Documentos de Académico

Documentos de Profesional

Documentos de Cultura

17 1SSC

Cargado por

Ricardo100%(1)100% encontró este documento útil (1 voto)

14 vistas2 páginasManual de servicio

Título original

17-1SSC

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoManual de servicio

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

100%(1)100% encontró este documento útil (1 voto)

14 vistas2 páginas17 1SSC

Cargado por

RicardoManual de servicio

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF o lea en línea desde Scribd

Está en la página 1de 2

e

17, 19

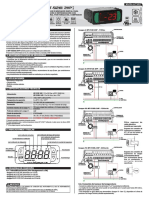

Series

Start-Up, Operation, and Maintenance

Instructions Supplement

Open-Drive and Hermetic Centrifugal Liquid Chillers

Safety Guide

Centrifugal liquid chillers are designed to provide

and reliable service when operated within design specifi

tons. When operating this equipment, Use good judgement

and safety precautions to avoid damage to equipment and

Property or injury to personne,

This Safety Guide is a supplement to the machine Instl-

lation instructions and tothe Start-Up, Operation and Mai.

tenance Instructions ofthe following Open-Drive and Her

‘metic Centrifugal Liquid Chillers

17CB, TDA, 17EA, 17EA and 17M.P,

ISCB, 19DG) 19DH, 19EA, 19EB and 19FA

Be sure you understand and follow the procedures and safety

precautions contained in the machine instructions as well

fs those listed ints supplement

fe

DO NOT USE OXYGEN wo pure ines orto nese 3

‘machine for any purpose. Oxygen as reacts viclenty with

fl, grease, and eter common substances

[NEVER EXCEED specified test pressures. VERIFY the a-

lovable cet pressure by checking the fasruction lterture

an the design pressures on the equipment nameplate.

DO NOT VALVE OFF any safety device

BBE SURE that all pressure relief devices aze property in-

Stalled snd functioning before opetating any mice.

BO NOT USE eyebots or eebot holes toni machine sc-

‘ions or the entire assembly.

NEVER OPERATE an open-drive machine, pumpout unit

‘r other equipment without coupling (or bet guards in pace.

‘This warning applies evento short runs such a8 4 motor rO-

tation check. Serious injury ean result from contact ith

moving pars,

DO NOT work on high volage equipment unless you ae a

qualified electrician,

DO NOT WORK ON electrical components, including con-

twol panels, switches, starters, or ofl heater until you are

sure ALL OWER IS OFF and no residual voltage can leak

from capacitors or solid-state components

LOCK OPEN AND TAG electrical circuits during servic-

ing. IF WORK IS INTERRUPTED, confiem that all c=

Cults are deenergized before resuming Work

DO NOT syphon refigerant by mouth

AVOID SPILLING liquid refrigerant on skin or getting it

into the eyes. USE SAFETY GOGGLES, Wash any spills

Tanuacer eeerves fe taht duces ov change ey Ho, speteatere oY Sei

Siplomrar a 1 and 1 Scie atason Sap Operon tae Mnianance cons

‘Calsug ho 9179",

from the skin with soap and water. If any enters the eyes,

IMMEDIATELY FLUSH EYES with water and consult ¢

physician

NEVER APPLY an open flame or live steam to a refriger

ant eylinder. Dangerous overpressure can result, When nec

essary to heat refrigerant, use only warm (110 Fis3 ©)

DO NOT REUSE disposable (nonreturnable) cylinders nor

allempt to refill them, It is DANGEROUS AND ILLE-

GAL: Before disposing of the eylinder, recover all remain

ing refrigerant from the cylinder in accordance with EPA

(Environmental Protection Agency) guidelines. Loosen the

valve collar and unserew and discard the valve stem DO

NOT INCINERATE

(CHECK THE REFRIGERANT TYPE before charging ms

chine. High pressure refrigerant in alow pressure machine

ean cause vessels 10 rupture ifthe reli devices cannot ban-

fle the refrigerant volume.

DO NOT ATTEMPT TO REMOVE fitings, covers, ete

‘hile machine is under pressure or while machine is ri

ning. Be sure pressure is at zero psig before breaking any

refrigerant connection

CAREFULLY INSPECT all relief valves, upture diss and

other relief devices AT LEAST ONCE A YEAR. If mae

Chine operates in a corrosive atmosphere, inspect the de-

ices a more frequent intervals

DO NOT ATTEMPT TO REPAIR OR RECONDITION any

relief valve when corrosion of build-up of foreign material

(rust, dirt, scale, ete.) is found within the valve body or

mechanist. Replace the valve.

DO NOT VENT refrigerant relief valves within a building

vent to outside. The accumulation of refrigerant in an en-

closed space ean displace oxygen and cause asphyxiation,

DO NOT instal elief valves in series or backwards

USE CARE when working near or in line with a com

pressed spring. Sudden release of the spring can calse it

land objects in its path to act as projects.

DO NOT STEP on refegerant ins. Broken Tine can whip

about and cause personal inury

DO NOT climb over 8 machine, Use platform, catwalk or

Staging. Follow sate practices when using ladders

USE MECHANICAL EQUIPMENT (crane, host, et.) 19

Cor move iipecian cover er te ey song

Even if components are light, use sich equipment when

there is «Hk of slipping oF losing your balance

Tanout na ant wine neery swore

Famine gt Th Rapaoes Naw

DO NOT WELD OR FLAME CUT any refrigerant line

‘or vessel until all refrigerant has been removed from the

vessel

‘BE AWARE that certain automatic tat arrangements CAN

ENGAGE THE STARTER. Open the disconnect ahead of

the starter in addition to shutting off the machine or pump.

USE only repair or replacement part tha meet the code re-

‘quirements of the original equipment.

DO NOT VENT OR DRAIN water boxes containing indus-

tral brines, liquid, gases or semisolids without permission

fof your Process Control Group.

DO NOT LOOSEN water box cover bolts until the water

bor has been completely drained,

enya

care: Capron

DOUBLE-CHECK that coupling nut wrenches, dial indi-

‘lors of other items have been removed before rotating sny

Shas,

DO NOT LOOSEN a packing gland nut before checking

‘thatthe nut has a positive thread engagement

PERIODICALLY INSPECT all valves, fittings and piping

for corrosion, rst, leaks, or damage

PROVIDE A DRAIN connection in the vent line near each

pressure relief device to prevent @ build-up of condensate

‘Mrctacturr sore theron to econ, or changes any Bom spettouone or ceigne waht haves and iho Tearing solpetone

Boe PORT Ceaog Ne. S30T3) Panta MUSA

FomrriSS0 Pgh toad ity Reset New

ob Te "Soplemons a 17 ar 1 See hasan, Sat Un, Ops a Mane nce

También podría gustarte

- Chiller York YRHCDocumento40 páginasChiller York YRHCRicardo100% (2)

- Control Pro Dialog Series 30 GX 30 HXCDocumento36 páginasControl Pro Dialog Series 30 GX 30 HXCRicardo100% (2)

- P 018 Ar 1 22 - 42 4908 PDFDocumento12 páginasP 018 Ar 1 22 - 42 4908 PDFRicardoAún no hay calificaciones

- AV435846673149es ES0101Documento2 páginasAV435846673149es ES0101RicardoAún no hay calificaciones

- 6 Flyer Compresores Rotativos GMCC2Documento3 páginas6 Flyer Compresores Rotativos GMCC2Maria Aydee Leon VAún no hay calificaciones

- Bomba de Condensado Mini Orange Aspen PumpsDocumento1 páginaBomba de Condensado Mini Orange Aspen PumpsRicardoAún no hay calificaciones

- Manual Del Producto 111Documento4 páginasManual Del Producto 111Christian BlancoAún no hay calificaciones

- Tabla AplicacionDocumento36 páginasTabla AplicacionGuadalupe Aké Euán50% (2)

- Manual Del Producto 111Documento4 páginasManual Del Producto 111Christian BlancoAún no hay calificaciones

- Manual de Variador WEG - CFW08 EspañolDocumento219 páginasManual de Variador WEG - CFW08 Españolcarlosmedina11188% (17)

- 2016 Smartstart Student Application LA SpanishDocumento2 páginas2016 Smartstart Student Application LA SpanishRicardoAún no hay calificaciones

- CVGF Svx03a em - 12012008Documento128 páginasCVGF Svx03a em - 12012008RicardoAún no hay calificaciones

- Micro ChillerDocumento2 páginasMicro ChillerRicardoAún no hay calificaciones

- Bombas Agua Presurizadas Cerweny - Manual - Control PDFDocumento4 páginasBombas Agua Presurizadas Cerweny - Manual - Control PDFjoserod17Aún no hay calificaciones

- Manual de Variador WEG - CFW08 EspañolDocumento219 páginasManual de Variador WEG - CFW08 Españolcarlosmedina11188% (17)

- RTHD Iom SpanishDocumento68 páginasRTHD Iom SpanishRicardoAún no hay calificaciones

- Rtwa-70 125Documento206 páginasRtwa-70 125Ricardo100% (2)