Documentos de Académico

Documentos de Profesional

Documentos de Cultura

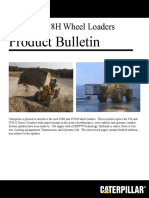

Safety: Cat Machines and Systems Are Designed With Safety As The First Priority

Cargado por

Pedro0 calificaciones0% encontró este documento útil (0 votos)

16 vistas1 páginaThe document summarizes various safety features of Cat machines and systems. It describes integral ROPS cabs that provide operator protection, payload guidelines for safe operation, optional rear and lighting systems for improved visibility, precise braking and steering systems, and standard safety features like slip resistant surfaces, restraints, guards, and switches to disable machines for safe servicing. Safety is an integral part of all machine and system designs according to the document.

Descripción original:

asx<

Título original

p17

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF, TXT o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoThe document summarizes various safety features of Cat machines and systems. It describes integral ROPS cabs that provide operator protection, payload guidelines for safe operation, optional rear and lighting systems for improved visibility, precise braking and steering systems, and standard safety features like slip resistant surfaces, restraints, guards, and switches to disable machines for safe servicing. Safety is an integral part of all machine and system designs according to the document.

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

16 vistas1 páginaSafety: Cat Machines and Systems Are Designed With Safety As The First Priority

Cargado por

PedroThe document summarizes various safety features of Cat machines and systems. It describes integral ROPS cabs that provide operator protection, payload guidelines for safe operation, optional rear and lighting systems for improved visibility, precise braking and steering systems, and standard safety features like slip resistant surfaces, restraints, guards, and switches to disable machines for safe servicing. Safety is an integral part of all machine and system designs according to the document.

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

Está en la página 1de 1

Safety

Cat machines and systems are designed with safety as the first priority.

Product Safety. Caterpillar has been and

continues to be proactive in developing

machines that meet or exceed safety

standards. Safety is an integral part

of all machine and systems designs.

Integral ROPS Cab. Resiliently mounted

to the frame to reduce vibration and

sound, the integral ROPS structure,

which provides “five-sided protection”

for the operator, is designed as an

extension of the truck frame.

Payload Guidelines. Safety is integral to

maintaining the highest productivity in

mining machine operation. Caterpillar

10/10/20 payload guidelines provide a

reference for managing payloads.

WAVS Camera (optional). An optional

rear vision camera system provides

visibility to the rear of the machine

through an LCD monitor in the cab.

The monitor can be set to activate only

when the truck is in reverse, and the

display is equipped with a sensor to

detect ambient light, which automatically

brightens or dims the display.

High Intensity Discharge (HID) Lights

(optional). Thirty-five Watt HID lights

can replace the standard high beam

65 Watt Halogen lights. The powerful

HID lights are almost two times brighter Steering System. A twin, double-acting A stairway lamp illuminates the cab

and 50 percent more efficient, improving cylinder steering system is designed to access stairs and can be activated at

night time visibility. deliver precise control under all loading ground level during entry and shut off

and underfoot conditions. The steering with a switch in the cab.

Brake Systems. Four corner oil-cooled

hydraulic system is separate from the

braking system provides excellent control Standard Safety Features.

main hydraulic system to prevent cross-

in slippery conditions. The service brakes • Slip resistant surfaces

contamination and overheating.

and retarding system are actuated by

modulated hydraulic pressure, while Engine Shutoff Switch. A secondary • 75 mm (3 in) wide orange three-

secondary and parking brake functions engine shutoff switch is located at point operator restraint

are spring applied and hydraulic released. ground level.

• Heated, wide-angle mirrors

This reliable and durable system ensures

Electrical System Disconnect. A battery

braking in the event of complete hydraulic • Body raised indicator

disconnect switch, located directly above

failure. Either the parking or secondary • Guard rails

the front bumper, provides ground-level

brake systems on this truck will hold it

lockout of the electrical system.

on a grade up to 15 percent while carrying • Reverse neutralizer when dumping

a rated load. Ladder/Secondary Egress. Wide

• Low interior sound level

stationary stairways and platforms

on both sides of the machines, allow • Service platform level transmission,

easy ingress and egress. hoist and steering disable switch

• Service platform level starter

disable switch

17

También podría gustarte

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationDe EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationAún no hay calificaciones

- Robot Mechanisms and Mechanical Devices IllustratedDe EverandRobot Mechanisms and Mechanical Devices IllustratedCalificación: 4 de 5 estrellas4/5 (1)

- M O D E L S 1 2 2 7 / 1 2 3 7: Permanent Magnet Motor Speed ControllersDocumento3 páginasM O D E L S 1 2 2 7 / 1 2 3 7: Permanent Magnet Motor Speed ControllersSergio Recabarren100% (1)

- NR-EA/NDR-EA Reach TrucksDocumento6 páginasNR-EA/NDR-EA Reach TrucksConitos Outlet FactoryAún no hay calificaciones

- MODEL 1210: Permanent Magnet Motor Speed ControllerDocumento3 páginasMODEL 1210: Permanent Magnet Motor Speed ControllertlevageAún no hay calificaciones

- OOF Upport Arrier: Capacity HydraulicsDocumento4 páginasOOF Upport Arrier: Capacity HydraulicsDietz LaAún no hay calificaciones

- Curtis DC Drive 50123 - 1210 - RevCDocumento3 páginasCurtis DC Drive 50123 - 1210 - RevCjmoure100% (1)

- 1227-1237 RevGDocumento3 páginas1227-1237 RevGtlevageAún no hay calificaciones

- AmmanawalceokolkowaneDocumento12 páginasAmmanawalceokolkowaneWorld AmusementAún no hay calificaciones

- Godrej Electric: 2, 5 and 6 Tonne CapacityDocumento8 páginasGodrej Electric: 2, 5 and 6 Tonne CapacityVideet DeshmukhAún no hay calificaciones

- Specs - Generator - GenKing 55KVADocumento3 páginasSpecs - Generator - GenKing 55KVAjamesAún no hay calificaciones

- Generator King Scania 500kva Gks 550 Spec SheetDocumento3 páginasGenerator King Scania 500kva Gks 550 Spec SheetMedian HpAún no hay calificaciones

- Aichi Vertical Lift Mast Spec SheetDocumento8 páginasAichi Vertical Lift Mast Spec SheettestAún no hay calificaciones

- Maintenance: Semcon Land Rover Owner Guide Ver 1.00 LANGUAGE: English-En MARQUE: Landrover MODEL: Freelander 2Documento1 páginaMaintenance: Semcon Land Rover Owner Guide Ver 1.00 LANGUAGE: English-En MARQUE: Landrover MODEL: Freelander 2Dejan KovačAún no hay calificaciones

- Damper Testing: The World of Damper Test MachinesDocumento11 páginasDamper Testing: The World of Damper Test MachinesFajarAún no hay calificaciones

- Link Belt Rough Terrain Cranes Spec f75124Documento6 páginasLink Belt Rough Terrain Cranes Spec f75124Artur Erre Emme100% (1)

- Class3 MSW025-30F SpecsheetDocumento4 páginasClass3 MSW025-30F SpecsheetgamunozdAún no hay calificaciones

- Model 1266 A/R Sepex: Separately Excited Electronic Motor Speed ControllerDocumento4 páginasModel 1266 A/R Sepex: Separately Excited Electronic Motor Speed ControllermbgprsmsAún no hay calificaciones

- Src250 Rough-Terrain Crane 25 Tons Lifting Capacity: Quality Changes The WorldDocumento20 páginasSrc250 Rough-Terrain Crane 25 Tons Lifting Capacity: Quality Changes The Worldanon_485665212Aún no hay calificaciones

- 375 - 375L Specalog (AEHQ3850) PDFDocumento28 páginas375 - 375L Specalog (AEHQ3850) PDFsuwarjitechnic100% (1)

- Unit 4 - Telemotor Helm OrdersDocumento92 páginasUnit 4 - Telemotor Helm Ordersmecete8514Aún no hay calificaciones

- Apm Terminals Hopper Manual: Port of CallaoDocumento34 páginasApm Terminals Hopper Manual: Port of CallaoSaray Fernández SaavedraAún no hay calificaciones

- Bernard Butterfly ValveDocumento9 páginasBernard Butterfly ValveCharles BenwariAún no hay calificaciones

- CLARK WPX FeatureBrochureDocumento8 páginasCLARK WPX FeatureBrochureThanh NgocAún no hay calificaciones

- Bedlift Specification GuideDocumento14 páginasBedlift Specification GuideKopi HitamAún no hay calificaciones

- CAT-777F-Direction and Speed ControlDocumento2 páginasCAT-777F-Direction and Speed ControlCybergoAún no hay calificaciones

- Shorts Stock I Valve Lift Controller WebDocumento2 páginasShorts Stock I Valve Lift Controller WebAnton LyakhovAún no hay calificaciones

- Specs - Generator - GenKing 150KVADocumento3 páginasSpecs - Generator - GenKing 150KVAjamesAún no hay calificaciones

- Ati Load Transfer Panel-Lehf3241-02Documento2 páginasAti Load Transfer Panel-Lehf3241-02CARLOSAún no hay calificaciones

- Cargadores 938H.Documento40 páginasCargadores 938H.Harol Ariel Sanchez MezaAún no hay calificaciones

- Hazmat - Vehicle - 2023 12 08 17 45 10Documento115 páginasHazmat - Vehicle - 2023 12 08 17 45 10Sunil MishraAún no hay calificaciones

- Taylor Lifts SMSCatalogueDocumento18 páginasTaylor Lifts SMSCatalogueMohd Abu AjajAún no hay calificaciones

- JKR Basic Lift ComponentsDocumento47 páginasJKR Basic Lift ComponentsKayrol Amry0% (1)

- SYNCHRO DCQ-419-July 202009-CL PDFDocumento13 páginasSYNCHRO DCQ-419-July 202009-CL PDFA MalikAún no hay calificaciones

- Camion Articulado D400EDocumento16 páginasCamion Articulado D400Edarwin100% (1)

- ACH580 Override Functionality Appl Guide 3AUA0000206522 RevD ENDocumento16 páginasACH580 Override Functionality Appl Guide 3AUA0000206522 RevD ENAmilcar CastilloAún no hay calificaciones

- L1350Documento4 páginasL1350RodrigoAndrésMondacaArriazaAún no hay calificaciones

- Convertible Top BMW E90Documento12 páginasConvertible Top BMW E90jailemeilleurfrereaumondeAún no hay calificaciones

- Carlos Silva General CharacteristicsDocumento2 páginasCarlos Silva General CharacteristicsAmine MohamedAún no hay calificaciones

- KDT Evo-General CharacteristicsDocumento2 páginasKDT Evo-General CharacteristicsDjelloul AbdelhadiAún no hay calificaciones

- Kft-Bal - Telma Retarder - en - de - FR - Es - It PDFDocumento44 páginasKft-Bal - Telma Retarder - en - de - FR - Es - It PDFAlejandro ZuñigaAún no hay calificaciones

- BRO MAHA Alle Zwei-Saeulen en 2014-05-06Documento16 páginasBRO MAHA Alle Zwei-Saeulen en 2014-05-06GaborAún no hay calificaciones

- Aexq3623 01Documento4 páginasAexq3623 01claudio santosAún no hay calificaciones

- RTC8035Documento6 páginasRTC8035Mauricio JerezAún no hay calificaciones

- Clark C25C25C - буклетDocumento14 páginasClark C25C25C - буклетЕвгений ПоляковAún no hay calificaciones

- Motor Operated Valve RotorkDocumento12 páginasMotor Operated Valve RotorkGeorge Asuncion100% (3)

- Link Belt Rough Terrain Cranes Spec C0e2cdDocumento6 páginasLink Belt Rough Terrain Cranes Spec C0e2cdMauricio JerezAún no hay calificaciones

- Elliott Boom Trucks 10 To 18 TonsDocumento47 páginasElliott Boom Trucks 10 To 18 TonsPaula PlataAún no hay calificaciones

- Z40 Service Training 139240 RevP1Documento98 páginasZ40 Service Training 139240 RevP1DANIEL100% (1)

- Conveyer Brake SystemsDocumento4 páginasConveyer Brake SystemsTran DucAún no hay calificaciones

- Empty Container HandlerDocumento8 páginasEmpty Container Handlerubaldo caraballoAún no hay calificaciones

- Sulzer 6rlb76 Me Bridge Control SystemDocumento206 páginasSulzer 6rlb76 Me Bridge Control SystemJoseph AbrahamAún no hay calificaciones

- SpecificationsDocumento4 páginasSpecificationsForomaquinas100% (3)

- Yale Reach Truck NR-NDR-DB Specification SheetDocumento6 páginasYale Reach Truck NR-NDR-DB Specification SheetNoelia Brand100% (1)

- Hydraulic Rough Terrain Crane: The RTC-8050 Features The Confined Area Lifting Capacities (Calc) SystemDocumento28 páginasHydraulic Rough Terrain Crane: The RTC-8050 Features The Confined Area Lifting Capacities (Calc) SystemRoger Fremio Lievano CastroAún no hay calificaciones

- Abrir Linkbelt RTC8050 SpecDocumento28 páginasAbrir Linkbelt RTC8050 Specoscar alberto0% (1)

- SanyDocumento14 páginasSanyRudi SugiartoAún no hay calificaciones

- DL300A EspecificacionesDocumento20 páginasDL300A EspecificacionesRuiz D. AntonioAún no hay calificaciones

- Liftparker Mobil: Parking and Temporary Storage of Vehicles Up To 3200 KGDocumento6 páginasLiftparker Mobil: Parking and Temporary Storage of Vehicles Up To 3200 KGSid Ali RABEHIAún no hay calificaciones

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationDe EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationAún no hay calificaciones

- Weight/Payload Calculation: Dual Slope Steel Liner Rubber Liner No Liner (16 MM) (102 MM)Documento1 páginaWeight/Payload Calculation: Dual Slope Steel Liner Rubber Liner No Liner (16 MM) (102 MM)PedroAún no hay calificaciones

- Retarding Performance: Gross WeightDocumento1 páginaRetarding Performance: Gross WeightPedroAún no hay calificaciones

- Gradeability/Speed/Rimpull: Gross WeightDocumento1 páginaGradeability/Speed/Rimpull: Gross WeightPedroAún no hay calificaciones

- Electronic Hoist Control. Provides TheDocumento1 páginaElectronic Hoist Control. Provides ThePedroAún no hay calificaciones

- Retarding Performance: Gross WeightDocumento1 páginaRetarding Performance: Gross WeightPedroAún no hay calificaciones

- P 14Documento1 páginaP 14PedroAún no hay calificaciones

- Transmission EngineDocumento1 páginaTransmission EnginePedroAún no hay calificaciones

- Structures: Rugged Cat Structures Are The Backbone of The 777F Off-Highway Truck's DurabilityDocumento1 páginaStructures: Rugged Cat Structures Are The Backbone of The 777F Off-Highway Truck's DurabilityPedroAún no hay calificaciones

- Rops SuspensionDocumento1 páginaRops SuspensionPedroAún no hay calificaciones

- P 20Documento1 páginaP 20PedroAún no hay calificaciones

- Customer Support: Cat Dealers Have What It Takes To Keep Trucks ProductiveDocumento1 páginaCustomer Support: Cat Dealers Have What It Takes To Keep Trucks ProductivePedroAún no hay calificaciones

- Brake System: Reliable Braking With Superior Control Gives The Operator The Confidence To Focus On ProductivityDocumento1 páginaBrake System: Reliable Braking With Superior Control Gives The Operator The Confidence To Focus On ProductivityPedroAún no hay calificaciones

- TCS ARC 1 Service Brake Sensor 2 Engine Sensor 3 Arc 4 ARC Switch 5 Brakes 6 Service Brakes 7 Axle Speed Sensor 8 TcsDocumento1 páginaTCS ARC 1 Service Brake Sensor 2 Engine Sensor 3 Arc 4 ARC Switch 5 Brakes 6 Service Brakes 7 Axle Speed Sensor 8 TcsPedroAún no hay calificaciones

- Information & Monitoring SystemsDocumento1 páginaInformation & Monitoring SystemsPedroAún no hay calificaciones

- Power Train - TransmissionDocumento1 páginaPower Train - TransmissionPedroAún no hay calificaciones

- Off-Highway TruckDocumento1 páginaOff-Highway TruckPedroAún no hay calificaciones

- SelectionDocumento1 páginaSelectionPedroAún no hay calificaciones

- Rebuildable Steel Breathers: For High-Flow ApplicationsDocumento2 páginasRebuildable Steel Breathers: For High-Flow ApplicationsPedroAún no hay calificaciones

- Gottwald ProductsDocumento4 páginasGottwald ProductsPedroAún no hay calificaciones

- Bio DieselDocumento11 páginasBio DieselPedroAún no hay calificaciones

- UD05674B Baseline Access Control Terminal DS-KIT802 User Manual V2.0 20180228Documento121 páginasUD05674B Baseline Access Control Terminal DS-KIT802 User Manual V2.0 20180228iresh jayasingheAún no hay calificaciones

- EN - 61558 - 2 - 4 (Standards)Documento12 páginasEN - 61558 - 2 - 4 (Standards)RAM PRAKASHAún no hay calificaciones

- An Introduction To Coolants PDFDocumento57 páginasAn Introduction To Coolants PDFPETER ADAMAún no hay calificaciones

- Data0305 KX18DCDocumento3 páginasData0305 KX18DCAbdelhamid SammoudiAún no hay calificaciones

- EAC Software SetupDocumento19 páginasEAC Software SetupBinh Minh NguyenAún no hay calificaciones

- REST Society For Research International: Rsri Membership Application FormDocumento1 páginaREST Society For Research International: Rsri Membership Application FormmeenasarathaAún no hay calificaciones

- Paul Ryan ResumeDocumento3 páginasPaul Ryan ResumePaul RyanAún no hay calificaciones

- 563000-1 Web Chapter 4Documento22 páginas563000-1 Web Chapter 4Engr Ahmad MarwatAún no hay calificaciones

- SV50SP2RevB Released User DocumentsDocumento8 páginasSV50SP2RevB Released User DocumentsAhmed RamadanAún no hay calificaciones

- Assessment of Learning 1 Quiz 1Documento3 páginasAssessment of Learning 1 Quiz 1imalwaysmarked100% (4)

- Workshop Manual Group 21-26 - 7745282 PDFDocumento228 páginasWorkshop Manual Group 21-26 - 7745282 PDFabdelhadi houssinAún no hay calificaciones

- Transformer HandbookDocumento116 páginasTransformer HandbookAnder H. CaulfieldAún no hay calificaciones

- Oracle® Auto Service Request: Exadata Database Machine Quick Installation Guide Release 5.0Documento12 páginasOracle® Auto Service Request: Exadata Database Machine Quick Installation Guide Release 5.0ManifoldAún no hay calificaciones

- List of The Registered UAE CompaniesDocumento3 páginasList of The Registered UAE Companiesirfan aminAún no hay calificaciones

- MIS Officer Job Description and Person SpecificationDocumento3 páginasMIS Officer Job Description and Person SpecificationviewpawanAún no hay calificaciones

- RVR FM Product ListDocumento37 páginasRVR FM Product Listaspwq0% (1)

- G249 MXBDocumento8 páginasG249 MXBAndres SorinAún no hay calificaciones

- X-Universe - Rogues Testament by Steve MillerDocumento281 páginasX-Universe - Rogues Testament by Steve MillerRoccoGranataAún no hay calificaciones

- Premium Protection Synthetic Motor Oils (AMO & ARO)Documento2 páginasPremium Protection Synthetic Motor Oils (AMO & ARO)brian5786Aún no hay calificaciones

- Fuses & Circuit Breakers PDFDocumento13 páginasFuses & Circuit Breakers PDFCarlos Luis Santos SomcarAún no hay calificaciones

- NASM3Documento4 páginasNASM3GFS ConsultoriaAún no hay calificaciones

- Asme Y14.41 2003Documento105 páginasAsme Y14.41 2003Emanuel Ovejita Arrese100% (3)

- Manual de TallerDocumento252 páginasManual de TallerEdison RodriguezAún no hay calificaciones

- Structuro 203: A High Performance Concrete Super Plasticiser, Based On PolycarboxylicDocumento2 páginasStructuro 203: A High Performance Concrete Super Plasticiser, Based On PolycarboxylicVenkata Raju KalidindiAún no hay calificaciones

- Second Invitation OriginalDocumento4 páginasSecond Invitation Originalsudhakar80Aún no hay calificaciones

- Generator ProtectionDocumento11 páginasGenerator Protectionyogeshsahu100% (2)

- IEC 61439 - 2011 New Standard PDFDocumento21 páginasIEC 61439 - 2011 New Standard PDFSamsung JosephAún no hay calificaciones

- Lancaster LinksDocumento3 páginasLancaster LinksTiago FerreiraAún no hay calificaciones

- Manual Hardware Lenovo Yoga BookDocumento68 páginasManual Hardware Lenovo Yoga BookRADU OCTAVIAN100% (2)

- Faqs and User Manual - Returns Offline Tool: Goods and Services Tax NetworkDocumento161 páginasFaqs and User Manual - Returns Offline Tool: Goods and Services Tax NetworklathaAún no hay calificaciones