Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Introduction To Instrumentation: Cost, Reliability and Accuracy

Cargado por

Chidiebere Samuel OkogwuDescripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Introduction To Instrumentation: Cost, Reliability and Accuracy

Cargado por

Chidiebere Samuel OkogwuCopyright:

Formatos disponibles

Shell Nigeria Graduate Training Programme Instrumentation

Introduction

INTRODUCTION TO INSTRUMENTATION

Instrumentation has become so much a part of our daily lives that we no longer take

notice of it.

• Each time you alter the temperature of your air conditioner you assume that

the room temperature will respond accordingly. You do not give much thought

to the sensor located inside which ensures that the set temperature is

maintained.

• A motor car contains more sophisticated examples of sensors. When you turn

the ignition switch on, the ignition light and the oil pressure warning light come

on. When you start the engine, these lights go off. As you begin to drive away

the speedometer indicates the speed at which you are travelling. While driving

you cast occasional glances at the fuel gauge or at the water temperature

gauge. Do we ever wonder what type of device senses the oil pressure, or the

water temperature or the level of fuel in the tank?

• The choice of an appropriate sensor is a vitally important one. Mostly, the

choice is neither obvious nor easy to make, because it involves some form of

compromise between cost, reliability and accuracy.

COST, RELIABILITY AND ACCURACY

1. Cost is an important factor to a manufacturer producing 500,000 cars

per annum. An increase of 50 Naira in the cost of a component for

each car translates into an increase of 25 million Naira per annum in

raw material costs.

2. The reliability of the car is also an important factor. How would you feel

about your car if you could not rely on the sensors, or have to replace

them frequently?

3. The requirements of accuracy are related to the overall context of the

measurement. Whereas it is important that the speedometer gives a

reasonably accurate indication of the road speed (usually to within

Olatunbosun, A Page 1 of 3 Univation

Shell Nigeria Graduate Training Programme Instrumentation

Introduction

10%), you do not expect to be informed to the nearest litre how much

fuel is in the tank. What is needed is an appropriate indication of

when to fill up. Repeatability is more important than accuracy in this

case.

TASKS OF AN INSTRUMENTATION SYSTEM

1. Translate the physical variable being measured (the measurand) into another

physical variable (i.e. conversion of energy in one form to another form). This

can be used to drive an indicating device: for example, the oil pressure may

be converted by a pressure sensor into an electrical voltage whose magnitude

is proportional to the pressure sensed. Devices used in achieving this are

often called transducers.

2. Transmits the signal generated by the transducer to a signal/data-processing

unit.

3. Manipulates and prepares the signal/data into forms amenable for display or

performance of specified control action.

INSTRUMENTA TION SYSTEMS AND THEIR COMPONENTS

The word instrumentation means the science and technology of complete systems

designed to measure physical quantities so as to obtain data, which are transmitted

to recording and display devices, and/or to control devices.

When control devices are involved they are used to control the state of the physical

quantity being measured.

Every instrumentation system contains one or more of each of the following

elements or components.

• A sensor for detecting (sensing) the physical quantity being measured.

• A transducer for converting the energy of the detected physical quantity into

another energy form (signal).

Please note that the term signal could be used for energy form in form of electrical

current, pneumatic pressure or other variable quantity which is produced at the

Olatunbosun, A Page 2 of 3 Univation

Shell Nigeria Graduate Training Programme Instrumentation

Introduction

output of the transducer, and which is used to convey information to the rest of the

system.

• A transmission path for transmitting this signal from the transducer to the

rest of the system. Examples of transmission paths are electrical cables,

optical fibres, pneumatic pipes, and data buses and radio links.

• Some form of recording device, display device or means of comparing

the measured data with some desired reference value so that their

difference can exercise appropriate control of the process upon which the

measurements are being made.

Olatunbosun, A Page 3 of 3 Univation

También podría gustarte

- Automotive Electronic Diagnostics (Course 2)De EverandAutomotive Electronic Diagnostics (Course 2)Calificación: 4 de 5 estrellas4/5 (2)

- CHAPTER 3 Monitoring and ControlDocumento32 páginasCHAPTER 3 Monitoring and Controlmichaelmude16Aún no hay calificaciones

- MEASUREMENT TechniqueDocumento13 páginasMEASUREMENT Techniqueseherr719Aún no hay calificaciones

- Pesona Optometry2Documento12 páginasPesona Optometry2Muhammad Irfan Naufal RamlanAún no hay calificaciones

- Presntation (Installing Instrumentation and Control Devices)Documento35 páginasPresntation (Installing Instrumentation and Control Devices)habtemariam mollaAún no hay calificaciones

- Industrial InstrumentationDocumento74 páginasIndustrial InstrumentationAjish AJAún no hay calificaciones

- WhitePaper ConductivityMeasurements-USP645 EN 30431332 LRDocumento8 páginasWhitePaper ConductivityMeasurements-USP645 EN 30431332 LRAlexis CastroAún no hay calificaciones

- Mie IntroductionDocumento77 páginasMie IntroductionKalikene MwambeloAún no hay calificaciones

- Designing of Indigenous Monitoring SystemDocumento16 páginasDesigning of Indigenous Monitoring SystemNasir AbdullahAún no hay calificaciones

- Basics of InstrumentDocumento66 páginasBasics of InstrumentnizamuddinAún no hay calificaciones

- Sensors and TransducersDocumento9 páginasSensors and TransducersJuBi1461Aún no hay calificaciones

- I&m 1Documento22 páginasI&m 1Aleeza AshfaqueAún no hay calificaciones

- Lecture 2 - Characteristics of MSDocumento33 páginasLecture 2 - Characteristics of MSSceva AquilaAún no hay calificaciones

- Emi R16 - Unit-1Documento21 páginasEmi R16 - Unit-1Giridhar ChowdaryAún no hay calificaciones

- MECE4103: Mechanical Processes Instrumentation and Control: Chapter One: General Concepts of Measurement SystemDocumento30 páginasMECE4103: Mechanical Processes Instrumentation and Control: Chapter One: General Concepts of Measurement SystemPuwa CalvinAún no hay calificaciones

- Transducer Notes Made by Shoaib KhanDocumento5 páginasTransducer Notes Made by Shoaib KhanShoaib KhanAún no hay calificaciones

- Some Fiber Optic Measurement ProceduresDocumento6 páginasSome Fiber Optic Measurement ProceduresAmir SalahAún no hay calificaciones

- Condition Based Maintenance (CBM) : AbstractDocumento25 páginasCondition Based Maintenance (CBM) : AbstractCesarAún no hay calificaciones

- Iot Iat 2Documento6 páginasIot Iat 2lordgaming2407Aún no hay calificaciones

- CHAPTER ONE: Measurement Error AnalysisDocumento32 páginasCHAPTER ONE: Measurement Error AnalysisAbel AzieAún no hay calificaciones

- Chapter 1 PDFDocumento67 páginasChapter 1 PDFdassu misganaAún no hay calificaciones

- Unit-I: Department of Ece Electronic Measurements & InstrumentationDocumento82 páginasUnit-I: Department of Ece Electronic Measurements & Instrumentationdon aAún no hay calificaciones

- Measuring InstrumentsDocumento50 páginasMeasuring InstrumentsUnnati GuptaAún no hay calificaciones

- Smart DevicesDocumento16 páginasSmart DevicesmanojchandrasekharanAún no hay calificaciones

- Book of Sir Naveed RamzanDocumento175 páginasBook of Sir Naveed RamzanSomaan Alam100% (1)

- CH 1 - Intro J5800Documento54 páginasCH 1 - Intro J5800mohd_mizanAún no hay calificaciones

- 100 Instrumentation Interview Questions and AnswersDocumento17 páginas100 Instrumentation Interview Questions and AnswersFaisal AmirAún no hay calificaciones

- Chapter 3-Monitoring and ControlDocumento12 páginasChapter 3-Monitoring and Controlshauryamehta07Aún no hay calificaciones

- Lesson 1Documento18 páginasLesson 1Paul Simon NacisAún no hay calificaciones

- Ch1 InstDocumento13 páginasCh1 InstMohammed AlshibliAún no hay calificaciones

- Chapter 1Documento40 páginasChapter 1Dagem GetachewAún no hay calificaciones

- Intrumentastion and Control For HND IDocumento43 páginasIntrumentastion and Control For HND Iolamilekan00100Aún no hay calificaciones

- Pengukuran Prover PDFDocumento6 páginasPengukuran Prover PDFDZHOKAR AKBARAún no hay calificaciones

- Pesona OptometryDocumento13 páginasPesona OptometryMuhammad Irfan Naufal RamlanAún no hay calificaciones

- Definition of Fundamental TermsDocumento2 páginasDefinition of Fundamental TermsShid JullAún no hay calificaciones

- Control & Instrumentation-1Documento123 páginasControl & Instrumentation-1Ashish Vashisth100% (8)

- Sensor Classification and How To Choose A SensorDocumento7 páginasSensor Classification and How To Choose A SensorAkhilesh Reddy KarraAún no hay calificaciones

- Meas Ins1Documento148 páginasMeas Ins1HilalAldemir0% (1)

- Instrumentation Controls: What Is Instrumentation Technology?Documento15 páginasInstrumentation Controls: What Is Instrumentation Technology?mahesh4975Aún no hay calificaciones

- CLB 21303 Process Instrumentatio N and ControlDocumento48 páginasCLB 21303 Process Instrumentatio N and ControlanisAún no hay calificaciones

- Presentation - InstrumentationDocumento57 páginasPresentation - Instrumentationmahesh4975Aún no hay calificaciones

- Introduction To MechatronicsDocumento48 páginasIntroduction To Mechatronicsgiriaj kokareAún no hay calificaciones

- Remote Diagnistics For TransformersDocumento5 páginasRemote Diagnistics For TransformersMutahirrasoolAún no hay calificaciones

- Condition Based Maintenance (CBM)Documento18 páginasCondition Based Maintenance (CBM)DMEAún no hay calificaciones

- Lecture Notes 1Documento4 páginasLecture Notes 1Arpit SharmaAún no hay calificaciones

- Lect1 - E-1Documento54 páginasLect1 - E-1Desalegn sirnaAún no hay calificaciones

- Chapter1 Piceng215Documento56 páginasChapter1 Piceng215Hawraa JaafarAún no hay calificaciones

- InstrumentationDocumento27 páginasInstrumentationHusnain ArshadAún no hay calificaciones

- CLB 21303 Process Instrumentation and ControlDocumento48 páginasCLB 21303 Process Instrumentation and ControlSyafiqIsmiAún no hay calificaciones

- KMM411E - Lesson7b - Control System Instrumentation - 14nov2022Documento53 páginasKMM411E - Lesson7b - Control System Instrumentation - 14nov2022hairen jegerAún no hay calificaciones

- Data Acquisition: Detectors: TransducersDocumento11 páginasData Acquisition: Detectors: TransducersVasile RaduAún no hay calificaciones

- Remotre Monitoring of Transformer Health Over The InternetDocumento48 páginasRemotre Monitoring of Transformer Health Over The InternetMohan RajAún no hay calificaciones

- Sensors and Signal ProcessingDocumento22 páginasSensors and Signal ProcessingvinodhAún no hay calificaciones

- 6 Engine Computer Systems2Documento36 páginas6 Engine Computer Systems2Khairulz AnuarAún no hay calificaciones

- Instrumentation and Measurement (3 + 1)Documento27 páginasInstrumentation and Measurement (3 + 1)Haider AliAún no hay calificaciones

- Lec 0 Introduction To MeasurementDocumento5 páginasLec 0 Introduction To MeasurementKhalifa EltayebAún no hay calificaciones

- Comparing Magnitudes of Some Variables With A Standard ValueDocumento8 páginasComparing Magnitudes of Some Variables With A Standard Valueenok henaAún no hay calificaciones

- Instrumentation and Measurements - MaterialDocumento150 páginasInstrumentation and Measurements - MaterialYAVANA BAún no hay calificaciones

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisDe EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisCalificación: 4 de 5 estrellas4/5 (2)

- Alternative Source For Gas Supply To Indorama ProjectDocumento4 páginasAlternative Source For Gas Supply To Indorama ProjectChidiebere Samuel OkogwuAún no hay calificaciones

- Errosion: Nozzle Segment Indication ZonesDocumento1 páginaErrosion: Nozzle Segment Indication ZonesChidiebere Samuel OkogwuAún no hay calificaciones

- 3202.31.DIES - INSTRUMENT CABLE SCHEDULE.24015 - Rev02Documento6 páginas3202.31.DIES - INSTRUMENT CABLE SCHEDULE.24015 - Rev02Chidiebere Samuel OkogwuAún no hay calificaciones

- Start Time SN Job Step Hazard Harzard Controls Status CommentsDocumento3 páginasStart Time SN Job Step Hazard Harzard Controls Status CommentsChidiebere Samuel OkogwuAún no hay calificaciones

- 3202.31.DIES.24097 - Rev01 - Instruments Material Take-off-R0Documento19 páginas3202.31.DIES.24097 - Rev01 - Instruments Material Take-off-R0Chidiebere Samuel OkogwuAún no hay calificaciones

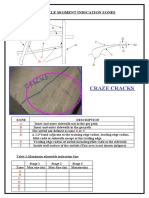

- Craze Cracks: Nozzle Segment Indication ZonesDocumento1 páginaCraze Cracks: Nozzle Segment Indication ZonesChidiebere Samuel OkogwuAún no hay calificaciones

- Thin Material: Nozzle Segment Indication ZonesDocumento1 páginaThin Material: Nozzle Segment Indication ZonesChidiebere Samuel OkogwuAún no hay calificaciones

- Start Time SN Job Step Hazard Hazard Controls Status CommentsDocumento3 páginasStart Time SN Job Step Hazard Hazard Controls Status CommentsChidiebere Samuel OkogwuAún no hay calificaciones

- Nozzle Segment Indication Zones: A B C B D D E FDocumento1 páginaNozzle Segment Indication Zones: A B C B D D E FChidiebere Samuel OkogwuAún no hay calificaciones

- PM List I&C (1258)Documento6 páginasPM List I&C (1258)Chidiebere Samuel OkogwuAún no hay calificaciones

- Kvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionDocumento2 páginasKvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionChidiebere Samuel OkogwuAún no hay calificaciones

- Kvaerner Energy LTD Thermal Power Division C.S.D. Field Technical InstructionDocumento2 páginasKvaerner Energy LTD Thermal Power Division C.S.D. Field Technical InstructionChidiebere Samuel OkogwuAún no hay calificaciones

- Bulging: Nozzle Segment Indication ZonesDocumento1 páginaBulging: Nozzle Segment Indication ZonesChidiebere Samuel OkogwuAún no hay calificaciones

- Kvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionDocumento2 páginasKvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionChidiebere Samuel OkogwuAún no hay calificaciones

- Kvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionDocumento1 páginaKvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionChidiebere Samuel OkogwuAún no hay calificaciones

- Kvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionDocumento2 páginasKvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionChidiebere Samuel OkogwuAún no hay calificaciones

- Kvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionDocumento2 páginasKvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionChidiebere Samuel OkogwuAún no hay calificaciones

- Field Technical Instruction: John Brown Engineering Customer Service DivisionDocumento2 páginasField Technical Instruction: John Brown Engineering Customer Service DivisionChidiebere Samuel OkogwuAún no hay calificaciones

- Technical Information Letter: Excessive Gas Fuel Flow at Start-Up (F-Class)Documento5 páginasTechnical Information Letter: Excessive Gas Fuel Flow at Start-Up (F-Class)Chidiebere Samuel Okogwu100% (1)

- Kvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionDocumento2 páginasKvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionChidiebere Samuel OkogwuAún no hay calificaciones

- Kvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionDocumento2 páginasKvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionChidiebere Samuel OkogwuAún no hay calificaciones

- Technical Information Letter: Load Coupling Nut EventDocumento1 páginaTechnical Information Letter: Load Coupling Nut EventChidiebere Samuel OkogwuAún no hay calificaciones

- Technical Information Letter: Energy Services Engineering Product Service TIL 1576Documento4 páginasTechnical Information Letter: Energy Services Engineering Product Service TIL 1576Chidiebere Samuel Okogwu100% (2)

- Technical Information Letter: Evaporative Cooler Commissioning ProcedureDocumento2 páginasTechnical Information Letter: Evaporative Cooler Commissioning ProcedureChidiebere Samuel OkogwuAún no hay calificaciones

- Technical Information Letter: TIL 1378-1 Ge Energy Services Product Service 12 December 2002Documento1 páginaTechnical Information Letter: TIL 1378-1 Ge Energy Services Product Service 12 December 2002Chidiebere Samuel OkogwuAún no hay calificaciones

- Technical Information Letter: TIL 1357-2 Ge Energy Services Product Service 15 JULY 2002Documento2 páginasTechnical Information Letter: TIL 1357-2 Ge Energy Services Product Service 15 JULY 2002Chidiebere Samuel OkogwuAún no hay calificaciones

- Kirsty Simone Bonner: Core Competencies and AchievementsDocumento3 páginasKirsty Simone Bonner: Core Competencies and AchievementsChidiebere Samuel OkogwuAún no hay calificaciones

- Technical Information Letter: TIL1365-2 Ge Energy Services Product Service 21 OCTOBER 2002Documento3 páginasTechnical Information Letter: TIL1365-2 Ge Energy Services Product Service 21 OCTOBER 2002Chidiebere Samuel OkogwuAún no hay calificaciones

- Technical Information Letter: PurposeDocumento1 páginaTechnical Information Letter: PurposeChidiebere Samuel OkogwuAún no hay calificaciones

- 1208-3: Changes in Steam Turbine and Generator Parts Corrosion Protection PackagingDocumento3 páginas1208-3: Changes in Steam Turbine and Generator Parts Corrosion Protection PackagingChidiebere Samuel OkogwuAún no hay calificaciones

- Maximum Equivalent Stress Safety ToolDocumento2 páginasMaximum Equivalent Stress Safety ToolDonfack BertrandAún no hay calificaciones

- T-79 4202 Solutions 4Documento4 páginasT-79 4202 Solutions 4bobopowerAún no hay calificaciones

- I Used To Be A Desgin StudentDocumento256 páginasI Used To Be A Desgin StudentMLAún no hay calificaciones

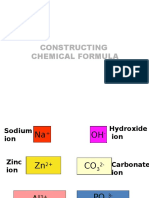

- Chemical EquationsDocumento22 páginasChemical EquationsSiti Norasikin MuhyaddinAún no hay calificaciones

- PDS Class Test 2: Let Us Establish The Pointer From Autumn Break To PDS!!!Documento26 páginasPDS Class Test 2: Let Us Establish The Pointer From Autumn Break To PDS!!!Abhinaba SahaAún no hay calificaciones

- Four Daewoo Motors Ex-Executives Acquitted of Fraud Charges - The Economic TimesDocumento1 páginaFour Daewoo Motors Ex-Executives Acquitted of Fraud Charges - The Economic TimescreateAún no hay calificaciones

- Tri-City Times: Doctors Are in The SchoolhouseDocumento26 páginasTri-City Times: Doctors Are in The SchoolhouseWoodsAún no hay calificaciones

- Bond Pricing and Bond Yield New - 1Documento66 páginasBond Pricing and Bond Yield New - 1Sarang Gupta100% (1)

- Oil and Gas Dessertation TopicsDocumento8 páginasOil and Gas Dessertation TopicsNitin SharmaAún no hay calificaciones

- DD Form 2657 BlankDocumento3 páginasDD Form 2657 BlankdavejschroederAún no hay calificaciones

- 21st CenturyDocumento23 páginas21st CenturyTimmy ValdezAún no hay calificaciones

- Technical Information iTEMP TMT180: Temperature Head Transmitter For Resistance Thermometers Pt100Documento8 páginasTechnical Information iTEMP TMT180: Temperature Head Transmitter For Resistance Thermometers Pt100Muhammad AbdulQaderAún no hay calificaciones

- PA-STARNet Overview and Fact SheetDocumento2 páginasPA-STARNet Overview and Fact SheetDaryl JonesAún no hay calificaciones

- Clay Norris federal criminal complaintDocumento11 páginasClay Norris federal criminal complaintWKYC.comAún no hay calificaciones

- HSE Program 2017 - FinalDocumento12 páginasHSE Program 2017 - FinalAbdul Hamid Tasra100% (2)

- Blinx01's Ultimate DVD Subbing GuideDocumento12 páginasBlinx01's Ultimate DVD Subbing GuideloscanAún no hay calificaciones

- Malhotra 01Documento30 páginasMalhotra 01adiba10mktAún no hay calificaciones

- 5 - GSR2014 - Full Report - Low Res PDFDocumento216 páginas5 - GSR2014 - Full Report - Low Res PDFPavel VicentiuAún no hay calificaciones

- MAN 6266 - Interview Assignment PDFDocumento2 páginasMAN 6266 - Interview Assignment PDFjoseAún no hay calificaciones

- Goodyear Aviation: Data BookDocumento22 páginasGoodyear Aviation: Data BookBien NguyenAún no hay calificaciones

- Nur Shazleen Afina 2021794579 Forum DiscussionDocumento4 páginasNur Shazleen Afina 2021794579 Forum DiscussionNur Shazleen AfinaAún no hay calificaciones

- Final Thesis For Blocking Social Media SitesDocumento15 páginasFinal Thesis For Blocking Social Media SitesRhoebieAún no hay calificaciones

- Calibers InfotechDocumento6 páginasCalibers InfotechshitalAún no hay calificaciones

- Peter Drucker - The EconomistDocumento3 páginasPeter Drucker - The EconomistDz KAún no hay calificaciones

- Cambium PTP 250 Series 02-14 System Release NoteDocumento6 páginasCambium PTP 250 Series 02-14 System Release NotemensoAún no hay calificaciones

- Unit 5 - Week 4: Assignment 4Documento4 páginasUnit 5 - Week 4: Assignment 4RITESH NANDANAún no hay calificaciones

- Table of Content - 6279Documento4 páginasTable of Content - 6279Wing Laam Tam (Bobo)Aún no hay calificaciones

- Fuji Micrex SXDocumento73 páginasFuji Micrex SXRetno WulandariAún no hay calificaciones

- CSS2 DLL Week 4Documento4 páginasCSS2 DLL Week 4May Ann ComitanAún no hay calificaciones

- TDS - 2 Pack PU Clear Sealer - Exterior (F92N0ECS)Documento2 páginasTDS - 2 Pack PU Clear Sealer - Exterior (F92N0ECS)Krishna Vacha100% (1)