Documentos de Académico

Documentos de Profesional

Documentos de Cultura

PB SN Phase Diagram 22x28 AA

Cargado por

alonso_matias88Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

PB SN Phase Diagram 22x28 AA

Cargado por

alonso_matias88Copyright:

Formatos disponibles

The Pb – Sn Phase Diagram

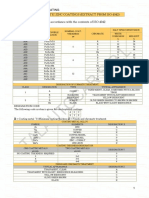

Load Platen Speed**

Surface Abrasive Size lb. (N) (rpm) Time (min.)

240

CarbiMet® Paper 240-grit SiC* 4 (18) 1

CarbiMet® Paper 320-grit SiC* 4 (18) 240 1

CarbiMet® Paper 400-grit SiC* 4 (18) 240 1

CarbiMet® Paper 600-grit SiC* 4 (18) 240 1

MicroCloth® pad 5-mm Al2O3 4 (18) 150 7

MicroCloth® pad 1-mm Al2O3 4 (18) 150 5

Dendritic -Pb face-centered cubic MicroCloth® pad 0.3-mm Al2O3 4 (18) 150 4

dendrites of cast pure lead, Pollack’s 0.05-mm MasterPrep®

Pure Sn, as-polished, polarized light;

reagent, DIC

MicroCloth® pad

Alumina

4 (18) 150 3 twinned -Sn (tetragonal) grains

0.05-mm MasterMet®

MicroCloth® pad - VibroMet® 2 60

Colloidal Silica

*Coat the SiC paper with paraffin wax; use water as a coolant

Reproduced courtesy of ASM International ** Use contra rotation and a low head speed for best results

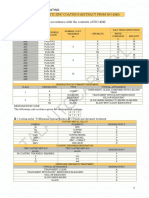

The binary Pb-Sn phase diagram has been studied for over 100 years and is a classic eutectic. Lead (Pb) has an atomic number of 82

and a high density. Its crystal structure is face-centered cubic (fcc). At 50 C, 2% Sn is soluble in Pb and at the eutectic temperature,

183 C, the maximum solubility of Sn in -Pb is 19%. The melting point of pure Pb is 327.46 C. Tin (Sn) has an atomic number of 50

and exists in the form at room temperature. -Sn has a tetragonal crystal structure. At room temperature, there is almost no solubility

of Pb in Sn and at the eutectic temperature, 183 C, there is a maximum solubility of 2.5% Pb in -Sn. The eutectic reaction,

L -Pb + -Sn, occurs at 61.9% Sn and at 183 C. The shape of the eutectic Pb constituent varies from lamellar to spheroidal with

Sn as the continuous phase, as shown in the examples below.

High-purity Pb and Sn are very difficult metallographic subjects and the alloys of Pb and Sn are somewhat easier to prepare, but still Pb – 90% Sn, as polished, polarized

Cast Pb – 10% Sn; fine precipitates of rather difficult. The above table lists our preferred preparation procedure. Vibratory polishing is essential for best results. Pollack’s light; B-Sn dendrites with mechanical

-Sn in a -Pb matrix; Pollack’s reagent (100 mL water, 10 g citric acid, 10 g ammonium molybdate) is one of the best etchants for Pb and Pb-Sn alloys; 2% nital is a twins and an -Pb and -Sn eutectic

reagent

good etch for pure tin.

Pb – 40% Sn, Pollack’s etch; -Pb Pb – 60% Sn, Pollack’s etch, BF; near Pb-61.9 % Sn, slow cool, 2% nital etch,

Cast Pb – 20% Sn, as-polished: -Pb Pb – 80% Sn, Pollack’s etch; note the

dendrites (white) and an -Pb/-Sn eutectic microstructure of -Pb and -Sn BF; -Pb/-Sn eutectic matrix

dendrites (white) and -Pb - -Sn mechanical twins in -Sn dendrites

eutectic (dark) eutectic and the -Pb/-Sn eutectic

Pb – 60% Sn, Pollack’s etch, DIC; near Pb – 61.9 % Sn eutectic, as above but Pb-70% Sn, Pollack’s etch, polarized

Pb – 30% Sn, as-polished; -Pb Pb – 50% Sn, Pollack’s etch; dark -Pb eutectic microstructure of -Pb and -Sn DIC; -Pb/-Sn eutectic

dendrites and a fine -Pb/-Sn eutectic light; primary -Sn dendrites (with

dendrites and an -Pb/-Sn eutectic

twins) and the -Pb/-Sn eutectic

Worldwide Headquarters • Tel: (847) 295-6500 • Fax: (847) 295-7979 • Web: www.buehler.com

También podría gustarte

- The Graphite FutureDocumento21 páginasThe Graphite FutureEdgard Vásquez100% (1)

- Metco 16C 10-040Documento8 páginasMetco 16C 10-040JSH100Aún no hay calificaciones

- Fabrication of CMOS Integrated Circuits Process OverviewDocumento56 páginasFabrication of CMOS Integrated Circuits Process OverviewVinay GoddemmeAún no hay calificaciones

- Stainless Steel Mig 316LSI WireDocumento1 páginaStainless Steel Mig 316LSI WireAli TalebiAún no hay calificaciones

- Ceramic Materials PropertiesDocumento1 páginaCeramic Materials PropertiesIntanasa NurdentiAún no hay calificaciones

- 7 Eaf BofDocumento28 páginas7 Eaf BofMuhammad Umar Al FaruqAún no hay calificaciones

- Leaded Nickel SilverDocumento1 páginaLeaded Nickel Silvermp87_ingAún no hay calificaciones

- Al Si Phase DiagramDocumento1 páginaAl Si Phase Diagramalonso_matias88Aún no hay calificaciones

- Materials Preparation For Microstructural Analysis.: MethodDocumento1 páginaMaterials Preparation For Microstructural Analysis.: MethodRon RonaldsAún no hay calificaciones

- Inoculation of Cast IronDocumento12 páginasInoculation of Cast Ironsangita JadhavAún no hay calificaciones

- Iron and Steel Making ProcessDocumento22 páginasIron and Steel Making Processmaghfira100% (1)

- Astm A967Documento2 páginasAstm A967kumarkk1969Aún no hay calificaciones

- Carbo L Ag 40 SN eDocumento1 páginaCarbo L Ag 40 SN efadfadg2Aún no hay calificaciones

- YG-1 Complete CatalogueDocumento1156 páginasYG-1 Complete CatalogueMuchamad Fajar NugrohoAún no hay calificaciones

- Industrial Application of CVD and PVDDocumento18 páginasIndustrial Application of CVD and PVDYong Jae Kwon50% (2)

- W6 Lecture 6.surface Hardening of Steel PDFDocumento28 páginasW6 Lecture 6.surface Hardening of Steel PDFYota KimireAún no hay calificaciones

- 95 2 Semiconductor PDFDocumento27 páginas95 2 Semiconductor PDFsumitzz4737Aún no hay calificaciones

- M.tech FinalDocumento43 páginasM.tech FinalRaghav AcharyaAún no hay calificaciones

- Vacuum Deposition Technical GuideDocumento28 páginasVacuum Deposition Technical GuidejorgeAún no hay calificaciones

- Density Computations For Ceramics: N V A A NDocumento10 páginasDensity Computations For Ceramics: N V A A NAaila AkhterAún no hay calificaciones

- Carbide ToolingDocumento90 páginasCarbide ToolingHuron Industrial SupplyAún no hay calificaciones

- Thin Film Evaporation Guide: Revision 2017Documento14 páginasThin Film Evaporation Guide: Revision 2017Mike WoodAún no hay calificaciones

- 113resuelto Procesamiento-Ceramicos ch13Documento26 páginas113resuelto Procesamiento-Ceramicos ch13Isac NumAún no hay calificaciones

- Rogers Si3n4 DCB Amb 20130117Documento17 páginasRogers Si3n4 DCB Amb 20130117anon_901131682Aún no hay calificaciones

- Renk Metal Therm 89Documento1 páginaRenk Metal Therm 89rajeskumarAún no hay calificaciones

- DSM-0265.2 Self-Fluxing With HardphaseDocumento5 páginasDSM-0265.2 Self-Fluxing With HardphaseApichitAún no hay calificaciones

- Procedure Development For Brazing Inconel 718 Honeycomb Sandwich StructuresDocumento8 páginasProcedure Development For Brazing Inconel 718 Honeycomb Sandwich StructuresAchmad Arifudin HidayatullohAún no hay calificaciones

- WJ 1973 10 s433 PDFDocumento8 páginasWJ 1973 10 s433 PDFAditya PrajasAún no hay calificaciones

- LOCTITE ABLESTIK 2600BT en - GLDocumento2 páginasLOCTITE ABLESTIK 2600BT en - GLJess OrtonAún no hay calificaciones

- Flgyt 3020 Technical SpecDocumento16 páginasFlgyt 3020 Technical SpecdaniqoAún no hay calificaciones

- NiCu-7 solid wire for welding nickel-copper alloysDocumento1 páginaNiCu-7 solid wire for welding nickel-copper alloyssatnamAún no hay calificaciones

- Rare Earth Magnet Design Considerations: Jinfang Liu and Peter DentDocumento19 páginasRare Earth Magnet Design Considerations: Jinfang Liu and Peter DentharimadhavareddyAún no hay calificaciones

- Ficha Tecnica Superaleaciones Ni - SuperalloysDocumento5 páginasFicha Tecnica Superaleaciones Ni - SuperalloysANDRES DOMINGUEZAún no hay calificaciones

- 2014 - 11 - Cast Iron Metallurgy PDFDocumento28 páginas2014 - 11 - Cast Iron Metallurgy PDFfelipeAún no hay calificaciones

- Selection Chart For Welding and Brazing Rods - Weldclass - 2021.08Documento2 páginasSelection Chart For Welding and Brazing Rods - Weldclass - 2021.08velan73Aún no hay calificaciones

- Electrolytic Zinc Coating PDFDocumento2 páginasElectrolytic Zinc Coating PDFzoran100% (1)

- ISO 4020 ExtractDocumento2 páginasISO 4020 ExtractBartek HajaAún no hay calificaciones

- Electrolytic Zinc Coatings (Extract From Iso 4042)Documento2 páginasElectrolytic Zinc Coatings (Extract From Iso 4042)Abhishek DhawanAún no hay calificaciones

- 1) ISO 4042 - Electrolytic - Zinc - CoatingDocumento2 páginas1) ISO 4042 - Electrolytic - Zinc - CoatingManoj Jajam100% (1)

- Bill of Quantity for XYZ ProjectDocumento2 páginasBill of Quantity for XYZ Projectmoney coxAún no hay calificaciones

- Metco 34F 10-046Documento8 páginasMetco 34F 10-046JSH100Aún no hay calificaciones

- 7 Eaf BofDocumento36 páginas7 Eaf BofRijalAún no hay calificaciones

- Belt Specifications - R19-Fabcon - 2rc - 5 - tr24 - 00-00 - Fa-Kc2tr2401Documento2 páginasBelt Specifications - R19-Fabcon - 2rc - 5 - tr24 - 00-00 - Fa-Kc2tr2401eng.mark.iskanderAún no hay calificaciones

- Bringing Split Flotation To Reality - The Cannington ExperienceDocumento8 páginasBringing Split Flotation To Reality - The Cannington Experienceseansara1100% (1)

- Crystal Structures June 23Documento25 páginasCrystal Structures June 23gwenny_castleAún no hay calificaciones

- Ecolizer - Reduced PDFDocumento5 páginasEcolizer - Reduced PDFRaquel Tejero OlivaAún no hay calificaciones

- Low Rank CoalsDocumento40 páginasLow Rank CoalsWulan Dwikusuma AsihAún no hay calificaciones

- Surda Mine Report Details Post Pillar Mining and Froth Flotation ProcessesDocumento20 páginasSurda Mine Report Details Post Pillar Mining and Froth Flotation Processesvictory shahbazAún no hay calificaciones

- DSM-0274.0 Bronze AlloysDocumento5 páginasDSM-0274.0 Bronze AlloyskerbaubiruAún no hay calificaciones

- Nickel in HardmetalsDocumento9 páginasNickel in Hardmetalsandrea assanelliAún no hay calificaciones

- WWW - Toptech.tw: Metallographic Sample Preparation Equipment Cutting/ Mounting/ Grinding & PolishingDocumento44 páginasWWW - Toptech.tw: Metallographic Sample Preparation Equipment Cutting/ Mounting/ Grinding & Polishingtien thanh doAún no hay calificaciones

- Session 11 Physical Vapour DepositionDocumento26 páginasSession 11 Physical Vapour DepositionMurali DontuAún no hay calificaciones

- Fibre Architecture Design, Processing and Testing of High Temperature CompositesDocumento51 páginasFibre Architecture Design, Processing and Testing of High Temperature CompositesShubham Deep100% (1)

- Electrochemical Selective Chlorination of Titanium OreDocumento1 páginaElectrochemical Selective Chlorination of Titanium OreBryan Roncal LlajarunaAún no hay calificaciones

- Pembuatan Baja PADA EAF (Electric Arc Furnace)Documento35 páginasPembuatan Baja PADA EAF (Electric Arc Furnace)VanyaAún no hay calificaciones

- Fora 400Documento4 páginasFora 400PeterWayAún no hay calificaciones

- GUHRING Pionex ThreadingDocumento20 páginasGUHRING Pionex ThreadingIvan PavičićAún no hay calificaciones

- Brochure ProFlake EnglishDocumento4 páginasBrochure ProFlake EnglishDhruv SevakAún no hay calificaciones

- Catalogo Isothermal 2012.02.29Documento25 páginasCatalogo Isothermal 2012.02.2984jncxyxpbAún no hay calificaciones

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363De EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363Aún no hay calificaciones

- Surface Treatments and Coating SDocumento8 páginasSurface Treatments and Coating Salonso_matias88Aún no hay calificaciones

- The Al-Si Phase Diagram: Using Microstructur Al Analysis To Solve PR Actic Al ProblemsDocumento9 páginasThe Al-Si Phase Diagram: Using Microstructur Al Analysis To Solve PR Actic Al ProblemsThiru MuruganAún no hay calificaciones

- Bulloni PDFDocumento6 páginasBulloni PDFGialluca DemicisAún no hay calificaciones

- General-Purpose Photoelectric Sensor: Wide Selection of High Performance Small DC Sensors Offers Longer Sensing DistancesDocumento18 páginasGeneral-Purpose Photoelectric Sensor: Wide Selection of High Performance Small DC Sensors Offers Longer Sensing Distancesalonso_matias88Aún no hay calificaciones

- Al Si Phase DiagramDocumento1 páginaAl Si Phase Diagramalonso_matias88Aún no hay calificaciones

- Domain Theory - College of Science and EngineeringDocumento12 páginasDomain Theory - College of Science and EngineeringMd Nurul AbsarAún no hay calificaciones

- Synthesis of SERS Active Ag2S Nanocrystals Using Oleylamine As Solvent, ReducingDocumento5 páginasSynthesis of SERS Active Ag2S Nanocrystals Using Oleylamine As Solvent, Reducing陈君泽Aún no hay calificaciones

- Adsorption IsothermsDocumento62 páginasAdsorption IsothermsAsaad BashirAún no hay calificaciones

- Grade 10 Chemistry Week 3 Lesson 1Documento4 páginasGrade 10 Chemistry Week 3 Lesson 1Nikoli MajorAún no hay calificaciones

- Chapter9 EscabarteDocumento30 páginasChapter9 EscabarteDarwin CruzAún no hay calificaciones

- Solution Manual For Chemistry An Atoms Focused Approach Second Edition Second EditionDocumento37 páginasSolution Manual For Chemistry An Atoms Focused Approach Second Edition Second EditionAndrewMartinezjrqo100% (44)

- Modern Physics NotesDocumento41 páginasModern Physics NotesSumit Kumar50% (2)

- Minor Project PresentationDocumento22 páginasMinor Project Presentationmaheshwar299Aún no hay calificaciones

- Materials Science EngineeringDocumento182 páginasMaterials Science EngineeringSaravananNandhuAún no hay calificaciones

- Long-Wavelength Infrared Semiconductor Lasers PDFDocumento406 páginasLong-Wavelength Infrared Semiconductor Lasers PDFKunchur Narayan100% (1)

- (CRYSTAL Imperfections) - 2Documento41 páginas(CRYSTAL Imperfections) - 2Utsav NiroulaAún no hay calificaciones

- Alkenes Test Mark SchemeDocumento3 páginasAlkenes Test Mark Schememj777goldilocks7777Aún no hay calificaciones

- Ass Mahfuz Sir Byb SiamDocumento10 páginasAss Mahfuz Sir Byb SiamNowfal Hasan SiamAún no hay calificaciones

- DFT PresentationDocumento63 páginasDFT PresentationhammmoudaAún no hay calificaciones

- Pathria SolutationDocumento4 páginasPathria Solutationkrasavchik_8650% (2)

- 1 s2.0 003810987190278X MainDocumento3 páginas1 s2.0 003810987190278X Mainbruno.soaresAún no hay calificaciones

- Rietveld Texture Analysis From Synchrotron Diffraction Images I Calibration and Basic AnalysisDocumento9 páginasRietveld Texture Analysis From Synchrotron Diffraction Images I Calibration and Basic Analysisbalrog9007Aún no hay calificaciones

- Nuclear Physics Solved Examples - AskIITiansDocumento3 páginasNuclear Physics Solved Examples - AskIITiansthiripura sundariAún no hay calificaciones

- Solutions Chapter 1Documento16 páginasSolutions Chapter 1BluaAún no hay calificaciones

- Introduction To Basic ElectronicsDocumento40 páginasIntroduction To Basic ElectronicsPatrick TeodoroAún no hay calificaciones

- World's Leading Physics Textbooks by PearsonDocumento49 páginasWorld's Leading Physics Textbooks by PearsonIjack HrangchalAún no hay calificaciones

- Semiconductor Device FundamentalsDocumento13 páginasSemiconductor Device Fundamentalsnoor_dcet0% (4)

- MSC Curricula Physics LOCF FINALSnHDocumento55 páginasMSC Curricula Physics LOCF FINALSnHANU SAJIAún no hay calificaciones

- Optical Properties of Solids Prof. Mark Fox: Autumn SemesterDocumento81 páginasOptical Properties of Solids Prof. Mark Fox: Autumn SemesterInuk YouAún no hay calificaciones

- And Lue ISBN Test BankDocumento59 páginasAnd Lue ISBN Test Bankrobert100% (19)

- JEE - MODULE 4 - CHEM - Organic ChemistryDocumento214 páginasJEE - MODULE 4 - CHEM - Organic ChemistryHrittik Das100% (1)

- 2 - Structure of Crystalline SolidsDocumento18 páginas2 - Structure of Crystalline Solidslhudielyn abeAún no hay calificaciones

- Pharmaceutical SuspensionsDocumento56 páginasPharmaceutical SuspensionsDessu AshagrieAún no hay calificaciones

- NISER SPS Integrated PHD ProgrammeDocumento39 páginasNISER SPS Integrated PHD ProgrammeSatyaki ChowdhuryAún no hay calificaciones

- PN Junction IsolationDocumento8 páginasPN Junction Isolationrenjith r nairAún no hay calificaciones