Documentos de Académico

Documentos de Profesional

Documentos de Cultura

En 4800xpcspec01

Cargado por

Luisfer FloresDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

En 4800xpcspec01

Cargado por

Luisfer FloresCopyright:

Formatos disponibles

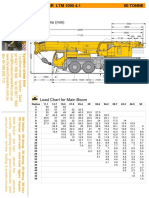

4800XPC

Electric Mining Shovel

General Specification

meters

feet

22 72.2

20 65.6

18 59.1

16 52.5

14 45.9

12 39.4

10 32.8

8 26.2

6 19.7

4 13.1

2 6.6

0 0

2 6.6

meters 6 4 2 0 2 4 6 8 10 12 14 16 18 20 22 24

feet 19.7 13.1 6.6 0 6.6 13.1 19.7 26.2 32.8 39.4 45.9 52.5 59.1 65.6 72.2 78.7

CL ROTATION

Working ranges Capacity

Height of cut 18.9 m 62 ft. 2 in. Nominal payload* 122.5 mt 135 st

Radius of cut 24.0 m 78 ft. 7 in. Nominal dipper capacity

SAE struck 65.7-70.3 m3 86-92 yd3

Max dump reach (furthest

19.4 m 63 ft. 6 in. SAE 2:1 72.5-77.6 m3 92.7-99.1 yd3

distance to center of truck)

Rated suspended load 209 mt 230 st

Dumping height*

10.8 m 35 ft. 7 in.

(door open) Optimum truck size

360 mt 400 st

(360 mt (400 st) truck shown)

Floor level radius 16.2 m 53 ft. 3 in.

*Payload and dipper capacity are dependent on many factors.

Tail swing radius 9.9 m 32 ft. 7 in.

Contact Komatsu Mining for an analysis of your specific application.

Operator eye level 10.1 m 33 ft. 1 in.

2 P&H 4800XPC electric mining shovel

A

B

Swing

H Three modular P&H planetary gear cases of proven design and a single

G piece forged swing gear transmit torque for fast cycle times.

D Spring-set air release disc brakes – one per motor.

F

E

Splash lube filtration system.

Overall dimensions

A Width 15.0 m 49 ft. 3 in. Propel

B Length 15.2 m 50 ft. 0 in. Propel on demand provides rapid transfer to propel mode. Rapid transfers

C Height over gantry 14.7 m 48 ft. 2 in. allow frequent positioning of the shovel to the bank resulting in faster

cycle times and more efficient digging.

D Width of crawler shoes 2540 mm 100 in.

Two rugged P&H planetary gear cases of proven design independently

E Width of crawlers (100") 11.1 m 36 ft. 5 in. transmit torque to the drive sprockets, producing the tractive effort

F Length of crawlers 11.5 m 37 ft. 8 in. required for fast, efficient propel and positioning operations.

G Ground clearance 0.7 m 2 ft. 2 in. P&H brand Delta drive low tension sprocket drive system with heavy

Height — ground to bottom of duty cast crawler shoes.

H 3.3 m 10 ft. 9 in.

counterweight slabs Spring-set air release disc brakes – one per motor.

Crowd

Twin low inertia AC motors minimize shock loading and boom jacking.

Power requirements

Direct drive crowd eliminates belt maintenance for

Supply voltage* 7200 or 13800V 6000, 6600, 7200 or 11000 improved responsiveness.

3 Phase, 60 Hz 3 Phase, 50 Hz

Modular crowd motors with integral pinions provide for simplified

Supply transformer (Minimum) 3750 kVA motor replacement.

Minimum short circuit VA available at shovel 30 MVA Two input pinions share load for extended life.

*Voltage per customer requirements Dual spring-set air release brakes for reliable redundant operation.

Adaptive controls technology Hoist

Smart control and application of power to improve payload and digging All gearing housed in single enclosed gear case with filtered and

performance of machine. cooled oil fed to all bearings in addition to splash lubrication for reliable

operation and ease of maintenance.

Increases shovel digging power without sacrificing life.

Large 68" diameter hoist drum for extended rope bending life. Ferrule

Reduces loading from non productive impacts. becket system and dual electric tuggers are standard for efficient

Decreases operator fatigue by limiting rocking motions of the shovel rope change.

especially in difficult digging conditions. Spring-set air release disc brakes – one per motor.

Hoist rope fleeting sheave protects rope from excessive oscillation.

Product designs, specifications and/or data in this document are provided for informational purposes only

Komatsu Mining Corp. Group and are not warranties of any kind. Product designs and/or specifications may be changed at any time without

notice. The only warranties that apply to sales of products and services are standard written warranties,

mining.komatsu which will be furnished upon request.

Komatsu, Joy, Montabert, P&H, Delta and other trademarks and service marks used herein are the property

of Komatsu Ltd., Komatsu Mining Corp., or their respective owners or licensees.

© 2018 Komatsu Mining Corp. All rights reserved.

EN-4800XPCSPEC01-0318-V1

También podría gustarte

- Electric Mining Shovel General Specification: Capacity Working RangesDocumento2 páginasElectric Mining Shovel General Specification: Capacity Working RangesfabioxavAún no hay calificaciones

- Electric Mining Shovel Digital Drive Control: Operating Specifi CationDocumento4 páginasElectric Mining Shovel Digital Drive Control: Operating Specifi CationJuan Antonio TovarAún no hay calificaciones

- P&H 4100XPC Operating SpecificationDocumento4 páginasP&H 4100XPC Operating SpecificationDaniel ZHAún no hay calificaciones

- 4100XPC Spec Sheet 120ton XS-4189Documento4 páginas4100XPC Spec Sheet 120ton XS-4189bas100% (1)

- 4100C BOSS - P& H MinePro ServicesDocumento4 páginas4100C BOSS - P& H MinePro ServicesRoberto MorenoAún no hay calificaciones

- 4100XPC AcDocumento4 páginas4100XPC AcRavi Krishnan100% (2)

- 译文 - 多级离心泵Multistage centrifugal pumpDocumento10 páginas译文 - 多级离心泵Multistage centrifugal pumpVocal SamirAún no hay calificaciones

- Marshal HMA Mixture Design ExampleDocumento2 páginasMarshal HMA Mixture Design ExampleTewodros TadesseAún no hay calificaciones

- Farmland DimensionsDocumento1 páginaFarmland DimensionsKumar KingslyAún no hay calificaciones

- AXIALDocumento1 páginaAXIALforyouuonly1234Aún no hay calificaciones

- Front ViewDocumento1 páginaFront ViewMohan KumarAún no hay calificaciones

- Atmospheric Solutions 2021 DigitalDocumento5 páginasAtmospheric Solutions 2021 Digitalrafael garciaAún no hay calificaciones

- Wind Speed and Generator Output Data For Calculating A Power Curve For A Wind TurbineDocumento1 páginaWind Speed and Generator Output Data For Calculating A Power Curve For A Wind TurbineDennis Dale FanogaAún no hay calificaciones

- TANAHDocumento3 páginasTANAHDoniIskandarAún no hay calificaciones

- NullDocumento13 páginasNullnivas3d.mechAún no hay calificaciones

- Opzv Series: Tubular Gel BatteryDocumento4 páginasOpzv Series: Tubular Gel BatteryAhmed ZeharaAún no hay calificaciones

- Finding Volume of Regular Shaped ObjectsDocumento2 páginasFinding Volume of Regular Shaped ObjectsLouise YongcoAún no hay calificaciones

- CE-13 Bitumen Content Lab ReportDocumento4 páginasCE-13 Bitumen Content Lab ReportAhmad AwanAún no hay calificaciones

- Technical Section: DIN 79 Square Tolerance, For Shafts and Square BoresDocumento1 páginaTechnical Section: DIN 79 Square Tolerance, For Shafts and Square BoresVelibor StokicAún no hay calificaciones

- San Valentin Futuro ProyectoDocumento1 páginaSan Valentin Futuro ProyectoHanani Hernan Aguilar LoconiAún no hay calificaciones

- Anchorage Beam Load-Deflection Graphs ComparedDocumento8 páginasAnchorage Beam Load-Deflection Graphs ComparedShahzor AbroAún no hay calificaciones

- Creating A Green World: 2" Water Gun DUPLEXDocumento1 páginaCreating A Green World: 2" Water Gun DUPLEXatulkkabadiAún no hay calificaciones

- JEE Main Quiz-28 (Student Copy)Documento9 páginasJEE Main Quiz-28 (Student Copy)ashutosh.mishra0051Aún no hay calificaciones

- 12 Volt D.C Relay Data SheetDocumento4 páginas12 Volt D.C Relay Data SheetcallkalaiAún no hay calificaciones

- Quantum Mechanics: A Mathematical IntroductionDocumento144 páginasQuantum Mechanics: A Mathematical Introductionroyce.schaden20Aún no hay calificaciones

- BP Stats Review 2019 Full Report 43Documento1 páginaBP Stats Review 2019 Full Report 43Sakaros BogningAún no hay calificaciones

- Figure 1: Voice Traffic GeneratorDocumento6 páginasFigure 1: Voice Traffic GeneratorPriyanga05Aún no hay calificaciones

- New Gojra Map - Final 8th August 2021Documento1 páginaNew Gojra Map - Final 8th August 2021fzafar676Aún no hay calificaciones

- SF No 28 Kadhampadi ModelDocumento1 páginaSF No 28 Kadhampadi ModelmanojAún no hay calificaciones

- SF No 28 Kadhampadi ModelDocumento1 páginaSF No 28 Kadhampadi ModelmanojAún no hay calificaciones

- ChartsDocumento4 páginasChartsDaniela Alvarado GarcíaAún no hay calificaciones

- 313F L GC: Hydraulic ExcavatorDocumento10 páginas313F L GC: Hydraulic ExcavatorAntónio Pedro TavaresAún no hay calificaciones

- Control Room For Gas StationDocumento22 páginasControl Room For Gas StationSmart ShivaAún no hay calificaciones

- Pareto Chart: Contributor # of Defects % CumDocumento4 páginasPareto Chart: Contributor # of Defects % CumpraveenAún no hay calificaciones

- Mcbs Internal Resistance, Power Loss and Max. Permissible Earth-Fault Loop ImpedanceDocumento1 páginaMcbs Internal Resistance, Power Loss and Max. Permissible Earth-Fault Loop ImpedanceSattawat PuntaAún no hay calificaciones

- Precipitación de Los Años 1997-2010Documento8 páginasPrecipitación de Los Años 1997-2010Vanessa Vera ReyesAún no hay calificaciones

- Volume WorksheetsDocumento20 páginasVolume WorksheetsBelinda LapsitAún no hay calificaciones

- Pipe Quality Manual 1Documento1 páginaPipe Quality Manual 1Nasir AhmadAún no hay calificaciones

- Qingdao Luhang Marine Airbag SpecsDocumento1 páginaQingdao Luhang Marine Airbag SpecsantonAún no hay calificaciones

- 90 Tonne Liebherr Crane Load Chart and SpecsDocumento3 páginas90 Tonne Liebherr Crane Load Chart and SpecsclaudobaAún no hay calificaciones

- Conversion Chart: Tableaux de Conversion Des Valeurs de SerrageDocumento1 páginaConversion Chart: Tableaux de Conversion Des Valeurs de SerrageHoracio Quispe FernandezAún no hay calificaciones

- ChartsDocumento4 páginasChartsDeepan KumarAún no hay calificaciones

- Flujo Multifasico 4.4Documento14 páginasFlujo Multifasico 4.4Ramses SuárezAún no hay calificaciones

- Rajesh Kumar Future of Coal Based Generation Jan2018Documento23 páginasRajesh Kumar Future of Coal Based Generation Jan2018Nicholas DavisAún no hay calificaciones

- 118 Care Home Visp L.PDF - Sergison Bates ArchitectsDocumento5 páginas118 Care Home Visp L.PDF - Sergison Bates ArchitectsMax PigaAún no hay calificaciones

- 43UL3J TV dimensions in mmDocumento1 página43UL3J TV dimensions in mmOscar WanAún no hay calificaciones

- Data Scanner ExampleDocumento3 páginasData Scanner ExampleMayAún no hay calificaciones

- Book Kashmir Studies (QA) 2021Documento246 páginasBook Kashmir Studies (QA) 2021Reema KhanAún no hay calificaciones

- Water Presentation Latest CivilDocumento9 páginasWater Presentation Latest CivilDurgaraju MallikarjunAún no hay calificaciones

- Think and HistoryDocumento1 páginaThink and HistoryfaizAún no hay calificaciones

- Government Publications: Key PapersDe EverandGovernment Publications: Key PapersBernard M. FryAún no hay calificaciones

- NLM Kinematics Rotational Dynamics Centre of Mass Work, Power, Energy Circular MotionDocumento4 páginasNLM Kinematics Rotational Dynamics Centre of Mass Work, Power, Energy Circular MotionghcAún no hay calificaciones

- Calibration of Wave Probe: Ex. No.: 1 Date: 16.07.18Documento2 páginasCalibration of Wave Probe: Ex. No.: 1 Date: 16.07.18Murali Kuna ShekaranAún no hay calificaciones

- Btech Plate 1 GFPDocumento1 páginaBtech Plate 1 GFPKia changgiAún no hay calificaciones

- KVT 3.140 Vacuum Pumps UsDocumento6 páginasKVT 3.140 Vacuum Pumps UschikoAún no hay calificaciones

- Environmental Hydrology For Data ScienceDocumento11 páginasEnvironmental Hydrology For Data ScienceKeshav RaoAún no hay calificaciones

- COMPUTATIONDocumento1 páginaCOMPUTATIONXaira Alexa Mari CastroAún no hay calificaciones

- MODEC, Inc. 2019 Half-Year Financial Results Analysts PresentationDocumento16 páginasMODEC, Inc. 2019 Half-Year Financial Results Analysts Presentationfle92Aún no hay calificaciones

- Bolt and Screw Torque SpecsDocumento3 páginasBolt and Screw Torque SpecsBilal TayyabAún no hay calificaciones

- OverallDocumento2 páginasOverallpawan yadavAún no hay calificaciones

- Css Recommended BooksDocumento6 páginasCss Recommended Booksaman khanAún no hay calificaciones

- Return On Marketing InvestmentDocumento16 páginasReturn On Marketing Investmentraj_thanviAún no hay calificaciones

- Manual Cisco - DPC3925Documento106 páginasManual Cisco - DPC3925HábnerTeixeiraCostaAún no hay calificaciones

- Easa Ad 2023-0133 1Documento6 páginasEasa Ad 2023-0133 1Pedro LucasAún no hay calificaciones

- Multinational Business Finance 12th Edition Slides Chapter 12Documento33 páginasMultinational Business Finance 12th Edition Slides Chapter 12Alli Tobba100% (1)

- The Barber of SevilleDocumento1 páginaThe Barber of SevilleAine MulveyAún no hay calificaciones

- rfg040208 PDFDocumento2372 páginasrfg040208 PDFMr DungAún no hay calificaciones

- Volume Meters Models 962 and 963 Series CDocumento8 páginasVolume Meters Models 962 and 963 Series CVictor Edy Facundo DelzoAún no hay calificaciones

- Quotation For Villa Maintainance at Al RiqqaDocumento2 páginasQuotation For Villa Maintainance at Al RiqqaAkosh AchuAún no hay calificaciones

- Effective Postoperative Pain Management StrategiesDocumento10 páginasEffective Postoperative Pain Management StrategiesvenkayammaAún no hay calificaciones

- Fmi Code GuideDocumento82 páginasFmi Code GuideNguyễn Văn Hùng100% (4)

- Om 08.12.2022Documento18 páginasOm 08.12.2022raviAún no hay calificaciones

- PESU BTech Jan2017 6thsemCourseInfoDocumento51 páginasPESU BTech Jan2017 6thsemCourseInforakshithrajAún no hay calificaciones

- SC WD 1 WashHandsFlyerFormatted JacobHahn Report 1Documento3 páginasSC WD 1 WashHandsFlyerFormatted JacobHahn Report 1jackson leeAún no hay calificaciones

- Essential Components of an Effective Road Drainage SystemDocumento11 páginasEssential Components of an Effective Road Drainage SystemRaisanAlcebarAún no hay calificaciones

- Online Dispute ResolutionDocumento18 páginasOnline Dispute ResolutionMak YabuAún no hay calificaciones

- 5 Nighttime Image Enhancement Using A NewDocumento7 páginas5 Nighttime Image Enhancement Using A NewNithish CenaAún no hay calificaciones

- Key plan and area statement comparison for multi-level car park (MLCPDocumento1 páginaKey plan and area statement comparison for multi-level car park (MLCP121715502003 BOLLEMPALLI BINDU SREE SATYAAún no hay calificaciones

- SteroidsDocumento2 páginasSteroidsShawn FreemanAún no hay calificaciones

- ISO 22301 Mandatory DocumentDocumento2 páginasISO 22301 Mandatory Documenttrackuse100% (1)

- Evaluation of The Cyanotic Newborn Part IDocumento9 páginasEvaluation of The Cyanotic Newborn Part Ijwan ahmedAún no hay calificaciones

- Human PhysiologyDocumento4 páginasHuman Physiologyshahzain92Aún no hay calificaciones

- GCAF Online Inspector Practice ExamDocumento5 páginasGCAF Online Inspector Practice Examcamwills2100% (1)

- BLDG TECH Juson Assignment Lecture 1Documento23 páginasBLDG TECH Juson Assignment Lecture 1Ma. Janelle GoAún no hay calificaciones

- High Performance, Low Cost Microprocessor (US Patent 5530890)Documento49 páginasHigh Performance, Low Cost Microprocessor (US Patent 5530890)PriorSmartAún no hay calificaciones

- Hiata 2Documento21 páginasHiata 2AnnJenn AsideraAún no hay calificaciones

- Xbox - RGH E Ltu: Jogo 3.0 4.0 HD NºDocumento11 páginasXbox - RGH E Ltu: Jogo 3.0 4.0 HD NºGabriel DinhaAún no hay calificaciones

- BSC6900 UMTS Hardware Description (V900R017C10 - 01) (PDF) - enDocumento224 páginasBSC6900 UMTS Hardware Description (V900R017C10 - 01) (PDF) - enmike014723050% (2)

- Porter 5 ForcesDocumento44 páginasPorter 5 ForcesSwapnil ChonkarAún no hay calificaciones

- Bildiri Sunum - 02Documento12 páginasBildiri Sunum - 02Orhan Veli KazancıAún no hay calificaciones