Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Cement All en

Cargado por

heraasku7194Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Cement All en

Cargado por

heraasku7194Copyright:

Formatos disponibles

CTS Cement | Advanced Cement Technology

CEMENT Rapid Set ® CEMENT ALL ® Datasheet

®

CEMENT ALL

Multipurpose Repair Mortar

high-strength, multipurpose, unique

PRODUCT NAME COLOR [light-grey]

Highlights:

Rapid Set® CEMENT ALL® The final color and surface appearance of

• Fast-Setting Multipurpose Repair Mortar CEMENT ALL may vary due to application

workable for 15 minutes techniques and environmental conditions.

ready for stress in 1 hour PRODUCT DESCRIPTION

curing only with water

CEMENT ALL is a high quality, easy to INSTALLATION THICKNESS

• High-Strength process, mineral multipurpose repair mortar Qualified for installation thickness from

in 1 hour already 20,0 N/mm² that is ideal where rapid strength, durability featheredge to 100 mm. For higher

and low shrinkage are desired. CEMENT installation thickness the use of Rapid Set®

• Non-Shrink ALL can be applied in thickness from CONCRETE MIX or Rapid Set® MORTAR

crack resistant featheredge to 100 mm. Initital set after MIX is recommended. For application as

15 minutes, ready for stress in 1 hour. wearing layer, the placing of test areas is

• Durable recommended.

under extreme conditions

frost/deicer resistant

FIELDS OF APPLICATION

CEMENT ALL is a multipurpose product PROCESSING

• Sulfate Resistant qualified for general concrete repair, PREPARATION OF SUB-BASE

resist against many chemical doweling and anchoring, injection, industrial Clean sub-base from loose debris, cement

attacks grouting, formed work and highway repair. slurry, dust, acids, oils and greases.

Indoors and outdoors, also in wet areas. For permabond compound the surface must

• Excellent Bond be free of cracks, even, rough and

directly - without bonding COMPOSITION openpore. The bond strength values

compound

CEMENT ALL is a high-performance required in the technical guidelines have to

• Multipurpose blend of Rapid Set® Cement and special be observed (the value must not be less

for repairs and new construction mineral aggregates. CEMENT ALL is than 1.0 N/mm²). Before the application,

horizontally and vertically non-metallic, without chlorides. CEMENT pre-wet the sub-base thoroughly. In case of

ALL is similar in appearance to Portland highly absorbent sub-bases, this process

• Installation Thickness cement repair materials and may be applied may have to be repeated several times.*

"0" - 100 mm using similar methods. The formation of a water film or puddles has

indoors and outdoors to be avoided.

• Improved Shelf-Life *If necessary, a primer on acrylic basis can be integrated.

KORODUR – Exclusive License Producer for Europe

®

CEMENT ALL

Multipurpose Repair Mortar

high-strength, multipurpose, unique

PROCESSING

TECHNICAL DATA at +20°C

CEMENT ALL may be processed using traditional methods.

The final finish should be applied as soon as possible.

Color light-grey CEMENT ALL may be troweled, floated or textured.

Apply in one complete layer, i.e. not in several layers, and as

Grain size 0 - 1 mm uniformly as possible. Do not apply on frozen sub-base.

When compacting, avoid the entry of air voids. To extend

Consumption 2,0 kg/m²/mm working time use Rapid Set® SET CONTROL® set retarding

admixture or adequate.

Layer thickness "0" - 100 mm

- recommended for ceiling/overhead 10 - 15 mm*

- recommended for wall 20 - 25 mm* CURING

*in the first working step depending on the Begin water curing as soon as the surface has lost ist moist

chosen consistency

sheen. Keep exposed surfaces wet for a minimum of 1 hour

Setting time until the product has achieved sufficient strength. When

initial set: 15 min. experiencing extended setting times, due to cold temperature

Referring to DIN EN 196-3

final set: 35 min.

Test report No. 0-54/0696-A1/12 or the use of a retarder, longer cure times may be required.

Ready for traffic after 60 min. PROCESSING TEMPERATURE

Do not apply CEMENT ALL at sub-base or environmental

Compressive strength after 60 min. > 20,0 N/mm² temperature below +5°C. Temperatures > +20°C will reduce

DIN EN 1015-11 after 180 min. > 31,0 N/mm²

Test report No. 0-54/0696-A1/12 the working time. Temperatures < +20°C may decrease the

after 7 days > 41,0 N/mm²

after 28 days > 62,0 N/mm² rate of strength gain.

Flexural strength after 60 min. > 6,0 N/mm² STORAGE

DIN EN 1015-11 after 24 hours > 8,0 N/mm² Dry, like cement.

Test report no. 0-54/0696-A1/12 after 7 days > 10,0 N/mm² Shelf-life approx. 12 months.

after 28 days > 11,0 N/mm²

HINTS

Tensile strength These products contain cement and have an alkaline reaction

in middle 2,1 N/mm²

DIN EN 1542

Test report no. 0-54/1171-A/12

demands fulfilled with moisture/water. Therefore protect hands and eyes. In

case of contact with eyes consult a doctor.

Static modulus of elasticity Our recommendations for application technique are based on

approx. 31.700 N/mm²

DIN EN 13412 our experiences. It is recommended to adapt processing and

demands fulfilled

Test report no. 05-54/0696-A2/12 material quantities to the given local conditions and we refer

Sulfate resistance in this context to our general terms of sale and delivery.

Test acc. Wittekindt demands fulfilled

Test report no. 05-54/0696-A2/12 License Producer for Europe:

KORODUR Westphal Hartbeton GmbH & Co. KG

Penetration test, penetration of penetration depth Works Bochum-Wattenscheid

water-endangering substances in middle 16,0 mm Hohensteinstr. 19

DAfStb-guideline demands fulfilled

44866 Bochum, Germany

Frost/deicer test (CDF) Phone: +49 (0) 23 27 / 94 57 - 0

BWA-guideline frost test demands fulfilled Certification: DIN EN ISO 9001:2008

Test report no. 0-54/0696-A3/12

Sales:

Chloride ion content

DIN EN 1015-17

in middle 0,009 KORODUR International GmbH

demands fulfilled Wernher-von-Braun-Str. 4

Test report no. 0-54/1171-C/12

92224 Amberg, Germany

MIXING Phone: +49 (0) 96 21 / 47 59 - 0

The use of pan type mixer or qualified stirrer is recommended. Fax: +49 (0) 96 21 / 3 23 41

Organize work so that all personnel and equipment / tools are in info@korodur.de

place before mixing. Use clean water for mixing. www.korodur.de

CEMENT ALL is mixed with 3,0 l to 4,75 l water per 25 kg bag.

Use less water to achieve higher strength values. Do not exceed Per June 2015

the maximum water admixture of 4,75 l per 25 bag. For increased

fluidity and workability use Rapid Set® FLOW CONTROL®

plasticizing admixture or adequate. Place water into the mixing

container and add CEMENT ALL while the mixer / stirrer is

running. To achieve a uniform consistency mix for 1 to 3 minutes.

DO NOT re-temper mixed material. © 2012 CTS Cement Manufacturing Corporation. Rapid

0615/419

Set, Cement All, Set Control, Flow Control and the Rapid

Set logo are trademarks of CTS. All rights reserved.

KORODUR – Exclusive License Producer for Europe

También podría gustarte

- SikaCeram-105 Multi PDFDocumento3 páginasSikaCeram-105 Multi PDFAb YassinAún no hay calificaciones

- Euroflor Ex 01Documento3 páginasEuroflor Ex 01Noussa NesAún no hay calificaciones

- Deco Mur 731Documento2 páginasDeco Mur 731Nazim SafsafAún no hay calificaciones

- Sika Ceram 100Documento2 páginasSika Ceram 100Souhaïl GhorbelAún no hay calificaciones

- Eurofloor Expo ProDocumento3 páginasEurofloor Expo ProNoussa NesAún no hay calificaciones

- NT Grave EmulsionDocumento4 páginasNT Grave EmulsionMihail SavkaAún no hay calificaciones

- Cemtop 400SDDocumento4 páginasCemtop 400SDMounir BoutaghaneAún no hay calificaciones

- Top FloorDocumento2 páginasTop FloorMarwa WalhaAún no hay calificaciones

- Sikaceram 106 ExtraDocumento3 páginasSikaceram 106 ExtraMon BoualAún no hay calificaciones

- FT 721Documento2 páginasFT 721Nazim SafsafAún no hay calificaciones

- BASF UCRETE MF Tds PDFDocumento4 páginasBASF UCRETE MF Tds PDFkhalidAún no hay calificaciones

- Hyperdesmo® PB 2KDocumento3 páginasHyperdesmo® PB 2KNoussa NesAún no hay calificaciones

- Medacim StaDocumento1 páginaMedacim StaRafik MezaliAún no hay calificaciones

- Paves 5form VPDocumento2 páginasPaves 5form VPHector-le-troyenAún no hay calificaciones

- FT 120Documento2 páginasFT 120Nazim SafsafAún no hay calificaciones

- SikaTop 141 Imperméabilisation PDFDocumento2 páginasSikaTop 141 Imperméabilisation PDFAhmed Frikha0% (1)

- DZ NP Sika Monotop SF 126 PDFDocumento3 páginasDZ NP Sika Monotop SF 126 PDFMohamed Seghir Benzemrane100% (2)

- Masteremaco P 221Documento2 páginasMasteremaco P 221Ibrahim GharibAún no hay calificaciones

- Wa0018.Documento2 páginasWa0018.amourjure45Aún no hay calificaciones

- FRCHAPDURPREMIXADocumento2 páginasFRCHAPDURPREMIXASHOZ TEC sasaAún no hay calificaciones

- FtsolumatDocumento2 páginasFtsolumatmirsette settemirAún no hay calificaciones

- FransızcaDocumento2 páginasFransızcadefneAún no hay calificaciones

- Crema MarfilDocumento1 páginaCrema Marfilperseidas2Aún no hay calificaciones

- Sika Monotop SF 126Documento3 páginasSika Monotop SF 126Amine MoudjebAún no hay calificaciones

- Epovic LM 12Documento2 páginasEpovic LM 12Abdessalam OSFORIAún no hay calificaciones

- MasterKure 102Documento2 páginasMasterKure 102Redha SabrAún no hay calificaciones

- PROCOL Extra 311Documento2 páginasPROCOL Extra 311Nazim SafsafAún no hay calificaciones

- NOVACRETE FTP StampColor Colorant DurcisseurDocumento2 páginasNOVACRETE FTP StampColor Colorant DurcisseurMahdi FEKIAún no hay calificaciones

- Almar To Ub ProjDocumento2 páginasAlmar To Ub Projtaoufiq37Aún no hay calificaciones

- THOR GRIP C2S2 - Fiche TechniqueDocumento3 páginasTHOR GRIP C2S2 - Fiche Techniquerroma_1983Aún no hay calificaciones

- EcoprimerDocumento2 páginasEcoprimerJihane El AdnaniAún no hay calificaciones

- Airium Thermofloor M600 FRDocumento2 páginasAirium Thermofloor M600 FRAdlen AlliouaneAún no hay calificaciones

- Sikaceram - 205 MDocumento4 páginasSikaceram - 205 MLamine HindAún no hay calificaciones

- Sika Chapdur PremixmDocumento3 páginasSika Chapdur PremixmAhmed AhmeedAún no hay calificaciones

- Les Fiches TechniquesDocumento14 páginasLes Fiches TechniquesNassima BOUGTEBAún no hay calificaciones

- ECOPRIMERDocumento2 páginasECOPRIMERBougteb nassimaAún no hay calificaciones

- Chapdur Premix MDocumento3 páginasChapdur Premix MOuassim EssaidiAún no hay calificaciones

- Sikatop - 122 ReparationmDocumento3 páginasSikatop - 122 ReparationmMohamed El BarkaouyAún no hay calificaciones

- SikaBond-50 Parquet FRCHDocumento5 páginasSikaBond-50 Parquet FRCHmayachi.tuniberAún no hay calificaciones

- Cloison Placostil® SAD 160 Placoplatre® BA13 - EI 60 - 62dB - 3,05m - Placo®Documento32 páginasCloison Placostil® SAD 160 Placoplatre® BA13 - EI 60 - 62dB - 3,05m - Placo®Brice Patrice GollyAún no hay calificaciones

- Concrex Sub-Zero FRDocumento3 páginasConcrex Sub-Zero FRGuillome CipolataAún no hay calificaciones

- Concrex Cold Set FRDocumento4 páginasConcrex Cold Set FRGuillome CipolataAún no hay calificaciones

- FR NP Sika Fastfix 131Documento4 páginasFR NP Sika Fastfix 131rheochronosAún no hay calificaciones

- WallcoatDocumento2 páginasWallcoatMuhamadu LamineAún no hay calificaciones

- Enrobé Coulé À Froid PDFDocumento4 páginasEnrobé Coulé À Froid PDFkhalidboutahriAún no hay calificaciones

- Morcem® Dry FDocumento4 páginasMorcem® Dry FMezouar AbdennacerAún no hay calificaciones

- Freitafloor Liant EP HQ SR v2Documento2 páginasFreitafloor Liant EP HQ SR v2Yog SothothAún no hay calificaciones

- Fiche Descriptive Traitement de Surface Octobre 2020 CompresseDocumento6 páginasFiche Descriptive Traitement de Surface Octobre 2020 CompressepersoazizAún no hay calificaciones

- Emufal SolidDocumento3 páginasEmufal SolidFouad Ait100% (1)

- Sika Monotop 412sDocumento3 páginasSika Monotop 412sdominique bourger lembenbe ntedeAún no hay calificaciones

- Sikalastic - 220 WDocumento3 páginasSikalastic - 220 WYassin AdhriAún no hay calificaciones

- Notice - Technique - Pose Carreaux de CimentDocumento6 páginasNotice - Technique - Pose Carreaux de CimentKaby StuffAún no hay calificaciones

- Hyperdesmo (Classic Version)Documento3 páginasHyperdesmo (Classic Version)Noussa NesAún no hay calificaciones

- Puma Ce DZ FR 2021 04Documento5 páginasPuma Ce DZ FR 2021 04Abdellah AbdellahAún no hay calificaciones

- Sika FT Sikatop 121Documento5 páginasSika FT Sikatop 121Mohamed El BarkaouyAún no hay calificaciones

- Soprodur. Coulis D Injection. Comment Agir en Présence de Zones Creuses - Tout Arracher Ou PréserverDocumento8 páginasSoprodur. Coulis D Injection. Comment Agir en Présence de Zones Creuses - Tout Arracher Ou Préserverrroma_1983Aún no hay calificaciones

- Medapoxy SolDocumento2 páginasMedapoxy SolManiaAún no hay calificaciones

- Meda ImpregnationDocumento2 páginasMeda Impregnationazri mouhamedAún no hay calificaciones

- CorrigéDocumento4 páginasCorrigéjaadane.fatimazahra8Aún no hay calificaciones

- M05 - Installation Des Canalisations Électriques GE-EB PDFDocumento45 páginasM05 - Installation Des Canalisations Électriques GE-EB PDFzakariasolo100% (3)

- Les Dalles Rectangulaires13Documento8 páginasLes Dalles Rectangulaires13Hamza AbidiAún no hay calificaciones

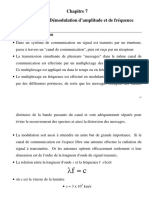

- Chapitre 7.1 Modulation Et Démodulation PreseDocumento40 páginasChapitre 7.1 Modulation Et Démodulation PreseAffak Affak100% (1)

- Manuel de Conception Des Scripts V1.2.xDocumento30 páginasManuel de Conception Des Scripts V1.2.xاليزيد بن توهاميAún no hay calificaciones

- MD20.3 PLANUREX-Planetengetriebe de en FRDocumento68 páginasMD20.3 PLANUREX-Planetengetriebe de en FRhasan arifAún no hay calificaciones

- Ferrovissime 2020 11 12Documento84 páginasFerrovissime 2020 11 12Joseph FazioAún no hay calificaciones

- Mon RapportDocumento20 páginasMon RapportDjalal BellourAún no hay calificaciones

- Stabilité Des Pentes PDFDocumento15 páginasStabilité Des Pentes PDFDY SAXAún no hay calificaciones

- Les Nombres AdimensionnelsDocumento4 páginasLes Nombres AdimensionnelsCyrille Kontchou KamdoumAún no hay calificaciones

- Manuel Samsung B2710Documento88 páginasManuel Samsung B2710Tuxetech TuxAún no hay calificaciones

- Doseur2 PDFDocumento35 páginasDoseur2 PDFOussama EljaafariAún no hay calificaciones

- Elaborer Un PPSPSDocumento12 páginasElaborer Un PPSPSlimmoud100% (1)

- Algebre de BooleDocumento6 páginasAlgebre de BooleBabacar TounkaraAún no hay calificaciones

- SSR 2015-16 ElectricalDocumento1901 páginasSSR 2015-16 ElectricalVenkataLakshmiKorrapatiAún no hay calificaciones

- Moteur Stirling ESIB MPSIDocumento9 páginasMoteur Stirling ESIB MPSIDakhlaouiAún no hay calificaciones

- Guidage Central 1207Documento4 páginasGuidage Central 1207Claudine ElisseevAún no hay calificaciones

- Catalogue - Stabox, GoujonDocumento104 páginasCatalogue - Stabox, GoujonymitevAún no hay calificaciones

- Cours Montage Des Roulements1Documento2 páginasCours Montage Des Roulements1Guy EffaAún no hay calificaciones

- Lecture Schema Electrique BepDocumento4 páginasLecture Schema Electrique BepMBIA FIDELIN YVES100% (2)

- RAPPORT HYDRO - Idriss Monthe - s196395Documento19 páginasRAPPORT HYDRO - Idriss Monthe - s196395Idriss MonthéAún no hay calificaciones

- MemoireDocumento110 páginasMemoiremouloudbelh54Aún no hay calificaciones

- Horowitz Horror Stories You'll Wish You Never Read (PDFDrive)Documento116 páginasHorowitz Horror Stories You'll Wish You Never Read (PDFDrive)martinduval348Aún no hay calificaciones

- Plaquette AccédantsDocumento6 páginasPlaquette AccédantsJennifer Balilli - TaylorAún no hay calificaciones

- Gestion de La MemoireDocumento12 páginasGestion de La MemoireFadwa ZedAún no hay calificaciones

- Cahier Des Charges Technique PDFDocumento5 páginasCahier Des Charges Technique PDFDominique AngoaAún no hay calificaciones

- Rapport D'avarie PDFDocumento11 páginasRapport D'avarie PDFkahl98367% (3)

- Thème 1 SVT: Activités Internes de La TerreDocumento9 páginasThème 1 SVT: Activités Internes de La TerreMayaAún no hay calificaciones

- Xps Ac Doc CablageDocumento1 páginaXps Ac Doc CablageThierry LAMBOTTEAún no hay calificaciones

- Matériauw PDFDocumento194 páginasMatériauw PDFKàoutarAllaboucheAún no hay calificaciones