramingKeysha ApriliaAún no hay calificaciones

- Civil - Technical SpecificationsDocumento28 páginasCivil - Technical SpecificationskhalidAún no hay calificaciones

- Open Web Steel Joists InstallationDocumento5 páginasOpen Web Steel Joists Installationjack.simpson.changAún no hay calificaciones

- Section 05500 Metal FabricationsDocumento7 páginasSection 05500 Metal FabricationsMØhãmmed ØwięsAún no hay calificaciones

- Glass-Fiber Reinforced Precast Concrete Panel SpecificationDocumento11 páginasGlass-Fiber Reinforced Precast Concrete Panel SpecificationMhmd AbdoAún no hay calificaciones

- 05 40 00ssbDocumento12 páginas05 40 00ssbJerico NamucoAún no hay calificaciones

- Section 05120 Structural SteelDocumento9 páginasSection 05120 Structural SteelMØhãmmed ØwięsAún no hay calificaciones

- Aluminum StructureDocumento7 páginasAluminum StructureGrahamAún no hay calificaciones

- Table Metal StairDocumento6 páginasTable Metal StairJohneey DeepAún no hay calificaciones

- Handrail & PlatformDocumento58 páginasHandrail & Platformvhung TranAún no hay calificaciones

- Concrete ReinforcingDocumento7 páginasConcrete ReinforcingZul StudiozAún no hay calificaciones

- SteelDocumento16 páginasSteelAmjad PervazAún no hay calificaciones

- 05450-Pre Engineered Metal TrussesDocumento4 páginas05450-Pre Engineered Metal TrussesRamsey RasmeyAún no hay calificaciones

- Metal StairsDocumento5 páginasMetal Stairsshivayogi asundiAún no hay calificaciones

- King Abdullah Bin Abdulaziz Project Mataf Extension - DesignDocumento14 páginasKing Abdullah Bin Abdulaziz Project Mataf Extension - DesignshoebAún no hay calificaciones

- GRATINGS Rev.1Documento7 páginasGRATINGS Rev.1mohdAún no hay calificaciones

- Steel Floor Decking InstallationDocumento4 páginasSteel Floor Decking InstallationRal GLAún no hay calificaciones

- FL - Ta1056Documento4 páginasFL - Ta1056ery achjariAún no hay calificaciones

- 055100Documento5 páginas055100Abdul basithAún no hay calificaciones

- CompositeJoistStandardSpecifications PDFDocumento8 páginasCompositeJoistStandardSpecifications PDFcorrokokoAún no hay calificaciones

- Structural Steel Framing SpecificationDocumento9 páginasStructural Steel Framing SpecificationJuanPaoloYbañezAún no hay calificaciones

- SECTION 051200 Structural Steel Part 1 - GeneralDocumento8 páginasSECTION 051200 Structural Steel Part 1 - GeneralBrijithAún no hay calificaciones

- SECTION 09110 Metal Stud SystemDocumento3 páginasSECTION 09110 Metal Stud SystemIm ChinithAún no hay calificaciones

- Early Works Package - Specification B (Section 317210) - Tunnel Primary Support - Ground ReinforcementDocumento3 páginasEarly Works Package - Specification B (Section 317210) - Tunnel Primary Support - Ground ReinforcementZain AbidiAún no hay calificaciones

- TTO-ST-0-SPC-05100 - Structural Steel SpecificationDocumento18 páginasTTO-ST-0-SPC-05100 - Structural Steel Specificationsara saravananAún no hay calificaciones

- COLD-FORMED METAL FRAMING Rev.1Documento7 páginasCOLD-FORMED METAL FRAMING Rev.1mohdAún no hay calificaciones

- Concrete ReinforcmentDocumento5 páginasConcrete ReinforcmentNoor Mohamed AzeezAún no hay calificaciones

- Uniform General Conditions For Construction Contracts, State of Texas, 2010 (UGC) - ConstructionDocumento13 páginasUniform General Conditions For Construction Contracts, State of Texas, 2010 (UGC) - ConstructionTaher AmmarAún no hay calificaciones

- Metal Gratings TA1056 - MBI Sampang Agung Factory Extension 1Documento6 páginasMetal Gratings TA1056 - MBI Sampang Agung Factory Extension 1ery achjariAún no hay calificaciones

- FL Cold Formed Metal FramingDocumento10 páginasFL Cold Formed Metal FramingTaher AmmarAún no hay calificaciones

- Alamein Downtown Towers Metal FabricationsDocumento15 páginasAlamein Downtown Towers Metal FabricationsWENDING HUAún no hay calificaciones

- 05 - 12 - 00 - 00 (05120) - Steel FramingDocumento12 páginas05 - 12 - 00 - 00 (05120) - Steel FramingMatthew Ho Choon LimAún no hay calificaciones

- 02 SpecificationsDocumento194 páginas02 SpecificationsNabeel Adeeb Alshare100% (1)

- Uniform General Conditions For Construction Contracts, State of Texas, 2010 (UGC) - ConstructionDocumento10 páginasUniform General Conditions For Construction Contracts, State of Texas, 2010 (UGC) - ConstructionsbunAún no hay calificaciones

- Steel Stairs, Ladders and Platforms - MSTDocumento13 páginasSteel Stairs, Ladders and Platforms - MSTwafikmh4Aún no hay calificaciones

- Mixville Pond Dam Cheshire, Connecticut September 4, 2014: Concrete Reinforcing 03 20 00 - 1Documento4 páginasMixville Pond Dam Cheshire, Connecticut September 4, 2014: Concrete Reinforcing 03 20 00 - 1Juan José Ricaldi MirandaAún no hay calificaciones

- Connecting Details DWG 001Documento9 páginasConnecting Details DWG 001Yadhu .msa17Aún no hay calificaciones

- Pages From Hollow Core Slab DesingDocumento8 páginasPages From Hollow Core Slab DesingMahmoud ShakerAún no hay calificaciones

- Analytical Methods: Physical Properties of Dairy PowdersDocumento17 páginasAnalytical Methods: Physical Properties of Dairy Powdersrize1159Aún no hay calificaciones

- Traffic Light - SSR&BDR Audit Form - SSR11Documento4 páginasTraffic Light - SSR&BDR Audit Form - SSR11rize1159Aún no hay calificaciones

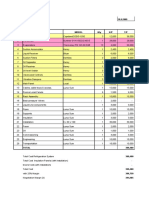

- Hydraulic calculation for pumpsDocumento22 páginasHydraulic calculation for pumpsrize1159Aún no hay calificaciones

- GF AD01 Bid Event ScheduleDocumento2 páginasGF AD01 Bid Event Schedulerize1159Aún no hay calificaciones

- Computer ModelDocumento48 páginasComputer ModelMohamed SelimAún no hay calificaciones

- RFP Pricing Document Rev 005 - 15 11 2010Documento38 páginasRFP Pricing Document Rev 005 - 15 11 2010rize1159Aún no hay calificaciones

- TONGDocumento4 páginasTONGrize1159Aún no hay calificaciones

- (Painting Works) : Inspection and Test PlanDocumento2 páginas(Painting Works) : Inspection and Test Planrize1159Aún no hay calificaciones

- Colorado Springs Residential Water Use CalculatorDocumento7 páginasColorado Springs Residential Water Use CalculatorNghiaAún no hay calificaciones

- Air Curtain Installation Scorecard - Aug 2012 (FINAL)Documento1 páginaAir Curtain Installation Scorecard - Aug 2012 (FINAL)rize1159Aún no hay calificaciones

- FBR Tax FilingDocumento48 páginasFBR Tax FilingMuhammad Waqas Hanif100% (1)

- Energy TreeDocumento1 páginaEnergy Treerize1159Aún no hay calificaciones

- Shahi - Tazaj - SAPCO 19.9.2009Documento2 páginasShahi - Tazaj - SAPCO 19.9.2009rize1159Aún no hay calificaciones

- BHP Tank Fit Up Inspection Report TemplateDocumento1 páginaBHP Tank Fit Up Inspection Report Templaterize1159Aún no hay calificaciones

- GF AD01 Bid Event ScheduleDocumento2 páginasGF AD01 Bid Event Schedulerize1159Aún no hay calificaciones

- Noniterative Design of Multiple Effect Evaporators Using Excel Add InsDocumento10 páginasNoniterative Design of Multiple Effect Evaporators Using Excel Add InsGalang Hanif AbdulahAún no hay calificaciones

- Dimensional Inspection ReportDocumento2 páginasDimensional Inspection Reportrize1159Aún no hay calificaciones

- F2-DP-2017-Pasta-Ondrej-priloha-Vypocet Cerpadla Na KavitaciDocumento20 páginasF2-DP-2017-Pasta-Ondrej-priloha-Vypocet Cerpadla Na Kavitacirize1159Aún no hay calificaciones

- GeavstetraDocumento4 páginasGeavstetrarize1159Aún no hay calificaciones

- Domestic Water Sizing CalculationDocumento5 páginasDomestic Water Sizing CalculationNghiaAún no hay calificaciones

- Tide Load 4 Z05Documento30 páginasTide Load 4 Z05NghiaAún no hay calificaciones

- Field Installation ChecklistDocumento7 páginasField Installation Checklistrize1159Aún no hay calificaciones

- Cooling LoadDocumento91 páginasCooling LoadPiyush PandeyAún no hay calificaciones

- Heat Loss Insulated PipeDocumento14 páginasHeat Loss Insulated PipeJonson CaoAún no hay calificaciones

- Cacl P 001Documento5 páginasCacl P 001rize1159100% (1)

- Avoiding Common Pitfalls in Cooling Tower Pump Intake DesignDocumento8 páginasAvoiding Common Pitfalls in Cooling Tower Pump Intake DesignMark ChongAún no hay calificaciones

- REFREG CHARGE CALCDocumento12 páginasREFREG CHARGE CALCKhadija MirajAún no hay calificaciones

- Cooling Tower LiquidGas (LG) RatioDocumento3 páginasCooling Tower LiquidGas (LG) Ratiorize1159Aún no hay calificaciones

- Triple Effect EvaporatorDocumento6 páginasTriple Effect EvaporatorPrashil Prakash Lakhete100% (4)

- Cooling Tower 1 PDFDocumento4 páginasCooling Tower 1 PDFrize1159Aún no hay calificaciones

- Data Sheet 31 - Fig Tp703 Flat Plate StrainerDocumento1 páginaData Sheet 31 - Fig Tp703 Flat Plate StrainerSteve NewmanAún no hay calificaciones

- Hindalco SpecificationDocumento15 páginasHindalco SpecificationRavi JainAún no hay calificaciones

- Design of RC StructuresDocumento1 páginaDesign of RC Structureskamalnitrr0% (3)

- Prensa Cables Armados Con Compound - 02Documento1 páginaPrensa Cables Armados Con Compound - 02Vipper80Aún no hay calificaciones

- AWS D1.1 WPS and PQR FormsDocumento4 páginasAWS D1.1 WPS and PQR FormsAdam Al AufaAún no hay calificaciones

- Inspection and Test Plan For Water Tube BoilerDocumento13 páginasInspection and Test Plan For Water Tube BoilerVinh Do Thanh100% (1)

- CHEMISTRYproject 2Documento16 páginasCHEMISTRYproject 209shasAún no hay calificaciones

- Fibreglass Boat Repair and Maintenance ManualDocumento91 páginasFibreglass Boat Repair and Maintenance ManualEric UrangaAún no hay calificaciones

- Vertikal Cement MillDocumento8 páginasVertikal Cement MillMohamad Taufik (abang topek)Aún no hay calificaciones

- BD 7-01 (Weathering Steel For Highway Structures)Documento20 páginasBD 7-01 (Weathering Steel For Highway Structures)djfeghaliAún no hay calificaciones

- BUTTING Pipeline Systems For The Pneumatic ConveyingDocumento16 páginasBUTTING Pipeline Systems For The Pneumatic ConveyingAleksandar KosticAún no hay calificaciones

- Annex 1slab DesingDocumento3 páginasAnnex 1slab DesingSurendra MaharjanAún no hay calificaciones

- Astm A178 A178m-02 PDFDocumento4 páginasAstm A178 A178m-02 PDFZaida Isadora Torres Vera100% (1)

- Cutback Bitumen MC 3000Documento2 páginasCutback Bitumen MC 3000muhirwa raymondAún no hay calificaciones

- Dilli Haat JanakpuriDocumento19 páginasDilli Haat JanakpuriApeksha Sethi81% (21)

- Rusting Is A Chemical Process ThatDocumento5 páginasRusting Is A Chemical Process ThatGopal GuptaAún no hay calificaciones

- BAR BENDING SCHEDULEDocumento26 páginasBAR BENDING SCHEDULESurendra MaharjanAún no hay calificaciones

- DR - Fixit Pidicrete - CF BRLDocumento1 páginaDR - Fixit Pidicrete - CF BRLnickdash09Aún no hay calificaciones

- Kreg Jig R3 Manual INT Mejor PDFDocumento67 páginasKreg Jig R3 Manual INT Mejor PDFSoy KinoAún no hay calificaciones

- 3818Documento9 páginas3818ssaurav89Aún no hay calificaciones

- FAR EAST POWER CABLE CO - XLPE Cable Systems Users Guide (Far East Cable...Documento16 páginasFAR EAST POWER CABLE CO - XLPE Cable Systems Users Guide (Far East Cable...César Díaz LiberonaAún no hay calificaciones

- BX 3 Data Sheet Technical Information ASSET DOC 8281172Documento11 páginasBX 3 Data Sheet Technical Information ASSET DOC 8281172Mohammed ElmakAún no hay calificaciones

- Influence of Mould Materials On Wear Behavior of A365 AlloyDocumento6 páginasInfluence of Mould Materials On Wear Behavior of A365 Alloyilyong hanAún no hay calificaciones

- A Curtain Wall System Is An Outer Covering of A Building in Which The Outer Walls Are NonDocumento23 páginasA Curtain Wall System Is An Outer Covering of A Building in Which The Outer Walls Are Nonbisrat meseretAún no hay calificaciones

- Course Outline For Reinforced Concrete IDocumento2 páginasCourse Outline For Reinforced Concrete ITefera TemesgenAún no hay calificaciones

- CRJGR Nrya DD S1.SSG Arc Asd 07860Documento1 páginaCRJGR Nrya DD S1.SSG Arc Asd 07860ihsanrahimAún no hay calificaciones

- Fundamentals of Manufacturing and Process Report (Group - 4)Documento6 páginasFundamentals of Manufacturing and Process Report (Group - 4)Lovely VisakhaAún no hay calificaciones

- S04 BoomDocumento60 páginasS04 BoomJorsh GonzalesAún no hay calificaciones

- 23.1 Insulation of PipingDocumento21 páginas23.1 Insulation of PipingSaid SalemAún no hay calificaciones

- Gbtâ 3524-2015 enDocumento11 páginasGbtâ 3524-2015 enMohanrajMJAún no hay calificaciones