Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Aircel VF

Cargado por

eliusgomezDescripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Aircel VF

Cargado por

eliusgomezCopyright:

Formatos disponibles

VF SERIES

Non-Cycling Refrigerated Compressed Air Dryer

The Aircel VF Series (10 - 1,200 scfm) offers the highest efficiencies at varying

flow conditions in a lightweight, compact design. No other dryer in the industry

can offer the efficiency ratings achieved by the VF Series dryers in variable

flow operation. VF Series dryers are built with the patented Variable Flow

heat exchanger, which allows for desired dew point performance regardless

of flow variations. Typically, other dryers with mechanical moisture separators

lose performance as compressed airflow velocity increases or decreases

substantially around the nominal design point.

The VF Series high efficiency heat exchanger utilizes a three-step process

to thoroughly remove condensed moisture from the chilled compressed air.

This process provides separation efficiency in excess of 98% throughout the

dryer’s entire flow range. Our VF non-cycling range is focused on reliable,

constant dew point performance in all flow conditions. With its excellent heat

VF-10 - VF-1200 transfer coefficients and low-pressure drop, these dryers will outperform the

competition in protecting your compressed air system, machinery and tools;

and will improve your manufacturing processes.

VF Series Features Sustainable Energy Savings

• Precooling and reheating of compressed air for high

efficiency & low energy consumption.

VF Series

Proven Performance from 0-100% Load

• Stainless steel plate heat exchanger (VF-10 to VF-60).

• Aluminum block heat exchanger with integrated high

efficiency separator (VF-75 to VF-1200).

• Environmentally friendly R-134a (VF-10 to VF-800)

VF SERIES

and R-404a (VF-1000 to VF-1200) refrigerant.

• Refrigerant suction pressure gauge.

How it Works

• Refrigerant discharge pressure gauge (VF-200 +). Hot, saturated compressed air is first stage separator/mist eliminator where

precooled by exiting cold air in the air-to- liquids and contaminants are reliably

• Inlet pressure and temperature gauge (VF-400 +). air heat exchanger. The precooled air then removed and ejected from the system via a

enters the evaporator where it is cooled programmable timer drain valve. The cold

• Advanced scroll technology (VF-500 and up). to its final dew point. The mixture of cold air is then reheated by the incoming hot air

• External moisture separator & zero-air loss drain (VF-800 +). air and condensation flows into the three- before leaving the dryer.

• Heavy-duty industrial powder coated cabinet w/ access panel. Air Inlet Air Outlet

• NEMA 1 Standard.

Separation Cell

VF Series Benefits Air -To-Refrigerant

Air-to-Air Heat Exchanger

Stainless Steel Mist Eliminator

Heat Exchanger

• Environmentally friendly R-134a & R-404a refrigerant.

• Highly efficient moisture separation.

• Zero-air loss drains standard. Refrigerant Inlet

• Precise dew point at any load.

• Reduced power and energy consumption.

VF-75 - VF-1200

• Lightweight & compact. Refrigerant Outlet

VF SERIES

TECHNICAL SPECIFICATIONS

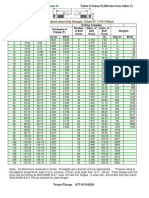

VF SERIES Model Comparison

Capacity Connection Nominal Ref HP Air-Cooled kW Full Load Voltage Dimensions (inches) Pressure max. Weight

Model Height Width Depth Refrigerant

@ CAGI1 (scfm) (inches NPT) Installed (size) (full load) Amps (Standard) (psig) (lbs)

VF-10 10 1/2 1/5 0.15 6 115-1-60 15 16 16 200 71 R-134a

VF COMPACT

VF-15 15 1/2 1/5 0.15 6 115-1-60 15 16 16 200 74 R-134a

SERIES

VF-25 25 1/2 1/5 0.15 6 115-1-60 15 16 16 200 76 R-134a

VF-40 40 3/4 1/4 0.24 7 115-1-60 15 16 16 200 78 R-134a

VF-50 50 3/4 1/4 0.60 7 115-1-60 15 16 16 200 80 R-134a

VF-60 60 3/4 1/3 0.86 11 115-1-60 15 16 16 200 102 R-134a

VF-75 75 1 1/3 0.86 11 115-1-60 22 24 18 200 124 R-134a

VF-100 100 1 1/2 1.33 16 115-1-60 22 24 18 200 138 R-134a

VF-125 125 1 3/4 1.72 21 115-1-60 22 24 18 200 156 R-134a

VF-150 150 1 3/4 1.72 21 115-1-60 22 24 18 200 162 R-134a

VF-200 200 1-1/2 1 1.98 12 230-1-60 30 36 25 200 240 R-134a

VF-250 250 1-1/2 1-1/2 3.10 5 460-3-60 30 36 25 200 332 R-134a

VF-300 300 2 1-1/2 3.58 6 460-3-60 30 36 25 200 345 R-134a

VF-400 400 2 2 4.85 9 460-3-60 45 34 45 175 567 R-134a

VF-500 500 2 3-1/2 6.53 12 460-3-60 45 34 45 175 582 R-134a

VF-600 600 3 3-1/2 6.76 13 460-3-60 45 34 45 175 598 R-134a

VF-800 800 3 5 6.61 15 460-3-60 48 38 54 175 790 R-134a

VF-1000 1000 3 5 6.84 17 460-3-60 48 38 54 175 800 R-404a

VF-1200 1200 3 6 10.98 20 460-3-60 48 38 54 175 852 R-404a

1 Capacity rated in accordance with CAGI ADF 100 @ 100 psig, 100°F inlet, 100°F ambient, and a PDP of 38°F. Ambient air temp.: 35°-120°F, inlet air temp.: 140°F max., operating pressure: 175-200 psig max.

Due to a continuous program of product improvement, specification and dimensions are subject to change without notice.

VF SERIES The Compressed Air and Gas Institute (CAGI)

has developed standards to protect users of

pressure. To adjust the dryer capacity from

these “CAGI conditions” to your specific

Capacity Correction Factors compressed air & gas equipment. ADF100 the

current standard for refrigerated compressed

application, please use the correction factors

below for differing ambient air temperatures

air dryers, specifies the dryers performance to (C1), inlet air temperatures (C2), system

To Size the Dryer Capacity for Actual Conditions be rated at 100°F inlet temperature, 100°F pressures (C3), and varying dew point

ambient temperature, and 100 psig system requirements (C4).

Adjusted Capacity = scfm x C1 x C2 x C3 x C4

To calculate the capacity of a given dryer based on non-standard operating

conditions, multiply the standard capacity by the appropriate correction

factor(s). Capacity correction factors for differing ambient air temperature (C1)

EXAMPLE: Dryer Model: VF-100 Ambient Temperature (°F) 70 80 90 100 110 115 120

Standard Capacity: 100 scfm

Actual Operating Conditions: 90°F ambient temperature: C1 = 1.05 Correction Factor 1.10 1.07 1.05 1 0.94 0.85 0.65

100°F inlet temperature: C2 = 1.0

125 psig system pressure: C3 = 1.07

38°F required dew point: C4 = 1.0 Capacity correction factors for differing inlet air temperature (C2)

Adjusted Capacity = 100 scfm x 1.05 x 1.0 x 1.07 x 1.0 = 112.4 scfm Inlet Temperature (°F) 80 90 100 110 120 140

Correction Factor 1.50 1.21 1 0.82 0.72 0.61

To Select the Dryer Model for Actual Conditions

Capacity correction factors for differing system air pressure (C3)

Adjusted Capacity = scfm/C1/C2/C3/C4

To choose a dryer based on a given flow at non-standard operating System Pressure (psig) 50 75 100 125 150 175 200 225 250

conditions, divide the given flow by the appropriate correction factor(s).

Correction Factor 0.85 0.95 1 1.07 1.13 1.18 1.20 1.22 1.24

EXAMPLE: Given Flow: 75 scfm

Actual Operating Conditions: 80°F ambient temperature: C1 = 1.07

90°F inlet temperature: C2 = 1.21 Capacity correction factors for differing pressure dew point requirements (C4)

100 psig system pressure: C3 = 1.0

Required dew point: 38°F pdp: C4 = 1.0 Dew Point (°F) 38 41 45 50

Adjusted Capacity = 75 scfm / 1.07 / 1.21 / 1.0 / 1.0 = 57.9 scfm

Selected Dryer Model: VF-60 Correction Factor 1 1.12 1.17 1.22

AIRCEL PHONE SALES INFORMATION

323 Crisp Circle (800) 767-4599 sales@airceldryers.com

Maryville, Tennessee Local: (865) 681-7066 REQUEST LITERATURE

www.AircelDryers.com 37801 Fax: (865) 681-7069 litrequest@airceldryers.com

También podría gustarte

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsDe EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsCalificación: 5 de 5 estrellas5/5 (1)

- Condensadora 13ACX 2-5 TR LENNOXDocumento36 páginasCondensadora 13ACX 2-5 TR LENNOXDiegoAún no hay calificaciones

- Carrier 40LZADocumento2 páginasCarrier 40LZAEl siAún no hay calificaciones

- FX 400-2000Documento8 páginasFX 400-2000francisco jose arruda de sousaAún no hay calificaciones

- Packaged Non Inverter - PLXPMT1725A R410A Static Blower H Series 50HzDocumento8 páginasPackaged Non Inverter - PLXPMT1725A R410A Static Blower H Series 50HzMavista TechnicAún no hay calificaciones

- USAIRTOWER AirtowerSeries 07-2019!46!37027Documento8 páginasUSAIRTOWER AirtowerSeries 07-2019!46!37027vkees1987Aún no hay calificaciones

- VHRDocumento2 páginasVHRGenevieve PaulAún no hay calificaciones

- Dunham Bush Air Cooled Screw Chiller AFVX B 6SR SeriesDocumento33 páginasDunham Bush Air Cooled Screw Chiller AFVX B 6SR SeriesAhmed Sofa100% (1)

- Static Blower: FDN-H Series FGN-H SeriesDocumento7 páginasStatic Blower: FDN-H Series FGN-H SeriesAung Thiha SoeAún no hay calificaciones

- Chicago Pneumatic QRS 20-30 HP (2013 Brochure)Documento6 páginasChicago Pneumatic QRS 20-30 HP (2013 Brochure)Philip ShaverAún no hay calificaciones

- AC Screw Fixed Speed Feb 2017Documento20 páginasAC Screw Fixed Speed Feb 2017KamalMuralikumarAún no hay calificaciones

- Product Data: Fv4C Performancet Series Fan Coil Sizes 002 Thru 006Documento18 páginasProduct Data: Fv4C Performancet Series Fan Coil Sizes 002 Thru 006John doAún no hay calificaciones

- AVX B R134a 50 60Hz Technical CatalogDocumento32 páginasAVX B R134a 50 60Hz Technical CatalogSaneesh SJAún no hay calificaciones

- Buran Refrigeration Compressed Air DryerDocumento6 páginasBuran Refrigeration Compressed Air DryerrflickAún no hay calificaciones

- AwshcDocumento9 páginasAwshcEduardo RivasAún no hay calificaciones

- Az (P) Y1 Series: Johnson Controls - Hitachi Air ConditioningDocumento9 páginasAz (P) Y1 Series: Johnson Controls - Hitachi Air ConditioningKen M PratamaAún no hay calificaciones

- JTHD 0216 PDFDocumento16 páginasJTHD 0216 PDFkunkzAún no hay calificaciones

- Danhum Bush Scre Chiller CatalogueDocumento32 páginasDanhum Bush Scre Chiller CatalogueTalha BaigAún no hay calificaciones

- EWAD-CF EEDEN15-435 Data Books EnglishDocumento42 páginasEWAD-CF EEDEN15-435 Data Books EnglishrpufitaAún no hay calificaciones

- Air Cooled Screw Chillers: VLHAFX Series 50HzDocumento28 páginasAir Cooled Screw Chillers: VLHAFX Series 50HzKamalMuralikumarAún no hay calificaciones

- DB AVX-B-R134a-50-60HzDocumento32 páginasDB AVX-B-R134a-50-60Hzrahimi mohamadAún no hay calificaciones

- Equipo Tipo VentanaDocumento4 páginasEquipo Tipo VentanaelektricistaAún no hay calificaciones

- Databook Ewwd-Vz A - Eeden16 (En)Documento31 páginasDatabook Ewwd-Vz A - Eeden16 (En)Abian100% (1)

- 30xa 21PD PDFDocumento136 páginas30xa 21PD PDFAndrés HernándezAún no hay calificaciones

- Commercial Split Systems Air Conditioning Condensing Units: Product DataDocumento52 páginasCommercial Split Systems Air Conditioning Condensing Units: Product Datahipolito padronAún no hay calificaciones

- 38au 7 25 03PDDocumento60 páginas38au 7 25 03PDhccingeniriasasAún no hay calificaciones

- Brochure Delta Room Cool A Series-V2Documento18 páginasBrochure Delta Room Cool A Series-V2Phúc TrầnAún no hay calificaciones

- ACDS-R410A-50-60Hz MS0495C 0315 CsDocumento40 páginasACDS-R410A-50-60Hz MS0495C 0315 CsMARCOSAún no hay calificaciones

- Hankison HPR HPRN UsDocumento8 páginasHankison HPR HPRN Usmelvin hoferAún no hay calificaciones

- Opa 116-201 TD 0521Documento12 páginasOpa 116-201 TD 05217tddprzxbbAún no hay calificaciones

- AVX A R134a 50 60Hz - MS04102B 0416 - Cs - Lo PDFDocumento40 páginasAVX A R134a 50 60Hz - MS04102B 0416 - Cs - Lo PDFEnrique EndoAún no hay calificaciones

- Daikin 2010Documento12 páginasDaikin 2010Marcos SilvaAún no hay calificaciones

- XC21-AC-Engineering Data-10-2010Documento36 páginasXC21-AC-Engineering Data-10-2010kman548Aún no hay calificaciones

- Xas 650 - 900 Jd8 t4f BrochureDocumento4 páginasXas 650 - 900 Jd8 t4f BrochureKarlos Miguel Lopez GomezAún no hay calificaciones

- PRS XA (T) S 440, 400 English Rock HillDocumento8 páginasPRS XA (T) S 440, 400 English Rock HillDaniel Monroy CollaoAún no hay calificaciones

- Manual Paquete 5 TonDocumento4 páginasManual Paquete 5 TonOscar MorenoAún no hay calificaciones

- Equipo Separado TWA-TWEDocumento60 páginasEquipo Separado TWA-TWENestor GonzalezAún no hay calificaciones

- Carrier FV4B SeriesDocumento20 páginasCarrier FV4B SeriesjojoafernandezAún no hay calificaciones

- Literature IND Refrig-SeriesDocumento8 páginasLiterature IND Refrig-SeriesQuân Nguyễn ĐìnhAún no hay calificaciones

- Equipo BardDocumento12 páginasEquipo BardanahijanethAún no hay calificaciones

- SHF CruisairDocumento2 páginasSHF CruisairninatenaAún no hay calificaciones

- Armstrong 4SCU14LB-OMNIGUARD SPECSHEETDocumento9 páginasArmstrong 4SCU14LB-OMNIGUARD SPECSHEETMichael MartinAún no hay calificaciones

- The Wall-Mount™ Air Conditioners - 9.0 Eer, (60Hz) : G R R-410ADocumento12 páginasThe Wall-Mount™ Air Conditioners - 9.0 Eer, (60Hz) : G R R-410AcarlosAún no hay calificaciones

- JT4BD Gibson SpecificationsDocumento20 páginasJT4BD Gibson SpecificationsRichard PhillipsAún no hay calificaciones

- LG 201404 Chiller Cat'g Centrifugal enDocumento20 páginasLG 201404 Chiller Cat'g Centrifugal enDedy Novandi100% (1)

- HPR 2013-WebDocumento4 páginasHPR 2013-WebQuân TrầnAún no hay calificaciones

- FCU HSP 3 Rows StandardDocumento58 páginasFCU HSP 3 Rows StandardEmad ArafaAún no hay calificaciones

- Publ5406 (0713)Documento28 páginasPubl5406 (0713)thức cù vănAún no hay calificaciones

- 201511ERACS.C Air-Cooled ChillerDocumento16 páginas201511ERACS.C Air-Cooled ChillerZaw Moe KhineAún no hay calificaciones

- Total Refrigeration Systems: Easy To Buy, Install and OperateDocumento8 páginasTotal Refrigeration Systems: Easy To Buy, Install and OperateMikechal AwacayAún no hay calificaciones

- Aero Indoor and Weathertight Outdoor Air Handlers: Product DataDocumento172 páginasAero Indoor and Weathertight Outdoor Air Handlers: Product DataANGEL MURILLOAún no hay calificaciones

- Irits 0818 082 Oil Flooded 90 160kw Datasheet 60hzDocumento2 páginasIrits 0818 082 Oil Flooded 90 160kw Datasheet 60hzDANIELAAún no hay calificaciones

- S3378 1217Documento12 páginasS3378 1217eliot martinezAún no hay calificaciones

- Brochure XK (EN)Documento10 páginasBrochure XK (EN)ASrpinAún no hay calificaciones

- Daikin Packaged Unit UAYQ-C Series Engineering DataDocumento58 páginasDaikin Packaged Unit UAYQ-C Series Engineering DataMichaelAún no hay calificaciones

- Technical GuideDocumento16 páginasTechnical Guidetpvd9wnwjgAún no hay calificaciones

- Ms0488a 0810 PDFDocumento40 páginasMs0488a 0810 PDFEduardo Luis SouzaAún no hay calificaciones

- The Wall-Mount™ Air Conditioners - 9.0 Eer, (60Hz) : G R R-410aDocumento16 páginasThe Wall-Mount™ Air Conditioners - 9.0 Eer, (60Hz) : G R R-410aYhonny OviedoAún no hay calificaciones

- Kendo Catalog Rev1Documento16 páginasKendo Catalog Rev1LAB DONKASAún no hay calificaciones

- Emc-1 Service Polar 115Documento65 páginasEmc-1 Service Polar 115eliusgomez100% (5)

- EMC I Operating - Polar 115Documento31 páginasEMC I Operating - Polar 115eliusgomez100% (2)

- Quick Start Guide: USB 2.0 10/100 Mbps Ethernet Adapter USB 2.0 Gigabit Ethernet Adapter USB 3.0 Gigabit Ethernet AdapterDocumento16 páginasQuick Start Guide: USB 2.0 10/100 Mbps Ethernet Adapter USB 2.0 Gigabit Ethernet Adapter USB 3.0 Gigabit Ethernet AdaptereliusgomezAún no hay calificaciones

- Bardac DrivesDocumento1 páginaBardac DriveseliusgomezAún no hay calificaciones

- Gwf-Shifting & Plow Folding - Ribbon Shifter - Prefolder (Plow Folder) - Plow ModuleDocumento6 páginasGwf-Shifting & Plow Folding - Ribbon Shifter - Prefolder (Plow Folder) - Plow ModuleeliusgomezAún no hay calificaciones

- Lecture 1 (Introduction)Documento18 páginasLecture 1 (Introduction)mAún no hay calificaciones

- Manual Rosemount 1495 Orifice Plate 1496 Orifice Flange Union en 76098 PDFDocumento74 páginasManual Rosemount 1495 Orifice Plate 1496 Orifice Flange Union en 76098 PDFKamalAún no hay calificaciones

- Locator Seal Assembly: DescriptionDocumento1 páginaLocator Seal Assembly: DescriptionLuis David Concha CastilloAún no hay calificaciones

- TP-WMS-05940-SPC-A4-D1-L-Specification For ValvesDocumento34 páginasTP-WMS-05940-SPC-A4-D1-L-Specification For Valvesbmanojkumar16Aún no hay calificaciones

- 9 Flow in Pipes - With FiguresDocumento59 páginas9 Flow in Pipes - With FiguresCarlos SerranoAún no hay calificaciones

- Class L1A1Documento6 páginasClass L1A1JORGELUISRIVASAún no hay calificaciones

- Parte 3.-Piping Design Carrier HandBookDocumento122 páginasParte 3.-Piping Design Carrier HandBookNestor Sanchez Villasmil100% (8)

- FT8 - Cold Air Buffer - P&W FT8 - Solar Turbines Technical BLOGDocumento7 páginasFT8 - Cold Air Buffer - P&W FT8 - Solar Turbines Technical BLOGLibyanManAún no hay calificaciones

- EN - Piovan - VPC VP NAS VALVE - DSC - 18 - 00Documento2 páginasEN - Piovan - VPC VP NAS VALVE - DSC - 18 - 00BEN YOUSSEF HATEMAún no hay calificaciones

- Air Vessel Sizing For Water Hammer Prevention in PipelinesDocumento4 páginasAir Vessel Sizing For Water Hammer Prevention in PipelinesHeiner PalaciosAún no hay calificaciones

- Chapter 4 Drag and LiftDocumento51 páginasChapter 4 Drag and LiftMohammad YunusAún no hay calificaciones

- Eaton Gas-Liquid Separator CatalogDocumento35 páginasEaton Gas-Liquid Separator CatalogEaton FiltrationAún no hay calificaciones

- 08-Pressure - Blowers 1Documento58 páginas08-Pressure - Blowers 1Pedro SchiaviAún no hay calificaciones

- Stanco Slaker - Brochure - Low Res ProofDocumento2 páginasStanco Slaker - Brochure - Low Res ProofGuglielmo CancelliAún no hay calificaciones

- John Dee Necronomicon TransDocumento14 páginasJohn Dee Necronomicon Transugas666999Aún no hay calificaciones

- Hydraulics Part List March2013 Rexroth LineDocumento5 páginasHydraulics Part List March2013 Rexroth LineDaniela SouzaAún no hay calificaciones

- Pipe Class 3SDNCDocumento4 páginasPipe Class 3SDNCkar78kaviAún no hay calificaciones

- hck1 7Documento8 páginashck1 7Roger Alexander Vilchez CastroAún no hay calificaciones

- HGS-HSM-SL-18-007 - (Rev2) Engine Back Pressure For SOx Scrubber InstallationDocumento2 páginasHGS-HSM-SL-18-007 - (Rev2) Engine Back Pressure For SOx Scrubber Installationajshsu5682Aún no hay calificaciones

- QHS-2000 Beverage Machine InstructionDocumento13 páginasQHS-2000 Beverage Machine InstructionCoteneanuIonutAún no hay calificaciones

- Turbo - Module 3.2 - Centrifugal Pump - Workdone, Head, Losses and EfficienciesDocumento27 páginasTurbo - Module 3.2 - Centrifugal Pump - Workdone, Head, Losses and EfficienciesEpicNewtonAún no hay calificaciones

- Etna - Fire Pump Systems in Accordance With EN 12845 Standard Technical LeafletDocumento28 páginasEtna - Fire Pump Systems in Accordance With EN 12845 Standard Technical LeafletRedha Sabr100% (1)

- Fluid Mechanics I Lab - MENG 370L: Experiment 3: Venturi MeterDocumento20 páginasFluid Mechanics I Lab - MENG 370L: Experiment 3: Venturi MeterMahdi GharibAún no hay calificaciones

- Exp - No - 4Documento4 páginasExp - No - 4Joshua Joseph LlamasAún no hay calificaciones

- Solving Hydraulic System Overheating ProblemsDocumento9 páginasSolving Hydraulic System Overheating Problemsmahadev100% (1)

- Revision Question Bank ME 2204Documento11 páginasRevision Question Bank ME 2204Rajendra Kumar YadavAún no hay calificaciones

- NACA Conical Boatail Pressure AffectsDocumento15 páginasNACA Conical Boatail Pressure AffectsCliff ThriveAún no hay calificaciones

- Twin-Scroll TurbochargerDocumento24 páginasTwin-Scroll TurbochargerJih Yan LaiAún no hay calificaciones

- 03 - Tabla Bridas AwwaDocumento1 página03 - Tabla Bridas AwwaLuis CarlosAún no hay calificaciones