Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Cat A1 SOP 04 Working On or Near Energized Electrical Equipment PDF

Cargado por

Rached Ben AyedTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Cat A1 SOP 04 Working On or Near Energized Electrical Equipment PDF

Cargado por

Rached Ben AyedCopyright:

Formatos disponibles

SUNCOR ENERGY PRODUCTS

DISTRIBUTION TERMINAL OPERATING MANUAL

STANDARD OPERATING PROCEDURE

SAFE-WORK PRACTICES

Working On Or Near Energized Electrical Equipment

CAT A-1 SOP #4

Lifesaving Rules Supporting Document

Verify isolation before work begins and use

the specific life protecting equipment

Date Issued: January 2010 Revision Date: December 2016

Review Date: December 2019 Revision # 2016-01

Reviewers: B. Buchanan Approver: Mike Cassaday

R. Rattray

1.0 PURPOSE

The purpose of this document is to define and communicate the precautions and requirements

that must be observed when exposed to electrical hazards while performing work on or near

energized electrical equipment, conductors, or circuits.

All Suncor employees and Contractor personnel performing work at Suncor Distribution

Facilities shall comply with the minimum requirements contained in this standard.

2.0 SCOPE

This Standard Operating Procedure shall apply to all employees and contractors who are required

to work on or energized electrical equipment, conductors or circuits while at assets owned and

operated by Suncor Energy Distribution Terminals.

References in this document to “Suncor Personnel” include directors, officers, employees,

contract workers, consultants and agents of Suncor.

DISTRIBUTION TERMINAL OPERATING MANUAL

Working With Energized Electrical Equipment

CAT A-1 SOP #4

3.0 REFERENCED DOCUMENTS

OEMS Element 9, Operational & Maintenance Controls

PSM Standard, Operating & Safe Work Procedures, CO-S12A

Distribution Standard Operating Procedure, Electrical Isolation, SOP Cat A-2, SOP #09

Distribution Standard Operating Procedure, Work Permitting, Cat A-1, SOP #06

Distribution Standard Operating Procedure, Personal Protective Equipment,

CSA Standard Z-462-15

CSA Standard Z-460-13, Control of Hazardous Energy

Applicable Provincial Occupational Health & Safety Regulations

4.0 PRECAUTIONARY STATEMENTS

4.1 Specific Hazards

Typical hazards that may be encountered while executing mechanical isolations may include;

Ergonomic Hazards

Awkward Body Position

Parts of Body in Line of Fire

Work Environment Hazards

Exposure to electrical hazards

Exposure to hydrocarbons or other chemicals

Limited access / egress

Lock-Out Procedure

Personal Limitations

Distractions in work area

Confusing instructions

No training or lack of training

Fitness for duty

Working With Energized Electrical Eqt. 2016-01 Page 2 of 19

Current Version of Document Maintained Electronically

Printed Versions are Uncontrolled

DISTRIBUTION TERMINAL OPERATING MANUAL

Working With Energized Electrical Equipment

CAT A-1 SOP #4

4.2 Training

Proper training and demonstrated competency are prerequisites to performing this Standard

Operating Procedure. Training shall be provided by a competent person and records shall be

maintained.

All employees who are required to utilize this procedure must review and successfully complete

competency verification on a frequency not to exceed three years.

All Suncor employees and contractor personnel performing electrical work at Suncor

Distribution Facilities shall provide the records with information necessary to ensure the

capabilities in performing the electrical task safely.

4.3 Personal Protective Equipment

Personal protective equipment as outlined in Distribution Standard Operating Procedure, Cat A-

1, SOP #10 or as specified in the Safe Work Permit depending on the work to be completed as

per the job scope requirements.

Arc flash specific PPE requirements for equipment which has had no calculated energy analysis

( Arc Flash Label ) are determined by identifying the “risk” using Table 4A and 4B and selecting

PPE from Table 5 of CSA Z462-15; or when arc energy calculation has been made ( Arc Flash

Label ) by using Annex H Table H.2 of CSA Z-462-15 Selection of Arc-rated Clothing and other

PPE.

5.0 RESPONSIBILITIES

Terminal Management;

Responsible for ensuring full implementation and compliance of this standard operating

procedure.

Responsible for providing all equipment and personnel training that is required for

compliance with this standard.

Responsible to complete regular audits of electrical isolation activities and document

findings in Suncor reporting tool.

Working With Energized Electrical Eqt. 2016-01 Page 3 of 19

Current Version of Document Maintained Electronically

Printed Versions are Uncontrolled

DISTRIBUTION TERMINAL OPERATING MANUAL

Working With Energized Electrical Equipment

CAT A-1 SOP #4

Responsible to ensure all Terminal Employees who are required to utilize electrical isolation

activities as part of their normal job function are verified for competency at an interval not to

exceed three years.

Responsible to ensure facility has completed an arc flash study and facility is appropriately

labelled.

Responsible to ensure if no study has been carried out that the equipment falls within the

parameters set out in Table 4B, with respect to the voltage, type of equipment, available fault

current and the clearing time of the overcurrent device at the equipment being worked on.

Operating Authority;

Responsible to ensure all sources of energy are isolated and verify the equipment is at zero

energy state.

Visit work site with Performing Authority and review requirements of the safe work permit

including the isolation points.

Notify the Performing Authority of any changing conditions or potential impacts to the work

area.

Preparing and issuing the safe work permit.

Performing Authority;

Responsible to review and accept the Safe Work Permit on behalf of themselves or on behalf

of associated Workers who will be required to complete work under that permit.

Responsible to verify that all sources of energy are isolated.

Visit work site with Operating Authority and review requirements of the safe work permit

including the isolation points.

Notify the Operating Authority of any changing conditions or potential impacts to the work

area.

Perform task as outlined on the Safe Work Permit in a safe and responsible manner.

6.0 SUSTAINMENT AND CONTINUAL IMPROVEMENT

This document is classified as a Critical Safe-Work Practice and as such must comply with the

Critical Safe-Work Practice Standard outlined in Distribution Procedure Program,

Cat A-3, SOP #01.

Working With Energized Electrical Eqt. 2016-01 Page 4 of 19

Current Version of Document Maintained Electronically

Printed Versions are Uncontrolled

DISTRIBUTION TERMINAL OPERATING MANUAL

Working With Energized Electrical Equipment

CAT A-1 SOP #4

Distribution Leadership Team shall initiate document review process.

To ensure this Standard Operating Procedure documents meets all applicable OEMS standards,

this document is to be reviewed at a frequency not to exceed 3 years or when conditions change

to warrant a review

7.0 DEFINITIONS

Terminal Management; highest level of authority on site, may be manager, supervisor or a

delegated responsibility

Electric shock; is contact with energized electrical equipment, conductors or circuit parts that

cause the flow of electrical current through the body

Arc flash; is a flash created by current flow through the air between two or more conductors, or

circuit parts and/or the equipment enclosure (ground) which ionizes and super heats the air very

rapidly

Arc Flash Boundary; when an arc flash hazard exists, an approach limit at a distance from a

prospective arc source within which a person could receive a second-degree burn if an electrical

arc flash were to occur.

*** NOTE ***

A second-degree burn is possible by an exposure of unprotected skin to an electric

arc flash above the incident-energy level of 5 J/cm² (1.2 cal./cm)²

Persons crossing into the arc flash protection boundary are required to wear the

appropriate PPE as determined by selection from Table 5 when no calculation has been

completed, or Annex H when Energy Analysis has been completed

Working With Energized Electrical Eqt. 2016-01 Page 5 of 19

Current Version of Document Maintained Electronically

Printed Versions are Uncontrolled

DISTRIBUTION TERMINAL OPERATING MANUAL

Working With Energized Electrical Equipment

CAT A-1 SOP #4

Arc Blast; is the release of tremendous pressures as a result of an arc fault where current flows

through the air between two conductors or a conductor and ground

Electrical equipment; includes machinery, plant, works, wires, pipes, poles, conduits,

apparatus, appliances and equipment, designed or used, or intended for use, for or in connection

with generation, transmission, supply, distribution or use of electrical energy for any purpose;

Limited Approach Boundary; is a shock protection boundary to be crossed by only qualified

persons (at a distance from a live part as specified by Tables 1A and 1B of CSA Z462-15) which

is not to be crossed by unqualified persons unless escorted by a qualified person

Restricted Approach Boundary; is a a shock protection boundary to be crossed by only

qualified persons (at a distance from a live part as specified by Tables 1A and 1B of CSA Z462-

15) which, due to its proximity to a shock hazard, requires the use of shock protection techniques

and equipment when crossed

8.0 PREREQUISITIES

Only qualified person(s) with skills and knowledge to the construction and operation of electrical

equipment and installations and has received safety training on the hazards involved shall

perform the work.

9.0 HAZARDS

There are three main electrical hazards:

<1> ELECTRIC SHOCK

<2> ARC FLASH

<3> ARC BLAST

However, when working on electrical equipment, other additional hazards must be reviewed,

such as: height, confined space, environment, etc.

Working With Energized Electrical Eqt. 2016-01 Page 6 of 19

Current Version of Document Maintained Electronically

Printed Versions are Uncontrolled

DISTRIBUTION TERMINAL OPERATING MANUAL

Working With Energized Electrical Equipment

CAT A-1 SOP #4

9.1 ELECTRIC SHOCK

Electric shock is contact with energized electrical equipment, conductors or circuit parts that

cause the flow of electrical current through the body. The severity of the shock is determined by

the amount of electrical current, the total time that it flows through the body, and where it flows

through the body. A current as low as 23 milliamps may be fatal due to respiratory paralysis and

100 milliamps due to heart ventricular fibrillation. Humid or wet conditions or sweaty skin

increase the potential for electrical shock.

The shock hazard must be considered at any voltage greater than or equal to 50V as defined in

CSA Z462. Lower frequencies associated with variable frequency drives and the like, increase

the risk of electrocution by lowering the level of current at which we can let go of an energized

conductor or circuit part (10Hz as low as 10 mA- 100Hz as high as 100 mA and at normal

frequency (60Hz - 60 mA).

9.2 ARC FLASH

Electrical equipment that faults and creates an arc flash can expose a worker to extreme heat

causing severe burn. Arc flashes are created by current flow through the air between two or

more conductors, or circuit parts which ionizes and super heats the air very rapidly. Some

secondary hazards related to arc flash are:

Fire

Toxic smoke inhalation from vaporized copper

Sound pressure that could damage hearing

High intensity, UV/IR light that may damage eyesight

Flying molten metal that may cause injury

An electrical equipment arc flash can produce temperatures up to 20,000⁰C (35,000⁰F), a

temperatures at which materials are vaporized. This explosive release of energy can result in

injuries caused by an intense blast of heat, noise, light and air pressure which can spread molten

metal at great distances. When the explosion occurs within a motor control centre or switchgear,

the release is intensified.

Working With Energized Electrical Eqt. 2016-01 Page 7 of 19

Current Version of Document Maintained Electronically

Printed Versions are Uncontrolled

DISTRIBUTION TERMINAL OPERATING MANUAL

Working With Energized Electrical Equipment

CAT A-1 SOP #4

9.3 ARC BLAST

Is associated with the release of tremendous pressures as a result of an arc fault where current

flows through the air between two conductors or a conductor and ground. Vaporized copper,

molten metal, pressure waves, shrapnel, intense noise and toxic smoke/gases are some of the

resultants of an arc blast.

Dangers associated with an arc blast event are high pressure, sound and shrapnel. The high

pressures can easily exceed hundreds or even thousands of pounds per square foot, knocking

workers off ladders, rupturing ear-drums, and collapsing lungs. The sound associated with these

pressures can exceed 165 dB. Finally, material and molten metal is expelled away from the arc

at speeds exceeding 1120 kilometres per hour (700 MPH), fast enough for shrapnel to

completely penetrate the human body.

10.0 BASIC ELECTRICAL SAFETY PRECAUTIONS AND REQUIREMENTS

Safety related work practices shall be employed to prevent electric shock or other injuries

resulting from either direct or indirect electrical contacts, when work is performed on electrical

equipment, conductors or circuit parts which are or may be energized. The specific safety-

related work practices shall be consistent with the nature and extent of the associated electrical

hazards.

Energized electrical conductors or circuit parts to which an employee may be exposed shall be

de-energized before the employee works on them, unless the employer can demonstrate that de-

energizing introduces additional or increased hazards or is infeasible due to equipment design or

operational limitations. Energized electrical conductors or circuit parts that operate at less than

50 volts to ground need not be de-energized if there will be no increased exposure to electrical

burns or to explosion due to electric arcs. Extra-low voltage will require thermal PPE when it is

determined that the incident energy that is available is greater than 1.2 cal./cm².

Working With Energized Electrical Eqt. 2016-01 Page 8 of 19

Current Version of Document Maintained Electronically

Printed Versions are Uncontrolled

DISTRIBUTION TERMINAL OPERATING MANUAL

Working With Energized Electrical Equipment

CAT A-1 SOP #4

*** NOTE ***

Examples of increased or additional hazards include interruption of life support equipment,

deactivation of emergency alarm systems, or shutdown of hazardous location ventilation

equipment.

*** NOTE ***

Examples of work that must be performed on energized circuit parts because of infeasibility due

to equipment design or operational limitations includes testing of circuits that can only be

performed with circuit energized.

Recommended Electrical Practices for Distribution Terminals are as follows:

All electrical equipment should be considered energized until it is proven de-energized.

by a qualified person using approved test equipment to confirm “0” voltage. No

personnel should begin work on de-energized parts until this verification has been

completed.

Do not rush when planning or carrying out the electrical work.

All near misses and electrical incidents (arc flash and shock) shall be reported

immediately. These incidents should be fully investigated, lessons learned and

recommendations implemented.

Working With Energized Electrical Eqt. 2016-01 Page 9 of 19

Current Version of Document Maintained Electronically

Printed Versions are Uncontrolled

DISTRIBUTION TERMINAL OPERATING MANUAL

Working With Energized Electrical Equipment

CAT A-1 SOP #4

No worker should begin any electrical work until he/she fully understands the

instructions received and in no circumstances should that person exceed those

instructions. Should any person consider that the instructions given cannot be carried out

safely, that person should refer the matter immediately to an appropriate supervisor.

No worker should interfere with ground connections, locks, tags, danger or warning

signs, or safety devices; or attempt to close a switch that is in the open position.

Only use tools that are properly insulated and approved to the appropriate standard.

Test every circuit and every conductor, every time before you touch. Use Test-Before

Touch procedure.

Do not work on any electrical circuit where the area is damp or wet until insulated rubber

matting or rated footwear is available and utilized, and the circuit is isolated and

grounded.

During the execution of a task if any changes are noticed from planned procedures, then

immediately stop the task, think and analyze, assess the risk, control the risk and then

resume work.

11.0 ALERTING TECHNIQUES

The following alerting techniques shall be used to warn and protect all persons from hazards

which could cause injury due to electric shock, arc flash or failure of electric equipment parts.

Safety signs, safety symbols, or accident prevention tags shall be used where necessary to

warn employees about electrical hazards which may endanger them.

Working With Energized Electrical Eqt. 2016-01 Page 10 of 19

Current Version of Document Maintained Electronically

Printed Versions are Uncontrolled

DISTRIBUTION TERMINAL OPERATING MANUAL

Working With Energized Electrical Equipment

CAT A-1 SOP #4

Barricades shall be used in conjunction with safety signs where it is necessary to prevent

or limit individual access to work areas exposing individuals to non-insulated energized

conductors or circuit parts. Conductive barricades may not be used where they might

cause an electrical contact hazard.

If signs and barricades do not provide sufficient warning and protection from electrical

hazards, a standby/signal person shall be stationed to warn and protect employees from

entering the area. An attendant may also be utilized when the task duration is known to be

short, thus eliminating the need to establish the physical barrier or when a physical

barrier is infeasible.

12.0 CONDUCTIVE APPAREL

Conductive articles of jewellery and clothing (such as watch bands, bracelets, rings, keys, chains,

necklaces, metalized aprons, cloth with conductive thread, or metal headgear) shall not be worn.

13.0 ELECTRICAL SAFETY INTERLOCKS

Electrical safety interlocks are mechanical linkages, electrical equipment or other devices which

prevent exposure to energized parts or circuits and operation of the equipment when

starter/breaker doors are opened.

Electrical interlocks must not be defeated or disabled other than for testing or during

maintenance checks. It shall be noted on the permit that interlocks will be defeated.

Only an Authorized and/or Qualified Electrical Worker may defeat an electrical safety interlock,

and then only temporarily while he or she is working on the equipment. The interlock system

shall be returned to its operable condition when the work is completed.

Working With Energized Electrical Eqt. 2016-01 Page 11 of 19

Current Version of Document Maintained Electronically

Printed Versions are Uncontrolled

DISTRIBUTION TERMINAL OPERATING MANUAL

Working With Energized Electrical Equipment

CAT A-1 SOP #4

14.0 ELECTRICALLY SAFE WORK CONDITION

An electrically safe work condition shall be achieved when performed in accordance with the

procedures of CSA Z462-15, and verified by the following process:

1) Determine all possible sources of electrical supply to the specific equipment. Check

applicable up-to-date single line drawings, diagrams and identification tags.

2) After properly interrupting the load current, ( Refer to SOP #09 Electrical Isolation )

open the disconnecting device(s) for each source.

3) Where it is possible, visually verify that all blades of the disconnecting devices are fully

open or draw out type circuit breakers are withdrawn to the fully disconnected position.

4) Apply Lock Out/Tag Out devices in accordance with Suncor Standards.

5) Use an adequately rated voltage detector (certified to the appropriate standard) to test

each conductor phase to phase and phase to ground to verify they are de-energized.

Before and after each test, determine that the voltage detector is operating satisfactorily.

Test-Before-Touch.

6) Where possible induced voltages or stored electrical energy exist, ground the phase

conductors or circuit parts before touching them. If it is know that capacitors exist in a

circuit allow discharge time as recommended by the manufacturer or as defined in the

Canadian Electrical Safety Code. Rule 26-222. Where it could be reasonably anticipated

that the conductors or circuit parts being de-energized could contact other exposed

energized conductors or circuit parts, apply ground connecting devices rated for the

available fault duty.

Working With Energized Electrical Eqt. 2016-01 Page 12 of 19

Current Version of Document Maintained Electronically

Printed Versions are Uncontrolled

DISTRIBUTION TERMINAL OPERATING MANUAL

Working With Energized Electrical Equipment

CAT A-1 SOP #4

15.0 ELECTRICALLY SAFE WORK PROCEDURES

An “electrical safe work procedure” is a written step by step description of how to perform a job

from start to finish. A safe work procedure will include the appropriate safe work practices and

will highlight the safety requirements.

16.0 MAINTENANCE

All tools and equipment shall be properly maintained so as to reduce risk of injuries to

employees or damage to property. Supervision shall ensure that all preventative maintenance is

carried out by qualified personnel according to established schedules and that records are

maintained.

All electrical workers shall regularly check all tools and equipment that they are working with,

and shall take out of service any tools or equipment that poses a hazard due to a need for repair.

Employees are expected to inspect and monitor equipment and report problems to the

appropriate supervisor.

Personally issued safety equipment is the responsibility of the individual to ensure tests, checks

or maintenance are conducted as necessary and recorded.

Records are a necessary part of the Suncor Distribution’s maintenance program. Documentation

of inspections, maintenance and repairs will be kept on file in the appropriate location.

Complete a field Level Risk Assessment (FLRA) for every work and ensure procedures are on

hand detailing the work to be performed.

It is necessary to complete an Energized Electrical Work Permit (EEWP) for all work that is not

testing and/or trouble-shooting or inspection while outside the restricted approach boundary.

Working With Energized Electrical Eqt. 2016-01 Page 13 of 19

Current Version of Document Maintained Electronically

Printed Versions are Uncontrolled

DISTRIBUTION TERMINAL OPERATING MANUAL

Working With Energized Electrical Equipment

CAT A-1 SOP #4

When conducting Hi-pot testing and Megger testing, appropriate warning signs, for example,

DANGER – HIGH VOLTAGE, should be posted on or near the entrance doors and flagging

tape should be used to cordon off areas of high hazards.

In the case of Infra-Red (IR) scans, precautions should be taken to prevent accidental contact of

energized terminals by personnel, either by shielding the energized terminals or by providing

barriers around the area.

Ensure personal safety grounds are installed where applicable.

At the completion of the job, ensure all tools and equipment are accounted for. Thoroughly

inspect the electrical equipment that was worked on to ensure no tools or other materials are left

inside the equipment.

Ensure all utility and personal safety grounds (if they were required) are disconnected following

appropriate Lock Out/Tag Out procedures.

Ensure any capacitors that are in the system are bled off (e.g. 0 voltage) prior to maintenance

and that bleed resistors are installed.

Working With Energized Electrical Eqt. 2016-01 Page 14 of 19

Current Version of Document Maintained Electronically

Printed Versions are Uncontrolled

DISTRIBUTION TERMINAL OPERATING MANUAL

Working With Energized Electrical Equipment

CAT A-1 SOP #4

All personnel performing the electrical task shall ensure the following steps are taken before

performing all electrical tasks:

(refer to “ELECTRICAL WORK FLOW CHART”)

1) Perform – Risk Assessment

2) If “LOW” risk – complete “FIELD LEVEL RISK ASSESSMENT” (FLRA) form

3) If “HIGH” risk:

justification for “LIVE WORK”

site review by qualified person

complete:

o “FLRA” form

o “Energized Electrical Work Permit” (EEWP) form

refer to “Approach Limits Diagram” (Boundaries for Arc Flash

Protection and Shock)

refer to “Hazard Risk Clothing Category Table”

o “Electrical Safe Work Procedure” may be required

4) Obtain “Operations Permit”

17.0 PROCEDURE DEVIATION

Deviations from this standard operating procedure must be authorized using the Management of

Change procedure. Deviations must be documented and documentation must include the relevant

facts supporting the deviation decision.

Working With Energized Electrical Eqt. 2016-01 Page 15 of 19

Current Version of Document Maintained Electronically

Printed Versions are Uncontrolled

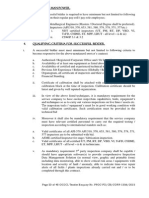

APPROACH LIMITS DIAGRAM Boundaries for Arc Flash Protection and Shock

Unqualified Personnel - Plus Unqualified Personnel – Plus No Unqualified Personnel

PPE PPE

Supervised by Qualified Awareness and continuously Qualified Personnel – Plus

Person escorted by Qualified Personnel Competent for Job

Approved Risk Analysis

Qualified Person – Plus Qualified Personnel – Plus Approved Work Procedure

PPE PPE Electrical Work Permit

Competent for Job Competent for Job PPE

Tools and Equipment

No ingress to Prohibited

1.2 Cal / cm

Onset of 2nd Degree

ARC FLASH

Burn

BOUNDARY LIMITED RESTRICTED

SAFE FROM FLASH SAFE FROM SHOCK SHOCK PROTECTION BOUNDARY

ARC FLASH BOUNDARY

SHOCK PROTECTION BOUNDARY

NOTES BOUNDARY

Voltage Limited Restricted

LIMITED, and RESTRICTED shock protection boundaries shown on table at

right or shown on “Arc Flash and Shock Hazard” label on equipment 3’ 6” 1’ 0”

480V 1.07 m 305 mm

ARC FLASH BOUNDARY, shown on “Arc Flash and Shock Hazard” label on 3’ 6” 1’ 0”

electrical equipment 600V

1.07 m 305 mm

Required CLOTHING CATEGORY or Table Reference to perform task 5.0 ft 2’ 2”

4160V

shown on “Arc Flash and Shock Hazard Label” in cal./cm² on equipment 1.52 m 680 mm

5.0 ft 2’ 2”

13800V 1.52 m 680 mm

ENERGIZED ELECTRICAL WORK PERMIT FORM

PART I; TO BE COMPLETED BY THE REQUESTER:

Job / Work Order Number __________________________

1. Description of circuit/ equipment / job location; _____________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

2. Description of work to be done; _________________________________________________________________

_______________________________________________________________________________________________

3. Justification of why the circuit / equipment cannot be de-energized or the work deferred until the next scheduled

outage;______________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

Requester / Title; ____________________________________________ Date _____________________________

PART II TO BE COMPLETED BY THE ELECTRICALLY QUALIFED PERSONS DOING THE WORK

Check When Complete

1. Detail job description to be used in performing the above detailed work _______________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

2. Description of the safe work practices to be employed _____________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

3. Results of the shock hazard analysis____________________________________________________________

_______________________________________________________________________________________________

4. Determination of Shock Protection Boundaries____________________________________________________

5. Results of Flash Hazard Analysis ______________________________________________________________

_______________________________________________________________________________________________

6. Determination of Flash Hazard Boundaries ____________________________________________________

7. Necessary personal protective equipment to safely perform the assigned task ___________________________

_______________________________________________________________________________________________

8. Means employed to restrict the access of unqualified persons from the work area ________________________

_______________________________________________________________________________________________

9. Evidence of completion of a job briefing including discussion of any job related hazards __________________

10. Do you agree the above described work can be done safely? Yes No

IF NO, WORK IS NOT TO PROCEED

Electrically Qualified Person(s) ____________________________________ Date ______________________

Electrically Qualified Person(s) ____________________________________ Date ______________________

PART III APPROVAL BY SITE AUTHORITY TO PERFORM THE WORK WHILE ELECTRICALLY

ENERGIZED

Terminal Management ______________________________ Date _____________________________________

DISTRIBUTION TERMINAL OPERATING MANUAL

Working With Energized Electrical Equipment

CAT A-1 SOP #4

ELECTRICAL WORK FLOW CHART

ELECTRICAL WORK ORDER

RISK ASSESSMENT

HIGH LOW

Above 50V and Below 50V OR

LIVE Parts NO Live Parts

JUSTIFICATION

For “Live Work”

SITE REVIEW FORM REQUIRED

By Electrically Qualified 1) Field level Risk Assessment

Person in Charge

FORMS REQUIRED

1) Field Level Risk Assessment

2) Energized Electrical Work Permit Form

Description of Work

Shock and Arc Flash Analysis, ( Refer to Approach Limits Diagram )

PPE Required for Task, ( Refer to Hazard Risk Clothing Table )

Task Briefing

3) Electrical Safe Work Procedure

OBTAIN SAFE WORK PERMIT

( EXPLAIN TASK TO BE PERFORMED FULLY )

Working With Energized Electrical Eqt. 2016-01 Page 18 of 19

Current Version of Document Maintained Electronically

Printed Versions are Uncontrolled

DISTRIBUTION TERMINAL OPERATING MANUAL

Working With Energized Electrical Equipment

CAT A-1 SOP #4

DATE AUTHOR DESCRIPTION REVISION

Jan 2011 R. Rattray New document issue. Initial Issue

Sept 2011 G. Gielen Re-write of entire document 2011-01

November 2012 R. Rattray Re-formatted for PSM 2012-01

Changed Document Owner to Distribution

December 2013 R. Rattray 2013-01

Leadership Team

December 2016 R. Rattray Re-Formatted for new LSR 2016-01

Working With Energized Electrical Eqt. 2016-01 Page 19 of 19

Current Version of Document Maintained Electronically

Printed Versions are Uncontrolled

También podría gustarte

- Egyptian Variation Guidelines for Non-Sterile ProductsDocumento79 páginasEgyptian Variation Guidelines for Non-Sterile ProductsmmmmmAún no hay calificaciones

- ENTS 400 NewDocumento62 páginasENTS 400 Newmohammadimranshah0% (1)

- JSA SAFETY ANALYSIS FOR DE-ETHANIZER PIPING TESTDocumento4 páginasJSA SAFETY ANALYSIS FOR DE-ETHANIZER PIPING TESTMajdiSahnounAún no hay calificaciones

- GEA CMS CatalogueDocumento23 páginasGEA CMS Cataloguek.r.sureshbabuAún no hay calificaciones

- New Insights in Repairing Damaged Pipes and Pipelines Using Composite Materials Chris AlexanderDocumento41 páginasNew Insights in Repairing Damaged Pipes and Pipelines Using Composite Materials Chris AlexanderAlp AltınokAún no hay calificaciones

- B15 PCH 50 SP 004 CDocumento134 páginasB15 PCH 50 SP 004 CWarlexAún no hay calificaciones

- Sow NDTDocumento1 páginaSow NDTderwaishjeeAún no hay calificaciones

- Piping Spec BL ClassDocumento1 páginaPiping Spec BL Classnestor ferrel floresAún no hay calificaciones

- GAIL Tender 24 and 18 Inch SizesDocumento107 páginasGAIL Tender 24 and 18 Inch SizesSusheel GuptaAún no hay calificaciones

- 2005 Petro Lab GuidelinesDocumento11 páginas2005 Petro Lab Guidelinesalomaritrq100% (1)

- Sampling ProcedureDocumento70 páginasSampling Proceduredantuluri chanduAún no hay calificaciones

- A 1 Gen MC SP 0001Documento8 páginasA 1 Gen MC SP 0001api-19762124100% (1)

- Inspect LPS with ATLAS ChecklistDocumento2 páginasInspect LPS with ATLAS ChecklistRaja Jagadeesan100% (1)

- 01 - 1030 James Rowley - Hydratight PDFDocumento17 páginas01 - 1030 James Rowley - Hydratight PDFaaAún no hay calificaciones

- Saudi Aramco GI manual indexDocumento14 páginasSaudi Aramco GI manual indexmmmAún no hay calificaciones

- CHECKLIST SHEET P & ID PIPING AND INSTRUMENTATION CHART PR-03Documento6 páginasCHECKLIST SHEET P & ID PIPING AND INSTRUMENTATION CHART PR-03Yousef SalahAún no hay calificaciones

- Piping Engineering: Phillips 66 Lake Charles Project Specific AddendumDocumento16 páginasPiping Engineering: Phillips 66 Lake Charles Project Specific AddendumChirag ShahAún no hay calificaciones

- 3.2 Preventive Maintenance Program Plan - Revised 2022Documento39 páginas3.2 Preventive Maintenance Program Plan - Revised 2022Wayne WellsAún no hay calificaciones

- Certification Program: Aws - CwiDocumento5 páginasCertification Program: Aws - CwiaasattiAún no hay calificaciones

- N2 - Rev ADocumento13 páginasN2 - Rev AChirag ShahAún no hay calificaciones

- SOP 16 Management of FuellingDocumento7 páginasSOP 16 Management of Fuellingshamroz khanAún no hay calificaciones

- Guidelines for selecting flangesDocumento6 páginasGuidelines for selecting flangesMohit BauskarAún no hay calificaciones

- Cost Summary For Equipment Installation Work (PKG-1/2/3) : PROJECT: Ruwias Refinery ExpansionDocumento9 páginasCost Summary For Equipment Installation Work (PKG-1/2/3) : PROJECT: Ruwias Refinery ExpansionjnmanivannanmechAún no hay calificaciones

- Tender Document For CraneDocumento10 páginasTender Document For Craneamechmar5935Aún no hay calificaciones

- Introduction and Evaluation of ReliabilityDocumento15 páginasIntroduction and Evaluation of ReliabilityRebbyno Deendri Andika100% (1)

- 00000-Hx-0001 - Pressure Vessels General SpecificationsDocumento8 páginas00000-Hx-0001 - Pressure Vessels General SpecificationsFernando SpinolaAún no hay calificaciones

- CNC Oxyacetylene Flame Cutting MachineDocumento12 páginasCNC Oxyacetylene Flame Cutting MachineNaman JoharAún no hay calificaciones

- Workload ExampleDocumento2 páginasWorkload ExampleAllaiza Mei Reyes LazaroAún no hay calificaciones

- Need for Effective HSE ManagementDocumento59 páginasNeed for Effective HSE ManagementtissaanuradhaAún no hay calificaciones

- Piping Engineering: Marathon Petroleum Co. Project Specific AddendumDocumento17 páginasPiping Engineering: Marathon Petroleum Co. Project Specific AddendumChirag ShahAún no hay calificaciones

- SS 01 - Dec 2012Documento10 páginasSS 01 - Dec 2012Manish WaghareAún no hay calificaciones

- 0041-00-BGST-15030 - SoW - FinalDocumento74 páginas0041-00-BGST-15030 - SoW - FinalEnrico CallegariAún no hay calificaciones

- Api 580Documento6 páginasApi 580Fernando ArévaloAún no hay calificaciones

- Using A Car Seal To Lock A Ball ValveDocumento30 páginasUsing A Car Seal To Lock A Ball ValvesnamprogAún no hay calificaciones

- Saic K 4001Documento2 páginasSaic K 4001BilalAún no hay calificaciones

- Loading SystemsDocumento48 páginasLoading SystemsFabio MiguelAún no hay calificaciones

- ELC-SC-1675-L - Installation ElectricalDocumento40 páginasELC-SC-1675-L - Installation Electricaldidik_wahyudiAún no hay calificaciones

- ENI Zubair Oil Field Multiphase Flowmeter DocumentsDocumento4 páginasENI Zubair Oil Field Multiphase Flowmeter DocumentsMohammed HijaziAún no hay calificaciones

- Scope of WorkDocumento13 páginasScope of Worknicko.arya.dharmaAún no hay calificaciones

- Following of Structures Using An Unmanned Aerial Vehicle (UAV) (2006)Documento14 páginasFollowing of Structures Using An Unmanned Aerial Vehicle (UAV) (2006)milliniAún no hay calificaciones

- Upgrade Waste Water Systems Electrical Tie-InsDocumento75 páginasUpgrade Waste Water Systems Electrical Tie-InsHaleem Ur Rashid Bangash100% (1)

- Models B27X and B28X Birotor Plus Meter Models B29X Non-Ferrous Birotor Plus MeterDocumento32 páginasModels B27X and B28X Birotor Plus Meter Models B29X Non-Ferrous Birotor Plus MeterHelver Pachón0% (1)

- DistilationDocumento105 páginasDistilationbahaaabdelnaserAún no hay calificaciones

- DNV-RP-F106 (2003) - Factory Applied External Pipeline Coatings For Corrosion ControlDocumento32 páginasDNV-RP-F106 (2003) - Factory Applied External Pipeline Coatings For Corrosion ControlJohnnyAún no hay calificaciones

- Corrosion Resistance Performance of Epoxy Coatings Incorporated With Unmilled Micro Aluminium PigmentsDocumento14 páginasCorrosion Resistance Performance of Epoxy Coatings Incorporated With Unmilled Micro Aluminium Pigmentssmith100% (1)

- RPS MMR Piping ClassDocumento42 páginasRPS MMR Piping ClassKathia Espinoza RojasAún no hay calificaciones

- C2 - RevADocumento16 páginasC2 - RevAChirag ShahAún no hay calificaciones

- Corrosion and PreventionDocumento17 páginasCorrosion and PreventionSaut EduardAún no hay calificaciones

- Inspection and Assessment of Damaged Subsea PipelinesDocumento9 páginasInspection and Assessment of Damaged Subsea PipelinesВалерий ГерасимовичAún no hay calificaciones

- Internal & External Inspection GuidelinesDocumento5 páginasInternal & External Inspection Guidelinesgeverett2765Aún no hay calificaciones

- Saudi Aramco Test Report: Laboratory Hood Test SATR-K-4005 15-Dec-09 HvacDocumento4 páginasSaudi Aramco Test Report: Laboratory Hood Test SATR-K-4005 15-Dec-09 HvacWaleed MedhatAún no hay calificaciones

- Engineering Encyclopedia: Visual InspectionDocumento31 páginasEngineering Encyclopedia: Visual InspectionAnonymous S9qBDVky50% (2)

- SAIC-J-6501 Rev 8Documento12 páginasSAIC-J-6501 Rev 8Rashid ArshadAún no hay calificaciones

- Cathodic Protection - WikipediaDocumento12 páginasCathodic Protection - WikipediaSanthosh Reddy BAún no hay calificaciones

- We Are Hiring: Postion Job SpecificationDocumento1 páginaWe Are Hiring: Postion Job SpecificationAdnan ZafarAún no hay calificaciones

- Evaluate Operator Performance of Aerial LiftsDocumento9 páginasEvaluate Operator Performance of Aerial Liftssiswadi salatigaAún no hay calificaciones

- CER Example Registry: Professional Development ProgramDocumento13 páginasCER Example Registry: Professional Development ProgramPradyut TiwariAún no hay calificaciones

- Why Arc Flash Studies Are Important: Understanding Arc Flash HazardsDocumento3 páginasWhy Arc Flash Studies Are Important: Understanding Arc Flash HazardsSellappan MuthusamyAún no hay calificaciones

- Arc-Flash Hazard AnalysisDocumento134 páginasArc-Flash Hazard Analysisramesh1950Aún no hay calificaciones

- The IEE Wiring Regulations Explained and IllustratedDe EverandThe IEE Wiring Regulations Explained and IllustratedCalificación: 4 de 5 estrellas4/5 (14)

- File 2 DATN dịch tiếng Anh sang Việt mô hình máy phát điện SEGDocumento28 páginasFile 2 DATN dịch tiếng Anh sang Việt mô hình máy phát điện SEGdangvanthanh150873Aún no hay calificaciones

- Fix 3Documento12 páginasFix 3Eng TrAún no hay calificaciones

- GM THM 4L80E ATRA MANUAL Repair Rebuild Book Transmission Guide 4L80 E PDFDocumento100 páginasGM THM 4L80E ATRA MANUAL Repair Rebuild Book Transmission Guide 4L80 E PDFDaniel GonzalezAún no hay calificaciones

- Whirlpool ADP 6600 WH Service ManualDocumento15 páginasWhirlpool ADP 6600 WH Service ManualMarcelo Sergio HamerAún no hay calificaciones

- UGC MarketingDocumento16 páginasUGC MarketingJK MarketingAún no hay calificaciones

- Wind farm project NPV and LCOE analysisDocumento5 páginasWind farm project NPV and LCOE analysisPedro Galvani72% (32)

- Urban Transit Systems and Technology Vuchic PDFDocumento614 páginasUrban Transit Systems and Technology Vuchic PDFARAVIND PATIL100% (1)

- Value Chain Engineering Assignemnt IIDocumento22 páginasValue Chain Engineering Assignemnt IImaria50% (2)

- 80305a PDFDocumento7 páginas80305a PDFlorisseAún no hay calificaciones

- Example of BVP ProblemsDocumento3 páginasExample of BVP ProblemsAbhishek KumarAún no hay calificaciones

- Strategic Human Resource Development I SlidesDocumento26 páginasStrategic Human Resource Development I SlidesAbhiman Behera50% (2)

- Hydran 201ti Gea12933 HRDocumento2 páginasHydran 201ti Gea12933 HRlxd.hepAún no hay calificaciones

- B406-4 Rev. DDocumento86 páginasB406-4 Rev. Danshit1Aún no hay calificaciones

- Palm Tower 3 Coverage ReportDocumento61 páginasPalm Tower 3 Coverage ReportHassan DaudAún no hay calificaciones

- Enterprise, Innovation Creativity 2018-19 S3 CourseworkDocumento7 páginasEnterprise, Innovation Creativity 2018-19 S3 CourseworkSajidAún no hay calificaciones

- Online Ticket Reservation SystemDocumento100 páginasOnline Ticket Reservation SystemPiya SharmaAún no hay calificaciones

- Tata Safari 2.2L Headlamp Level Adjustment GuideDocumento3 páginasTata Safari 2.2L Headlamp Level Adjustment GuidePraveen SinghAún no hay calificaciones

- DehumidificationDocumento9 páginasDehumidificationRafael Echano AcederaAún no hay calificaciones

- F Pv28T: PR EN 2714-013A/B/C/DDocumento2 páginasF Pv28T: PR EN 2714-013A/B/C/DFredAún no hay calificaciones

- ZQYM Diesel Cummins Series Injector 2023.07Documento13 páginasZQYM Diesel Cummins Series Injector 2023.07harbh9355Aún no hay calificaciones

- Fiat 4061 PDFDocumento6 páginasFiat 4061 PDFSamir YehyaAún no hay calificaciones

- CSD Counter Drone Systems ReportDocumento23 páginasCSD Counter Drone Systems ReportmrkuroiAún no hay calificaciones

- Lecture 4-Unit 1 Lesson 4Documento23 páginasLecture 4-Unit 1 Lesson 4Jameel MalikAún no hay calificaciones

- Fuels and Chemicals - Auto Ignition TemperaturesDocumento5 páginasFuels and Chemicals - Auto Ignition TemperaturesyoesseoyAún no hay calificaciones

- ZZZXDocumento14 páginasZZZXJay R DenostaAún no hay calificaciones

- Rigging View Modular Overland ConveyorDocumento84 páginasRigging View Modular Overland Conveyorrtyuibnm100% (2)

- VW Golf Diagnostic Scan Reveals Multiple Fault CodesDocumento17 páginasVW Golf Diagnostic Scan Reveals Multiple Fault Codeskikin strongAún no hay calificaciones

- Chapter 1: Introduction: 1.1 The Construction ProjectDocumento10 páginasChapter 1: Introduction: 1.1 The Construction ProjectamidofeiriAún no hay calificaciones

- PLSQL 4 2 Practice RodrigoDocumento6 páginasPLSQL 4 2 Practice RodrigoRodrigoRojasHuerta100% (1)

- Sensor Performance Characteristics DefinitionsDocumento12 páginasSensor Performance Characteristics DefinitionsKhairul FahzanAún no hay calificaciones