Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Adjustment PDF

Cargado por

ken0 calificaciones0% encontró este documento útil (0 votos)

22 vistas94 páginasTítulo original

ADJUSTMENT.pdf

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

22 vistas94 páginasAdjustment PDF

Cargado por

kenCopyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

Está en la página 1de 94

DMC:

DMC-I° ADJUSTMENT PROCEDURES

WARNING

The following procedures are intended for

the use of qualified and authorized

personnel ONLY. In the interest of your

personal safety and the safety of others,

do NOT attempt ANY procedure that you

are NOT qualified and authorized to

perform.

‘These Procedures must be done in accordance with the applicable rules

of the latest edition of the National Electrical Code, Article 620; the latest

edition of ASME A17.1, Safety Code for Elevators and any governing

local codes.

‘Alldrawings and information herein are the proprietary property of Dover

Elevator Systems, Inc. and are loaned subject to retum on demand and

‘must not be made public or copied, nor used, directly or indirectly, in any

‘manner detrimental to the interest of Dover Elevator Systems, Inc.

Every attempt has been made to ensure that this manual is as accurate

and up-to-date as possible. However, Dover Elevator Systems, Inc.

assumes no liability for consequences resulting from any error or

omission. The material contained herein is subjectto revision, and Dover

Elevator Systems, Inc., makes every effort to inform its product users of

these revisions as they occur. Please report any problems with this

‘manual to the Technical Operations Dept.

ADJUSTMENT

PLEASE CHECK THE CHANGE

INFORMATION SECTION OF

THIS MANUAL

(©DOVER ELEVATOR SYSTEMS, INC. 1992 aA Printed in USA December, 1994

ADJUSTMENT

INTRODUCTION

The DMC-I® ADJUSTMENT PROCEDURES are

divided into three sections: DMC-I®, DMC-I/M™, and

DMC-/A™

Pages are identified as follows:

Introductory Pages: Section Number (3), followed by

dash and a sequential capital letter as the page “num-

ber’. Example: 3-A.

DMC-I? ADJUSTMENT: Section Number (3) followed

by a dash and a sequential page number.

Example: 3-1.

DMC-I/M™ ADJUSTMENT: Section Number (3) fol-

lowed by an M (Modernization), a dash anda sequential

page number. Example: 3M-1.

DMC-V/A™ ADJUSTMENT: Section Number (3) fol-

lowed by an A, a dash and a sequential page number.

Example: 34-1.

and tables are identified in sequential order, that is,

Table 1...etc. If a new subsection begins (for example,

DMC-I/M™), numbering is started over.

‘Text Revisions are designated with a “Change Bar'—a

black mark in the left margin beside the revision. The

(©DOVER ELEVATOR SYSTEMS, INC. 1962

a8

mark will begin at the bottom of the line that precedes

the revised text and will end at the bottom of the last ine

of the revision. The “Change Bar” will be removed

should the page be revised again so that only the latest

revisions will be s0 marked.

Engineering changes occur between manual revi-

sions. Please check the CHANGE INFORMATION

Section for these changes. The ADJUSTMENT section

should be kept current by incorporating revisions as

they are received.

Each Procedure should be read carefully and com-

pletely before starting that Procedure. Special attention

should be given to all CAUTIONS and WARNINGS.

Refer to SAFETY SUMMARY for explanation. Proce-

‘dures should be followed in the order in which they are

written.

All Test Equipment, Supplies and Parts should be on

hand prior to starting the ADJUSTMENT Procedures.

‘These should be maintained in or near the machine

room for future use.

ALL Standard Safety Precautions should be followed

‘onthe job site. Refer to SAFETY SUMMARY for Safely

Precautions pertaining to DMC-I® equipment.

Printad in USA December, 1994

DMC:

ADJUSTMENT

CONTENTS

Preliminary Setup

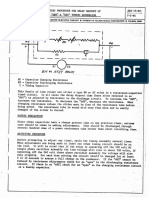

Power Unit Power Supply

‘Swing Return Power Supply Check ........

‘Swing Return MTA Connectors .......++++

Safety String Check Out .

IE -RPR And PLM Adjustment

Car Top Inspection Operation

‘Selector Mechanical Adjustments

Selector Magnet Placement .

Door Operator Mechanical Adjustments ....... 3-10

CLC Installation, Power-up And Check Out

‘Communications Test .

Rear Door Enable

3415

345

345

Hoistway Set-up . 316

Door Setup . 3417

‘Nudging Duty eee 3418

Final Door Adjustments... 319

+ Qpen Adjustments 319

+ Close Adjustments

+ Torque ..

+ Re-open Adjustment 2000...

+ High ‘Clamp Adjustment -

+ Save Door Adjustments . 5

Selector Slowdown Adjustments .

Valve Adjustments . oon

Floor Level Adjustment eee

Terminal Slowdown Switc fees B24

‘AC Overloads .. seeeees 925

Solid State Starters ....... sevens 325,

Operational Adjustments ........

Group Adjustments .

Option Testing .

pMc-ym™

Preliminary Set-up ......

Power Unit Power Supply Check .

Car Top Box Power Supply Check ......

Car Top Box MTA Connectors

Safety String Check Out...

IL RPR And PLM Adjustment ..

Car Top Inspection Operation

Selector Mechanical Adjustments ..

Selector Magnet Placement .

Door Operator Mechanical Adjustments .

HD-85 Door Operator

+ Re-Used Door ©;

+ All Operators.

CLC Power-up And Check

‘Communications Test .

(DOVER ELEVATOR SYSTEMS, INC. 1985, 1995

Rear Door Enable ..

Canadian B44 Code Enable .

Floor Validation .....1.00seseese

* Group Adjusiments

* Car Adjustments .

Hoistway Setup .

Door Set-up ....

Fast Device Connection .

Nudging Duty

Final Door Adjustments,»

. justments

+ Close Adjustments:

+ Torque ..

Re-open Adjustment ...-

High Speed Clamp Adjust

‘Save Door Adjustments .

Selector Slowdown Adjustments .

Valve Adjustments .

Floor Level Adjustment

Terminal Slowdown Switch Check

Operational Adjustments

AC Overloads ..

Solid State Starters .

Group Adjustments .

Option Testing .

DMCc-VA™

Preliminary Set-up

Power Unit Power Supply Check .

‘Swing Return Power Supply Check ...

‘Swing Retum MTA Connectors .......

Safety String Check Out.......cseecesenees SAM

RPR And PLM Adjustment ........00+. SAS

Car Top Inspection Operation ........+sce+e4 SAG

Door Operator Mechanical Adjustments .

CLC installation, Power-up And Check Out

‘Communications Test .

Canadian B44 Code Enable

Floor Validation

Door Set-up .

Nudging Duty

Final Door Adjustments.

djustments

+ Open

Shee Adustments

Torque Adjustment

ee-open Adjustment

+ High Speed clamp ad

+ Save Door Adjustments .

Valve Adjustments ..

Operational Adjustments ..

Group Adjustments .

Option Testing

Pintod in USA May, 1995

También podría gustarte

- 60 C1S7015DDocumento6 páginas60 C1S7015DkenAún no hay calificaciones

- Honda Generator ManualDocumento63 páginasHonda Generator ManualkenAún no hay calificaciones

- Unitec Parts Catalog Part Number Index With Page NumbersDocumento977 páginasUnitec Parts Catalog Part Number Index With Page NumberskenAún no hay calificaciones

- Syracuse University - Lyman HallDocumento27 páginasSyracuse University - Lyman HallkenAún no hay calificaciones

- Freedom ToolDocumento72 páginasFreedom ToolkenAún no hay calificaciones

- MCE IMC-SCRRevE8 42027200E PDFDocumento449 páginasMCE IMC-SCRRevE8 42027200E PDFken100% (1)

- Dover Dmc1-A 5-89 MasterDocumento46 páginasDover Dmc1-A 5-89 Masterken100% (1)

- Mitsubishi z300 ManualDocumento67 páginasMitsubishi z300 ManualkenAún no hay calificaciones

- MCE IMC-AC (Rel 4) ASME 2000 (42-02-2205 Rev C2) 2 PDFDocumento462 páginasMCE IMC-AC (Rel 4) ASME 2000 (42-02-2205 Rev C2) 2 PDFkenAún no hay calificaciones

- Dover I2i3 ValveDocumento62 páginasDover I2i3 Valveken100% (2)

- Dover Dmc1 MDocumento129 páginasDover Dmc1 Mken78% (9)

- Haughton Brake DataDocumento14 páginasHaughton Brake Dataken100% (1)

- Haughton Relay Adj GenlDocumento22 páginasHaughton Relay Adj GenlkenAún no hay calificaciones

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (121)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2104)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)