Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Electrical Findings 6

Cargado por

Lester MuscaDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Electrical Findings 6

Cargado por

Lester MuscaCopyright:

Formatos disponibles

ELECTRICAL SAFETY INSPECTION REPORT

HAMS GARMENTS LTD.,

SOUTH VANGNAHATI, SREEPUR, GAZIPUR, BANGLADESH.

Factory List:

1. Hams Garments Ltd.

Inspected on April 03, 2014

ELECTRICAL SAFETY INSPECTION REPORT

HAMS GARMENTS LTD., GAZIPUR, BANGLADESH

1. INTRODUCTION

The Factory was surveyed for electrical safety by Woosun Energy and Construction Co., Ltd.

(WEC). The purpose of the survey was to identify significant electrical safety issues and to provide

recommendations for remediation based on applicable standards specified by the Accord. The

scope of this initial electrical safety inspection was limited to the review and identification of major

electrical safety issues. The inspection did not include identification of minor deficiencies, which will

be further addressed as part of follow-up inspections.

2. LIMITATIONS

The information in this electrical safety inspection report was obtained during a visit to the facility

and during interviews with local factory management. It has not been possible to provide

independent verification for all the information and data collected, and, therefore, WEC cannot

accept general responsibility for omissions or errors arising from inaccuracies in this report from the

information obtained.

The findings and recommendations in this report are not intended to imply, guarantee, ensure or

warrant compliance with any government regulations. Additionally, the results do not imply in any

way that compliance with the findings or recommendations as stated in this report will eliminate all

hazards, risks or exposures or that hazards, risks or exposures not referred to in this report do not

exist. Compliance with the findings and recommendations stated in this report does not relieve the

factory owner from obligation to comply with specific project requirements, industry standards, or

the provisions of any local government regulations.

3. GENERAL BUILDING INFORMATION

1. Factory Name : HAMS GARMENTS LTD

2. Factory Address : SOUTH VANGNAHATI, SREEPUR, GAZIPUR, BANGLADESH

3. Accord ID : 09294

4. Inspection Participants : Md. Mahfuzur Rahman, AGM, HR, Admin & Compliance,

Hams Garments Ltd.,

Ph: +88 01929998126, 01916788409,

E-mail: mahfuz@hamsgroupbd.com.

Mohammad solaiman, DGM, maintenance, Hams

Garments Ltd.,

Ph: +88 01730304193, 01534305981,

E-mail: mohammad.solaiman@hams.com.bd.

HAMS GARMENTS LTD. Page 2 of 13

4. Building Data

a. General:

There are three buildings and two sheds owned by the Hams Garments Ltd., and only one

building is used for production. As reported in the meeting, the construction of building one

started in 2008 and production commenced in 2010.

The floor wise utilization of Building one is as follows:

Ground floor: Sweing, finished store

1st floor: Sample and sweing

2nd floor: Marchendising, sweing, sampling

3rd floor : Dinning, cutting, prayer

4th floor: Finished goods, cutting, finishing

The floor wise utilization of Building two is as follows:

Ground floor: Daycare and Medical

1st Floor: MD's Conference room

2nd floor: Officers dinning

The floor wise utilization of Building two is as follows:

Ground floor: Generator room

1st floor: Control room

2nd floor: Compressor room

The floor wise utilizations of Shed one and two are as follows:

Shed One (steel structure):

Ground floor: Knitting

1st floor: yarn store

Shed Two:

Ground floor: Dyeing

1st floor: Office and laboratory.

b. Floor Layout Information

: 3,622 sq. m.

Figure 1: Main building ground floor paln

HAMS GARMENTS LTD. Page 3 of 13

Figure 2: Ground floor plan of daycare building

Figure 3: Generator building

c. Electrical System:

The main supply for Hams Garments Ltd. is from 1,287 kVA gas operated generator. REB

supply is used only for compound and emergency lights. They also have two diesel operated

generators as back up supply (637 kVA and 262 kVA)

HAMS GARMENTS LTD. Page 4 of 13

Figure 4: Single line diagram

Figure 5: 500 kVA transformer

Figure 6: Gas operated generator

HAMS GARMENTS LTD. Page 5 of 13

d. Electrical Installations:

The electrical installations in the factory are found to be satisfactory except the workmanship.

The main and service cables are not properly laid and terminated.

Figure 7: Cables not layed properly

e. Operation and Maintenance:

The normal operation and maintenance are carried out by the in-house team and they outsource the

major repair and maintenance works to external organization. As reported, they perform visual check

on all electrical installations including transformer, HT, LT panels and the distribution boards for any

abnormality.

4. FINDINGS AND RECOMMENDATIONS

Table below summarizes the major electrical safety issues identified during the inspection.

Recommendations have been provided to address each issue.

An implementation schedule shall be developed by the factory to remediate each of the findings.

The specific timing of improvements, including any requested extensions due to design /

installation constraints, shall be submitted to the Accord for approval.

HAMS GARMENTS LTD. Page 6 of 13

Finding #: E- 1

Category: TRANSFORMER ROOM

Finding:

Insulating rubber mat provided in front of

panel is inadequate

Recommendation:

The insulating rubber mat in front of panel

must be replaced with proper size and grade

Insulating rubber mat in front of

panel is inadequate

Remediation Timeframe: 3 Months

Finding #: E- 2

Category: DISTRIBUTION & LT PANELS

Finding:

Dedicated earth connection for panel frame

not installed.

Recommendation:

Firmly connect the panel frame and door

using a earth bonding.

Panel earthing not connected

Remediation Timeframe: Within 1 Month

Finding #: E- 3

Category: TRANSFORMER ROOM

Finding:

The arching horn on the transformer is not

paired.

Recommendation:

The arching horn on the transformer must

be installed in a pair and their gap must

be properly aligned and maintained.

The arching horn is not paired.

Remediation Timeframe: 3 Months

HAMS GARMENTS LTD. Page 7 of 13

Finding #: E- 4

Category: TRANSFORMER ROOM

Finding:

No earth connection to the transformer

guard

Recommendation:

The transformer guard must be firmly

connected to the earth at least at one

point near to the opening

No earth connection to the

transformer guard

Remediation Timeframe: Within 1 Month

Finding #: E- 5

Category: DISTRIBUTION & LT PANELS

Finding:

Cables are not marked with proper phase

colors.

Recommendation:

All the power cables shall be provided with

proper phase color marking.

No phase color marking

Remediation Timeframe: 3 Months

Finding #: E- 6

Category: TRANSFORMER ROOM

Finding:

Combustible materials used to cover the

power cables

Recommendation:

Combustible materials must be replaced with

non-combustible ones to cover the cables

for protection.

Combustible materials used to

cover the power cables

Remediation Timeframe: 3 Months

HAMS GARMENTS LTD. Page 8 of 13

Finding #: E- 7

Category: WIRINGS

Finding:

The wires are not covered fully by PVC

Case Capping

Recommendation:

The wires shall be fully covered by PVC

case capping with Ts and bends

The wires are not covered

Remediation Timeframe: 3 Months fully by PVC Case Capping

Finding #: E- 8

Category: ELECTRICAL SHAFT

Finding:

Openings for cables are not sealed with fire

rated sealant.

Recommendation:

The cable shafts running through the floor

and ceiling openings shall be closed

properly to avoid physical damages to the

cables with fire rated sealant. Openings for cables

are not sealed

Remediation Timeframe: 3 Months

Finding #: E- 9

Category: WIRINGS

Finding:

The ceiling junction box is not closed

Recommendation:

The ceiling junction boxes shall be either

connected with appropriate fittings or closed

with cap.

The ceiling junction box is not closed

Remediation Timeframe: 3 Months

HAMS GARMENTS LTD. Page 9 of 13

Finding #: E- 10

Category: CABLE RACEWAY & DUCTS

Finding:

Cables supported on cable trays/raceways

are not firmly fixed.

Recommendation:

The cables should be tied/ clamped firmly on

the cable tray in a proper way without causing

damage to the cables and wires

Cables not fixed properly

Remediation Timeframe: 3 Months

Finding #: E- 11

Category: DISTRIBUTION & LT PANELS

Finding:

Phase barrier/separators between different

phases with voltage exceeding 400V are

not installed.

Recommendation:

Phase barriers between different phases

must be installed to avoid arc flashing.

Phase barrier/separator missing

Remediation Timeframe: Within 1 Month

Finding #: E- 12

Category: DISTRIBUTION & LT PANELS

Finding:

Cables entering or exiting Distribution panel

are not firmly fixed.

Recommendation:

Cables entering panel must be firmly fixed

through base plates using cable glands.

Cables not fixed

Remediation Timeframe: 3 Months

HAMS GARMENTS LTD. Page 10 of 13

Finding #: E- 13

Category: DISTRIBUTION & LT PANELS

Finding:

Wires and cables inside distribution panel

not arranged and firmly fixed.

Recommendation:

Cables and wiring inside panels must be

arranged and firmly fixed to avoid

unintendedly touching other parts.

Wires not fixed properly

Remediation Timeframe: Within 1 Month

Finding #: E- 14

Category: TRANSFORMER ROOM

Finding:

Transformer is covered with lint and dust.

Recommendation:

Transformer must be cleaned during routine

maintenance.

Transformer is covered

with lint and dust.

Remediation Timeframe: 3 Months

Finding #: E- 15

Category: TRANSFORMER ROOM

Finding:

The dust trap oil container below transformer

breather is not filled with transformer oil.

Recommendation:

Dust trap must be filled with transformer oil

to required level as instructed by the

manufacturer.

The dust trap oil container is empty

Remediation Timeframe: 3 Months

HAMS GARMENTS LTD. Page 11 of 13

Finding #: E- 16

Category: SERVICE LINE

Finding:

Service line enters the building through the

building wall unprotected.

Recommendation:

Wirings shall be laid in cable trays or else

and supported throughout its length.

Service line left unprotected

Remediation Timeframe: 3 Months

Finding #: E- 17

Category: TRANSFORMER ROOM

Finding:

Oil level in conservator tank of transformer is

low.

Recommendation:

Transformer oil must be filled to the required

level after shutting down the transformer.

Oil level in conservator tank of

Remediation Timeframe: 3 Months transformer is low.

Finding #: E- 18

Category: SERVICE LINE

Finding:

HT cable entering electrical room is not

protected.

Recommendation:

All cables passing through permanent wall must

be protected against possible physical damages

and stress at the point of entry/exit and

remaining gaps must be sealed with similar

materials or higher fire rating materials. HT cable entering electrical

room is not protected.

Remediation Timeframe: 3 Months

HAMS GARMENTS LTD. Page 12 of 13

Finding #: E- 19

Category: GENERATOR ROOM

Finding:

Cables terminating at generator output control

panel are not supported on ladder or riser.

Recommendation:

Cables must be supported on tray/riser and

protected from possible physical damages.

Generator output to the panel

Remediation Timeframe: 3 Months

HAMS GARMENTS LTD. Page 13 of 13

También podría gustarte

- HUD Homes Baltimore - 20571 SUMMERSONG LANE, GERMANTOWN MD 20874Documento29 páginasHUD Homes Baltimore - 20571 SUMMERSONG LANE, GERMANTOWN MD 20874Nishika JGAún no hay calificaciones

- Fan Schedule Motors Control Panels InterfaceDocumento2 páginasFan Schedule Motors Control Panels Interfacekkn1234Aún no hay calificaciones

- Inspection of MCC - EEPDocumento3 páginasInspection of MCC - EEPwaseemAún no hay calificaciones

- New Doha Airport MCC Panel Fault DiagnosticsDocumento3 páginasNew Doha Airport MCC Panel Fault Diagnosticskkn1234Aún no hay calificaciones

- Electrical Substation Routes TanerDocumento71 páginasElectrical Substation Routes TanerpolAún no hay calificaciones

- Electrical Maintenance of Electrical Installation: Ayan Ghose Junior Engineer Ranaghat Electrical Section, PWDDocumento13 páginasElectrical Maintenance of Electrical Installation: Ayan Ghose Junior Engineer Ranaghat Electrical Section, PWDnatureayanAún no hay calificaciones

- Inspect LPS with ATLAS ChecklistDocumento2 páginasInspect LPS with ATLAS ChecklistRaja Jagadeesan100% (1)

- MDB Specs PDFDocumento9 páginasMDB Specs PDFAbdElrahman AhmedAún no hay calificaciones

- KHATIB ABDUL RAHIM CV... HDocumento4 páginasKHATIB ABDUL RAHIM CV... HAbdulrahimAún no hay calificaciones

- Abstract of National Electrical Code For Transformer's ProtectionDocumento2 páginasAbstract of National Electrical Code For Transformer's ProtectionJignesh ParmarAún no hay calificaciones

- Section 26 11 13-Unit Sub-Stations PDFDocumento10 páginasSection 26 11 13-Unit Sub-Stations PDFmasoodaeAún no hay calificaciones

- Hvac CVDocumento2 páginasHvac CVsarfaraz055Aún no hay calificaciones

- Maintenance of GroundingDocumento7 páginasMaintenance of GroundingBharatiyulamAún no hay calificaciones

- Electrical Distribution Equipment, Questions & Answers, Part IIDocumento91 páginasElectrical Distribution Equipment, Questions & Answers, Part IIهانى خير100% (3)

- Maintenance of Electropneumatic Contactor of Electric Locomotive-EngDocumento56 páginasMaintenance of Electropneumatic Contactor of Electric Locomotive-Engerode els erodeAún no hay calificaciones

- Prevent Electrical FailuresDocumento11 páginasPrevent Electrical FailuresSelvn SubramanianAún no hay calificaciones

- 26.Lv SystemDocumento10 páginas26.Lv Systempepenapao1217Aún no hay calificaciones

- Inspection and maintenance of EX electrical equipmentDocumento6 páginasInspection and maintenance of EX electrical equipmentMY PCAún no hay calificaciones

- Earth Rod Resistance 001Documento6 páginasEarth Rod Resistance 001Asanka RodrigoAún no hay calificaciones

- Fault Diagnostic in MDB Panels PDFDocumento2 páginasFault Diagnostic in MDB Panels PDFkkn1234Aún no hay calificaciones

- Sample ReportDocumento12 páginasSample Reportyahya100% (1)

- JSA - Low Voltage PanelDocumento19 páginasJSA - Low Voltage PanelASLAM MULANIAún no hay calificaciones

- D-CAT Diesel Fuels and Fuel Systems (2012)Documento64 páginasD-CAT Diesel Fuels and Fuel Systems (2012)mkAún no hay calificaciones

- LV Underground Cable Jointing TrainingDocumento11 páginasLV Underground Cable Jointing TrainingQais Alsafasfeh100% (2)

- Short CircuitDocumento4 páginasShort CircuitShashi NaganurAún no hay calificaciones

- Global Facilities - Electrical - Electrical Specification Design StandardDocumento202 páginasGlobal Facilities - Electrical - Electrical Specification Design StandardaizatmaricanAún no hay calificaciones

- Infrared Thermography A Versatile TechnologyDocumento7 páginasInfrared Thermography A Versatile TechnologyJintotholath JjAún no hay calificaciones

- PREVENTIVE MAINTENANCE CHECKLIST FOR POWER PRESS MACHINEDocumento1 páginaPREVENTIVE MAINTENANCE CHECKLIST FOR POWER PRESS MACHINESanjay MalhotraAún no hay calificaciones

- MFM Consolidated Preventive Maintenance Ver 2 - 3132017Documento201 páginasMFM Consolidated Preventive Maintenance Ver 2 - 3132017Paul CansinoAún no hay calificaciones

- TrafoDocumento5 páginasTrafoAnonymous vcadX45TD7Aún no hay calificaciones

- SOP - PowerDocumento32 páginasSOP - PowerpothanAún no hay calificaciones

- Improving Electrical Safety Management-TNB PDFDocumento24 páginasImproving Electrical Safety Management-TNB PDFSopi LabuAún no hay calificaciones

- Electrocution RefineryDocumento3 páginasElectrocution Refinerysonn the greatAún no hay calificaciones

- The Earthing System: Sometimes Simply Called Earthing', Is The Total Set ofDocumento10 páginasThe Earthing System: Sometimes Simply Called Earthing', Is The Total Set ofDaily FunAún no hay calificaciones

- Inspection of Electric EquipmentDocumento26 páginasInspection of Electric Equipmentkalyan ReddyAún no hay calificaciones

- Electrical Power Provider ProfileDocumento39 páginasElectrical Power Provider ProfileRonicel Caryl de RamosAún no hay calificaciones

- CEA Inspection Compliance Report SummaryDocumento4 páginasCEA Inspection Compliance Report Summarykalyan ReddyAún no hay calificaciones

- Ring Main UnitsDocumento28 páginasRing Main UnitsChristian EstebanAún no hay calificaciones

- Commissioning FormDocumento3 páginasCommissioning FormPamangus TappulakAún no hay calificaciones

- Periodic Inspection NotesDocumento16 páginasPeriodic Inspection NotesShirishAún no hay calificaciones

- Measuring Earth ResistanceDocumento13 páginasMeasuring Earth Resistancemadhava_srinivasan174Aún no hay calificaciones

- Detail of ConsultantDocumento3 páginasDetail of ConsultantMohamed ThowfeekAún no hay calificaciones

- Earthpit Resistance Testing RecordsheetDocumento1 páginaEarthpit Resistance Testing RecordsheetawsomeAún no hay calificaciones

- Basic Electrical Engineering: Define The Terms With Their UnitsDocumento58 páginasBasic Electrical Engineering: Define The Terms With Their Unitsbujjibabu1977Aún no hay calificaciones

- HVPE Operation and MaintenanceDocumento116 páginasHVPE Operation and MaintenanceMinerva AbantoAún no hay calificaciones

- Solar PV Inverter Test ProceduresDocumento62 páginasSolar PV Inverter Test ProceduresskylarksAún no hay calificaciones

- Electrical Design EnggDocumento3 páginasElectrical Design EnggprudduAún no hay calificaciones

- Spec EarthingDocumento10 páginasSpec EarthingDolyAún no hay calificaciones

- General Low Voltage Cable Supply Connection GuidelineDocumento2 páginasGeneral Low Voltage Cable Supply Connection GuidelineDFAún no hay calificaciones

- Guidelines To Visual Inspection of Electrical InstallationsDocumento4 páginasGuidelines To Visual Inspection of Electrical InstallationsadgasAún no hay calificaciones

- Summer Training at SeccoDocumento13 páginasSummer Training at SeccoHassan SaeedAún no hay calificaciones

- SubstationsDocumento33 páginasSubstationsTabi4every1100% (1)

- Motor Bump Test Record Sheet: Project: Motor Tag No Marker: Starter Type: Rating: EX CertificationDocumento6 páginasMotor Bump Test Record Sheet: Project: Motor Tag No Marker: Starter Type: Rating: EX CertificationMuhammad AshfaqueAún no hay calificaciones

- Knowledge is "Real Power": Introduction to Power QualityDe EverandKnowledge is "Real Power": Introduction to Power QualityAún no hay calificaciones

- Big Boss Corporation Ltd. Electrical Safety Inspection ReportDocumento8 páginasBig Boss Corporation Ltd. Electrical Safety Inspection ReportYaser AkarAún no hay calificaciones

- Electrical Safety Inspection Report: A & B Outerwear LTDDocumento12 páginasElectrical Safety Inspection Report: A & B Outerwear LTDAkula VeerrajuAún no hay calificaciones

- Sample Electrical AuditDocumento10 páginasSample Electrical AuditNiroj MohapatraAún no hay calificaciones

- Refinery Electrical Safety AuditDocumento3 páginasRefinery Electrical Safety AuditSankara SubramanianAún no hay calificaciones

- Electrical Safety Inspection Report TemplateDocumento9 páginasElectrical Safety Inspection Report TemplateSOPHYAún no hay calificaciones

- GR Exp 1970 - 03Documento24 páginasGR Exp 1970 - 03PedralhadaAún no hay calificaciones

- CBA10 A 2Documento1 páginaCBA10 A 2Lester MuscaAún no hay calificaciones

- CBA10 ADocumento1 páginaCBA10 ALester MuscaAún no hay calificaciones

- Solar Floodlight and Lamp Pole Package DealDocumento2 páginasSolar Floodlight and Lamp Pole Package DealLester MuscaAún no hay calificaciones

- Littel FuseDocumento1 páginaLittel FuseLester MuscaAún no hay calificaciones

- CBA10 ADocumento1 páginaCBA10 ALester MuscaAún no hay calificaciones

- Order Form For Littelfuse Door Lock2Documento6 páginasOrder Form For Littelfuse Door Lock2Lester MuscaAún no hay calificaciones

- EDI40AS1-EDI55AS1 Active Control AutomationDocumento2 páginasEDI40AS1-EDI55AS1 Active Control AutomationLester MuscaAún no hay calificaciones

- CBA10 B 2Documento1 páginaCBA10 B 2Lester MuscaAún no hay calificaciones

- Isuzu Engine 45kva Single QuotationDocumento4 páginasIsuzu Engine 45kva Single QuotationLester MuscaAún no hay calificaciones

- Isuzu Engine 45kva Single QuotationDocumento4 páginasIsuzu Engine 45kva Single QuotationLester MuscaAún no hay calificaciones

- Littelfuse Purchase Order 2534017Documento1 páginaLittelfuse Purchase Order 2534017Lester Musca100% (1)

- MTS 100a and 125aDocumento1 páginaMTS 100a and 125aLester MuscaAún no hay calificaciones

- Endorsement Letter - Musca LesterDocumento1 páginaEndorsement Letter - Musca LesterLester MuscaAún no hay calificaciones

- Littel Fuse ApprovalDocumento1 páginaLittel Fuse ApprovalLester MuscaAún no hay calificaciones

- ATV630C31N4 variable speed drive data sheetDocumento13 páginasATV630C31N4 variable speed drive data sheetLester MuscaAún no hay calificaciones

- FIELD SERVICE REPORT INSPECTIONDocumento8 páginasFIELD SERVICE REPORT INSPECTIONLester MuscaAún no hay calificaciones

- FIELD SERVICE REPORT INSPECTIONDocumento6 páginasFIELD SERVICE REPORT INSPECTIONLester MuscaAún no hay calificaciones

- User Requirements SpecificationDocumento3 páginasUser Requirements SpecificationLester MuscaAún no hay calificaciones

- Report On International Efficiency Efficiency Classes For Low Voltage AC MotorsDocumento13 páginasReport On International Efficiency Efficiency Classes For Low Voltage AC MotorsmersiumAún no hay calificaciones

- Engr. Kevin S. Erto, Rme: ContactDocumento1 páginaEngr. Kevin S. Erto, Rme: ContactLester MuscaAún no hay calificaciones

- No Cylinder Maintenance Location Date KW-HR Total Amount (PHP)Documento6 páginasNo Cylinder Maintenance Location Date KW-HR Total Amount (PHP)Lester MuscaAún no hay calificaciones

- Construction of Server Room ORO 05302018Documento1 páginaConstruction of Server Room ORO 05302018Lester MuscaAún no hay calificaciones

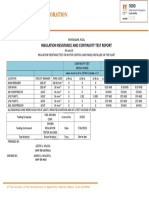

- Oro Oxygen Corporation: Insulation Resistance and Continuity Test ReportDocumento2 páginasOro Oxygen Corporation: Insulation Resistance and Continuity Test ReportLester MuscaAún no hay calificaciones

- New Flipchart ScriptDocumento5 páginasNew Flipchart ScriptLester MuscaAún no hay calificaciones

- Insulation Test Report Sta Rosa NeDocumento2 páginasInsulation Test Report Sta Rosa NeLester MuscaAún no hay calificaciones

- Oro Oxygen Corporation: Electrical ThermalDocumento1 páginaOro Oxygen Corporation: Electrical ThermalLester MuscaAún no hay calificaciones

- Electrical ExamDocumento2 páginasElectrical ExamLester MuscaAún no hay calificaciones

- Oro Oxygen Corporation: Insulation Resistance and Continuity Test ReportDocumento1 páginaOro Oxygen Corporation: Insulation Resistance and Continuity Test ReportLester MuscaAún no hay calificaciones

- Oro Oxygen Corporation: Insulation Resistance and Continuity Test ReportDocumento2 páginasOro Oxygen Corporation: Insulation Resistance and Continuity Test ReportLester MuscaAún no hay calificaciones

- Cat Tools Addition enDocumento82 páginasCat Tools Addition enSunil SinghAún no hay calificaciones

- Proposed Rates for Sukowati Pad C Well ConstructionDocumento11 páginasProposed Rates for Sukowati Pad C Well ConstructionReza WahyuantoAún no hay calificaciones

- Features:: Advanced Protection TechnologiesDocumento2 páginasFeatures:: Advanced Protection Technologiesdnps2011Aún no hay calificaciones

- Road RollerDocumento1 páginaRoad RollerSafety ManagerAún no hay calificaciones

- Extra 300 PDFDocumento2 páginasExtra 300 PDFCharleneAún no hay calificaciones

- Catalogo Cargadora 972GDocumento28 páginasCatalogo Cargadora 972GRodrigo CatotaAún no hay calificaciones

- Engineering InsuranceDocumento2 páginasEngineering InsuranceBikash KumarAún no hay calificaciones

- Grundfos 28-80Documento6 páginasGrundfos 28-80anAún no hay calificaciones

- 10 Product List Tata JD 315Documento2 páginas10 Product List Tata JD 315KAIDEAR100% (4)

- Dust Collector ValvesDocumento8 páginasDust Collector ValvesAnonymous lswzqloAún no hay calificaciones

- TRIPATRA'S TANGGUH LNG PROJECT Indonesian EPC company Tripatra recruiting for Tangguh LNG Project rolesDocumento28 páginasTRIPATRA'S TANGGUH LNG PROJECT Indonesian EPC company Tripatra recruiting for Tangguh LNG Project rolesKholil JavaAún no hay calificaciones

- CU-22L Tissue Culture Chamber: Lighting SystemDocumento2 páginasCU-22L Tissue Culture Chamber: Lighting SystemAjay KumarAún no hay calificaciones

- English Solar Farm Proposal by TSF Oct 123Documento38 páginasEnglish Solar Farm Proposal by TSF Oct 123Atiqah HamzahAún no hay calificaciones

- Letter Seeking Technical SupportDocumento10 páginasLetter Seeking Technical Supportlouiegi001Aún no hay calificaciones

- TLB Bseries 30621GBDocumento16 páginasTLB Bseries 30621GBPiotr PogorzelczykAún no hay calificaciones

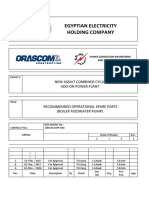

- 1601352-BFP-046 - Recommended Operational Spare Parts For BFP - Rev.CDocumento2 páginas1601352-BFP-046 - Recommended Operational Spare Parts For BFP - Rev.CMena KamelAún no hay calificaciones

- AD355 Builders Manual ExampleDocumento15 páginasAD355 Builders Manual Examplejntramey100% (1)

- Reciprocating PumpDocumento4 páginasReciprocating PumpTejashri PoteAún no hay calificaciones

- Fabrication & Performance Testing1Documento27 páginasFabrication & Performance Testing1DIPAK VINAYAK SHIRBHATEAún no hay calificaciones

- PMMRR 1997 - Book PDFDocumento113 páginasPMMRR 1997 - Book PDFwasita wadariAún no hay calificaciones

- Dl8000 Preset ControllerDocumento74 páginasDl8000 Preset ControllerFIRMANSYAHAún no hay calificaciones

- Inst TMRT Brochure PDFDocumento2 páginasInst TMRT Brochure PDFgrupa2904Aún no hay calificaciones

- Ceramkii WebDocumento2 páginasCeramkii WebD01Aún no hay calificaciones

- LM W2340aDocumento52 páginasLM W2340aBruno Alexander MachadoAún no hay calificaciones

- 7300 CV Quick Start Programming GuideDocumento10 páginas7300 CV Quick Start Programming Guidenitin hadkeAún no hay calificaciones

- Pipe Flow Design 1: Results DataDocumento7 páginasPipe Flow Design 1: Results DatahawyegAún no hay calificaciones

- VEGETABLE MARKET Waste, APMC (BIOMETHANATION)Documento7 páginasVEGETABLE MARKET Waste, APMC (BIOMETHANATION)svmapuskar100% (6)

- XLERPLATE Steel Size ScheduleDocumento12 páginasXLERPLATE Steel Size SchedulePajaroloco CarpinteroAún no hay calificaciones

- Inconel 82 PDFDocumento1 páginaInconel 82 PDFMiguel MorenoAún no hay calificaciones

- 8400 Replacement Parts GuideDocumento4 páginas8400 Replacement Parts GuideOleksandr YermolenkoAún no hay calificaciones