Documentos de Académico

Documentos de Profesional

Documentos de Cultura

NBR Glove Latex CYATEX NK-220 High Tensile Soft Touch

Cargado por

Darren TanTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

NBR Glove Latex CYATEX NK-220 High Tensile Soft Touch

Cargado por

Darren TanCopyright:

Formatos disponibles

NEW!

1/4

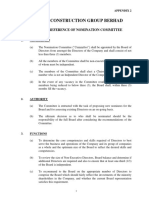

CYATEX NK-220

Nippon A&L Inc.

Nakajima Bldg., 8-8, Nihonbashi-Kabutocho, Chuo-ku, Tokyo, Japan

Tel: 81-3-5623-5701

Fax: 81-3-5623-5711

CYATEX NK-220

High Tensile and soft to the touch!

NBR Latex for Gloves

“CYATEX” means Nippon A&L’s Synthetic Rubber Latexes.

NEW!

2/4

CYATEX NK-220

CYATEX NK-220

CYATEX NK-220 is carboxylated Butadiene-Acrylonitrile copolymer latex, i.e. NBR latex, for

gloves.

CYATEX NK-220 is designed for the manufacture of gloves, prepared by coagulant dipping.

CYATEX NK-220 is specially designed to show high tensile and soft to the touch.

CYATEX NK-220 also has many advantages including;

1. High flexibility/ softness

2. No protein and No silicone

3. Good resistance against oil or chemicals

4. Lower odor

5. Anti electrostatic property

6. Less bubbling

Typical properties

Total solids/ % 44-46

pH 8.0-9.5

Viscosity/ mPa・s 300 maximum

Particle size/ nm 100-150

Specific gravity approx. 1.0

Tg/ ℃ -28

Bond acrylonitrile content/ % 26

Free acrylonitrile content/ % n.d.

Emulsifier system anionic

Storage and handling

CYATEX NK-220 must be stored in closed containers between +5℃ and +40℃. Long time

storage below 0℃ causes freezing and above +60℃ causes thermal coagulation. Please refer

to the Material Safety Data Sheet for safety and environmental information.

“CYATEX” means Nippon A&L’s Synthetic Rubber Latexes.

NEW!

3/4

CYATEX NK-220

Method of Producing NBR gloves

1. Preparation

1) Latex Compound

Table 1. Recommended Recipe

Ingredients Dry Wet

1. 45% NK-220 100 222.2

2. 2% Potassium hydroxide 0.7 35.0

3. 50% Sulfur dispersion 0.6 1.2

4. 50% Zinc oxide dispersion 1.7 3.4

5. 50% ZnBDC(BZ) dispersion1) 0.2 0.4

6. 50% ZnEDC(EZ) dispersion2) 0.6 1.2

7. 50% Titanium dioxide dispersion 1.5 3.0

8. Water - 62.7

Total (32%) 105.3 329.1

1) Zinc di-n-butyldithiocarbamate

2) Zinc di-ethyldithiocarbamate

Compound procedure

1) At first, put latex into maturation (or compounding) tank.

2) Secondly, put 2% KOH solution into latex under agitation.

3) Thirdly, put sulfur dispersion into latex under agitation.

4) Finally, put the composite of zinc oxide, accelerator (BZ and EZ) and titanium dioxide

dispersion into latex under agitation.

(Targets of pH and TSC are 9.0-9.5 and 30-32%, respectively.)

2) Coagulant

Table 2. Recommended Recipe

Ingredients Dry Wet

1. Water 72.2

2. Ca(NO3)2・4H2O 12.0 17.3

3. 20% Wetting agent3) 0.1 0.5

4. 40% Calcium carbonate slurry 4.0 10.0

Total 16.1 100.0

3) Em-810 (Polyoxyethylene octylphenylether) [Kao Co. Ltd]

“CYATEX” means Nippon A&L’s Synthetic Rubber Latexes.

NEW!

4/4

CYATEX NK-220

2. Dipping process

Typical dipping procedure is as follows.

① Preheating of mold 80℃×120sec

② Dipping into the coagulant 10sec

(coagulant: 60℃)

③ Drying 80℃×120sec

④ Dipping into the latex compound 27sec

(latex compound: 30℃) (dwell time 7sec)

⑤ Drying (gelling oven) 80℃×120sec

⑥ Beading

⑦ Leaching at 40-50℃(hot water) 60sec×3times

⑧ Drying 80℃×3min

⑨ Curing 110-130℃×20min

⑩ Stripping

3. Physical properties

Table 3. Physical properties of gloves made from NK-220

NK-220 NK-218F NK-219

Thickness/ mm 0.10-0.12 0.10-0.12 0.10-0.12

Modulus at 300%/ MPa 2.8 2.9 3.5

Modulus at 500%/ MPa 6.8 7.0 10.5

Tensile strength/ MPa 28.8 24.5 28.5

Elongation at break/ % 760 750 680

*Film condition : 50% RH, 23℃ before test

“CYATEX” means Nippon A&L’s Synthetic Rubber Latexes.

También podría gustarte

- Five Ways That ESG Creates Value PDFDocumento12 páginasFive Ways That ESG Creates Value PDFAtifKhanAún no hay calificaciones

- Room Temperature Synthesis of Copper Oxide Nanoparticles Morphological Evaluation and Their Catalytic Applications For Degradation of Dyes and C-N Bond Formation Reaction PDFDocumento11 páginasRoom Temperature Synthesis of Copper Oxide Nanoparticles Morphological Evaluation and Their Catalytic Applications For Degradation of Dyes and C-N Bond Formation Reaction PDFAshpavi ArunAún no hay calificaciones

- Environmental, Social and Governance: How Companies Could Respond To ESG DevelopmentDocumento2 páginasEnvironmental, Social and Governance: How Companies Could Respond To ESG DevelopmentDarren TanAún no hay calificaciones

- Optimization of Operational Condition of A Condensate Stabilization Plant and Investigation of Effective Parameters On Reid Vapor Pressure (RVP)Documento2 páginasOptimization of Operational Condition of A Condensate Stabilization Plant and Investigation of Effective Parameters On Reid Vapor Pressure (RVP)okoro matthewAún no hay calificaciones

- Thermodynamics 4Documento38 páginasThermodynamics 413670319Aún no hay calificaciones

- AICHE2004Documento19 páginasAICHE2004Antonio GuarascioAún no hay calificaciones

- Treat LPGs With AminesDocumento12 páginasTreat LPGs With Amineskaaskopdawie5755Aún no hay calificaciones

- Brine SelectionDocumento1 páginaBrine SelectionKarthikeyan SankarrajanAún no hay calificaciones

- A New Cubic Equation of State by Mert Atilhan 2004Documento136 páginasA New Cubic Equation of State by Mert Atilhan 2004Anonymous Vbv8SHv0bAún no hay calificaciones

- Resolving Process Distillation Equipment OpportunitiesDocumento13 páginasResolving Process Distillation Equipment Opportunitiesrvkumar61Aún no hay calificaciones

- Mont Belvieu, Texas Ethane Storage Hub: Warnings For AppalachiaDocumento7 páginasMont Belvieu, Texas Ethane Storage Hub: Warnings For AppalachiaJames BruggersAún no hay calificaciones

- Seven Steps To Enterprise Risk ManagementDocumento10 páginasSeven Steps To Enterprise Risk ManagementPranabDash2013Aún no hay calificaciones

- Air Separation Plants History and Technological Progress 2019 Tcm19 457349Documento28 páginasAir Separation Plants History and Technological Progress 2019 Tcm19 457349Jambanlaya JasdAún no hay calificaciones

- 05 Chem Bond - Modul - ChemistryDocumento11 páginas05 Chem Bond - Modul - Chemistryrudi_z100% (1)

- Plugin Risk Management Plan SampleDocumento12 páginasPlugin Risk Management Plan SampleMohammad Kanani ZadehAún no hay calificaciones

- POWER Magazine - May 2023-1Documento43 páginasPOWER Magazine - May 2023-1MarcialgonzalezpAún no hay calificaciones

- Feasibility Study of Hydrogen Chloride ProductionDocumento4 páginasFeasibility Study of Hydrogen Chloride ProductionIntratec SolutionsAún no hay calificaciones

- Platforming of Naphtha: A Process Design ReportDocumento150 páginasPlatforming of Naphtha: A Process Design ReportNoman Aslam100% (1)

- FINAL Presentation For ARA ConferenceDocumento26 páginasFINAL Presentation For ARA Conferencesaleh4060Aún no hay calificaciones

- PHD Duncan Paterson PDFDocumento246 páginasPHD Duncan Paterson PDFManuel ChAún no hay calificaciones

- Management of Risk Guidance For Practitioners and The International Standard On Risk Management ISO31000 2009Documento15 páginasManagement of Risk Guidance For Practitioners and The International Standard On Risk Management ISO31000 2009Jameel Ur Rasheed AnsariAún no hay calificaciones

- Thermodynamic Modelling of Asphaltene Precipitation and Related Phenomena 2015 Advances in Colloid and Interface ScienceDocumento12 páginasThermodynamic Modelling of Asphaltene Precipitation and Related Phenomena 2015 Advances in Colloid and Interface ScienceEzequiel AbrilAún no hay calificaciones

- ESG - Ey-Cbm-Unlocking-Esg-Strategic-ValueDocumento9 páginasESG - Ey-Cbm-Unlocking-Esg-Strategic-ValueDarren TanAún no hay calificaciones

- International Thermodynamic Tables of the Fluid State: Propylene (Propene)De EverandInternational Thermodynamic Tables of the Fluid State: Propylene (Propene)Aún no hay calificaciones

- R-501 Diagnostics of Ammonia Converter uneven catalyst bed temperaturesDocumento35 páginasR-501 Diagnostics of Ammonia Converter uneven catalyst bed temperaturesTalal AshrafAún no hay calificaciones

- Hydrometallurgical Process: Analysis of Free, Total & WAD Cyanide in Gold Leach Slurry & WastewaterDocumento1 páginaHydrometallurgical Process: Analysis of Free, Total & WAD Cyanide in Gold Leach Slurry & WastewaterJUNIORAún no hay calificaciones

- Case Story DK - Green Methanol - Web 1Documento4 páginasCase Story DK - Green Methanol - Web 1Pao M. MorenoAún no hay calificaciones

- AERI's Sustainable Energy Strategy for AlbertaDocumento6 páginasAERI's Sustainable Energy Strategy for AlbertaHendry DrajatAún no hay calificaciones

- PET flakes recycled into UV-curable resinsDocumento10 páginasPET flakes recycled into UV-curable resinsR_M_M_Aún no hay calificaciones

- Pyrolysis PlantDocumento8 páginasPyrolysis PlantSherry HenryAún no hay calificaciones

- KGIMTPDocumento12 páginasKGIMTPZarra FaktAún no hay calificaciones

- A Design Adn Rating Method For Shell and Tube Heat ExchangerDocumento8 páginasA Design Adn Rating Method For Shell and Tube Heat Exchangerhuynhthanhtamga1981100% (1)

- Troubleshooting Liquid Carryover in Gas Compression Systems MySep White PaperDocumento11 páginasTroubleshooting Liquid Carryover in Gas Compression Systems MySep White Paperthlim19078656Aún no hay calificaciones

- PostCompres 1Documento1 páginaPostCompres 1CaliforniaWatchAún no hay calificaciones

- Transat Particles in PipesDocumento17 páginasTransat Particles in Pipesمحمد توفيق عراقيAún no hay calificaciones

- Electrolyser-Operating Manual PDFDocumento6 páginasElectrolyser-Operating Manual PDFcderin20000% (1)

- Adsorption Equilibrium of Methane, Carbon Dioxide, and Nitrogen On Zeolite 13X at High PressuresDocumento7 páginasAdsorption Equilibrium of Methane, Carbon Dioxide, and Nitrogen On Zeolite 13X at High Pressuresswlim9999Aún no hay calificaciones

- Glutaraldehyde Bulk HandlingDocumento4 páginasGlutaraldehyde Bulk HandlingnubblerAún no hay calificaciones

- Design of Heat Exchanger Using Falcon Optimisation Algorithm PDFDocumento63 páginasDesign of Heat Exchanger Using Falcon Optimisation Algorithm PDFAnchuri LokeshAún no hay calificaciones

- 104SE-Combining New and Old Technologies - Inlet Diffuser and Random Packing Dramatically Improve Reactor PerformanceDocumento10 páginas104SE-Combining New and Old Technologies - Inlet Diffuser and Random Packing Dramatically Improve Reactor PerformanceSHIAún no hay calificaciones

- Ergun Equation SphericityDocumento10 páginasErgun Equation SphericitySaurabh KumarAún no hay calificaciones

- Design Concentratiion-Class B FuelsDocumento14 páginasDesign Concentratiion-Class B Fuelsmiguel angel garciaAún no hay calificaciones

- FreetDocumento32 páginasFreetHamed GeramiAún no hay calificaciones

- SEPURAN® Noble - Membrane Technology For Efficient Hydrogen Generation PDFDocumento6 páginasSEPURAN® Noble - Membrane Technology For Efficient Hydrogen Generation PDFHabli MawardiAún no hay calificaciones

- Xylenes and EthylbenzeneDocumento13 páginasXylenes and EthylbenzeneAbhishek SinghAún no hay calificaciones

- HSFCCDocumento22 páginasHSFCCdonald55555100% (1)

- Final Guideline Document - Control of Sulfuric Acid Production Units, EPA-450 2-77-019 PDFDocumento188 páginasFinal Guideline Document - Control of Sulfuric Acid Production Units, EPA-450 2-77-019 PDFChristopher BrownAún no hay calificaciones

- Guide to the Physical and Chemical Properties of MethanolDocumento24 páginasGuide to the Physical and Chemical Properties of MethanolKellyCristinaAún no hay calificaciones

- Steam Methane Reforming Reaction Process Intensification by Using A ReactorDocumento14 páginasSteam Methane Reforming Reaction Process Intensification by Using A ReactorserchAún no hay calificaciones

- Understanding O&G-MDSO 801 (2nd Vol)Documento156 páginasUnderstanding O&G-MDSO 801 (2nd Vol)Anonymous IwqK1Nl100% (1)

- Nitic Acid Phase EquilibriaDocumento12 páginasNitic Acid Phase Equilibriaingbarragan87Aún no hay calificaciones

- Comparison of Approaches To Determine Hydrogen Consumption During Catalytic Hydrotreating of Oil Fractions PDFDocumento9 páginasComparison of Approaches To Determine Hydrogen Consumption During Catalytic Hydrotreating of Oil Fractions PDFrohl55Aún no hay calificaciones

- 1-A Comparison of Steady-State Eq and Rate-Based ModelsDocumento10 páginas1-A Comparison of Steady-State Eq and Rate-Based ModelsVinh Vật VãAún no hay calificaciones

- Catalagram: A Refining Technologies PublicationDocumento44 páginasCatalagram: A Refining Technologies PublicationMón Quà Vô GiáAún no hay calificaciones

- HTHA Autoclave TestingDocumento13 páginasHTHA Autoclave TestingTim MunstermanAún no hay calificaciones

- Nicholas Oligomerization PDFDocumento16 páginasNicholas Oligomerization PDFTanase DianaAún no hay calificaciones

- Removal of Benzene From GasolineDocumento24 páginasRemoval of Benzene From GasolineNicholas Cecil Munsami100% (1)

- Renewable Energy Resources: Introduction & Economic Analysis of A Gasification PlantDocumento36 páginasRenewable Energy Resources: Introduction & Economic Analysis of A Gasification PlantfaizanAún no hay calificaciones

- Catalytic Reforming Reactions in NaphthasDocumento16 páginasCatalytic Reforming Reactions in NaphthasjaquelinegondimAún no hay calificaciones

- Midw Technology As A Drop-In Catalyst SolutionDocumento11 páginasMidw Technology As A Drop-In Catalyst Solutiondie_1Aún no hay calificaciones

- AspenHYSYSRefiningV7 3 OpsDocumento478 páginasAspenHYSYSRefiningV7 3 OpsAnonymous w46Y2Qf84Aún no hay calificaciones

- VolsampDocumento153 páginasVolsampSonny HutomoAún no hay calificaciones

- Hydrocarbon Characterization for the Hydrocarbon Risk CalculatorDocumento72 páginasHydrocarbon Characterization for the Hydrocarbon Risk CalculatorSteve MahoneyAún no hay calificaciones

- State-Of-The-Art Nitrogen Rejection TechnologyDocumento16 páginasState-Of-The-Art Nitrogen Rejection Technologynabeel khanAún no hay calificaciones

- Oxidation of Organic Compounds: Medium Effects in Radical ReactionsDe EverandOxidation of Organic Compounds: Medium Effects in Radical ReactionsCalificación: 4 de 5 estrellas4/5 (1)

- International Thermodynamic Tables of the Fluid State, Argon, 1971: Division of Physical Chemistry, Commission on Thermodynamics and Thermochemistry, Thermodynamic Tables ProjectDe EverandInternational Thermodynamic Tables of the Fluid State, Argon, 1971: Division of Physical Chemistry, Commission on Thermodynamics and Thermochemistry, Thermodynamic Tables ProjectAún no hay calificaciones

- Preparation of Catalysts II: Scientific Bases for the Preparation of Heterogeneous CatalystsDe EverandPreparation of Catalysts II: Scientific Bases for the Preparation of Heterogeneous CatalystsAún no hay calificaciones

- Activity Risk Management PolicyDocumento6 páginasActivity Risk Management PolicyDarren TanAún no hay calificaciones

- The Professionalization of Risk Management: What Role Can The ISO 31000 Risk Management Principles Play?Documento32 páginasThe Professionalization of Risk Management: What Role Can The ISO 31000 Risk Management Principles Play?Darren TanAún no hay calificaciones

- The Flaws of The ISO 31000 Conceptualisation of RiskDocumento2 páginasThe Flaws of The ISO 31000 Conceptualisation of RiskDarren TanAún no hay calificaciones

- 3.4 Supporting Doc Risk Register Template With InstructionsDocumento8 páginas3.4 Supporting Doc Risk Register Template With InstructionsDarren TanAún no hay calificaciones

- Sunway Construction Group Berhad: Terms of Reference of Nomination and Remuneration CommitteeDocumento4 páginasSunway Construction Group Berhad: Terms of Reference of Nomination and Remuneration CommitteeDarren TanAún no hay calificaciones

- Bej2020 1 5Documento12 páginasBej2020 1 5Darren TanAún no hay calificaciones

- 3.4 Supporting Doc Risk Register Template With InstructionsDocumento8 páginas3.4 Supporting Doc Risk Register Template With InstructionsDarren TanAún no hay calificaciones

- GCU Research and Project Risk Register Template (GOOD1)Documento3 páginasGCU Research and Project Risk Register Template (GOOD1)Darren TanAún no hay calificaciones

- Risk EnterprisesDocumento23 páginasRisk EnterprisesBushra UsmanAún no hay calificaciones

- Aleksandar Aleksić, Branislav Jeremić, Miladin Stefanović, Marko Đapan Abstract: One of The Keys of Successful Business Last FewDocumento6 páginasAleksandar Aleksić, Branislav Jeremić, Miladin Stefanović, Marko Đapan Abstract: One of The Keys of Successful Business Last FewDarren TanAún no hay calificaciones

- Terms of Reference-Nomination Committee (Revised 20 Nov 2017)Documento2 páginasTerms of Reference-Nomination Committee (Revised 20 Nov 2017)Darren TanAún no hay calificaciones

- ISO 31000:2009-The New International Standard On Risk ManagementDocumento6 páginasISO 31000:2009-The New International Standard On Risk ManagementDarren TanAún no hay calificaciones

- Applying I So 3100 in Regulatory WorkDocumento19 páginasApplying I So 3100 in Regulatory WorkEfari BahchevanAún no hay calificaciones

- Enterprise Risk Management: A Case Study of A Moroccan Financial InstitutionDocumento18 páginasEnterprise Risk Management: A Case Study of A Moroccan Financial InstitutionmounirusAún no hay calificaciones

- Real-World Examples of Risk AssessmentDocumento17 páginasReal-World Examples of Risk AssessmentDarren TanAún no hay calificaciones

- 04RM - Risk-Assessment 2Documento32 páginas04RM - Risk-Assessment 2Darren TanAún no hay calificaciones

- 05RM Risk-TreatmentDocumento10 páginas05RM Risk-TreatmentDarren TanAún no hay calificaciones

- Aleksandar Aleksić, Branislav Jeremić, Miladin Stefanović, Marko Đapan Abstract: One of The Keys of Successful Business Last FewDocumento6 páginasAleksandar Aleksić, Branislav Jeremić, Miladin Stefanović, Marko Đapan Abstract: One of The Keys of Successful Business Last FewDarren TanAún no hay calificaciones

- Sciencedirect: Enterprise Risk Management Practices Among Malaysian FirmsDocumento6 páginasSciencedirect: Enterprise Risk Management Practices Among Malaysian FirmsDarren TanAún no hay calificaciones

- Implementing A Risk Management Standard: Constantin PREDADocumento10 páginasImplementing A Risk Management Standard: Constantin PREDASonido MagisterioAún no hay calificaciones

- The Risk Assessment Process ExplainedDocumento58 páginasThe Risk Assessment Process ExplainedDarren TanAún no hay calificaciones

- Ldna 25227 EnniiDocumento105 páginasLdna 25227 EnniiDarren TanAún no hay calificaciones

- Sustainable Manufacturing Innovation for the FutureDocumento6 páginasSustainable Manufacturing Innovation for the FutureDarren TanAún no hay calificaciones

- Ijaim 12 2014 0079Documento21 páginasIjaim 12 2014 0079Darren TanAún no hay calificaciones

- Astm A184 - A184m-01 STD Specs For Welded Deformed Steel BarDocumento4 páginasAstm A184 - A184m-01 STD Specs For Welded Deformed Steel BarCharwin PicaoAún no hay calificaciones

- Water Pitcher Filter EN: MODELS: Time, Agate, Amethyst, Orion, Jasper, Compact, Onyx Operating ManualDocumento2 páginasWater Pitcher Filter EN: MODELS: Time, Agate, Amethyst, Orion, Jasper, Compact, Onyx Operating ManualMstefAún no hay calificaciones

- Assignment No 1Documento3 páginasAssignment No 1Sumit NagpalAún no hay calificaciones

- Text Book: "Advanced Mechanics of Materials"Documento22 páginasText Book: "Advanced Mechanics of Materials"developmental biologyAún no hay calificaciones

- Conservation of An Amphora of The Spatheion TypeDocumento2 páginasConservation of An Amphora of The Spatheion TypeJaime Mujica SallesAún no hay calificaciones

- Eq Tip No. Short Column Effect: Prepared by ContactDocumento24 páginasEq Tip No. Short Column Effect: Prepared by ContactNasshikin RamliAún no hay calificaciones

- Literature Review of Glass FiberDocumento7 páginasLiterature Review of Glass Fiberaflsjizaf100% (1)

- Mekonen PDFDocumento5 páginasMekonen PDFAkatew Haile MebrahtuAún no hay calificaciones

- Chromatography Lab ReportDocumento6 páginasChromatography Lab ReportMohamad MerhabiAún no hay calificaciones

- Enhanced Oil Recovery (EOR) - Schlumberger GlossaryDocumento66 páginasEnhanced Oil Recovery (EOR) - Schlumberger GlossaryDiana La CruzAún no hay calificaciones

- Internship SeminarDocumento28 páginasInternship Seminarkavya kruthiAún no hay calificaciones

- Smith Fibercast Silver Streak Fiberglass Pipe Piping General SpecificationsDocumento2 páginasSmith Fibercast Silver Streak Fiberglass Pipe Piping General SpecificationsMichael J. BaneAún no hay calificaciones

- MSDS Intersorb Nonindicating Diving GradeDocumento5 páginasMSDS Intersorb Nonindicating Diving GradeEdward BennettAún no hay calificaciones

- Sample 1 Hardener and Epoxy Material Test ReportDocumento4 páginasSample 1 Hardener and Epoxy Material Test ReportWei Jiang NgAún no hay calificaciones

- PDQXDO GH LDYDYDMLOODV LQVWUXFFLRQHVDocumento34 páginasPDQXDO GH LDYDYDMLOODV LQVWUXFFLRQHVjarroyojAún no hay calificaciones

- Eee Module 1Documento75 páginasEee Module 1Anitha BRAún no hay calificaciones

- Bulk Foam Stability and Rheological Behavior of Aqueous Foams Prepared by Clay Particles and Alpha Olefin Sulfonate2019journal of Molecular LiquidsDocumento10 páginasBulk Foam Stability and Rheological Behavior of Aqueous Foams Prepared by Clay Particles and Alpha Olefin Sulfonate2019journal of Molecular LiquidsDavid LópezAún no hay calificaciones

- Whiting (CalciumCarbonate) MSDSDocumento6 páginasWhiting (CalciumCarbonate) MSDSrinda_indaAún no hay calificaciones

- Synthesis and Charn of in Situ Cross-Linked Hydrogel Based On Self-Assembly of Thiol-Modified Chitosan With PEG DiacrylateDocumento8 páginasSynthesis and Charn of in Situ Cross-Linked Hydrogel Based On Self-Assembly of Thiol-Modified Chitosan With PEG Diacrylatealchemik1515Aún no hay calificaciones

- Duplex & Super Duplex Intermetallic PhasesDocumento3 páginasDuplex & Super Duplex Intermetallic Phasesemperor_vamsiAún no hay calificaciones

- Filters ENDocumento11 páginasFilters ENChris GavevaAún no hay calificaciones

- Ceilcote 180 Flakeline+ds+engDocumento4 páginasCeilcote 180 Flakeline+ds+englivefreakAún no hay calificaciones

- Experimental Characterization of Al-Cu Thermal Contact ResistanceDocumento20 páginasExperimental Characterization of Al-Cu Thermal Contact Resistancenozue.tatsuhiro nozueAún no hay calificaciones

- Annex II - AMC 20-29Documento36 páginasAnnex II - AMC 20-29Victor Manuel Peña EsparteroAún no hay calificaciones

- Fsci Assignment ADocumento29 páginasFsci Assignment ARaj PrateekAún no hay calificaciones

- Single Replacement Reactions LabDocumento2 páginasSingle Replacement Reactions Labapi-239477691Aún no hay calificaciones

- 2.rock Mechanics Report PDFDocumento139 páginas2.rock Mechanics Report PDFVaradha rajanAún no hay calificaciones