Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Aluminum Wires and Rods 1

Cargado por

Oteranmorales0 calificaciones0% encontró este documento útil (0 votos)

38 vistas2 páginaswires rods

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF, TXT o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentowires rods

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

38 vistas2 páginasAluminum Wires and Rods 1

Cargado por

Oteranmoraleswires rods

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

Está en la página 1de 2

MATERIAL SAFETY DATA SHEET MAGNA WELDING ALLOYS

FILLER METALS AND WELDING ROD MAGNA INDUSTRIAL CO. LIMITED

"Essentially Similar" to U.S. Department 18/F., GUARDIAN HOUSE, HONG KONG.

of Labor TEL:(852) 2577 5187

Form OSHA 20. FAX:(852) 2577 3190

IDENTITY(As Used on Label and List) LAST ASSESSED: 18/08/2009

Magna 303 T.I.G.

SECTION I - HAZARDOUS INGREDIENTS / IDENTITY INFORMATION

Hazardous Ingredients CAS NO. TLV Hazard

Iron 7439-89-6 5mg/m3(as Fe2O3) Fume

Chromium 7440-47-3 0.5mg/m3 (Metal) Fume

Nickel 7440-02-0 1mg/m3(Metal) Fume

Manganese 7439-96-5 1mg/m3 Fume

SECTION II - PHYSICAL DATA

N.A.

SECTION III - FIRE AND EXPLOSION HAZARD DATA

Welding arc and sparks can ignite combustibles and flammables. Refer to American

National Standard Z49.1 for fire prevention during the use of welding and allied

procedures.

SECTION IV - REACTIVITY DATA

HAZARDOUS DECOMPOSITION PRODUCTS:

Welding fumes cannot be classified simply. The composition and quantity of both

are dependent upon the metal being welded, the process, procedures and

electrodes used. Other conditions which also influence the composition and

quantity of the fumes and gases to which workers may be exposed include:

coatings on the metal being welded (such as paint, plating, or galvanizing),

number of welds and volume of work area, quality and amount of ventilation,

position of welder's head with respect to the fume plume, as well as the

presence of contaminants in the atmosphere (such as chlorinated hydrocarbon

vapors from cleaning and degreasing activities).

When the electrode is consumed, the fume and gas decomposition products are

different in percent and form from the ingredients listed in Section I. Fume and

gas decomposition products, not the ingredients in the electrode, are important.

Decomposition products include those originating from the volatilization,

reaction, or oxidation of the materials shown in Section I plus those from base

metal, coating, etc. as noted above. These components are virtually always

present as complex compounds and not as metals (Characterization of Arc Welding

Fume: American Welding Society).

Reasonably expected decomposition products from normal use of this product

includes a complex of the oxides of the materials listed in Section I.3 The

present OSHA permissible exposure limit for hexavalent chromium is 0.05mg/m and

for nickel is 1mg/m3, which will result in a significant reduction from the

5mg/m3 general fumes level. Gaseous reaction products may include carbon

monoxide and carbon dioxide. Ozone and nitrogen oxides may be formed by the

radiation from the arc.

One recommended way to determine the composition and quantity of fumes and gases

to which workers are exposed is to take an air sample inside the welders helmet,

if worn, or in the worker's breathing zone. ANSI/AWS F1.1, available from the

American Welding Society, P.O. Box 351040, Miami, FL 33135.

SECTION V - HEALTH HAZARD DATA

Threshold Limit Value:

The ACGIH recommended general limit for welding fume NOC (Not Otherwise

Classified) is 5 mg/m3. The ACGIH 1984-85 preface states: "The TLV-TWA should be

Magna 303 T.I.G. Page 1

used as guides in the control of health hazards and should not be used as firm

lines between safe and dangerous concentrations." See Section IV for specific

fume constituents which may modify this TLV.

Effects of Overexposure:

FUMES AND GASES can be dangerous to your health. SHORT-TERM (ACUTE) OVEREXPOSURE

to welding fumes may result in discomfort such as: dizziness, nausea, or dryness

or irritation of nose, throat, or eyes. LONG TERM (CHRONIC) OVEREXPOSURE may

cause lung fibrosis or pneumoconiosis and is believed by some investigators to

affect pulmonary function. ARC RAYS can injure eyes and burn skin. ELECTRIC

SHOCK can kill. See Section VI.

Emergency & First Aid Procedures:

Call for medical aid. Employ first aid techniques recommended by the American Red

Cross.

Carcinogenicity

OSHA regulated: Chromium, Nickcl

SECTION VI - PRECAUTIONS FOR SAFE HANDLING AND USE/APPLICABLE CONTROL MEASURES

Read and understand the manufacturer's instructions and the precautionary label

on this product. See American National Standard Z-49.1, Safety in Welding and

Cutting, published by the American Welding Society, P.O. Box 351040, Miami, FL

33135 and OSHA Publication 2206 (29 C.F.R. 1910), U.S. Government Printing

Office, Washington, D.C. 20402 for more details on many of the following:

Ventilation:

Use enough ventilation, local exhaust at the arc, or both, to keep the fumes and

gases below the TLV's in the worker's breathing zone and the general area. Train

the welder to keep his head out of the fumes.

Respiratory Protection:

Use respirable fume respirator or air supplies respirator when welding in

confined space or where local exhaust or ventilation does not keep exposure

below TLV.

Eye Protection:

Wear helmet or use face shield with filter lens. As a rule of thumb, start with

a shade which is too dark to see the weld zone. Then go to the next lighter

shade which gives sufficient view of the weld zone. Provide protective screens

and flash goggles, if necessary, to shield others.

Protective Clothing:

Wear head, hand and body protection which help to prevent injury from radiation,

sparks and electrical shock. See ANSI Z-49.1. At a minimum, this includes

welder's gloves and protective face shield and may include arm protectors,

aprons, hats, shoulder protection, as well as dark substantial clothing. Train

the welder not to touch live electrical parts and to insulate himself from work

and ground.

Procedure for Cleanup of Spills or Leaks:

Not applicable.

Waste Disposal Method:

Prevent waste from contaminating surrounding environment. Discard any product,

residue, disposable container, or liner in an environmentally acceptable manner,

in full compliance with Federal, State and Local regulations.

Notes: We believe the statements, technical information and recommendations contained

herein are reliable, but they are given without warranty or guarantee of any

kind, express or implied, and we assume no responsibility for any loss, damage,

or expense, direct or consequential, arising out of their use.

Magna 303 T.I.G. Page 2

También podría gustarte

- La 71 MSDSDocumento2 páginasLa 71 MSDSdeepak2803Aún no hay calificaciones

- Material Safety Data Sheet (MSDS) : Msds No: Aluminum Electrode REVISED 12-2009Documento2 páginasMaterial Safety Data Sheet (MSDS) : Msds No: Aluminum Electrode REVISED 12-2009Rama Krishna Reddy DonthireddyAún no hay calificaciones

- S 800wtxm 12k Msds EngDocumento2 páginasS 800wtxm 12k Msds Eng이상훈Aún no hay calificaciones

- Material Safety Data Sheet (MSDS)Documento2 páginasMaterial Safety Data Sheet (MSDS)Heri SusantoAún no hay calificaciones

- MSDS NiCrDocumento2 páginasMSDS NiCrBety FajriaAún no hay calificaciones

- MSDS Tungsten Electrode Safety DataDocumento2 páginasMSDS Tungsten Electrode Safety DataSerkan ApayAún no hay calificaciones

- M - ENG - MSDS v1.2Documento157 páginasM - ENG - MSDS v1.2sunthron somchaiAún no hay calificaciones

- Material Safety Data Sheet: I. Product IdentificationDocumento2 páginasMaterial Safety Data Sheet: I. Product IdentificationElMacheteDelHuesoAún no hay calificaciones

- Aluminum Msds 8-05Documento3 páginasAluminum Msds 8-05mohamed AdelAún no hay calificaciones

- Material Safety Data Sheet: Section I - IdentificationDocumento2 páginasMaterial Safety Data Sheet: Section I - IdentificationluisarmandomayonietoAún no hay calificaciones

- 51 EX Msds 9-07Documento3 páginas51 EX Msds 9-07Mohamed AdelAún no hay calificaciones

- Rci RodDocumento2 páginasRci Rodabdul rochimAún no hay calificaciones

- M S D S: Aterial Afety ATA HeetDocumento4 páginasM S D S: Aterial Afety ATA HeetJhony MedranoAún no hay calificaciones

- Heat Fence Inorganic MineralsDocumento3 páginasHeat Fence Inorganic MineralsmeAún no hay calificaciones

- Material Safety Data SheetsDocumento5 páginasMaterial Safety Data SheetsSuryanarayanan VenkataramananAún no hay calificaciones

- 360, 370, 380 Brazing Rod MG MSDS 6-09Documento3 páginas360, 370, 380 Brazing Rod MG MSDS 6-09orcbane27Aún no hay calificaciones

- MSDS for US Forge E 6010 Covered ElectrodeDocumento3 páginasMSDS for US Forge E 6010 Covered Electrodemohamed AdelAún no hay calificaciones

- Lincoln 5P+ MsdsDocumento2 páginasLincoln 5P+ MsdssalcabesAún no hay calificaciones

- In-W610 (Merit LMC 6 - Er70s-6) - 1Documento2 páginasIn-W610 (Merit LMC 6 - Er70s-6) - 1Pratik LadAún no hay calificaciones

- M S D S: Aterial Afety ATA HeetDocumento4 páginasM S D S: Aterial Afety ATA HeetJhony MedranoAún no hay calificaciones

- Safely weld alloys with MSDSDocumento2 páginasSafely weld alloys with MSDSElMacheteDelHuesoAún no hay calificaciones

- MsdsDocumento3 páginasMsdsTobi MazzoccaAún no hay calificaciones

- MSDS METAL CORED WIREDocumento2 páginasMSDS METAL CORED WIREElMacheteDelHuesoAún no hay calificaciones

- 62super Ti Se en 0Documento4 páginas62super Ti Se en 0Jhony MedranoAún no hay calificaciones

- ZULFI E6013 Welding ElectrodesDocumento1 páginaZULFI E6013 Welding ElectrodesJunard M. Lu HapAún no hay calificaciones

- I. Product Identification: Material Safety Data SheetDocumento5 páginasI. Product Identification: Material Safety Data SheetSteel BridgeAún no hay calificaciones

- 103 Solution EC Msds 5-08Documento3 páginas103 Solution EC Msds 5-08Brian HernandezAún no hay calificaciones

- Material Safety Data Sheet: Emergency Phone Number: 1-866-272-4378Documento1 páginaMaterial Safety Data Sheet: Emergency Phone Number: 1-866-272-4378So MayeAún no hay calificaciones

- Flux Core Welding WireDocumento3 páginasFlux Core Welding Wiremuhamad bukhari abu hassanAún no hay calificaciones

- 32 EX Msds 9-07Documento3 páginas32 EX Msds 9-07Mohamed AdelAún no hay calificaciones

- Material Safety Data Sheet Material Safety Data Sheet: Section I - IdentificationDocumento2 páginasMaterial Safety Data Sheet Material Safety Data Sheet: Section I - IdentificationAdel AbduoAún no hay calificaciones

- Material Safety Data Sheet: I. Product IdentificationDocumento2 páginasMaterial Safety Data Sheet: I. Product Identificationmohamed AdelAún no hay calificaciones

- 1 TufTrak EC SMAW Msds 2-10Documento3 páginas1 TufTrak EC SMAW Msds 2-10mohamed AdelAún no hay calificaciones

- Material Safety Data Sheet: I. Product IdentificationDocumento2 páginasMaterial Safety Data Sheet: I. Product IdentificationElMacheteDelHuesoAún no hay calificaciones

- Material Safety Data Sheet: What Is The Material and What Do I Need To Know in An Emergency?Documento9 páginasMaterial Safety Data Sheet: What Is The Material and What Do I Need To Know in An Emergency?haharameshAún no hay calificaciones

- Material Safety Data Sheet: I. Product IdentificationDocumento2 páginasMaterial Safety Data Sheet: I. Product IdentificationElMacheteDelHuesoAún no hay calificaciones

- Mild Steel Solid Mig Wire MSDSDocumento2 páginasMild Steel Solid Mig Wire MSDSsalcabesAún no hay calificaciones

- 4 ESAB Solid Wires Nov 06Documento84 páginas4 ESAB Solid Wires Nov 06ananth84Aún no hay calificaciones

- Material Safety Data Sheet: I. Product IdentificationDocumento2 páginasMaterial Safety Data Sheet: I. Product IdentificationElMacheteDelHuesoAún no hay calificaciones

- MSDS AlloysDocumento15 páginasMSDS AlloysMaryam EradewiAún no hay calificaciones

- Material Safety Data Sheet: Section 1 - IdentificationDocumento4 páginasMaterial Safety Data Sheet: Section 1 - IdentificationAmjad MehmoodAún no hay calificaciones

- Material Safety Data Sheet: I. Product IdentificationDocumento2 páginasMaterial Safety Data Sheet: I. Product IdentificationadityadhAún no hay calificaciones

- MSDS Er70s 6Documento1 páginaMSDS Er70s 6RosyidiMuhammadMahfudzAún no hay calificaciones

- 4 EC SMAW Msds 5-08Documento4 páginas4 EC SMAW Msds 5-08Mohamed AdelAún no hay calificaciones

- Safety Data Sheet: 1. Product and Company IdentificationDocumento4 páginasSafety Data Sheet: 1. Product and Company Identificationmohamed AdelAún no hay calificaciones

- Msds Product Name: Aws E7018 Welding ElectrodeDocumento2 páginasMsds Product Name: Aws E7018 Welding ElectrodeAdel AbduoAún no hay calificaciones

- ARCAIR (MSDS) COPPERCLAD POINTED ELECTRODES Expires 16-07-02Documento3 páginasARCAIR (MSDS) COPPERCLAD POINTED ELECTRODES Expires 16-07-02PubcrawlAún no hay calificaciones

- Material Safety Data Sheet: Gouging Carbon ElectrodesDocumento5 páginasMaterial Safety Data Sheet: Gouging Carbon Electrodesranesh rajanAún no hay calificaciones

- Material Safety Data Sheet: I. Product IdentificationDocumento2 páginasMaterial Safety Data Sheet: I. Product Identificationmohamed AdelAún no hay calificaciones

- US Army Welding Operations IIDocumento80 páginasUS Army Welding Operations IISpace_HulkerAún no hay calificaciones

- Nickel Base Welding Wire MSDS Provides Health and Safety InformationDocumento7 páginasNickel Base Welding Wire MSDS Provides Health and Safety InformationLawrence Lancy LoboAún no hay calificaciones

- Safety Data Sheet (MSDS CHT711 2023.1.1) (CHT711 JT-71T1-) From Atlantic 20231228Documento5 páginasSafety Data Sheet (MSDS CHT711 2023.1.1) (CHT711 JT-71T1-) From Atlantic 20231228sergio.lopezAún no hay calificaciones

- Bezpečnostní List S-717 - EngDocumento8 páginasBezpečnostní List S-717 - Engz9zsbwnnfvAún no hay calificaciones

- Safety Data Sheet: 1. Chemical Product and Company IdentificationDocumento7 páginasSafety Data Sheet: 1. Chemical Product and Company IdentificationKyi HanAún no hay calificaciones

- MSDS For G490HM (KMWT) R01Documento7 páginasMSDS For G490HM (KMWT) R01Zvonimir OzanAún no hay calificaciones

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesDe EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesAún no hay calificaciones

- Handbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesDe EverandHandbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesCalificación: 5 de 5 estrellas5/5 (2)

- Occupational Radiation Protection in the Uranium Mining and Processing IndustryDe EverandOccupational Radiation Protection in the Uranium Mining and Processing IndustryAún no hay calificaciones

- Dust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesDe EverandDust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesAún no hay calificaciones

- Friction Stir Welding of 2XXX Aluminum Alloys including Al-Li AlloysDe EverandFriction Stir Welding of 2XXX Aluminum Alloys including Al-Li AlloysAún no hay calificaciones

- Chapter-2 MDID PDFDocumento77 páginasChapter-2 MDID PDFOteranmoralesAún no hay calificaciones

- Aluminum Wires and Rods 1Documento10 páginasAluminum Wires and Rods 1OteranmoralesAún no hay calificaciones

- Aluminum Wires and Rods 1Documento10 páginasAluminum Wires and Rods 1OteranmoralesAún no hay calificaciones

- HAAS VF-HS Mill Programming Book 2005Documento143 páginasHAAS VF-HS Mill Programming Book 2005Robert HamiltonAún no hay calificaciones

- Piping Works Daily ReportDocumento21 páginasPiping Works Daily ReportGomathyselviAún no hay calificaciones

- Lesson 9Documento23 páginasLesson 9Huynh Thanh TamAún no hay calificaciones

- CF1900SS-DF Example Spec - Rev1Documento1 páginaCF1900SS-DF Example Spec - Rev1parsiti unnesAún no hay calificaciones

- Addition of Nitrogen To GTAW Welding Duplex Steel 2205 and Its Effect On Fatigue Strength and Corrosion (2017)Documento5 páginasAddition of Nitrogen To GTAW Welding Duplex Steel 2205 and Its Effect On Fatigue Strength and Corrosion (2017)Azizy ZidaneAún no hay calificaciones

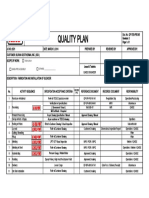

- JSW COB#3B and COB#4B Quality Assurance PlanDocumento1 páginaJSW COB#3B and COB#4B Quality Assurance PlanMd ArshadAún no hay calificaciones

- Thungsten ClassificationDocumento3 páginasThungsten ClassificationBoyan RadomirovAún no hay calificaciones

- Quality Plan for Fabrication and Installation of Silencer for Biliran Geothermal IncDocumento1 páginaQuality Plan for Fabrication and Installation of Silencer for Biliran Geothermal IncAldrin HernandezAún no hay calificaciones

- Using Welding Inspection ToolsDocumento9 páginasUsing Welding Inspection ToolsVinoth RajendraAún no hay calificaciones

- Esteem 27Documento3 páginasEsteem 27PremSagarJasujaAún no hay calificaciones

- EN 10210-1 Hot Finished Structure Hollow SectionDocumento26 páginasEN 10210-1 Hot Finished Structure Hollow Sectionlayth100% (2)

- Electroslag Welding..Documento25 páginasElectroslag Welding..Vicky SinghAún no hay calificaciones

- Ele426:Utilization and Traction: Course OutcomesDocumento1 páginaEle426:Utilization and Traction: Course OutcomesVinay PrakashAún no hay calificaciones

- GMCO FOR INDUSTRIAL SERVICES - Welding Procedure SpecificationsDocumento2 páginasGMCO FOR INDUSTRIAL SERVICES - Welding Procedure SpecificationsMohamedAún no hay calificaciones

- Welding and Joining ProcessesDocumento4 páginasWelding and Joining ProcessesImran AliAún no hay calificaciones

- Welding of Copper and Its AlloysDocumento30 páginasWelding of Copper and Its Alloysaj87_goswami100% (2)

- Welding - An Alternative To Sewing?Documento12 páginasWelding - An Alternative To Sewing?elisaAún no hay calificaciones

- Weld Repair Procedure For The Rear Axle A-Frame On 776 & 777 Off-Highway Trucks (0679, 3260, 3268)Documento25 páginasWeld Repair Procedure For The Rear Axle A-Frame On 776 & 777 Off-Highway Trucks (0679, 3260, 3268)Israel MirandaAún no hay calificaciones

- TransPocket 1500Documento6 páginasTransPocket 1500vcotofanaAún no hay calificaciones

- Fabrication Quality Dossier IndexDocumento22 páginasFabrication Quality Dossier IndexAli KayaAún no hay calificaciones

- Aws Eg2.0 - 2006 Guide For Training For Welding PersonnelDocumento161 páginasAws Eg2.0 - 2006 Guide For Training For Welding PersonnelRoberto SlataperAún no hay calificaciones

- Design of Cylindrical Tanks for Oil and Water StorageDocumento29 páginasDesign of Cylindrical Tanks for Oil and Water Storagejayaraman3Aún no hay calificaciones

- Ewf - Technical Sheet - Calculation of Preheat Temperature For Butt WeldsDocumento1 páginaEwf - Technical Sheet - Calculation of Preheat Temperature For Butt WeldsDries VandezandeAún no hay calificaciones

- Construction Solutions: Maximize Productivity. Optimize Weld Quality. Improve Your Bottom LineDocumento12 páginasConstruction Solutions: Maximize Productivity. Optimize Weld Quality. Improve Your Bottom LineAlberto LobonesAún no hay calificaciones

- Astm A928Documento8 páginasAstm A928Malcolm DowAún no hay calificaciones

- RIT INDORE GO KART CHAMPIONSHIP 2013 FINAL DESIGN REPORTDocumento14 páginasRIT INDORE GO KART CHAMPIONSHIP 2013 FINAL DESIGN REPORTShahmeer BalochAún no hay calificaciones

- Spanish Model III BrochureDocumento6 páginasSpanish Model III BrochureMaFher JimenezAún no hay calificaciones

- Handy Plasma 125: Plasma Arc Cutting Package - P/N 37884 115V 60HzDocumento24 páginasHandy Plasma 125: Plasma Arc Cutting Package - P/N 37884 115V 60Hzbouriahi hassaneAún no hay calificaciones

- EDO WMS Fuel Storage Tank R01Documento29 páginasEDO WMS Fuel Storage Tank R01ocayli100% (1)

- Polyurethane Lining and Coating Specification Penstock Welded Joints 20120327Documento12 páginasPolyurethane Lining and Coating Specification Penstock Welded Joints 20120327anbilselvamAún no hay calificaciones

- SVM178Documento278 páginasSVM178Jorge CarrascoAún no hay calificaciones