Documentos de Académico

Documentos de Profesional

Documentos de Cultura

215482686

Cargado por

Vian Galih Saputra0 calificaciones0% encontró este documento útil (0 votos)

38 vistas1 páginajhj

Derechos de autor

© © All Rights Reserved

Formatos disponibles

XLSX, PDF, TXT o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentojhj

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como XLSX, PDF, TXT o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

38 vistas1 página215482686

Cargado por

Vian Galih Saputrajhj

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como XLSX, PDF, TXT o lea en línea desde Scribd

Está en la página 1de 1

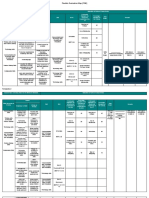

Pumps

Template Category Pumps

Template Version v1

Category Description Devices for moving fluid to serve (or serving) a building services system

Classification System

Classification Value

Suitability for Use Approved

Template Custodian CIBSE

Information Category Parameter Name Value Units Notes

Manufacturer Data

Specifications Manufacturer Grundfos A/S Text

Specifications Manufacturer Website http://www.grundfos.com URL

Specifications Product Range SPK 2 Text

Specifications Product Model Number 39DH0368 Text or code

Specifications CE Approval Text number, yes, no

Specifications Approvals Text e.g. WRAS number

Specifications Product Literature https://product-selection.grundfos.com/pro URL

Specifications Features Coolant pumps Text Free text to describe product

Construction Data

Specifications Application Text e.g. LTHW, CHW, etc.

Specifications Pump Type Immersible Text e.g. End Suction, Inline, Glandless, Vertical multistage etc.

Specifications Configuration Not applicable Text e.g close coupled, long coupled, split coupled etc

Specifications Drive Type Text e.g. Direct, Belt, Integrated drive

Specifications Casing Material Cast iron Text e.g cast iron, ductile iron, bronze etc

Specifications Impeller Material Stainless steel Text e.g bronze, plastic etc

Specifications Shaft Material Not applicable Text e.g. Stainless steel, brass etc.

Specifications Shaft Seal Type AUUV Text e.g carbon, silicon carbide etc

Specifications PN Rating Text e.g. as per ISO 7005

Specifications Colour Text e.g. RAL Colour

Specifications Finish Text e.g. polished, matt, gloss etc.

Specifications Connection Type Text e.g. flanged, screwed etc.

Dimensional Data

Specifications Impeller diameter mm to be a range, user input

Specifications Number of Impellers 8 Number

Specifications Suction Connection diameter 10 mm

Specifications Discharge Connection diameter 10 mm

Specifications Overall Length mm

Specifications Overall Width mm

Specifications Overall Height mm

Specifications Gross Weight 28.2 kg Equates to operating weight of unit

Specifications Shipping Weight kg Equates to dry weight of unit plus packaging allowance

Specifications Access Clearance Top mm Access required for maintenance of this item

Specifications Access Clearance Bottom mm Access required for maintenance of this item

Specifications Access Clearance Left mm Access required for maintenance of this item

Specifications Access Clearance Right mm Access required for maintenance of this item

Specifications Access Clearance Front mm Access required for maintenance of this item

Specifications Access Clearance Rear mm Access required for maintenance of this item

Performance Data

Specifications Speed Type fixed Text (fixed or variable)

Specifications Maximum Speed 3390-3460 RPM Maximum operating speed

Specifications Minimum Speed RPM Minimum operating speed

Specifications Flow 0.6389 l/s at max speed and BEP, based on SG1 - water

Specifications Head 351.1 kPa at max speed and BEP

Specifications NPSHr kPa at max speed and BEP

Specifications Maximum Operating Pressure kPa

Specifications Maximum Operating Temperature 194 degC

Specifications Bearing Design Life Text e.g. L10, L25

Specifications Efficiency Rating N/A Text e.g. MEI, EEI based on ErP directive

Specifications Performance Data https://product-selection.grundfos.com/pro URL link to technical documentation on free access website

Electrical Data

Specifications Voltage 220-255D/380-440Y Volts

Specifications Supply Phase 3 Number 1,3

Specifications Frequency 60 Hertz 50,60

Specifications Enclosure Rating Text IP numbers

Specifications Maximum Motor Power Rating 0.738 kW

Specifications Full load current 2,15-2,05/1,25-1,20 Amps At UK standard voltage

Specifications Maximum Starting Current 500-600 Amps Using DOL at UK standard voltage

Specifications Motor Type 71B Text TEFC, ODP

Specifications Number of Poles 2 Number 2,4,6,8

Specifications Motor Efficiency Class NEMA Premium / IE3 60Hz Text e.g. CEMEP, IE2, IE3

Sustainability

Sustainable Material BREEAM etc Embodied Carbon kgCO2 University of Bath ICE Data if none other available

Sustainable Material BREEAM etc Life Cycle Analysis Number BREEAM

Sustainable Material BREEAM etc Location of Manufacturer GridRef Northing,Easting

Sustainable Material BREEAM etc Green Guide for Specification Text A-E

Sustainable Material BREEAM etc Environmental Product Declaration Text 3rd Party Verification

Sustainable Material BREEAM etc Responsible Sourcing of Materials Text Endorsing Body

Sustainable Material ETL Energy Technology List URL Hyperlink to ETL webpage for product

Sustainable Material LEED v.4 Responsible Extraction of Materials Text

Sustainable Material LEED v.4 Material Ingredient Reporting Text

Operations & Maintenance

Facilities/Asset Management O&M Manual https://product-selection.grundfos.com/pro URL Hyperlink to Manufacturer O&M Data

Facilities/Asset Management Daily Text Maintenance tasks or SFG2012 codes

Facilities/Asset Management Weekly Text Maintenance tasks or SFG2012 codes

Facilities/Asset Management Monthly Text Maintenance tasks or SFG2012 codes

Facilities/Asset Management Quarterly Text Maintenance tasks or SFG2012 codes

Facilities/Asset Management 6 Monthly Text Maintenance tasks or SFG2012 codes

Facilities/Asset Management Annually Text Maintenance tasks or SFG2012 codes

Facilities/Asset Management Bespoke Timeframe Text Maintenance tasks or SFG2012 codes

Facilities/Asset Management Maintenance Required 0-300hrs Text Maintenance tasks required during this time frame

Facilities/Asset Management Maintenance Required 301-600hrs Text Maintenance tasks required during this time frame

Facilities/Asset Management Maintenance Required 601-1000hrs Text Maintenance tasks required during this time frame

Facilities/Asset Management Maintenance Required 1001-2000hrs Text Maintenance tasks required during this time frame

Facilities/Asset Management Maintenance Required 2001-4000hrs Text Maintenance tasks required during this time frame

Facilities/Asset Management Maintenance Required 40001-8000hrs Text Maintenance tasks required during this time frame

Facilities/Asset Management Maintenance Required 8001-12000hrs Text Maintenance tasks required during this time frame

Facilities/Asset Management Expected Life Years

Facilities/Asset Management Warranty ID Text

This spreadsheet is the property of CIBSE although it can be freely used in the ways described, and completed with data specific to particular products.

It is important that the Categories and Parameters given on the form are not changed. It is also important that where units of measurement are defined on the form that these too are followed.

Any comment or suggestion on their revision should be addressed to pdt@cibse.org

© CIBSE 2015 © The Chartered Institution of Building Services Engineers www.cibse.org

También podría gustarte

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- Addis Ababa University: College of Natural Sciences School of Information ScienceDocumento113 páginasAddis Ababa University: College of Natural Sciences School of Information Scienceአስምሮ ላቂያዉAún no hay calificaciones

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (400)

- NFPA72Documento1 páginaNFPA72aammxxiAún no hay calificaciones

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- Christine Jocson - EFAA1 - FEM - TemplateDocumento3 páginasChristine Jocson - EFAA1 - FEM - TemplateRomano Jocson100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (895)

- IEC 60071-1 Page 22Documento1 páginaIEC 60071-1 Page 22omid fathiAún no hay calificaciones

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- Srs Latest VersionDocumento11 páginasSrs Latest VersionVikram VarmaAún no hay calificaciones

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- Scott GroverDocumento3 páginasScott GroverJoe StephensAún no hay calificaciones

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- ABB Distribution Automation Protection Relay Price ListDocumento75 páginasABB Distribution Automation Protection Relay Price ListdasubelzaAún no hay calificaciones

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Book JWT Chapter 13Documento2 páginasBook JWT Chapter 13Muhammad JawadAún no hay calificaciones

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (588)

- Samsung Galaxy J2 Pro (2018) ManualDocumento127 páginasSamsung Galaxy J2 Pro (2018) ManualBruno CoutoAún no hay calificaciones

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (74)

- GJ2010B-OD GJ2010B NJ2010B-OD NJ2010B: AC/DC Surge Protection Solutions For Small CellDocumento2 páginasGJ2010B-OD GJ2010B NJ2010B-OD NJ2010B: AC/DC Surge Protection Solutions For Small Cellclaudia karina monteverde zazuetaAún no hay calificaciones

- DWDM I Mid Objective QBDocumento7 páginasDWDM I Mid Objective QBkishore5783100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- Romtip SW PcsDocumento5 páginasRomtip SW PcsLaithAl-abbadiAún no hay calificaciones

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (266)

- Certification Flasharray Architect Professional Study GuideDocumento21 páginasCertification Flasharray Architect Professional Study Guidemukive100% (1)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- Security Checkup Harmony Endpoint 2024-03-25T09!02!44 KenpipeSacco-797494aa-Hap2 FinalDocumento15 páginasSecurity Checkup Harmony Endpoint 2024-03-25T09!02!44 KenpipeSacco-797494aa-Hap2 FinalellyineahAún no hay calificaciones

- Dbms Solutions For Past Question PapersDocumento31 páginasDbms Solutions For Past Question PapersAriel PeterAún no hay calificaciones

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Datos de PresionesDocumento3 páginasDatos de PresionesWilson Jaime Saucedo LeonAún no hay calificaciones

- Very GoodDocumento5 páginasVery GoodManjulya YeddiAún no hay calificaciones

- Iridium SBDS Developers GuideDocumento36 páginasIridium SBDS Developers GuideAndres MoraAún no hay calificaciones

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2259)

- MTM Lab Report..501Documento96 páginasMTM Lab Report..501Usman BajwaAún no hay calificaciones

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- SFERE Energy Meter3706581013667435464Documento2 páginasSFERE Energy Meter3706581013667435464Cho Cho MyintAún no hay calificaciones

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- Xeon Phi CompleteDocumento88 páginasXeon Phi CompleteNecmettin yıldızAún no hay calificaciones

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- Multithreading Sorting AssignmentDocumento2 páginasMultithreading Sorting AssignmentTan BunChhayAún no hay calificaciones

- 1KEK Transferring Payables - Receivables To PCADocumento6 páginas1KEK Transferring Payables - Receivables To PCABrigitta BallaiAún no hay calificaciones

- Programming The GigatronDocumento5 páginasProgramming The GigatronEdsonAún no hay calificaciones

- HP Pavilion Gaming Latest AMD Ryzen 5 5600H Processor 15.6Documento5 páginasHP Pavilion Gaming Latest AMD Ryzen 5 5600H Processor 15.6Mr Deshmukh Girish SahebraoAún no hay calificaciones

- Deprecated and Replaced by Gw-Map-StateDocumento2 páginasDeprecated and Replaced by Gw-Map-StateharwoodkAún no hay calificaciones

- At TC ContactsDocumento5 páginasAt TC ContactsMaNiAún no hay calificaciones

- Html5 and Css3 Illustrated Introductory 2nd Edition Vodnik Solutions ManualDocumento15 páginasHtml5 and Css3 Illustrated Introductory 2nd Edition Vodnik Solutions ManualJoshua Warren100% (37)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (121)

- L6004L8 - TriacDocumento8 páginasL6004L8 - TriacValmir BarbosaAún no hay calificaciones

- Report Bonafide JeevaDocumento5 páginasReport Bonafide JeevaRamyaAún no hay calificaciones

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2102)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)