Documentos de Académico

Documentos de Profesional

Documentos de Cultura

M 110y

Cargado por

jawad0 calificaciones0% encontró este documento útil (0 votos)

120 vistas2 páginasLab apparatus manual

Título original

m-110y

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF, TXT o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoLab apparatus manual

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

120 vistas2 páginasM 110y

Cargado por

jawadLab apparatus manual

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

Está en la página 1de 2

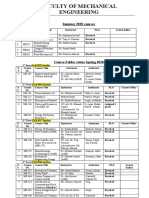

M-110Y Microfluidizer® Materials Processor TB-Y-3

High Pressure Laboratory Microfluidizer Processor

for High-Shear Fluid Processing

M-110Y Microfluidizer

Processor

Recommended for:

• Cell disruption

• Nanoemulsions

• Nanodispersions

• Submicron liposomes

• Submicron encapsulation

• Microcapsules

The M-110Y Microfluidizer processor

is a lab machine that provides the

highest shear rates of any competitive

processing equipment on the market

today, maximizing the energy-per-

unit fluid volume to produce uniform

submicron particle and droplet sizes. Model shown is subject to change depending on options selected

Process pressures range from 206- The M-110Y Microfluidizer processor

1586 bar (3,000-23,000 psi), enabling

the processing of a wide variety of for micro-mixing in the laboratory

products ranging from simple oil- • Unique wear-resistant ceramic or diamond (optional) fixed-

in-water emulsions to high-weight- geometry interaction chamber

percent solids in liquid suspensions,

• Guaranteed scaleup to production scale machines

as well as low to high concentration

cell disruption. The system is easy to • All wetted metal parts – 300 series stainless steel, 17-4PH

operate and is designed for clean-in- stainless steel, or Nitronic 60. Plunger is chrome-plated.

place without disassembly. • Pressure range: 206-1586 bar (3,000-23,000 psi)

• Open jacket cooling coil

• Easy clean-in-place and simple maintenance

• Air powered and explosion-proof

• Portable, benchtop unit

• Sanitary fittings

• Product path is immersible in cooling or heating bath

• CE compliant

• Sample size: 60 ml to continuous

*total equipment holdup volume with cooling coil is 42 ml

Patented

Microfluidizer

processor

produces uniform

dispersions with

submicron size

particles

Before Processing After Processing

Operating Principle Specifications

The M-110Y has an air powered Pressure Range 206-1586 bar (3,000 - 23,000 psi)

intensifier pump designed to supply Flow Rate Range 100-500 ml/min

the desired operating pressure at a

constant rate through fixed-geometry Feed Temperature Range -25°C to 75°C (-15°F to 165°F)

microchannels within the interaction Processor Air Requirements For 26 l/sec @ 5.0 bar (56 scfm @ 100 psi)

chamber. Maximum Operating Pressure 11 kw (15 hp) compressor required

As a result, the product stream Sample Size 60 ml to continuous

accelerates to high velocities, creating Dimensions LxWxH 28 x 41 x 76 cm (11” x 16” x 30”)

shear rates within the product stream

Weight 25 kg (55 lbs)

that are orders of magnitude greater

than any other conventional means.

All of the product experiences identical M-110Y Available Options

processing conditions, producing the

• 400 ml stainless steel manual pressure • Autoclavable (sterilizable to 121ºC) air

desired results, including uniform feed reservoir motor

particle and droplet size reduction

• 2 liter stainless steel reservoir • Air tank regulator

(often submicron), deagglomeration

and high yield cell disruption. • 7.6 liter (2 gallon) pressurized feed tank • Sanitary pressure transducer with digital

• 2 liter stainless steel pressurized reservoir readout

• Tungsten Carbide plunger in pump • Dual feed assembly

Air Regulator

• Special designs and construction • Diamond interaction chamber

materials upon request • Product temperature sensors and

indicators

Air Inlet • IQ/OQ documentation

Air Supply On/Off Valve Machine Stabilizer • Kalrez/Chemraz o-rings

• Factory acceptance test (FAT)

• Site acceptance test (SAT)

• Start-up training

Inlet Check Valve (ball type)

Product Inlet

Reservoir

Processed Product Outlet Air Pump

Cooling Coil

Prime/Relief

Product Inlet Reservoir Valve

(Glass Shown - 1 Liter Pressure Gauge

SS and 300 mL glass are

provided) Ceramic Interaction

Priming Outlet

Chamber (IXC)

M-110Y Side View Diamond (DIXC) is

optional

Product Outlet

Ceramic Auxiliary Processing Module (APM)

Prime/Relief Valve Diamond (DAPM) is optional

Cooling Coil

M-110Y Overhead View

Microfluidics reserves the right to change specifications without notice.

MATERIAL PROCESSING

Microfluidics International Corporation IDEX Material Processing Technologies

90 Glacier Drive, Suite 1000 • Westwood, MA 02090, USA Bramley Drive, Vale Park West, Evesham, Worcestershire, WR11 1JH, UK

Tel: 617-969-5452 • 800-370-5452 • Fax: 617-965-1213 Tel: (+44) (0) 1386 769 007 • Fax: (+44) (0) 870 1911116

Email: mixinginfo@idexcorp.com • www.microfluidicscorp.com Email: mixinginfo@idexcorp.com • www.microfluidicscorp.com © 1998, 2012 by Microfluidics. All rights reserved. 5/14 IH .5K

También podría gustarte

- Screw Chiller CatalogueDocumento24 páginasScrew Chiller CatalogueKamalMuralikumarAún no hay calificaciones

- General Chemistry NotesDocumento7 páginasGeneral Chemistry Notesdeveravanessa01Aún no hay calificaciones

- Multistage Pump PDFDocumento8 páginasMultistage Pump PDFmartin.ruben100% (2)

- 10 Handbook Standard For Portable Fire ExtinguishersDocumento205 páginas10 Handbook Standard For Portable Fire ExtinguishersJosesin SinsinAún no hay calificaciones

- BornemannSLHEN PDFDocumento8 páginasBornemannSLHEN PDFMichaelAún no hay calificaciones

- From Internet: Pipe Burst Working Pressure Calculator Barlow's FormulaDocumento5 páginasFrom Internet: Pipe Burst Working Pressure Calculator Barlow's FormulaDipakAún no hay calificaciones

- How Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisDe EverandHow Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisCalificación: 5 de 5 estrellas5/5 (1)

- Merichem Process Technologies Brochure (English)Documento31 páginasMerichem Process Technologies Brochure (English)Walid Fattah100% (3)

- Industrial Reverse Osmosis SystemsDocumento4 páginasIndustrial Reverse Osmosis Systemsashtj2000Aún no hay calificaciones

- Awwa C115 - A2c115 (1999)Documento23 páginasAwwa C115 - A2c115 (1999)kumarvizayin100% (1)

- Mineral Dressing PDFDocumento40 páginasMineral Dressing PDFArijit MondalAún no hay calificaciones

- Tetra Therm Aseptic FlexDocumento4 páginasTetra Therm Aseptic FlexHossam Abdel Aziz100% (1)

- Pile Jacking FullTextDocumento223 páginasPile Jacking FullTextGeorge Ardianda CrAún no hay calificaciones

- Tetra Pak Homogenizer 300: Homogenizer or High Pressure Pump For Liquid Food ApplicationsDocumento2 páginasTetra Pak Homogenizer 300: Homogenizer or High Pressure Pump For Liquid Food ApplicationsFátima RomeroAún no hay calificaciones

- Use of Water Reducers To Impove Grindability and Performance of PC Clinker PDFDocumento10 páginasUse of Water Reducers To Impove Grindability and Performance of PC Clinker PDFTran Huynh NamAún no hay calificaciones

- BETTIS Product Selection Guide: A Complete Offering of Valve Automation SolutionsDocumento6 páginasBETTIS Product Selection Guide: A Complete Offering of Valve Automation SolutionsVinothkumarAún no hay calificaciones

- Range: Keeping The World FlowingDocumento8 páginasRange: Keeping The World FlowingPiermarco ContrerasAún no hay calificaciones

- Chiller o Enfriador Parker Hiross Bulice-03-EnDocumento4 páginasChiller o Enfriador Parker Hiross Bulice-03-EnDaniel MarAún no hay calificaciones

- Go RangeDocumento8 páginasGo RangePedro Vives MelendezAún no hay calificaciones

- ProcessMaster Data SheetsDocumento2 páginasProcessMaster Data SheetsGenkimanAún no hay calificaciones

- Tetra Pak Homogenizer 30G: Homogenizer or High-Pressure Pump For Liquid Food ApplicationsDocumento2 páginasTetra Pak Homogenizer 30G: Homogenizer or High-Pressure Pump For Liquid Food ApplicationsThinura SamarawickramaAún no hay calificaciones

- Brochure 7401Documento2 páginasBrochure 7401Salman FayizAún no hay calificaciones

- Technical Features PETSEA RO SW-Y 60-80Documento27 páginasTechnical Features PETSEA RO SW-Y 60-80Alexander100% (1)

- Marlo MRO 8H Industrial Reverse Osmosis Systems BrochureDocumento4 páginasMarlo MRO 8H Industrial Reverse Osmosis Systems Brochuremezo catAún no hay calificaciones

- Brochure Bettis Product Selection Guide Us en 83876 PDFDocumento6 páginasBrochure Bettis Product Selection Guide Us en 83876 PDFIsidro RODRIGUEZ VILLEGASAún no hay calificaciones

- PK1024-MKF-MDB060-365097 01Documento9 páginasPK1024-MKF-MDB060-365097 01waqas_a_shaikh4348Aún no hay calificaciones

- Dopag LSR Silcomix enDocumento12 páginasDopag LSR Silcomix enChetan SharmaAún no hay calificaciones

- wrcc30 2015 GB - 3Documento52 páginaswrcc30 2015 GB - 3Daniela RossiAún no hay calificaciones

- Aquanomics ProfileDocumento33 páginasAquanomics ProfilesaurabhAún no hay calificaciones

- May Nen IntermechDocumento2 páginasMay Nen IntermechUchiha SaitamaAún no hay calificaciones

- Brochure Low Pressure Pumps 986724 PT PM 177 10 18 en PDFDocumento20 páginasBrochure Low Pressure Pumps 986724 PT PM 177 10 18 en PDFamicarelliAún no hay calificaciones

- Sabre en Lo 4pp v2Documento4 páginasSabre en Lo 4pp v2UliAlejandroRodriguezCoriangaAún no hay calificaciones

- Manual & Automatic Chemical ControlDocumento36 páginasManual & Automatic Chemical ControlKhaled SaadnehAún no hay calificaciones

- Autoclave General Catalogue2 Final 02 10 2016 PDFDocumento2 páginasAutoclave General Catalogue2 Final 02 10 2016 PDFAbiAún no hay calificaciones

- Safe, Precise and Cost-Effective Metering: Low-Pressure Metering Pumps Up To Over 1,000 L/HDocumento20 páginasSafe, Precise and Cost-Effective Metering: Low-Pressure Metering Pumps Up To Over 1,000 L/HRoberto TorresAún no hay calificaciones

- Global Pumps Company ProfileDocumento9 páginasGlobal Pumps Company Profileमोबाईल सुचना केन्द्रAún no hay calificaciones

- DC200 Equipment ManualDocumento3 páginasDC200 Equipment ManualAdrian S. QuirosAún no hay calificaciones

- Enviro M-3Documento2 páginasEnviro M-3maznahAún no hay calificaciones

- Ficha TecnicaDocumento4 páginasFicha TecnicaRodrigo LeónAún no hay calificaciones

- Grund FosDocumento22 páginasGrund FosCristian ParaschivAún no hay calificaciones

- Hightech BrochureDocumento8 páginasHightech BrochureEken SariliAún no hay calificaciones

- Self Cleaning Strainer 2022-CMPDocumento6 páginasSelf Cleaning Strainer 2022-CMPMohanrajaAún no hay calificaciones

- TS Sterling Sterlco TC110 Series - Rev09.13.2018Documento2 páginasTS Sterling Sterlco TC110 Series - Rev09.13.2018Omar A. HernandezAún no hay calificaciones

- PumpsDocumento5 páginasPumpsEloi Magpantay HernandezAún no hay calificaciones

- Speeddry Vacuum Concentrators: Fast and GentleDocumento16 páginasSpeeddry Vacuum Concentrators: Fast and Gentleeduardo corsAún no hay calificaciones

- Secador de Aire Sullair SR 500Documento16 páginasSecador de Aire Sullair SR 500Darwin Santamaría CalderónAún no hay calificaciones

- Counterflow Coolers: The CPM AdvantageDocumento4 páginasCounterflow Coolers: The CPM Advantageferry brandone njitacke tiamAún no hay calificaciones

- Rotary Screw Technical Datasheet ISO7396 1Documento5 páginasRotary Screw Technical Datasheet ISO7396 1ajayforever31Aún no hay calificaciones

- GEA Ariete Homogenizer 5315: Homogenizer & High Pressure Pump Technical DatasheetDocumento2 páginasGEA Ariete Homogenizer 5315: Homogenizer & High Pressure Pump Technical DatasheetJorge A. TorresAún no hay calificaciones

- WCVS0905Documento4 páginasWCVS0905Quynh NguyenAún no hay calificaciones

- Electroválvula Honeywell TN URDocumento20 páginasElectroválvula Honeywell TN URDiego B.E.Aún no hay calificaciones

- DRUVA O&G - Hydraulic - RegulatorDocumento12 páginasDRUVA O&G - Hydraulic - RegulatormauroAún no hay calificaciones

- Sullair Dryers Secador de AireDocumento12 páginasSullair Dryers Secador de AireLuis RoldanAún no hay calificaciones

- BOMAFA Steam Conditioning ValvesDocumento8 páginasBOMAFA Steam Conditioning ValvesbagastcAún no hay calificaciones

- Model Q5 Data Sheet L&WDocumento2 páginasModel Q5 Data Sheet L&WRolando GómezAún no hay calificaciones

- SpeedDry Vacuum Concentrators Provide Fast, Gentle Sample PreparationDocumento16 páginasSpeedDry Vacuum Concentrators Provide Fast, Gentle Sample PreparationkulathuiyerAún no hay calificaciones

- Nutsel Filter Press DataDocumento31 páginasNutsel Filter Press DataJay ShethAún no hay calificaciones

- Series R™ Helical Rotary Liquid Chillers: Product CatalogDocumento140 páginasSeries R™ Helical Rotary Liquid Chillers: Product CataloggabyorAún no hay calificaciones

- wrcc20 2015 GBDocumento44 páginaswrcc20 2015 GBMohamdAún no hay calificaciones

- Alpha 20 Stage III Technical Data Sheet Global enDocumento6 páginasAlpha 20 Stage III Technical Data Sheet Global enMario octavio HernándezAún no hay calificaciones

- Isi Swro PDFDocumento2 páginasIsi Swro PDFachmadinAún no hay calificaciones

- Isi SwroDocumento2 páginasIsi SwroachmadinAún no hay calificaciones

- Ficha Técnica Agua PuraDocumento1 páginaFicha Técnica Agua Purasara kubikaAún no hay calificaciones

- Valve Remote Control SystemDocumento12 páginasValve Remote Control Systemcrackerz83Aún no hay calificaciones

- TDS Alpha 20 Tier 3 (EN) Rev.02Documento6 páginasTDS Alpha 20 Tier 3 (EN) Rev.02Diego BernalAún no hay calificaciones

- Especificaciones Del Equipo de ExtraccionDocumento1 páginaEspecificaciones Del Equipo de Extraccionjohan_an94Aún no hay calificaciones

- Gea Ariete Homogenizer 5400 High Pressure Homogenizer Pump Technical Data - tcm25 38679 PDFDocumento2 páginasGea Ariete Homogenizer 5400 High Pressure Homogenizer Pump Technical Data - tcm25 38679 PDFJorge A. TorresAún no hay calificaciones

- Technicla Data UHPDocumento16 páginasTechnicla Data UHPsimsonAún no hay calificaciones

- Course Folders Status (Updated)Documento2 páginasCourse Folders Status (Updated)jawadAún no hay calificaciones

- Checklist For Lab CoursesDocumento2 páginasChecklist For Lab CoursesjawadAún no hay calificaciones

- AfterDocumento1 páginaAfterjawadAún no hay calificaciones

- Course Folders Status (Updated)Documento2 páginasCourse Folders Status (Updated)jawadAún no hay calificaciones

- Course Folder TagDocumento1 páginaCourse Folder TagjawadAún no hay calificaciones

- ME 521 Fluid Mechanics Course Spring 2021Documento1 páginaME 521 Fluid Mechanics Course Spring 2021jawadAún no hay calificaciones

- Checklist For Lab CoursesDocumento2 páginasChecklist For Lab CoursesjawadAún no hay calificaciones

- CLO Approval FormDocumento1 páginaCLO Approval FormjawadAún no hay calificaciones

- Reopening SOPsDocumento6 páginasReopening SOPsjawadAún no hay calificaciones

- PLO Mapping 2016-2018Documento8 páginasPLO Mapping 2016-2018jawadAún no hay calificaciones

- Intermediate Fluid Mechanics - Assignment Session #2Documento1 páginaIntermediate Fluid Mechanics - Assignment Session #2jawadAún no hay calificaciones

- ME 581+EM511 Spring 2021 Course OutlineDocumento3 páginasME 581+EM511 Spring 2021 Course OutlinejawadAún no hay calificaciones

- Check List PSSDocumento1 páginaCheck List PSSjawadAún no hay calificaciones

- Enhancement of Thermal Energy Storage Using Copper Mesh in Paraffin Based Packed BedDocumento10 páginasEnhancement of Thermal Energy Storage Using Copper Mesh in Paraffin Based Packed BedjawadAún no hay calificaciones

- To-Do List With Drop-Downs: Task Title Status PriorityDocumento6 páginasTo-Do List With Drop-Downs: Task Title Status PriorityjawadAún no hay calificaciones

- Blank Attendance SheetDocumento1 páginaBlank Attendance SheetjawadAún no hay calificaciones

- Problem Sheet 1 ME595Documento1 páginaProblem Sheet 1 ME595jawadAún no hay calificaciones

- MS Admission FormDocumento2 páginasMS Admission FormjawadAún no hay calificaciones

- Fall 2020 Time Table Effective From October 12, 2020Documento8 páginasFall 2020 Time Table Effective From October 12, 2020jawadAún no hay calificaciones

- Blank Attendance SheetDocumento1 páginaBlank Attendance SheetjawadAún no hay calificaciones

- ResultsDocumento1 páginaResultsjawadAún no hay calificaciones

- Problem Sheet 2 ME595 PDFDocumento1 páginaProblem Sheet 2 ME595 PDFjawadAún no hay calificaciones

- Assignment No. 1 ME-595 Solar Energy Utilization: Course Instructor: Asst. Prof. Dr. Muhammad AsifDocumento7 páginasAssignment No. 1 ME-595 Solar Energy Utilization: Course Instructor: Asst. Prof. Dr. Muhammad AsifjawadAún no hay calificaciones

- Quotation Sheet: Shanghai Cloud Chemical Co., LTDDocumento1 páginaQuotation Sheet: Shanghai Cloud Chemical Co., LTDjawadAún no hay calificaciones

- Resume - Jawad RabbiDocumento2 páginasResume - Jawad RabbijawadAún no hay calificaciones

- IERI International Internship Program Application FormDocumento3 páginasIERI International Internship Program Application FormjawadAún no hay calificaciones

- Resume - Jawad RabbiDocumento2 páginasResume - Jawad RabbijawadAún no hay calificaciones

- Assignment No. 1 ME-595 Solar Energy Utilization: Course Instructor: Asst. Prof. Dr. Muhammad AsifDocumento7 páginasAssignment No. 1 ME-595 Solar Energy Utilization: Course Instructor: Asst. Prof. Dr. Muhammad AsifjawadAún no hay calificaciones

- Personal Statment Version TwoDocumento1 páginaPersonal Statment Version TwojawadAún no hay calificaciones

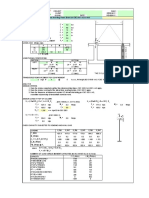

- Calculate loads on structural elementsDocumento2 páginasCalculate loads on structural elementsjawad33% (9)

- Sample Questions - Chapter 2Documento5 páginasSample Questions - Chapter 2Rasel IslamAún no hay calificaciones

- Semiconductor FabricationDocumento6 páginasSemiconductor FabricationSyed Raheel AdeelAún no hay calificaciones

- Evonik-Ancamine 2803Documento2 páginasEvonik-Ancamine 2803AceVũAún no hay calificaciones

- API STD 2000 Tank Venting Rate Calculation Using Latest MethodDocumento15 páginasAPI STD 2000 Tank Venting Rate Calculation Using Latest MethodHyungTae JangAún no hay calificaciones

- Carriers of The Protective Effectiveness of Used Motor OilsDocumento4 páginasCarriers of The Protective Effectiveness of Used Motor OilsChristian D JiménezAún no hay calificaciones

- Product Data Sheet SKD-S2: Spotcheck Non Aqueous DeveloperDocumento3 páginasProduct Data Sheet SKD-S2: Spotcheck Non Aqueous DeveloperMai Anh TaiAún no hay calificaciones

- Soil test kit instructions and reagent listDocumento8 páginasSoil test kit instructions and reagent listhromeroeAún no hay calificaciones

- Ractangular Over Head Water Tank (Complete)Documento43 páginasRactangular Over Head Water Tank (Complete)Hailemariyam SewagegnAún no hay calificaciones

- Thermal Issues in Materials Processing: Yogesh JaluriaDocumento14 páginasThermal Issues in Materials Processing: Yogesh JaluriarahulAún no hay calificaciones

- Basement Column Design Analysis and Capacity CheckDocumento3 páginasBasement Column Design Analysis and Capacity CheckPhanithAún no hay calificaciones

- Paul Meijering: Focusing On Quality and Relationships Ensures SuccessDocumento68 páginasPaul Meijering: Focusing On Quality and Relationships Ensures SuccesssagarAún no hay calificaciones

- High-solids zinc epoxy primer data sheetDocumento4 páginasHigh-solids zinc epoxy primer data sheetMina RemonAún no hay calificaciones

- Indice categorie di accessori nauticiDocumento56 páginasIndice categorie di accessori nauticiJohn FernandezAún no hay calificaciones

- Complaint AnalysisDocumento8 páginasComplaint AnalysisJKP OperationAún no hay calificaciones

- Art:10 1007/BF00776142Documento16 páginasArt:10 1007/BF00776142Camelia MoiseAún no hay calificaciones

- Elastic Critical Buckling Load by Second-Order Analysis (CSE573 Façade Engineering)Documento1 páginaElastic Critical Buckling Load by Second-Order Analysis (CSE573 Façade Engineering)kiddhoAún no hay calificaciones

- Perhitungan RBIDocumento3 páginasPerhitungan RBIdwi sutiknoAún no hay calificaciones

- Urban Ae Paper - 20669792 - 2023 - 07 - 28 - 16 - 48Documento14 páginasUrban Ae Paper - 20669792 - 2023 - 07 - 28 - 16 - 48Rabi DasAún no hay calificaciones

- 11.initial and Final Setting TimeDocumento2 páginas11.initial and Final Setting TimeMr Gk meenaAún no hay calificaciones

- Simulation of torsion in a beamDocumento10 páginasSimulation of torsion in a beamToBi MorrisonAún no hay calificaciones

- Functional Gage DesignDocumento32 páginasFunctional Gage DesignnaveedsidhuAún no hay calificaciones

- Evacuated Tube Collector SpecificationDocumento5 páginasEvacuated Tube Collector SpecificationJaswinder SinghAún no hay calificaciones