Documentos de Académico

Documentos de Profesional

Documentos de Cultura

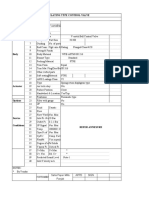

Control Valve - 3way

Cargado por

rockykrish0 calificaciones0% encontró este documento útil (0 votos)

57 vistas2 páginasControl Valve- 3way

Título original

Control Valve- 3way

Derechos de autor

© © All Rights Reserved

Formatos disponibles

DOCX, PDF, TXT o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoControl Valve- 3way

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como DOCX, PDF, TXT o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

57 vistas2 páginasControl Valve - 3way

Cargado por

rockykrishControl Valve- 3way

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como DOCX, PDF, TXT o lea en línea desde Scribd

Está en la página 1de 2

PROJECTS AND MANAGEMENT SERVICES

REV SPECIFICATION NUMBER CONTROL VALVES SH 1 OF 3

DATA SHEET

1 GENERAL TRAVEL INDICATOR : REQUIRED

2 MANUFACTURER : POSITIONER (REFER NOTE 2)

3 MODEL NO. : TYPE : SMART

4 TAG NOs: REFER FOLLOW UP SHEET OPERATING RANGE : FULL

SPLIT 0-50% SPLIT 50-100%

5 TYPE INPUT SIGNAL RANGE : 4-20mA HART

0.2-1 kg/cm(g)

6 VALVE (REFER NOTE 3) OUTPUT SIGNAL RANGE :

7 BODY STYLE : ANGLE GLOBE ON INCREASE IN OUTPUT SIGNAL VALVE SHALL

SPLIT Y-TYPE CAGE OPEN CLOSE

8 VALVE TYPE : BALL PLUG BUTTERFLY BY PASS : NO YES

SAUNDERS

9 PORT : SINGLE DOUBLE3-WAY INPUT/ OUTPUT GAUGES : YES NO

10 TRIM : BALANCE UNBALANCED SUPPLY GAUGES : YES NO

11 APPLICATION :ON-OFF MODULATING MOUNTING : YOKE

12 BODY SIZE : AREA CLASSIFICATION: INTRINSICALLY SAFE TO

ZONE 0 1 2

GAS GROUP : IIA IIB IIC

TEMP. CLASS: T1 T2 T3 T4 T5 T6

13 LEAKAGE CLASS : CLASS VI FOR LIQUID MATERIAL OF CONSTRUCTION

14 MIN. DIFF. PRESSURE REQD. TO OPEN THE VALVE BODY: CS SS

VALVE ALLOY STEEL ASTM A216 GR.WCB

REFER NOTE 10

15 BONNET:

SS316 ASTM A216 GR.WCB

GASKET: REFER NOTE 10

16 TRIM

STEM MATERIAL : SS 316 13% Cr. Steel

PLUG MATERIAL : SS 316 13% Cr. Steel

GUIDE/ CAGE MATERIAL : SS 316

BELLOWS MATERIAL :

17 BONNET DIAPHRAGM : BUNA N NITRILE

18 STD EXTENDED COOLING FIN BOLT MATERIAL: REFER NOTE 10

19 TRIM NUT MATERIAL: REFER NOTES 10

20 PORT : REDUCED FULL PACKING MATERIAL: PTFE

21 FLOW CHARACTERISTIC : QO LINEAR DOUBLE COMPRESSION GLAND:

EQ% PARABOLIC

22 GUIDE : CAGETOP & BOTTOM TOP CONNECTIONS & DIMENSIONS

BOTTOM

23 STEM SIZE : END CONNECTIONS:

SW BW

THREADED FLANGED

24 THREADED CONNECTION:

NPT(F) BSP(F)

SIZE:

25 VALVE ACTION FLANGED CONNECTION:

FLANGE RATING: REFER FOLLOW UP SHEET

26 PUSH DOWN TO: OPEN CLOSE CONDUIT CONNECTION: ½” NPT (F)

27 FAIL SAFE ACTION: REFER FOLLOW UP SHEET ACCESSORIES (REF. NOTE 2, 4)

28 FLOW DIRECTION: FTO FTC NAME PLATE/ METAL TAG: REQUIRED

29 MAX. ALLOWABLE AIR PRESSURE:

30 MIN. REQUIRED AIR PRESSURE:

31

32 ACTUATOR (REF. NOTES 1, 2)

33 TYPE : ELECTRO-MECH SERVO

34 PISTON DIAPHRAGM

35 SERVICE : ON-OFF MODULATING

36 MOUNTING : HORIZONTAL VERTICAL

37 SIZE/EFF. AREA :

38 SPRING TO: OPEN CLOSE

39 ON INCREASE IN SIGNAL STEM TO MOVE

UP DOWN

40 HANDWHEEL NO YES

41 ADJUSTABLE STOP : AS REQUIRED

42 RANGE OF SIGNAL TO ACTUATOR :

También podría gustarte

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDe EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsAún no hay calificaciones

- V-Tal-Mec-0003-Oc-14 - SLP-D-001-0002 - 00Documento3 páginasV-Tal-Mec-0003-Oc-14 - SLP-D-001-0002 - 00eskra garzonAún no hay calificaciones

- Data Sheet SphericalDocumento12 páginasData Sheet SphericalYosses Sang Nahkoda100% (2)

- Data Sheet of High Pressure PumpDocumento2 páginasData Sheet of High Pressure Pumpsajeesh5113699Aún no hay calificaciones

- Datasheet For Hopper (D-3103)Documento1 páginaDatasheet For Hopper (D-3103)Joe GrosirAún no hay calificaciones

- Native File For Pump (Example)Documento2 páginasNative File For Pump (Example)Venturindo SiteAún no hay calificaciones

- 6-Pressure Safety ValveDocumento1 página6-Pressure Safety ValveFari NazariAún no hay calificaciones

- General: Crude Oil - 219 Crude Oil - 219 1.117 82.6Documento1 páginaGeneral: Crude Oil - 219 Crude Oil - 219 1.117 82.6amirAún no hay calificaciones

- Shut Down Valve Sample DatasheetsDocumento6 páginasShut Down Valve Sample DatasheetsBABILIN V100% (1)

- 2055 Ed 2FGGF7 B1 9Documento1 página2055 Ed 2FGGF7 B1 9amirAún no hay calificaciones

- PG Pressure GaugeDocumento2 páginasPG Pressure GaugeAr RahmanAún no hay calificaciones

- File 5Documento1 páginaFile 5VENKATACHALAM SUBBARAJAún no hay calificaciones

- General: Crude Oil Crude Oil - 219 219Documento1 páginaGeneral: Crude Oil Crude Oil - 219 219amirAún no hay calificaciones

- General: Crude Oil Crude Oil - 219 219 1.117 1.14Documento1 páginaGeneral: Crude Oil Crude Oil - 219 219 1.117 1.14amirAún no hay calificaciones

- 0ZSEITCV075 Aux Boiler TCV Data SheetDocumento1 página0ZSEITCV075 Aux Boiler TCV Data Sheetjean-marie BOGUYAún no hay calificaciones

- Mansarovar Energy-Campo JazminDocumento169 páginasMansarovar Energy-Campo JazminFRANCISCO BADILLOAún no hay calificaciones

- ON-OFF Valves LTWDocumento2 páginasON-OFF Valves LTWMeoAún no hay calificaciones

- General: Crude Oil - 219 1.117 4.6 Crude Oil - 219Documento1 páginaGeneral: Crude Oil - 219 1.117 4.6 Crude Oil - 219amirAún no hay calificaciones

- Anexo 2 - Hoja de Datos Valvula de Diagragma (30-XV-4069)Documento1 páginaAnexo 2 - Hoja de Datos Valvula de Diagragma (30-XV-4069)Antezana RodriguezAún no hay calificaciones

- Data Sheet Flanged End Globe ValveDocumento1 páginaData Sheet Flanged End Globe ValveIbad Alam100% (1)

- Contoh SoalDocumento13 páginasContoh Soalmarkus andikaAún no hay calificaciones

- NitrogenDocumento1 páginaNitrogensurendharAún no hay calificaciones

- Hojas de Datos Valvulas de ControlDocumento4 páginasHojas de Datos Valvulas de ControlMauricio Cuevas HinojosaAún no hay calificaciones

- Extracted Pages From NAFD-CPFXXX-ECME-DSME-0042-AB - Data Sheet For Pressurized Deaerator (v-13550)Documento3 páginasExtracted Pages From NAFD-CPFXXX-ECME-DSME-0042-AB - Data Sheet For Pressurized Deaerator (v-13550)Mo OsAún no hay calificaciones

- Datasheet For Level Controller - IfbDocumento27 páginasDatasheet For Level Controller - Ifbfathan fathullahAún no hay calificaciones

- 50 V-Notch Valve2Documento1 página50 V-Notch Valve2SIL PROJECTSAún no hay calificaciones

- 100 V-Notch (Pulp)Documento1 página100 V-Notch (Pulp)SIL PROJECTSAún no hay calificaciones

- 300 # ANSI Piping DataDocumento13 páginas300 # ANSI Piping DataMekar MeinaAún no hay calificaciones

- ENQUIRY NO.: E-Mail Dated 28.03.2019 CLIENT: M/s.M.K.Roy & Bros Projects Limited. Our Offer Ref.: LI/101/QTN/ 5237 / 3742 /2018 - 2019 Date. 28.03.2019Documento3 páginasENQUIRY NO.: E-Mail Dated 28.03.2019 CLIENT: M/s.M.K.Roy & Bros Projects Limited. Our Offer Ref.: LI/101/QTN/ 5237 / 3742 /2018 - 2019 Date. 28.03.2019Vetsa VivekAún no hay calificaciones

- Tosaca: CX 45-21 RFQ PSVDocumento2 páginasTosaca: CX 45-21 RFQ PSVichi ezzahraAún no hay calificaciones

- Proyectos de Instrumentaci On "Flotation / Rougher" "Informe N#2"Documento4 páginasProyectos de Instrumentaci On "Flotation / Rougher" "Informe N#2"luis alvarezAún no hay calificaciones

- 150 # ANSI Piping DataDocumento21 páginas150 # ANSI Piping DataMekar MeinaAún no hay calificaciones

- Pa Fe 117Documento2 páginasPa Fe 117milton1987Aún no hay calificaciones

- Control Valves Datasheet PDFDocumento7 páginasControl Valves Datasheet PDFAlvin SmithAún no hay calificaciones

- Diesel Tank DSDocumento1 páginaDiesel Tank DSNurcahyo Djati W0% (1)

- Datasheet For Cyclone Hopper (D-3116)Documento1 páginaDatasheet For Cyclone Hopper (D-3116)Joe GrosirAún no hay calificaciones

- Padmount Specification Summary Sheet: Fluid: Temp: ConductorDocumento2 páginasPadmount Specification Summary Sheet: Fluid: Temp: Conductorpeloquin1349391Aún no hay calificaciones

- 0ZSIRLS001 SAMWONG SERA Contacteur de Niv Data SheetDocumento1 página0ZSIRLS001 SAMWONG SERA Contacteur de Niv Data Sheetjean-marie BOGUYAún no hay calificaciones

- 1-Fisher Specification and Sizing Sheets - RevCDocumento3 páginas1-Fisher Specification and Sizing Sheets - RevCheikelAún no hay calificaciones

- Foglio Progetto Tubazioni Ripr. Acque Oleose Ed Acide/alc.: DOC. N°: P12TV01005 Rev.02Documento85 páginasFoglio Progetto Tubazioni Ripr. Acque Oleose Ed Acide/alc.: DOC. N°: P12TV01005 Rev.02PaulAún no hay calificaciones

- Instrument Data Sheets: Revision HistoryDocumento9 páginasInstrument Data Sheets: Revision Historyerik masongAún no hay calificaciones

- Control Valve DatasheetDocumento1 páginaControl Valve DatasheetretrogradesAún no hay calificaciones

- Specification Cum General Arrangement Drawing Model No.: Srg-1 Reflex Level GaugeDocumento1 páginaSpecification Cum General Arrangement Drawing Model No.: Srg-1 Reflex Level GaugeHemant NimaseAún no hay calificaciones

- A307 Ius Uv DS 1201Documento2 páginasA307 Ius Uv DS 1201smartravi222Aún no hay calificaciones

- Data Sheet of Filtered WaterCentrifugal PumpDocumento2 páginasData Sheet of Filtered WaterCentrifugal Pumpsajeesh5113699Aún no hay calificaciones

- PQR Babbit SCDocumento34 páginasPQR Babbit SCagustinusAún no hay calificaciones

- Data Sheet For L.P Dosing SystemDocumento2 páginasData Sheet For L.P Dosing SystemV U P RaoAún no hay calificaciones

- 600 # ANSI Piping DataDocumento16 páginas600 # ANSI Piping DataMekar MeinaAún no hay calificaciones

- Specs Sheet Duplicate 9655021-3-4 & AD993180Documento8 páginasSpecs Sheet Duplicate 9655021-3-4 & AD993180Fathan KarimanAún no hay calificaciones

- TLDD-2016-2AAG-D06-0001 - Code 2Documento5 páginasTLDD-2016-2AAG-D06-0001 - Code 2Cao Huu Tung100% (1)

- Data Sheet Level Gauge: GeneralDocumento5 páginasData Sheet Level Gauge: GeneralJKKAún no hay calificaciones

- Heat Exchanger: E-3711: Connections Tube Side Shell SideDocumento1 páginaHeat Exchanger: E-3711: Connections Tube Side Shell SidealiAún no hay calificaciones

- Design Conditions Units Min Nor MaxDocumento2 páginasDesign Conditions Units Min Nor MaxJay RathodAún no hay calificaciones

- En2458 75 Lit60001 - 09Documento1 páginaEn2458 75 Lit60001 - 09Dela AmandaAún no hay calificaciones

- Lab 2 (Ii) HeDocumento8 páginasLab 2 (Ii) HeSchaieraAún no hay calificaciones

- Check Valve DescriptionDocumento1 páginaCheck Valve DescriptionmoodydoodyAún no hay calificaciones

- MPFM Data SheetDocumento2 páginasMPFM Data SheetPedro NuñezAún no hay calificaciones

- Globe Rev. A SHT 2Documento1 páginaGlobe Rev. A SHT 2Agus SupriadiAún no hay calificaciones

- General: CRUDE OIL / Liquid 313.9 / 313.9Documento1 páginaGeneral: CRUDE OIL / Liquid 313.9 / 313.9amirAún no hay calificaciones

- DELUGE VALVES DATASHEET Rev.01Documento1 páginaDELUGE VALVES DATASHEET Rev.01moodydoodyAún no hay calificaciones

- Electrical Machines and DrivesDocumento123 páginasElectrical Machines and Drivesanon-427532100% (14)

- Comedk Uget Brochure 2016 6th February Copy 1Documento42 páginasComedk Uget Brochure 2016 6th February Copy 1aayuAún no hay calificaciones

- What Is Calorie ..How Its WorkDocumento4 páginasWhat Is Calorie ..How Its WorkrockykrishAún no hay calificaciones

- Capex DrawingDocumento61 páginasCapex DrawingHs ChopraAún no hay calificaciones

- Battery Sizing CalculatorDocumento6 páginasBattery Sizing Calculatormfisol2000Aún no hay calificaciones

- AC Size Calculation (28!5!11)Documento4 páginasAC Size Calculation (28!5!11)jiguparmar1516Aún no hay calificaciones

- Start Delta Starter Vs Soft StarterDocumento24 páginasStart Delta Starter Vs Soft StarterKalpesh Singh100% (2)

- Admission Calendar CMC VelloreDocumento1 páginaAdmission Calendar CMC VellorerockykrishAún no hay calificaciones

- Ampacity of The Bus Bar Selected Must Then Be Verified by Checking Table 1Documento3 páginasAmpacity of The Bus Bar Selected Must Then Be Verified by Checking Table 1rockykrishAún no hay calificaciones

- Cable CaluclationDocumento3 páginasCable CaluclationrockykrishAún no hay calificaciones

- NM Dan NE (Yang Bener)Documento61 páginasNM Dan NE (Yang Bener)Andri RulandiAún no hay calificaciones

- Admission Calendar CMC VelloreDocumento1 páginaAdmission Calendar CMC VellorerockykrishAún no hay calificaciones

- NM Dan NE (Yang Bener)Documento61 páginasNM Dan NE (Yang Bener)Andri RulandiAún no hay calificaciones

- ProtectionDocumento2 páginasProtectionrockykrishAún no hay calificaciones

- Anandhayazhai LyricsDocumento2 páginasAnandhayazhai LyricsrockykrishAún no hay calificaciones

- C Q&aDocumento12 páginasC Q&aShri PandiyanAún no hay calificaciones

- Hardy Cross ExampleDocumento9 páginasHardy Cross ExamplerockykrishAún no hay calificaciones

- Mild Steel Sheets, Plates and Floor PlatesDocumento4 páginasMild Steel Sheets, Plates and Floor PlatesrockykrishAún no hay calificaciones

- HardyCross Ex13 30Documento8 páginasHardyCross Ex13 30rockykrishAún no hay calificaciones

- Upanayanam MuhurtaDocumento6 páginasUpanayanam Muhurtarockykrish0% (1)

- For XYZ: Electrical Safety AuditDocumento49 páginasFor XYZ: Electrical Safety AudittjchettyAún no hay calificaciones

- Datasheet - HK In5408 4525768Documento2 páginasDatasheet - HK In5408 4525768Ndambuki DicksonAún no hay calificaciones

- Ampacity of The Bus Bar Selected Must Then Be Verified by Checking Table 1Documento3 páginasAmpacity of The Bus Bar Selected Must Then Be Verified by Checking Table 1rockykrishAún no hay calificaciones

- Follow Up Sheet For Dew Point AnalyserDocumento1 páginaFollow Up Sheet For Dew Point AnalyserrockykrishAún no hay calificaciones

- PaymentDocumento1 páginaPaymentrockykrishAún no hay calificaciones

- Wet Pipe Sprinkler SystemDocumento12 páginasWet Pipe Sprinkler SystemrockykrishAún no hay calificaciones

- Tax Worksheet 2014marDocumento12 páginasTax Worksheet 2014marrockykrishAún no hay calificaciones

- What Really Matters in LifeDocumento13 páginasWhat Really Matters in LiferockykrishAún no hay calificaciones

- Bai Tap Av 12 Thi Diem Unit TwoDocumento7 páginasBai Tap Av 12 Thi Diem Unit TwonguyenngocquynhchiAún no hay calificaciones

- Intergard 475HS - Part B - EVA046 - GBR - ENG PDFDocumento10 páginasIntergard 475HS - Part B - EVA046 - GBR - ENG PDFMohamed NouzerAún no hay calificaciones

- Conjunctions in SentencesDocumento8 páginasConjunctions in SentencesPunitha PoppyAún no hay calificaciones

- DescriptiveDocumento1 páginaDescriptiveRizqa Anisa FadhilahAún no hay calificaciones

- Army Watercraft SafetyDocumento251 páginasArmy Watercraft SafetyPlainNormalGuy2Aún no hay calificaciones

- The Function and Importance of TransitionsDocumento4 páginasThe Function and Importance of TransitionsMarc Jalen ReladorAún no hay calificaciones

- A Summer Training ReportDocumento39 páginasA Summer Training ReportShubham SainyAún no hay calificaciones

- Template Remarks For IIDocumento18 páginasTemplate Remarks For IIjasleeneceAún no hay calificaciones

- Chemical Classification of HormonesDocumento65 páginasChemical Classification of HormonesetAún no hay calificaciones

- Genie PDFDocumento264 páginasGenie PDFjohanaAún no hay calificaciones

- Manuscript PDFDocumento50 páginasManuscript PDFMartina Mae Benig GinoAún no hay calificaciones

- Acute Leukemia The Scientist's Perspective and ChallengeDocumento438 páginasAcute Leukemia The Scientist's Perspective and ChallengemedskyqqAún no hay calificaciones

- Caldon Lefm 240ci Ultrasonic Flow Meters: Integral Manifold DesignDocumento6 páginasCaldon Lefm 240ci Ultrasonic Flow Meters: Integral Manifold DesignJim LimAún no hay calificaciones

- Prospectus (As of November 2, 2015) PDFDocumento132 páginasProspectus (As of November 2, 2015) PDFblackcholoAún no hay calificaciones

- The Consulting Industry and Its Transformations in WordDocumento23 páginasThe Consulting Industry and Its Transformations in Wordlei ann magnayeAún no hay calificaciones

- Portfolio AdityaDocumento26 páginasPortfolio AdityaAditya DisAún no hay calificaciones

- @InglizEnglish-4000 Essential English Words 6 UzbDocumento193 páginas@InglizEnglish-4000 Essential English Words 6 UzbMaster SmartAún no hay calificaciones

- Lupon National Comprehensive High School Ilangay, Lupon, Davao Oriental Grade 10-Household ServicesDocumento4 páginasLupon National Comprehensive High School Ilangay, Lupon, Davao Oriental Grade 10-Household ServicesJohn Eirhene Intia BarreteAún no hay calificaciones

- Catalogue Laboratory Products - Heraeus KulzerDocumento288 páginasCatalogue Laboratory Products - Heraeus KulzerDentaDentAún no hay calificaciones

- Bofa Turkish Banks-Back On The RadarDocumento15 páginasBofa Turkish Banks-Back On The RadarexperhtmAún no hay calificaciones

- Written Report in Instructional PlanningDocumento6 páginasWritten Report in Instructional PlanningRose Aura HerialesAún no hay calificaciones

- Computer in Community Pharmacy by Adnan Sarwar ChaudharyDocumento10 páginasComputer in Community Pharmacy by Adnan Sarwar ChaudharyDr-Adnan Sarwar Chaudhary100% (1)

- 12 Constructor and DistructorDocumento15 páginas12 Constructor and DistructorJatin BhasinAún no hay calificaciones

- Asme b16.3 (1998) Malleable Iron Threaded FittingsDocumento30 páginasAsme b16.3 (1998) Malleable Iron Threaded FittingsMarcos RosenbergAún no hay calificaciones

- Session 1: Strategic Marketing - Introduction & ScopeDocumento38 páginasSession 1: Strategic Marketing - Introduction & ScopeImrul Hasan ChowdhuryAún no hay calificaciones

- Acc 106 Account ReceivablesDocumento40 páginasAcc 106 Account ReceivablesAmirah NordinAún no hay calificaciones

- Ultrasonic Based Distance Measurement SystemDocumento18 páginasUltrasonic Based Distance Measurement SystemAman100% (2)

- Pepcoding - Coding ContestDocumento2 páginasPepcoding - Coding ContestAjay YadavAún no hay calificaciones

- The Global Entrepreneurship and Development Index 2014 For Web1 PDFDocumento249 páginasThe Global Entrepreneurship and Development Index 2014 For Web1 PDFAlex Yuri Rodriguez100% (1)

- Drawbot 1Documento4 páginasDrawbot 1SayanSanyalAún no hay calificaciones