Documentos de Académico

Documentos de Profesional

Documentos de Cultura

3 17

Cargado por

manowarTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

3 17

Cargado por

manowarCopyright:

Formatos disponibles

Algorithms for Reducing the Waste Rate of Reinforcement Bars

Sun-Kuk Kim*1, Won-Kee Hong2 and Jin-Kyu Joo3

1

Associate Professor, College of Architectural and Civil Engineering, Kyung Hee University, Korea

2

Assistant Professor, College of Architectural and Civil Engineering, Kyung Hee University, Korea

3

Project Manager, Shindongah E&C Co. Ltd., Korea

Abstract

Loss of rebars can be minimized with minimum use of discrete bars in market length. In order to achieve this

goal, the accurate and detailed information of rebars is extracted, followed by both rapid and efficient bar

combination. No paper has dealt directly with the reduction of rebar waste rates, although many researches

have proposed indirect approaches to enhance productivity, constructability, safety and quality in the process

of concrete reinforcement work. This paper, therefore, was prepared with the aim of developing algorithms to

supply rebars required to minimize material waste during cutting and bending of discrete bars in rebar shops.

At the same time, this study presented an automatic rebar detailing concept, a logical process of rebar combination

with pertinent algorithms and binary search algorithm for bar data to implement the proposed topic. The

effectiveness of the suggested algorithms was validated by case studies.

Keywords: rebar work; optimization; algorithm; waste rate; combination

Introduction The manual bar combination of either market length

Countries with highly capital-intensive construction or special length to minimize the loss of materials is not

use the computerized numerically controlled (CNC) an easy task since rebars of different diameters, lengths,

machine. The machine automatically produces shaped and locations are found in various locations in drawings.

rebars of up to 16 mm in diameter supplied in coils which In particular, in the rebar shop, the simultaneous

is described as machine type A by Navon, Rubinovitz optimum combination of the multi-projects to minimize

and Coffler (1996). In this case, the manufacturing the loss rate of material is an even more difficult problem.

process of rebars produces few scraps with almost zero The optimization algorithm using computers is one of

percent loss of raw materials. However, the generation the most effective ways to solve those problems.

of waste is inevitable in countries which do not supply Previous research has shown the benefits of computer

rebars in coils and even in capital-intensive countries applications to improve productivity, constructability,

which can not supply rebars of larger than 16 mm safety and quality in the process of concrete

diameter coils. reinforcement work. Bernold and Salim (1993) presented

The straight bars of market lengths, normally 8.0, 8.5, placement-oriented design and delivery of reinforcement

9.0, 9.5, .., are produced in Korea, since the raw materials based on both computer integration and feature-based

for rebars are not supplied in coils. The market length design concepts. They also proposed a concept of rebar

production generates relatively many scraps after rebars delivery and staging based on a placement plan to

are cutoff in required lengths. improve productivity on site (Salim and Berbold 1994).

The waste rate of scraps increases when raw materials Dunston and Bernold (1994) produced a strategy for the

are ordered without proper bar cutoff plans based on the robotic rebar bending based on experiments and

structural review of drawings. The loss rate of scraps developed a control model for accurate rebar bending

can be even higher as the diameter of rebars increases based on computer integrated manufacturing (CIM)

(Kim 2002). The loss of materials can be reduced when concepts (Dunston and Bernold 2000). Navon et al.

the most desired length of bars are ordered based on the (1995, 1996) described the benefits of computer-aided

sufficient review of drawings and bar schedules. Extra design and computer-aided manufacturing (CAD/CAM)

savings of rebars are possible when the special length of systems for concrete reinforcement and developed a

a certain amount of tonnage is ordered to steel mill. model for rebar constructability diagnosis and correction

in an object-oriented programming environment (Navon

*Contact Author: Sun Kuk Kim, Associate Professor, College of et al. 2000).

Architectural and Civil Engineering, Kyung Hee University,1 However, the direct approach to the optimization

Seochon-ri, Kiheung, Yongin, Kyonggi-do, 449-701, Korea algorithm to reduce the loss rate of rebars was not found

Tel: 82-31-201-2922 Fax: 82-31-203-0089 among these papers. The work carried out by Navon et

E-mail: kimskuk@khu.ac.kr al. (1995) was one of the few studies which addressed

(Received October 24, 2003 ; accepted April 6, 2004 ) the optimization algorithm for reducing the loss rate of

Journal of Asian Architecture and Building Engineering/May 2004/23 17

steel rebars. However, Navon did not present the detailed The quality of labor provided by the subcontractor

algorithm even though an optimization module based can significantly influence waste rate as well as rebar

on linear integer programming (LP) solver-LINDO was works. Site investigation (Kim, 1987) shows that waste

mentioned. of rebars decreases if optimum rebar combination and

This paper, therefore, was prepared with the aim of systematic inventory management are properly carried

developing algorithms to supply rebars required to out from ordering phase to manufacturing phase. The

minimize material waste during cutting and bending of optimum combination of rebars, calculated by computer,

discrete (single) bars in rebar shops. provides very useful information for the manufacturing

of rebars as well as systematic inventory management

Reasons for Loss of Rebars that reduces waste rate.

The waste rate can be estimated as high as 3 to 5% in

the bidding stage in countries where rebars are not Automatic Rebar Detailing Concept

supplied in coils. This rate can be even higher than 10% The rebar combination process begins with the

as the diameter of rebars increases. Kim (1987) showed preparation of Rebar Data Files (RDF) based on the

that the loss rate from plant projects is higher than that structural calculation. Structural design data, however,

of building construction in which rebars of typical length provides basic information related to arrangement of

and diameter are repeated in drawings. Major causes rebars. Detailed rebar information including

influencing the waste rate of rebars were identified from development and splice length, concrete cover and

several management processes of rebar work as follows. interference of rebars is not expressed explicitly in

(1) The highest rate of waste is observed when the structural drawings. Therefore, the automatic preparation

purchase order with redundancy is made to steel mill of RDF from the information of structural design

without accurate understanding of manufacturing requires a module that provides rebar detail. Fig 1

information, such as the structural drawings and bar graphically demonstrates the conceptual construction of

schedules. The waste of materials rapidly increases when RDF.

the proper attention is not paid to the surplus order of

raw materials during the construction stage. Therefore,

significant waste can be avoided if the required quantity

of rebars is precisely analyzed and reflected in the mill

order.

(2) Materials are also wasted when surplus rebars with

length of 2-3m are not reused after cutoffs. Better

economy is achieved using rebars with margins of shorter

than 1m without cutoff since the cost of labor related to

cutting less than 1m is more expensive. The rebars of

Fig.1. Automatic Rebar Detailing Concept

extra length, with either straight or L shape, found from

slabs and beams not only increase waste rate of materials After all structural design data of structural members

but also add additional weight to the structure. Waste of including number of bars, diameters, geometric size of

material as high as 1% can be saved when proper bars in each member, etc. are extracted from the structural

market length are selected for combination in order not design data file (SDDF), splice and development length,

to generate scraps of about 1m based on the structural concrete cover related to each structural member are,

review of drawings (Kim, 1987). then, obtained from the structural member specification

(3) It is also shown that approximately a 1% waste data file (MSDF). As a next step, rebar manufacturing

rate occurs when cutting planning without consideration detail is prepared according to Automatic Rebar

of bending margins is carried out. Detailing Algorithms (ARDA).

(4) One of the frequent causes of waste is the failure The ARDA consist of two tasks. The first task is to

of inventory management of rebars cut and bent. This automatically generate rebar details of all structural

type of waste is observed in urgent and large-scale members, and the second task is to estimate precise

construction projects. cutting lengths and quantities of rebars based on the

(5) It is sometimes found from construction practice details obtained in the first task. Each structural member

that the length and location of bar splices as well as needs several ARDA, depending on the arrangement

developments are not observed in compliance with codes condition of structural members. For example, many

to compensate for the loss of materials, since strict algorithms of beams are required for the estimation of

application of codes can create significant loss of precise cutting length and quantity of rebars, depending

materials. In these cases, therefore, the quality of rebar on bar types (bent bar, straight bar) and number of spans

works is not satisfactorily controlled. (single span, and multiple). Kim and Kim (1994)

(6) Inappropriate management of rebar shops and presented an automatic rebar detailing concept, and Kim

layout of cutting and bending machines is another source (2002) proposed various detailing algorithms for all

of waste of materials. structural members.

18 JAABE vol.3 no.1 May. 2004 Sun-Kuk Kim

An Overview of Rebar Optimization The special order is initially considered for the bar

The algorithm to reduce waste of rebars boils down combination process based on reading RDF prepared

to the question of how efficiently scraps generated during by ARDA. At the same time, optimal conditions

rebar work designated as structural drawings can be including waste rate (ε), quantity (q) and length (l) are

minimized. For the multiple rebars as shown in Fig. 2, read to minimize rebar waste for special orders as shown

the following steps are proposed for the algorithm in in Fig. 3. Rebars of lengths 7m, 8m and 9m, which can

which li = combined length of rebars, Li = length of rebars be easily purchased from the market by a normal order

to be ordered, barj = rebars extracted from drawings, i, j (Normal order 1), are combined to match the rest of the

= index, ni = number of li or Li, and ε = waste rate of rebars. The final combination of rebars with the market

combined bars. length of 6.0m, 6.5m, 7.5m, 10.0m, 11.0m and 12.0m

(Normal order 2) is performed to produce rebars whose

combinations were not found. The following are the

explanations of Fig. 3.

Fig.2. Example of rebar combination

1. Find li where 0 ≤ ni (L- li)/L ≤ ε (1)

2. Let sum = (2)

The sum is to be multiplied by the unit weight of each

size of bars. If sum ≥ tons where tons is the minimum

quantity for order, then li (i=1, 2, .., m) can be selected

for order and it is recorded into the resource field of

barj.

3. Decrease the length gradually according to the given

range. Fig.3. An overview of rebar combination process

4. Repeat the process 1 and 2 until Li < Min (barj).

(1) Rebar arrays are prepared by sorting out rebars of

Rebar Combination Process and Algorithms the same diameter based on readings of RDF prepared

Even though the proposed algorithm looks simple, it by ARDA. The arrays include length, number of identical

is difficult to find numerous combinations of rebars that bars and bar mark that retains the information of a bar

satisfy given conditions including waste rate of material, type, diameter, spacing, and serial number. The RDF

length and quantity for purchase order as well as structure is very similar to the one proposed by Navon,

construction schedule. Computers can replace time- Rubinovitz, and Coffler (1995).

consuming manual efforts, resulting in significant (2) The algorithm searches and combines rebars

savings of materials, managing cost and labor. Material satisfying all the given conditions such as waste rate and

waste can be minimized if the rebar combinations are quantity (for example, ε ≤ 1%, and q i ≥300tons,

obtained with not only market length but also special respectively) for rebar length specified by 6m ≤ Si ≤

lengths with minimum quantity for order supplied by 12m (0.1m interval). First consideration is given to the

steel mills. single bars for search since combinations for single bars

The standard lengths of rebars that can be purchased are not necessary. The search is extended to combinations

in Korean markets are 7m, 8m and 9m. Besides, It is that satisfy the given conditions with two bars. The search

also required by Korean Standards that 6m, 6.5m, 7.5m, and combination are repeated with up to four bars.

10m, 11m and 12m be provided for the construction sites. (3) The combination with more than four bars is not

If rebars are supplied by special order, waste can be attempted to avoid inefficient computing time since

avoided further. For instance, if rebars of 320 tons with effective inventory management of rebar shops is

both 8.7m length and 28mm diameter are delivered to difficult. It was observed from a sample project that

sites by special order where the same quantity of 8.7m searching short rebars to be combined with primary

rebars are required by structural design, the waste rate rebars of longer lengths minimizes computing time when

is zero. This waste rate increases up to 3.3% with a scrap more than two rebars are combined. The binary search

bar of 30 cm when 9m rebars are supplied by the normal algorithm, shown in Fig. 4, is adapted among various

order. Construction costs increase rapidly when multiple searching methods to minimize time in finding rebars

projects are carried out in rebar shops with poor to be combined based on given conditions from hundreds

management systems during the ordering stage. of rebars sorted with respect to length. This binary search

algorithm was proved by Horowitz and Sahni (1983).

JAABE vol.3 no.1 May. 2004 Sun-Kuk Kim 19

algorithm is fast, even if the chance to minimize waste

rate is lost.

(2) Best-fit algorithm: This algorithm tries all possible

combinations of every rebar stored in RDF; and a rebar

combination that yields the least waste rate is selected.

From the above example, the combination of a 7m rebar

and a 3m rebar out of a possible six rebar combinations

gives the least waste rate of zero while a waste rate of

2% calculated from 7m+2.8m rebar combination was

obtained by the First-fit algorithm. This algorithm will

not lose the chance to minimize waste rate, despite

unavoidable computational time.

(3) Modified-first-fit algorithm: This algorithm

applies differentiated waste rate. Main rebars are

combined within a specified waste rate (for example,

waste rate of 1%) and a relieved condition waste rate,

such as 3%, is applied to the rest of the rebars. However,

the overall waste rate must not be beyond the target waste

rate, such as 2%. It was shown from the algorithm test

that quantities combined based on the relieved waste rate

do not exceed 10% of total rebars under combination.

This algorithm is considered to be the best algorithm

empirically in maximizing combination efficiency and

applicability while minimizing computing time.

Fig.4. Binary search algorithm for rebar combination

Algorithms for Mathematical Programming

(4) The given conditions of e (ex. ε ≤ 3%) and 6m ≤ Li It was shown that several algorithms must be combined

≤ 12m (for Li = 7, 8, 9m) are, then, implemented to search to solve optimization problems minimizing rebar waste

and combine rebars left over from Routine 1 (Normal rates. This study presented solutions to the following

order 1). questions. (1) How can one prepare rebar-detailing

(5) Routines 2 and 3 are followed by the combinations algorithms from the information of structural design?

meeting the conditions of e (ex. ε ≤ 3%) and 6m ≤ Li ≤ (2) How can one find a logical process for rebar

12m (for Li = 6m, 6.5m, 7.5m, 10m, 11m, 12m) imposed combination? (3) What type of conditions must be

on rebars left over from Routines 2 and 3 (Normal order imposed to combine rebars for each process (first or best-

2). Search for the rebar combination in Routines 3 and 4 fit algorithm)? (4) How can one rapidly search bar data

also uses the algorithm shown in Fig. 4. to be used for rebar combination (binary search

Three algorithms for the combination process as algorithm)?

shown in Fig. 3 are presented in this study to solve the Besides, the problem as to how one can quickly

optimization problem which reduces the waste rate of calculate rebar quantity satisfying given requirements

rebars while taking computational time and practice into remains unanswered. Numerous calculations of rebar

consideration. quantity are required to generate a candidate solution

and numerous candidate solutions must be obtained to

(1) First-fit algorithm: This algorithm combines rebars find an optimum solution. Algorithms from

which were read from RDF based on the given waste mathematical programming are necessary to expedite

rate (ε). The algorithm terminates the combining process such complicated calculations. Solving of the

when waste rate calculated from the first rebar optimization of rebar work is described by linear

combination are within the specified rate, in spite of programming. Algorithms based on Equations (1) and

further possible reductions in waste rate with following (2) can be suggested using data read from RDF as a form

combinations. For example, if rebars with of length 10m of array.

is to be combined using rebars of 7m, 2.8m and 3.0m

with the specified waste rate of 3%, the algorithm, based Decision variables

on the order of rebars stored in RDF, finds the first P = total sum of combined rebars for all structural

combination of 7m+2.8m=9.8m with waste rate of 2% members

(((10-9.8)/10)*100). The waste rate calculated from this Q = total sum of rebars to be ordered for all structural

combination is less than the given waste rate of 3%. The members

combination of 7m long rebars with 3m rebars instead p1, …, pn = sum of rebars combined in a certain length,

of 2.8m rebars is not considered, even though the waste q1, …, qn = sum of rebars to be ordered in a certain length

rate from combining with 3m rebars is zero. This

20 JAABE vol.3 no.1 May. 2004 Sun-Kuk Kim

Objective Function structural members of all floors (1 st-20 th floor) of 5

buildings except the foundation. Table 1 is a combination

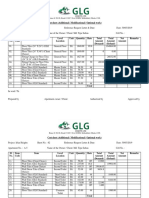

Minimize (3) list for the special order (combination number S1) of

10.6m long rebar. Rebars are combined with the

maximum material loss (waste rate) of 1.0% and

or (4) minimum quantity of 300 tons.

Subject to Table 1. Combination List for Special Order

(5)

(6)

Where the weight (tons) is the minimum quantity of a

purchase order, and ε represents the waste rate defined

by users. Decision variables, P, pi, Q, qi, of Equations

(3) and (4) are calculated by Equations (7), (8), (9) and

(10).

(7)

Where wi is the unit weight of the rebar. One rebar

element, pi, out of all rebars combined within a certain

length, {p1, .., pm}, is expressed as Equation (8).

(8) Table 2. Combination List for Normal Order

Where aj is the number of rebars combined within a

certain length and xj is the actual length of combined

rebars. The quantity of rebars to be ordered in a certain

length is given in Equation (9).

(9)

One rebar element, qi, out of all rebars to be ordered

in a certain length, {q1, .., qm}, is obtained from Equation

(10).

(10)

Where yi is the market length of rebars to be ordered.

Test Results of Proposed Algorithms

The algorithm presented in this study was programmed

with Visual C++ 4.0. Both the accuracy and applicability

D: Diameter in mm, L:Length in m, B.M.: Bar Mark, Nos: Number of bars’ under Table 2

to sites of the theory was validated by a case study of

high-rise residential buildings described as follows.

- Location : Yongin-si, Kyonggi-do, Korea The modified-first-fit algorithm was used to

- Total floor area : 92,435 m2 (20 stories x 5 buildings) economically combine rebars designated as in the first

- Structure : Bearing wall system column of Table 1. These rebars meet specified

- Duration of main structural work : June, 2000 - combining conditions. Single rebar lists without the need

December, 2000 (6 months except foundation work) of bar combination are shown by S1-1 through S1-10.

Five buildings managed by the same schedule of S1-11 is the list of special orders for combinations with

reinforcement work were considered for system tests in two rebars. For example, the waste rate is zero since the

this study even if the complex consisted of 20 buildings. rebars represented by S1-1 and S1-2 is 10.6m. S1-10

Tables 1 and 2 are the results of the combination for the generates a waste rate of 0.94 % and is included in the

16mm rebar most frequently used in the project. Every list. S1-11, which combines Bars 0085 and 0054, satisfied

rebar was assumed to be systematically managed during the condition of special order with waste rate of 0.28 %.

the 6 month construction period of the main structural The modified-first-fit algorithm, which selects long

framework. The combination was performed for rebars, is followed by the combination of short rebars to

JAABE vol.3 no.1 May. 2004 Sun-Kuk Kim 21

reduce computing time. All Bars 0085 are used for S-11 The difference of 40mm in length between Table 3

combination, whereas only 660 bars from bars 0054 (the and Fig. 5, called bending margin, resulted from the

total of 1645 bars) are used for the combination of S1- increase during bending process. In case of deformed

11 (Table 3). The rest of bars 0054 are used to combine bars, the bending margin is calculated by 2.5 times of

S1-24, S3-5, N1-18, N15-3 as shown in Table 1. the rebar size in diameter.

Finally, Table 1, containing results of the combination

of 23,945 rebars of length 10.6m, compares the order

weight of 395.955 tons with the net weight of 393.702

tons, demonstrating a waste rate of 0.469%. The real

diameter of the nominal 16mm diameter rebar is 15.9mm

while the unit weight is 1.56kg/m in KS (Korean

Standard). Rebar notations are defined by T16, H16 and

B16 instead of Y16 to clearly indicate the diameters and

locations of rebars. T, B, H, V and M represent top,

bottom, horizontal, vertical and middle bar, respectively.

Table 2 shows the combination list for normal orders

Fig. 5. A sample of bar tag

(combination number N1) of 9.0m long rebars. For this

combination, the maximum loss is 1% and there is no Table 4 are the results of rebar combination for special

limit to the minimum quantity for order. Rebars of 7, 8, orders (S1, S2, S3, …) and normal orders (N1, N2,…)

and 9m are combined first according to the algorithm based on given requirements, representing information

employed in this study and the combination based on including rebar length, number of rebars, weight of each

rebars of 6.0m, 6.5m, 7.5m, 10.0m, 11.0m and 12.0m is combination.

followed. However, the execution of combinations of

Table 4. Report of Combination Results

11m and 12m rebars is delayed till the order from site

due to the traffic condition.

Table 3 represents rebar sources of combination

managing all combined rebars by bar number. It provides

systematic tools for inventory management of rebar cut

off, enabling a bar bending process quickly and

effectively. Without these lists, it is difficult to locate

combined rebars for bar bending even if the rebar

combinations are successfully performed. For example,

since rebars 0054 are used for the combinations of S1-

11, S1-24, S3-5, N1-18, N15-3, one must keep track of

each combination to locate 1,645 rebars. Table 3

demonstrates results of all combined rebars, while rebars

of the same diameter can be printed out if necessary.

The detailed manufacturing information of Table 3 which

can be checked from the rebar schedule and bar tag as

shown in Fig. 5 is used to facilitate inventory

management of manufactured rebars. For instances, S1 is related to special purchase order,

one piece of information obtained from combination

Table 3. Rebar Sources of Combination

results shown in Table 1. Table 4, therefore, is used for

order of rebars manufactured according to combination

lists. It was shown from the combination of 16mm of

the sample project that total order quantity was 2,937.265

tons with the waste rate of 0.819%.

The reason that the total waste rate of 0.819 is larger

than those of S1 (0.469) and N1 (0.392) shown in Table

1 and 2 respectively is due to the larger waste rate of the

rest of the rebar combinations caused by the relieved

condition of the modified-first-fit algorithm. The waste

rate obtained from the secondary combination of rebars

left over from the main combination is calculated to be

over 3%. However, the influence of the secondary

combination on the overall waste rate is insignificant

because the rebar influenced by the secondary

combination is relatively small compared to the total

22 JAABE vol.3 no.1 May. 2004 Sun-Kuk Kim

quantity. The actual construction data revealed that the structural design data was a difficult task in this study.

project used 3,007.97 tons of 16mm rebar, generating A more efficient format, automatically using structural

the waste rate of 3.246%. The waste rate could have been design data for the management of rebar work, needs to

reduced down to 0.819%, saving 70.705 tons of rebar be developed in order to effectively deal with a series of

(2.427% waste rate) equivalent to 30,300 USD (about works including structural design, the preparation of

35 million Korean won) if the algorithm proposed by structural drawings and rebar details, and optimization

this study had been implemented for the construction of rebar work.

management of rebar work. If the construction of all 20

buildings under consideration had been carried out References

applying the algorithm of this paper, approximately 400 1) Bernold, L.E., and Salim, Md. (1993) “Placement-oriented design

tons of steel worth 170,000 USD (199 million Korean and delivery of concrete reinforcement.” J. Constr. Engrg. and

Mgmt., ASCE, 119 (2), 323-335

won) could have been saved. 2) Dunston, P.S., and Bernold, L.E. (1994) “Adaptive control for

robotic rebar bending.” Microcomputers in Civ. Engrg., Oxford,

Conclusions England, 9, 53-60

A Considerable waste rate occurs if sufficient attention 3) Dunston, P.S., and Bernold, L.E. (2000) “Adaptive control for safe

is not paid to the management of complex rebar work of and quality rebar fabrication.” J. Constr. Engrg and Mgmt, ASCE,

126 (2), 122-129

construction projects. A great deal of rebars can be saved 5) Horowitz, Ellis, and Sahni, Sartaj (1983) “Fundamentals of data

with increased productivity when purchase orders, structures”, Computer Science Press, Inc., Maryland, 342

manufactures and installations are carried out according 6) Kim, S.K. (1987). “A Report of Rebar Waste Rate Analysis of RC

to construction schedules, while both rebar details and Structures”, Daelim Industrial Co., Ltd., Korea, 16-17

7) Kim, S.K., and Kim, C.K. (1994) “Integrated Automation of

required optimal rebar quantities are prepared based on

Structural Design and Rebar Work in RC Structure”, J. Structure

the algorithm presented in this study. and Construction, the Architectural Institute of Korea, 10(1), 113-

The example run demonstrated the reduction in the 122

waste rate by about 2.4 percentage points by 8) Kim, S.K. (2002) “A System Development for Automatic Detail

implementing the algorithm of this paper. Relatively Design and Estimation of Rebar Work”, the 1 st year Research

Report, Gyeonggi Regional Small & Medium Business

much reduction of waste is expected from plant Administration, Korea, 84-90

construction involved with various types of rebars than 9) Navon, R., Rubinovitz, Y., and Coffler, M. (1995) “RCCS: Rebar

from the construction of high rise residential and CAD/CAM System” Microcomputers in Civ. Engrg., Oxford,

commercial buildings in which rebars of typical length England, 10, 385-400

and diameter are repeated throughout design. 10) Navon, R., Rubinovitz, Y., and Coffler, M. (1996) “Fully automated

rebar CAD/CAM system: economic evaluation and field

The example study also demonstrated the combination implementation.” J. Constr. Engrg and Mgmt, ASCE, 122 (2), 101-

algorithm, among all algorithms presented in this 108

research, enhances not only computing efficiency but 11) Navon, R., Shapira, A., and Shechori, Y. (2000) “Automated rebar

also the efficiency of rebar management related to constructability diagnosis.” J. Constr. Engrg and Mgmt, ASCE, 126

construction schedules. The modified-first-fit algorithm (5), 389-397

12) Salim, M., and Bernold, L.E. (1994) “Effects of design-integrated

is considered to be the best algorithm empirically in process planning on productivity in rebar placement.” J. Constr.

maximizing combination efficiency and applicability Engrg. and Mgmt., ASCE, 120 (4), 720-738

while minimizing computing time.

The prompt extraction of precise rebar data from

JAABE vol.3 no.1 May. 2004 Sun-Kuk Kim 23

También podría gustarte

- Reinforced Concrete Buildings: Behavior and DesignDe EverandReinforced Concrete Buildings: Behavior and DesignCalificación: 5 de 5 estrellas5/5 (1)

- 3 17 PDFDocumento7 páginas3 17 PDFmiguelcabezasb3268Aún no hay calificaciones

- Production Technology of ROPS Cab: Technical PaperDocumento8 páginasProduction Technology of ROPS Cab: Technical Paperjose rosasAún no hay calificaciones

- buildings-13-02279Documento24 páginasbuildings-13-02279x fAún no hay calificaciones

- Investigations For Deducing Wall Thickness of Aluminium Shell Casting Using Three Dimensional PrintingDocumento5 páginasInvestigations For Deducing Wall Thickness of Aluminium Shell Casting Using Three Dimensional PrintingR Moses KrupavaramAún no hay calificaciones

- Rapid Investment Casting: Direct and Indirect Approaches Via Fused Deposition ModellingDocumento9 páginasRapid Investment Casting: Direct and Indirect Approaches Via Fused Deposition ModellingNitin GroverAún no hay calificaciones

- Lecture 2 - Economy of FormworkDocumento39 páginasLecture 2 - Economy of FormworkHassan FadenAún no hay calificaciones

- 3D Printing of Reinforced Concrete Elements Technology and DesignDocumento14 páginas3D Printing of Reinforced Concrete Elements Technology and DesignSharifah Intan Amira Binti Sayed Mustaffa KamalAún no hay calificaciones

- Optimasi Pemotongan Besi Tulangan Pada Pekerjaan Struktur Menggunakan Metode Linear ProgrammingDocumento11 páginasOptimasi Pemotongan Besi Tulangan Pada Pekerjaan Struktur Menggunakan Metode Linear ProgrammingForming CA GondangAún no hay calificaciones

- Ijtsrd25231 PDFDocumento14 páginasIjtsrd25231 PDFanon_776112819Aún no hay calificaciones

- Surface RoughnessDocumento14 páginasSurface RoughnessqualityfreekAún no hay calificaciones

- Sand Casting Using RP and Conventional MethodsDocumento5 páginasSand Casting Using RP and Conventional MethodsjlplazaolaAún no hay calificaciones

- Development of Complex Patterns: Scope and Benefits of Rapid Prototyping in FoundriesDocumento5 páginasDevelopment of Complex Patterns: Scope and Benefits of Rapid Prototyping in FoundriesPrasad RaikarAún no hay calificaciones

- Segment Design - RETC 2003-From CD - Kramer Et Al-LDocumento14 páginasSegment Design - RETC 2003-From CD - Kramer Et Al-Lprotal7351100% (1)

- File 11Documento3 páginasFile 11leovinAún no hay calificaciones

- 3D Printing Technique Applied To Rapid Casting: Elena Bassoli and Andrea GattoDocumento8 páginas3D Printing Technique Applied To Rapid Casting: Elena Bassoli and Andrea GattouzairmetallurgistAún no hay calificaciones

- Circular Concrete Construction Through Additive FDM FormworkDocumento10 páginasCircular Concrete Construction Through Additive FDM Formworkhamed sadaghianAún no hay calificaciones

- FIBERSIM Software Streamlines Composite DesignDocumento9 páginasFIBERSIM Software Streamlines Composite DesignTakis PlimirasAún no hay calificaciones

- Al Billet CuttingDocumento5 páginasAl Billet Cuttingshaik abdullahAún no hay calificaciones

- IISRT Sohan SontakkeDocumento4 páginasIISRT Sohan SontakkeIISRTAún no hay calificaciones

- Cost optimisation of reinforced concrete flat slab designDocumento15 páginasCost optimisation of reinforced concrete flat slab designALIAún no hay calificaciones

- Design Methods For Flexibly Formed Concrete BeamsDocumento29 páginasDesign Methods For Flexibly Formed Concrete BeamsRoberto Pinto VillegasAún no hay calificaciones

- Optimization of Floor Design To Reduce Reinforcement Cost in RC SlabDocumento2 páginasOptimization of Floor Design To Reduce Reinforcement Cost in RC SlabMarcus MokAún no hay calificaciones

- Design and Manufacturing of A Non-Standard Chain Parts For A Scraper Chain Conveyor - A Case StudyDocumento7 páginasDesign and Manufacturing of A Non-Standard Chain Parts For A Scraper Chain Conveyor - A Case StudyMohammed GamilAún no hay calificaciones

- Additive Manufacturing LettersDocumento8 páginasAdditive Manufacturing Letterssrinathgudur11Aún no hay calificaciones

- Effect of Column Spacing On Economy of G+5 R.C Moment Resisting Frame - A Typical Computer Aided Case StudyDocumento18 páginasEffect of Column Spacing On Economy of G+5 R.C Moment Resisting Frame - A Typical Computer Aided Case StudyHarsh ShahAún no hay calificaciones

- Ijciet: International Journal of Civil Engineering and Technology (Ijciet)Documento8 páginasIjciet: International Journal of Civil Engineering and Technology (Ijciet)IAEME PublicationAún no hay calificaciones

- Reduction of Wastage of Rebar by Using BIM and Linear ProgrammingDocumento6 páginasReduction of Wastage of Rebar by Using BIM and Linear Programmingrohit.rk2009262Aún no hay calificaciones

- Optimization of Singly Reinforced RC Beams: ScienceDocumento9 páginasOptimization of Singly Reinforced RC Beams: ScienceKillian WismanAún no hay calificaciones

- Advantages of Structural Steel StructuresDocumento6 páginasAdvantages of Structural Steel StructuresHnin Nwe SoeAún no hay calificaciones

- Additively Manufacturing An Indexable Insert: IOP Conference Series: Materials Science and EngineeringDocumento6 páginasAdditively Manufacturing An Indexable Insert: IOP Conference Series: Materials Science and Engineeringsiva kumarAún no hay calificaciones

- Geometrical Metrology For Metal Additive ManufacturingDocumento24 páginasGeometrical Metrology For Metal Additive ManufacturingPhilipe Saraiva CruzAún no hay calificaciones

- Formwork Analysis Analysis of Formwork Types for Cost Optimization in Multistory BuildingsDocumento3 páginasFormwork Analysis Analysis of Formwork Types for Cost Optimization in Multistory BuildingsCIVIL DEPARTMENT MMANTCAún no hay calificaciones

- Advanced Composite Engineering Using MSC - Patran and FibersimDocumento15 páginasAdvanced Composite Engineering Using MSC - Patran and FibersimSandeep BandyopadhyayAún no hay calificaciones

- Design of Machining Fixture-685Documento9 páginasDesign of Machining Fixture-685Omofon UdohAún no hay calificaciones

- Cutting Waste Minimization of Rebar For Sustainable Structural Work: A Systematic Literature ReviewDocumento21 páginasCutting Waste Minimization of Rebar For Sustainable Structural Work: A Systematic Literature ReviewAlex AbrhaAún no hay calificaciones

- Experimental Study Aiming To Enhance The Surface Finish of Fused Deposition Modeled PartsDocumento4 páginasExperimental Study Aiming To Enhance The Surface Finish of Fused Deposition Modeled Partsnewkid2202Aún no hay calificaciones

- Rapid CastingDocumento23 páginasRapid CastingquarkenAún no hay calificaciones

- Design Long Hand Flanged Beam PDFDocumento66 páginasDesign Long Hand Flanged Beam PDFMauricio Bustamante HuaquipaAún no hay calificaciones

- A New Method For Roll Pass Design Optimi PDFDocumento12 páginasA New Method For Roll Pass Design Optimi PDFFarooq Ameer Jordan WalaAún no hay calificaciones

- 3130 111908 1 SMDocumento10 páginas3130 111908 1 SMAziz TrisnaputraAún no hay calificaciones

- Fibers: Reinforcement Systems For Carbon Concrete Composites Based On Low-Cost Carbon FibersDocumento21 páginasFibers: Reinforcement Systems For Carbon Concrete Composites Based On Low-Cost Carbon FibersJaveria AfzalAún no hay calificaciones

- Lampa Ijcim Dalsanto 2014Documento11 páginasLampa Ijcim Dalsanto 2014Sk.Abdul NaveedAún no hay calificaciones

- Data 1Documento12 páginasData 1ssc.shumailkhan.191167Aún no hay calificaciones

- Rapid Prototipyng Foundries ArticleDocumento5 páginasRapid Prototipyng Foundries ArticlebeiboxAún no hay calificaciones

- An Expert System For Process Planning of Sheet Metal Parts Produced On Compound Die For Use in Stamping IndustriesDocumento7 páginasAn Expert System For Process Planning of Sheet Metal Parts Produced On Compound Die For Use in Stamping Industriesmis2hijosAún no hay calificaciones

- 1421 PaperDocumento6 páginas1421 PaperTarik Hassan ElsonniAún no hay calificaciones

- Designing Bar-Mesh Modules of Reinforced Concrete StructuresDocumento20 páginasDesigning Bar-Mesh Modules of Reinforced Concrete StructuresTomasz WiatrAún no hay calificaciones

- Multi-Objective Optimization of Reinforced Concrete Frames Using Nsga-Ii AlgorithmDocumento8 páginasMulti-Objective Optimization of Reinforced Concrete Frames Using Nsga-Ii AlgorithmAusbel Joab Cuyo TtitoAún no hay calificaciones

- Journal 7 PDFDocumento10 páginasJournal 7 PDFSree KanthAún no hay calificaciones

- Design and Development of An Additive Manufactured Component by Topology OptimisationDocumento6 páginasDesign and Development of An Additive Manufactured Component by Topology OptimisationJon SnowAún no hay calificaciones

- Document 2 b7v1 27032016Documento6 páginasDocument 2 b7v1 27032016Mohamed Ismail ShehabAún no hay calificaciones

- Buildings 12 01904Documento22 páginasBuildings 12 01904aykutartacAún no hay calificaciones

- Redesign and Topology Optimization of An Industrial Robot Link For Additive ManufacturingDocumento10 páginasRedesign and Topology Optimization of An Industrial Robot Link For Additive ManufacturingGogyAún no hay calificaciones

- C.9. Design Considerations For Economical FormworkDocumento10 páginasC.9. Design Considerations For Economical FormworkRsjBugtongAún no hay calificaciones

- 3d Printing of Column Structures For Architectural ApplicationsDocumento10 páginas3d Printing of Column Structures For Architectural Applicationslethao2011Aún no hay calificaciones

- Advanced design optimization of steel portal frames using genetic algorithmsDocumento18 páginasAdvanced design optimization of steel portal frames using genetic algorithmsمازن ال بدريAún no hay calificaciones

- A Computational Model To AutomDocumento14 páginasA Computational Model To AutomRenzo Chávez HurtadoAún no hay calificaciones

- Advanced Design and Optimization of Steel Portal Frames: January 2010Documento18 páginasAdvanced Design and Optimization of Steel Portal Frames: January 2010basel abduAún no hay calificaciones

- Publication Conference PDFDocumento3 páginasPublication Conference PDFJunaid NabiAún no hay calificaciones

- Daily construction site manpower and equipment reportDocumento2 páginasDaily construction site manpower and equipment reportmanowarAún no hay calificaciones

- Guidelines 45Documento1 páginaGuidelines 45vkapo9325Aún no hay calificaciones

- 01 A1 Activated Sludge Model (GPS-X) & SimulationDocumento32 páginas01 A1 Activated Sludge Model (GPS-X) & SimulationmanowarAún no hay calificaciones

- 05 C1 Hydraulic Calculation-Sewage Treatment FacilityDocumento22 páginas05 C1 Hydraulic Calculation-Sewage Treatment FacilitymanowarAún no hay calificaciones

- CE 107: Introduction To Civil and Environmental EngineeringDocumento26 páginasCE 107: Introduction To Civil and Environmental Engineeringnahid rahmanAún no hay calificaciones

- Design Methods and RequirementsDocumento16 páginasDesign Methods and RequirementsmanowarAún no hay calificaciones

- ExcavationDocumento9 páginasExcavationmanowarAún no hay calificaciones

- Reinforcing Bar Bending Schedule for Sewage Treatment PlantDocumento1 páginaReinforcing Bar Bending Schedule for Sewage Treatment PlantmanowarAún no hay calificaciones

- Excavation VolumeDocumento2 páginasExcavation VolumemanowarAún no hay calificaciones

- Civil Question and AnswerDocumento20 páginasCivil Question and AnswerAbdul Hadi JeelaniAún no hay calificaciones

- Sewerage System Treatment Facilities Construction in ChattogramDocumento2 páginasSewerage System Treatment Facilities Construction in ChattogrammanowarAún no hay calificaciones

- Analysis of Multi-Storeyed BuildingDocumento9 páginasAnalysis of Multi-Storeyed BuildingIJIRSTAún no hay calificaciones

- Pond VolumeDocumento16 páginasPond VolumemanowarAún no hay calificaciones

- Circular Pile Rebar CalculationDocumento1 páginaCircular Pile Rebar CalculationmanowarAún no hay calificaciones

- CEN 213 Guide to Civil Engineering Materials & Building StonesDocumento13 páginasCEN 213 Guide to Civil Engineering Materials & Building StonesmanowarAún no hay calificaciones

- Building Codes. These Exist To Protect The Public Health and Safety. The Definitive DesignDocumento5 páginasBuilding Codes. These Exist To Protect The Public Health and Safety. The Definitive DesignmanowarAún no hay calificaciones

- Calculation of Wind Loads On Structures According To ASCE 7 - 2005 Wind Load Calculation ProceduresDocumento8 páginasCalculation of Wind Loads On Structures According To ASCE 7 - 2005 Wind Load Calculation ProcedureslsatchithananthanAún no hay calificaciones

- RSU Análisis PDFDocumento43 páginasRSU Análisis PDFPato VasquezAún no hay calificaciones

- Citation 323705983Documento1 páginaCitation 323705983manowarAún no hay calificaciones

- ReleaseNotesETABSv1801 PDFDocumento31 páginasReleaseNotesETABSv1801 PDFBMSF khaliqeAún no hay calificaciones

- Excerpts From Lecture Notes of Professor M. Ashraf Ali, BUETDocumento36 páginasExcerpts From Lecture Notes of Professor M. Ashraf Ali, BUETmanowarAún no hay calificaciones

- Extra Cost Sheet - A-5Documento14 páginasExtra Cost Sheet - A-5manowarAún no hay calificaciones

- Archi Floor PlanDocumento1 páginaArchi Floor PlanmanowarAún no hay calificaciones

- CUET ConferenceDocumento6 páginasCUET ConferencemanowarAún no hay calificaciones

- ESTIMATION OF FOOTING DETAILSDocumento16 páginasESTIMATION OF FOOTING DETAILSmanowarAún no hay calificaciones

- WIND LOAD CALCULATION - Pressure CoefficientDocumento2 páginasWIND LOAD CALCULATION - Pressure CoefficientmanowarAún no hay calificaciones

- Reinforcement Layout Slab DesignDocumento1 páginaReinforcement Layout Slab DesignmanowarAún no hay calificaciones

- InfoDocumento3 páginasInfomanowarAún no hay calificaciones

- Liu030 Nepal Bans Solo Mountain ClimbersDocumento2 páginasLiu030 Nepal Bans Solo Mountain Climberssanti.miranda.parrillaAún no hay calificaciones

- Project On International BusinessDocumento18 páginasProject On International BusinessAmrita Bharaj100% (1)

- C++ Programmierung (Benjamin Buch, Wikibooks - Org)Documento257 páginasC++ Programmierung (Benjamin Buch, Wikibooks - Org)stefano rossiAún no hay calificaciones

- Efficient Power Supply for Inductive LoadsDocumento7 páginasEfficient Power Supply for Inductive LoadsMary AndersonAún no hay calificaciones

- Matador - : Medical Advanced Training in An Artificial Distributed EnvironmentDocumento25 páginasMatador - : Medical Advanced Training in An Artificial Distributed EnvironmentNauman ChaudaryAún no hay calificaciones

- Course Handbook MSC Marketing Sept2022Documento58 páginasCourse Handbook MSC Marketing Sept2022Tauseef JamalAún no hay calificaciones

- IBM Systems Journal PerspectivesDocumento24 páginasIBM Systems Journal PerspectivesSmitha MathewAún no hay calificaciones

- Beyond B2 English CourseDocumento1 páginaBeyond B2 English Coursecarlitos_coolAún no hay calificaciones

- Relation of Jurisprudence With Other Social Sciences - LLB NotesDocumento4 páginasRelation of Jurisprudence With Other Social Sciences - LLB NotesPranjaliBawaneAún no hay calificaciones

- Edexcel A2 Biology 6BI06Documento7 páginasEdexcel A2 Biology 6BI06abhayAún no hay calificaciones

- 7 React Redux React Router Es6 m7 SlidesDocumento19 páginas7 React Redux React Router Es6 m7 Slidesaishas11Aún no hay calificaciones

- 3170308Documento3 páginas3170308Dhruv DesaiAún no hay calificaciones

- Audi A3 Quick Reference Guide: Adjusting Front SeatsDocumento4 páginasAudi A3 Quick Reference Guide: Adjusting Front SeatsgordonjairoAún no hay calificaciones

- EasyLogic PM2000 Series - METSEPM2130Documento4 páginasEasyLogic PM2000 Series - METSEPM2130ٍJordan SportAún no hay calificaciones

- Export - Import Cycle - PPSXDocumento15 páginasExport - Import Cycle - PPSXMohammed IkramaliAún no hay calificaciones

- Bonding in coordination compoundsDocumento65 páginasBonding in coordination compoundsHitesh vadherAún no hay calificaciones

- Pathways-Childrens Ministry LeaderDocumento16 páginasPathways-Childrens Ministry LeaderNeil AtwoodAún no hay calificaciones

- Assignment 2: Lesson Plan Analysis, Revision and Justification - Kaitlin Rose TrojkoDocumento9 páginasAssignment 2: Lesson Plan Analysis, Revision and Justification - Kaitlin Rose Trojkoapi-408336810Aún no hay calificaciones

- 01 WELD-2022 Ebrochure 3Documento5 páginas01 WELD-2022 Ebrochure 3Arpita patelAún no hay calificaciones

- 4 DiscussionDocumento2 páginas4 DiscussiondreiAún no hay calificaciones

- After EffectsDocumento56 páginasAfter EffectsRodrigo ArgentoAún no hay calificaciones

- BE 510 Business Economics 1 Problem Set 5 SolutionsDocumento5 páginasBE 510 Business Economics 1 Problem Set 5 SolutionsCreative Work21stAún no hay calificaciones

- Culinary Nutrition BasicsDocumento28 páginasCulinary Nutrition BasicsLIDYAAún no hay calificaciones

- Case Acron PharmaDocumento23 páginasCase Acron PharmanishanthAún no hay calificaciones

- Solidwork Flow Simulation TutorialDocumento298 páginasSolidwork Flow Simulation TutorialMilad Ah100% (8)

- Lending Tree PDFDocumento14 páginasLending Tree PDFAlex OanonoAún no hay calificaciones

- AP World History: Islamic Empires and Scientific AdvancementDocumento55 páginasAP World History: Islamic Empires and Scientific AdvancementJa'TasiaAún no hay calificaciones

- ACM JournalDocumento5 páginasACM JournalThesisAún no hay calificaciones

- Design Your Loyalty Program in 2 WeeksDocumento53 páginasDesign Your Loyalty Program in 2 WeeksLorena TacuryAún no hay calificaciones

- CGL Flame - Proof - MotorsDocumento15 páginasCGL Flame - Proof - MotorspriteshAún no hay calificaciones