Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Prueba Corrosiva

Cargado por

juan perez0 calificaciones0% encontró este documento útil (0 votos)

8 vistas11 páginasPrueba para realizar practica de corrocion

Título original

Prueba corrosiva

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoPrueba para realizar practica de corrocion

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

8 vistas11 páginasPrueba Corrosiva

Cargado por

juan perezPrueba para realizar practica de corrocion

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

Está en la página 1de 11

Designation: B 117-03

Standard Practice for

Operating Salt Spray (Fog) Apparatus*

This send is sued under te Sued dasigation B 117; the number immediately following the designation indicates the year of

cxignaladptce or ia he case of revision the year of las revision. Anumber in pucrthese indies te year of ast reapproval.A

Sinemet’ epilon (e) indsstes edna change since the st revo reappr

Ws sured fas een apprve for use by agencte f the Deparment of Defense.

1. Beope

LL This practice covers the apparatus, procedure, and

conditions required to create and maintain the salt spray (fog)

test environment. Suitable apparatus which may be used is

described in Appendix X1

1.2 ‘This practice does not prescribe the type of test speci-

men or expostire periods to be used for a specific product, nor

the interpretation to be given fo the results

1.3 The values stated in SI units are to be regarded as

standard. The inch-pound units in parentheses are provided for

information and may be approximate.

14 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard 10 establish appro

priate safety and health practices and determine the applica

bility of regulatory limitations. prior 10 nce

2, Referenced Documents

2.1 ASTM Standards:

B 368 Method for Copper-Accelerated Acetic Acid-Salt

Spray (Fog) Testing (CASS Test)?

D609 Practice for Preparation of Cold-Rolled Steel Panels,

for Testing Paint, Varnish, Conversion Coatings, and

Related Coating Products?

D 1193 Specification for Reagent Water*

D 1654 ‘Test Method for Evaluation of Painted or Coated

Specimens Subjected to Corrosive Environments?

E70 Test Method for pH of Aqueous Solutions with the

Glass Plectrodes

E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Methox!®

practic c under the justin of ASTM Commitee GD en Coosion

of Metals nd is the direct msponsbiliy of Subcommites GDS on Labortory

Conosion Tex

‘Curent een approved Octobe

“proved i 1959, ase previo eon apprave #2002 9 8 1

‘rm Hoo! of ASTM Standen, Vo O28.

> Aveual Book of ASTM Standards, Vo 05.0.

Yoi 1108

oi 1505,

Anan! Moot of ASTM Standen, Vol 1442

1, 2003, Pubtisied October 2003. Originally

ne

G85 Practice for Modified Salt Spray (Fog) Testing”

3. Significance and Use

3.1 This practice provides a controlled cocrosive enviton-

ment which has been utilized to produce relative corrosion

resistance information for specimens of metals and coated

metals exposed in a given test chamber.

3.2 Prediction of performance in natural environments has

seldom been correlated with salt spray results when used as

stand alone data

3.2.1 Comelation and extrapolation of corrosion perfor-

mance based on exposure to the test environment provided by

this practice are not always predictable.

3.2.2 Comelation und extrupolation should be considered

‘only in eases where appropriate corroborating long-term atmo-

spheric exposures have been conducted.

3.3 The reproducibility of results in the salt spray exposure

is highly dependent on the type of specimens tested and the

evaluation criteria selected, as well as the control of the

operating variables. In any testing program, sulficient repli-

cates should be included to establish the variability of the

results. Variability has been observed when similar specimens

are tested in different fog chambers even though the testing

conditions are nominally similar and within the ranges speci.

fied in this practice

4. Apparatus

4.1 The apparatus required for salt spray (fog) exposure

consists of a fog chamber, a salt solution reservoir, supply af

suitably conditioned compressed air, one or more atomizing

nozzles, specimen supports, provision for heating the chamber.

and necessary means of control. ‘The size and detailed con-

struction of the apparatus are optional, provided the conditions

obtained meet the requirements of this practice,

4.2 Drops of solution whieh accumulate on the ceiling or

cover of the chamber shall not be permitted to fall on the

specimens being exposed.

* aman Hoot of ASEM Standards, Vo! OBC

4.3. Drops of solution which fall from the specimens shall

not be returned to the solution reservoir for respraying.

44 Material of construction shall be such that it will not

affect the cocrosiveness of the fog

4.5 All water used for this practice shall conform to Type IV

water in Specification D 1193 (except that for this practice

limits for chlorides and sodium may be ignored). This does not

apply to running tap water. All other water will be referred to

as reagent grade.

5. Test Specimens

5.1 The type and number of test specimens to be used, as

well as the eriteria for the evaluation of the test results, shall be

defined in the specifications covering the material or product

being exposed or shall be mutually agreed upon between the

purchaser and the seller.

6, Preparation of Test Specimens

6.1 Specimens shall be suitably cleaned, The cleaning

method shall be optional depending on the nature of the surface

and the contaminants, Care shall be taken that specimens are

not recontaminated after ch by excessive or careless

6.2 Specimens for the evaluation of paints and other organic

coatings shall be prepared in accorckince with applicable

specification(s) for the material(s) being exposed, or as agreed

uupon between the purchaser and the supplier. Otherwise. the

test specimens shall consist of steel meeting the requirements

‘of Practice D 609 and shall be cleaned and prepared for coating

in accordance with the applicable procedure of Practice D 608,

63 Specimens coated with paints or nonmetall

shall not be cleaned or handled excessively prior to test

(64 Whenever itis desired to determine the development of

corrosion from an abraded area in the paint or organic coating,

scratch or scribed line shall be made through the coating with

‘a sharp instrument so as to expose the underlying metal before

testing. The conditions of making the seratch shall be as

defined in Test Method D 1654, unless otherwise agreed upon

beoween the purchaser and the seller.

6.5 Unless otherwise specified, the cut edges of plated,

coated, or duplex materials and areas containing identification

marks or in contact with the nicks or supports shall be

protected with a suitable coating stable under the conditions of

the practice

[Nor 1 Should ithe desirable to cut est spacimans from parts or from

preplaied, painted, or otherwise coated stel sheet, the cut edges shall be

protcied by coating them with pant, wax, wpe, or other effective media

so thatthe development of a galvanic effect between such edges and the

adjacent plated or otberse coated metal surface, i prevented.

7. Position of Specimens During Exposure

7.1 The position of the specimens in the salt spray chamber

during the test shall be such that the following conditions are

met:

7.1.1 Unless otherwise specified, the specimens shall be

supported or suspended between 15 und 30° from the vertical

and preferably parallel to the principal direction of flow of fog

through the chamber, based upon the dominant surface being,

tested,

7.1.2. The specimens shall not contact each other or any

‘metallic material or any material capable of acting as a wick.

7.1.3 Each specimen shall be placed to permit unencum

bered exposure to the fog.

7.1.4 Salt solution from one specimen shall not drip on any

other specimen,

Norz 2—Suitable materials Fr the construction or coating of rocks and

supports are glass, rubber, plastic, or suitably cowed wood. Bare metal

Shall not he used. Specimens shall proferanly he supported from the

bbotiom or the side. Slotted wooden strips are suitable forthe suppoct of at

‘panes, Suspensioa from glass hooks or waked string may be used 88 long

as the specified position of the specimons is obusincd, if necessary by

‘means of secondary suppom at ibe bouom of the specimens

8, Salt Solution

8.1 ‘The salt solution shall be prepared by dissolving $ + 1

parts by mass of sodium chloride in 95 parts of water

conforming to Type IV water in Specification D 1193 (except

that for this practice limits for chlorides and sodium may be

nored). Careful attention should be given to the chemical

content of the salt. The salt used shall be sodium chloride with

not more than 0.3 % by mass of total impurities. Halides

(Bromide, Fluoride, and [odide) other than Chloride shall

constitute less than 0.1 % by mass of the salt content. Copper

content shall be less than 0.3 ppm by mass. Sodium chloride

containing anti-caking agents shall not be used because such

agents may act as comosion inhibitors. See Table | for a listing

Of these impurity restrictions. Upon agreement between the

purchaser and the seller, analysis may be required

established for elements or compounds not spe

chemical composition ziven abave.

TABLE 1 Maximum Allowable Limits for Impurity Levels in

‘Sodium Chloride*®

Tnpurty Description ‘Alewable Anount

Told irearios = 09%

ales Gxomice, Foie and lnsce) exuding Chioide 01s

Corner -<03 pom

riveaking Ages 0%

common formula used fo alse the amour of sal rare by mass 1

‘achieve 48% eal aolion of knanm maze cf water i

(053 X tao of Water ~ Mase of Na roqured

‘Tromaa of natria | gpori mL To calcula tre mage of ea reuied in game

{omic 1 Lof a 5% sal scion, musty 059 by 1000 g (2527 ox. the mass of

4 Lf wae) Thi formula yields 9 recut of 691.07 C2) of NaC rogues for

‘cach Het of water fo achieve a8 Ss sal soon oy mass

‘The 0.69 mulpler for the sodium chlonde Wied above is defver bythe

tooving

10009 Inass of aut Lot watar ales by 085

(wate only 5% of fe toe mitre by MASS! Yes 1083 9

‘Tris 1053 gf Fetal mass ce mode of one of WAL Wen a 5% soaum

Cende soncerttation 1053 g minus se orginal weight the Lot water, 1000 9

Yyelde BS 9 fo the weight ofthe sod eflonde. 66 go! total sadurn cor

Gided fy "pe rig 1000 g et water yet a (L063 muller fer Be sccm

snore,

‘Az example ithe aquvalen f 2001 (5269 gall ot: e0dum chico

‘scluten mix 106 ig @3.7 B) of soslum chore ro 200 L (52.53 gal) of water

£200 Let water weighs 200,000 p. 200.000 9 of water» 059 (sosurn clorce

inulin = 10,600 93 sodium corde or 106

* Inower tnensure tale prope sallcanceiraon nas achieved wen ino

the sotdon, tis fecarrmended thal te solution be checked wih ether asaleter

nyeromeerersomctleravry ydroneter nen usrga saimeternyaromeser he

measurement snous be ween # ane % at 25° (71°F) When ing asbecC

(amy nyormets, te measurement SOuE Be Between 1.0255 ar 1 GA00 at

2ecure)

8.2 The pH of the salt solution shall be such that when

atomized at 35°C (95°F) the collected solution will be in the

pH range from 65 to 7.2 (Note 3). Before the solution is

atomized it shall be free of suspended solids (Note 4). The pH

measurement shall be made at 25°C (77°F) using. a suitable

glass pH¥-sensing electrode, reference electrode, and pH meter

system in accordance with ‘Test Method E 70.

Nove 3—Tempersture affects the pH of a salt solution prepared from

water setarated with entbon dioxide at wom Yemnpestare ad pH adjus

rmant may be made by the fellowing thrce methods

(2) When the pli of a sat solution is adjusted at room temperature, apa

atomized st 35°C (95°F), the pH of the collected sation will be higner

than the original solution dae tothe loss of carbon dioxide at the higher

vemperaure. When the pH of abe salt scluioa is adjusied at room

temperature ts tnretore pacossary to adjust it Below 6.5 so the collacied

solution after atomizing at 35°C (95°F) will meet the pH limits of 65 to

7.2, Fake ahout a 50-miL sample of the salt solution as prepared a room

temperature, beil genlly for 30s, cool, and determine the pH. Wher the

DDH of the salt solution is adjusted w 6.5 o 7.2 by this procedure, tbe pH

ff the atomized! and collected colon at 35°C (95°F) will come within

this range.

(@) Heating de salt solution wo boiling and cooling 10 35°C (85°F) and

maintaining i a 25°C (05°F) for approximataly 48 h before adjusting the

‘pH produces a solution the pli of which does no! materially change when

Blomized st 35°C (05°F),

(@) Hating the water from which the sat solution is propared to 35°C

(05°F or shone, 1 expel carbon dioxide, and adjusting the pH of the sal

solution within the limits of 6.5 to 7.2 produces a solution tae pH of which

does not mateially change when atomized at 35°C (95°F),

‘Nore 4-—The freshly prepared salt solution may be filtered or decanted

before it s placed inthe reserve, or the end of the tube leading from the

solution tthe atomizer my be covered wih a double ayer of cheesecloth

to prevent plagging of the nozzle.

Noe 5—The pH can be adjusted by additions of dilue ACS reagent

trade hydivehlori acid or stam hycroide setations.

9. Air Supply

9.1 ‘The compressed air supply to the Air Saturator Tower

shall be free of grease, oil, and dirt before use by passing

through well-maintained filters. (Note 6) This air should be

maintained at a sufficient pressure at the base of the Air

Saturator Tower to meet the suggested pressures of Table 2 at

the top of the Air Saturator Tower.

Now 6—The aie supply may be fed ftom oll and dit by passing It

Urough a suitable oilAsator extractor (that is commercially evaiablo) to

stop any oil from reaching the Air Saurator Tower. Many oiliwater

extractors have an expitstion indlestor, proper preventive maintenance

iervals should take these i

9.2 The compressed air supply to the atomizer nozzle or

nnozrles shall be conditioned by introducing it into the bottom

of a tower filled with water. A common method of introduc-

ing the air is through an air dispersion device (X1.4.1). The

level of the water must be maintained automatically to ensure

adequate humidification. tis common practice to maintain the

temperature in this tower between 46 and 49°C (114—121°F) to

offset the cooling effect of expansion to atmospheric pressure

during the atomization process, Table 2 in 0.3 of this practice

shows the temperature, at different pressures, that are com-

monly used to offset the cooling effect of expansion to

atmospheric pressure.

9.3 Careful attention should be given to the relationship of

tower temperature to pressure since this relationship can have

a direct impact to maintaining proper collection rates (Note 7).

Itis preferable to saturate the air at temperatures well above the

chamber temperature as insurance of a wet fog as listed in

‘Table 2,

‘TABLE 2 Suggested Temperature and Pressure guideline for the

top of the Air Saturator Tower for the operation of a test at 25°C

(95°F)

AlPieswuie KPa Temperaure °C Al Presule, PSI Teripeaute

8 “6 @ 1s

se a 1 Ww

nD a 6 1

4 Po 8 vy

Nore 7—If the tower is run ouside of these suggested temperature and

pressure ranges 1 acteve proper collection rates as described in 1022 of

thie practice, other means of verilying the proper corrosion rate in the

chamber should be investigated. such as the use of control specimens

{panels of Known performance inthe test conducted), Its preferred that

contro] panels be provided tha: brackot the expected test specimen

performance. The controls allow forthe uomnalization af ws conditions

daring repeated running of te text and will also allow compansons of test,

sesalts fom different repeats of the same test. (Refer to Appendix X3,

Evaluation of Comosive Condisons. fr mass loss procedures.

10, Conditions in the Salt Spray Chamber

10.1 Temperature—The exposure zone of the salt spray

chamber shall be maintained at 35+ 1.1 —1.7°C

(95 +2~3°F), Buch set point and its tolerance represents an

‘operational control point for equilibrium conditions at a single

location in the cabinet which may not necessarily represent the

uniformity of conditions throughout the cabinet. The tempera-

ture within the exposure zone of the closed cabinet shall be

recorded (Note 8) at least twice a day ut least 7h apart (except

‘on Saturdays, Sundays, and holidays when the salt spray test is

ot interrupted for exposing, rearranging, or removing test

specimens or to check and replenish the solution in the

reservoir)

Norz 8A suitable method to record the temperate is by a continu

‘os reconting device ar hy 2 thermometer which can be rea! fom autige

the closed cabinet. The recorded temperature must be obtained withthe

salt spray chamber closed 19 avoid a false low reading because of wet-balh

clfect when the chamber is open,

10.2 Atomization and Quantity of Fog—Place at least 1w0

clean fog collectors per atomizer tower within the exposure

zone so that no drops of solution will be collected from the test

specimens or any other source. Position the collectors in the

‘proximity of the test specimens, one nearest to any nozzle and

the other farthest from all nozzles. A typical ansingement is,

shown in Fig. 1. The fog shall be such that for each 80

em (12.4 in) of horizontal collecting area, there will be

collected from 1.0 to 2.0 mL. of solution per hour based on an

average run of at least 16 h (Note 8). The sodium chloride

‘concentration of the collected solution shall be 5 = 1 mass %

(Notes 9-11), The pH of the collected solution shall be 6.5 to

7.2. The pH measurement shall be made as described in 8.2

(Note 3),

Nore 9—Suitable collecting devices are glass or plitic Funnels with

También podría gustarte

- Tipos de Laboratorios MetrologiaDocumento7 páginasTipos de Laboratorios Metrologiajuan perezAún no hay calificaciones

- Materiales de Uso AeronauticoDocumento162 páginasMateriales de Uso Aeronauticoveroni-k-andrea98% (40)

- Metodologia Formulas NACA 4 DigitosDocumento10 páginasMetodologia Formulas NACA 4 Digitosjuan perez100% (1)

- Nuevo Ceramico de Uso AeronauticoDocumento21 páginasNuevo Ceramico de Uso Aeronauticojuan perezAún no hay calificaciones

- Glosario de MaquinasDocumento1 páginaGlosario de Maquinasjuan perezAún no hay calificaciones

- Materiales de Uso AeronauticoDocumento162 páginasMateriales de Uso Aeronauticoveroni-k-andrea98% (40)

- Glosario de MaquinasDocumento1 páginaGlosario de Maquinasjuan perezAún no hay calificaciones

- Core ToolsDocumento23 páginasCore Toolsjuan perezAún no hay calificaciones

- Ejemplo de Control de Información Documentada de Diseño y Producción de Motor Trent 1000Documento13 páginasEjemplo de Control de Información Documentada de Diseño y Producción de Motor Trent 1000juan perezAún no hay calificaciones

- PROYECTODocumento34 páginasPROYECTOjuan perezAún no hay calificaciones

- El Hombre en Busca Del Sentido ReseñaDocumento3 páginasEl Hombre en Busca Del Sentido Reseñajuan perezAún no hay calificaciones

- Procesos de FundicionDocumento10 páginasProcesos de Fundicionjuan perezAún no hay calificaciones

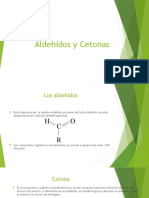

- Aldehídos y CetonasDocumento11 páginasAldehídos y Cetonasjuan perezAún no hay calificaciones

- Codigo de EticaDocumento2 páginasCodigo de Eticajuan perezAún no hay calificaciones

- Proyecto 1erDocumento1 páginaProyecto 1erjuan perezAún no hay calificaciones