Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Scanlight at Pre Commissioning Check List 21lft33359

Cargado por

Cesar GomezDescripción original:

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Scanlight at Pre Commissioning Check List 21lft33359

Cargado por

Cesar GomezCopyright:

Formatos disponibles

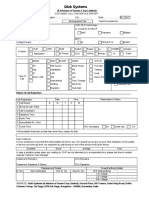

AT

PRE-COMMISSIONING

CHECK

PRE-COMMISSIONING

CHECK

LIST LIST

Scanlight AT

i A digital version of this document is available to download

and submit online at www.thorlux.com/commissioning

To secure your preferred commissioning date please

complete this form and email to siteservices@thorlux.co.uk CANCELLATIONS

If the commissioning date is cancelled at under five

Alternatively fax it to the Site Services Department working days notice a charge of £250 will be made

on 01527 584177

SITE DETAILS

PROJECT

COMPANY ADDRESS

TELEPHONE

POST CODE

SITE CONTACT

NAME TELEPHONE

DETAILS OF WHO IS REQUESTING COMMISSIONING

This information is important so that we know who to contact to advise visit dates, give progress reports/report issues to and

successful completion of our visit. Please complete all sections. Failure to do so will result in a delay booking your visit.

NAME ADDRESS

JOB TITLE

COMPANY

TELEPHONE POST CODE

MOBILE

21LFT 33359 Issue 2 - Page 1 of 5 F571 Jul. 17

AT PRE-COMMISSIONING

CHECK LIST

COMMISSIONING PRE-REQUISITES

• All Scanlight AT emergency fittings must be installed and powered for a minimum 51 hours uninterrupted supply.

• For Platform 3 the Scanlight AT control panel must be powered and connected to DDUs via CANbus cabling connections.

• Care must be taken with the polarity of the CANbus cabling see installation leaflets for details.

SITE INFORMATION

Preferred commissioning date Have any existing Scanlight AT zones been modified during

this installation?

YES NO

What is the floor to ceiling height?

Are new zones being connected to an existing Scanlight AT panel?

FROM TO

YES NO

What are the site working hours?

Is parking available on site?

FROM TO

Is special permission to work beyond these hours required?

YES NO

What is the site handover date?

If YES, how is this authorised?

Is a site safety induction briefing required?

Have lighting layout drawings been supplied by Thorlux?

YES NO

YES NO

If NO, a clean copy of the as-installed drawings will be required by the If YES, how is this arranged?

Commissioning Engineer for notation and record keeping purposes

PERSONAL PROTECTION EQUIPMENT REQUIRED ON SITE

Hard hat Ear defenders High visibility jacket

Safety boots Eye protection Gloves

Other

21LFT 33359 Issue 2 - Page 2 of 5 F571 Jul. 17

AT PRE-COMMISSIONING

CHECK LIST

CONTROL PANEL UPLOAD RATE

Please select how often you would like to be informed of the emergency lighting status.

14 = 14 days as standard Other

FAULTY FITTINGS

It is not possible for our engineers to carry spares for every luminaire in our range. Please list below the quantity, catalogue number

and the nature of fault i.e. no operation so that we can bring the exact spare/items required.

CAT. NO. CAT. NO. CAT. NO.

QUANTITY QUANTITY QUANTITY

FAULT FAULT FAULT

DELIVERIES

Please list outstanding items.

CAT. NO. CAT. NO. CAT. NO.

QUANTITY QUANTITY QUANTITY

21LFT 33359 Issue 2 - Page 3 of 5 F571 Jul. 17

AT PRE-COMMISSIONING

CHECK LIST

CHECKLIST

As fitted drawings to be provided by the installing contractor

clearly showing fitting(s) locations, CANbus route between at panel and DDU’s.

ALL FITTINGS MUST BE LEFT POWERED FOR MIN 51 HOUR PERIOD PRIOR TO COMMISSIONING.

• 24 hour charge from power up

• 3 hour recorded duration discharge for all fittings (after 24 hour charge)

• 24 hour recharge

DALI:

• 2 core communication to ALL fittings

• Voltage is 16v + - 6.5 VDC

• Non polarity sensitive

• Wired in radial

• Should never form ring circuit

• Max 30 fittings per circuit

• To check DALI communication prior to commissioning switch the ZRS key switch, all connected luminaires will illuminate for 30 seconds.

CAN BUS:

• Polarity sensitive

• High/Low must be followed

• Wired in series from AT panel with 1 end of line

Mains local

sub-circuit 1

LED Control Unit

Maximum

DALI and mains

64 devices

on first zone

Circuit

DALI Spur Unit

LED

AT Controller Downlighter

DALI to with LED test

3A unswitched next Spur Unit indicators

fused supply

Mains local

DALI sub-circuit 2

LED Control Unit

Distribution

Central control for Unit Maximum

whole building DALI and mains

30 luminaires

per zone

DALI Circuit

Spur Unit

Transmits test

results to the LED

Scanlight AT Downlighter

monitoring

website

with LED test

indicators

Sends e-mails

of test reports

to authorised

personnel

Zonal

Report DALI to

Switch next Spur Unit

2-core CANbus

to other DDU’s

21LFT 33359 Issue 2 - Page 4 of 5 F571 Jul. 17

AT PRE-COMMISSIONING

CHECK LIST

USER REGISTRATION REQUEST

COMPANY E-MAIL

TITLE TELEPHONE

FIRST NAME ADDRESS

SURNAME

JOB TITLE

PASSWORD POST CODE

E-mail notification if site status green - Healthy

YES NO

E-mail notification if site status red - Fault

YES NO

SCANLIGHT AT INDICATORS

FAULT ELP TRIDONIC MACKWELL

Green LED - ON

Normal mode Green LED - ON Green LED - ON

(Pulses every 10 seconds)

Commissioning Green LED - slow flash Green LED - ON Green LED - slow flash

Function test Green LED - fast flash Green LED - fast flash Green LED - fast flash

Duration test Green LED - slow flash Green LED - slow flash Green LED - slow flash

Lamp fault/open circuit/

Red LED - ON Red LED - ON Red LED - fast flash

short circuit

Battery fault Red LED - slow flash Red LED - slow flash Red LED - slow flash

Charge fault/Circuit fault Red LED - fast flash Red LED - fast flash Red LED - fast flash

Emergency mode LED OFF LED OFF LED OFF

Identification Red/Green LED - slow flash Red/Green LED - slow flash Red/Green LED - slow flash

PLEASE BE ADVISED IF OUR ENGINEERS ATTEND SITE

AND ARE UNABLE TO COMPLETE THEIR TASKS DUE

TO INCOMPLETE INSTALLATIONS, DAMAGED FITTINGS

OR CONTROLS, ALL ADDITIONAL VISITS AND/OR

COMPONENTS WILL BE CHARGED FOR

21LFT 33359 Issue 2 - Page 5 of 5 F571 Jul. 17

También podría gustarte

- Smart Pre Commissioning Check ListDocumento9 páginasSmart Pre Commissioning Check Listaaktgt MepAún no hay calificaciones

- IBG Command Reference, Vol 2 PDFDocumento1380 páginasIBG Command Reference, Vol 2 PDFGranite NOCAún no hay calificaciones

- Ministry of Interior Project: Inspection / Test Sheet CCTV System EW-01BDocumento3 páginasMinistry of Interior Project: Inspection / Test Sheet CCTV System EW-01BPERVEZ AHMAD KHANAún no hay calificaciones

- SCC PIW SD PE Taman Salmon SG BulohDocumento4 páginasSCC PIW SD PE Taman Salmon SG BulohJohan RamliAún no hay calificaciones

- O&m Manual ElectricalDocumento254 páginasO&m Manual Electricalahmed elalfy100% (2)

- 3670-BQ-DOCS-164 - 01 PA System TPDocumento20 páginas3670-BQ-DOCS-164 - 01 PA System TPBookmarks On ChromeAún no hay calificaciones

- SX-200 ML PABX Lightware 16 Volume 1Documento546 páginasSX-200 ML PABX Lightware 16 Volume 1Juan RiveraAún no hay calificaciones

- Mobilink Project On Site Swap SOPDocumento17 páginasMobilink Project On Site Swap SOPAung Min Soe100% (1)

- 10-2476 - Bosch D9068 5 Zone DACTDocumento64 páginas10-2476 - Bosch D9068 5 Zone DACTmajed al.madhajiAún no hay calificaciones

- Proposed Electrical Installation For Low Voltage Switchgear Communication Authority of KenyaDocumento21 páginasProposed Electrical Installation For Low Voltage Switchgear Communication Authority of Kenyahaider ahmedAún no hay calificaciones

- Verilink QUAD/IMUX User Manual: September 1999 P/N 880-502392-001-B1Documento91 páginasVerilink QUAD/IMUX User Manual: September 1999 P/N 880-502392-001-B1G MonetteAún no hay calificaciones

- IBTS Solar PV System Inspection Checklist 4Documento10 páginasIBTS Solar PV System Inspection Checklist 4Ebrahim MohamedAún no hay calificaciones

- CCL 108sg PBXDocumento13 páginasCCL 108sg PBXpratipAún no hay calificaciones

- Popular Electronics 1982 08Documento100 páginasPopular Electronics 1982 08Benjamin DoverAún no hay calificaciones

- Checklist For Structured Cabling System & Accessories InstallationDocumento1 páginaChecklist For Structured Cabling System & Accessories InstallationInfas YahyaAún no hay calificaciones

- Acceptance Test For BTSDocumento2 páginasAcceptance Test For BTSrngwena100% (1)

- Pre-Commissioning Checklist: Site Address / Details: EngineerDocumento2 páginasPre-Commissioning Checklist: Site Address / Details: Engineerariadi supriyantoAún no hay calificaciones

- TW5201 Remote Control Unit - Operators ManualDocumento20 páginasTW5201 Remote Control Unit - Operators ManualAlexander J RokowetzAún no hay calificaciones

- 579-716 4008 InstallationDocumento82 páginas579-716 4008 InstallationMohamed RizkAún no hay calificaciones

- CCR FormatDocumento1 páginaCCR FormatchrisAún no hay calificaciones

- Site/Equipment Audit Report: No. Description Result RemarksDocumento2 páginasSite/Equipment Audit Report: No. Description Result RemarksHammadAlviAún no hay calificaciones

- RoomCast - Installation Guide - V3.0Documento31 páginasRoomCast - Installation Guide - V3.0drone meiAún no hay calificaciones

- NT9005 v1-0 IM SP NA 29034514 R003 PDFDocumento68 páginasNT9005 v1-0 IM SP NA 29034514 R003 PDFSantamaria JamesAún no hay calificaciones

- Panel Simplex 2008Documento86 páginasPanel Simplex 2008JhonyLazoAún no hay calificaciones

- Rca Rs2656 Manual de UsuarioDocumento13 páginasRca Rs2656 Manual de UsuarioDarwin GironAún no hay calificaciones

- Jiuzhou dtt1609 Service Manual PDFDocumento44 páginasJiuzhou dtt1609 Service Manual PDFVishu JoshiAún no hay calificaciones

- Application For Service - Electrical Works Request (EWR) For New and Existing InstallationsDocumento1 páginaApplication For Service - Electrical Works Request (EWR) For New and Existing Installationssaururja saururjaAún no hay calificaciones

- 6 VSAT Installation and MaintenanceDocumento28 páginas6 VSAT Installation and MaintenanceAhmed EJAún no hay calificaciones

- VLP39++ Owners GuideDocumento96 páginasVLP39++ Owners GuideHarold PolkaAún no hay calificaciones

- SR - Maran Canopus - 4009 - WavecallDocumento17 páginasSR - Maran Canopus - 4009 - Wavecallsecui marianAún no hay calificaciones

- G69173-D1001-Y965 - Protocolo SAT VFDs Sinamics G120 - REV1Documento4 páginasG69173-D1001-Y965 - Protocolo SAT VFDs Sinamics G120 - REV1Adriana UstarizAún no hay calificaciones

- Hands On 1986 01 02Documento100 páginasHands On 1986 01 02RAUL RENDONAún no hay calificaciones

- Adept Status Code Summary For Embedded Products: Common Two-Digit Status CodesDocumento16 páginasAdept Status Code Summary For Embedded Products: Common Two-Digit Status CodesJavier MiramontesAún no hay calificaciones

- TK-780 (E - E3) Revised - B51-8523-10Documento66 páginasTK-780 (E - E3) Revised - B51-8523-10Gerardo HernándezAún no hay calificaciones

- 3G SSV & Cluster DT Training: Prepared By: Syed Raza Hasnain s80011117Documento30 páginas3G SSV & Cluster DT Training: Prepared By: Syed Raza Hasnain s80011117RAMIAún no hay calificaciones

- CELCOM - FTV - SSO - V1 84 - REGION - CLUSTER - NEWSITENAME - Rev 3 - Capacity UpgradeDocumento157 páginasCELCOM - FTV - SSO - V1 84 - REGION - CLUSTER - NEWSITENAME - Rev 3 - Capacity UpgradeRyan RacunAún no hay calificaciones

- Centillion 1200N Atm Switch Command Manual: Broadband STPDocumento316 páginasCentillion 1200N Atm Switch Command Manual: Broadband STPhungpm2013Aún no hay calificaciones

- Eaton Afdd Appl Guide Brochure Br003016en en UsDocumento7 páginasEaton Afdd Appl Guide Brochure Br003016en en UsMardiansyah AtrimaAún no hay calificaciones

- Dahua Ip Solar 4G Network Camera - Infiniteoptions Inc.Documento2 páginasDahua Ip Solar 4G Network Camera - Infiniteoptions Inc.Maria TheresaAún no hay calificaciones

- NXR-900/ NXR-901: Instruction Manual Mode D'EmploiDocumento8 páginasNXR-900/ NXR-901: Instruction Manual Mode D'EmploiSaymon GrauppeAún no hay calificaciones

- Day 2 1445 Alvaro SanchezDocumento16 páginasDay 2 1445 Alvaro SanchezJCARLOS COLQUEAún no hay calificaciones

- VSAT Installation and Maintenance 1Documento28 páginasVSAT Installation and Maintenance 1yonasAún no hay calificaciones

- ADJ Encore Burst 100 IP User ManualDocumento22 páginasADJ Encore Burst 100 IP User ManualAsistente Alcaldia QuetzaltenangoAún no hay calificaciones

- NIT - SaharanpurDocumento29 páginasNIT - SaharanpurLimitless PritamAún no hay calificaciones

- TK 880 SVC Man Rev e PDFDocumento75 páginasTK 880 SVC Man Rev e PDFstefanVasAún no hay calificaciones

- Módulo de Control Asistido Por Voz - ESCORT - VPM-1 - ESP PDFDocumento20 páginasMódulo de Control Asistido Por Voz - ESCORT - VPM-1 - ESP PDFHesams EnamoradoAún no hay calificaciones

- EN Fire Communicator: Operation and Installation GuideDocumento68 páginasEN Fire Communicator: Operation and Installation GuideRobAún no hay calificaciones

- Epbx User Manual 308Documento12 páginasEpbx User Manual 308Talha SaitAún no hay calificaciones

- R03 SA-DACT Dialer Installation SheetDocumento8 páginasR03 SA-DACT Dialer Installation SheetDiegoAún no hay calificaciones

- DRM/S T Acting For and On Behalf of The President of India Invites E-Tenders Against Tender No N-539-2-OT-19-20-39 ClosingDocumento32 páginasDRM/S T Acting For and On Behalf of The President of India Invites E-Tenders Against Tender No N-539-2-OT-19-20-39 ClosingArmaan MalikAún no hay calificaciones

- Docs 3Documento21 páginasDocs 3MD. Mazidul Islam MahfujAún no hay calificaciones

- Pre Order Contract Review /enquiry No.: Infused Systems PVT LTDDocumento3 páginasPre Order Contract Review /enquiry No.: Infused Systems PVT LTDSales Infused SystemsAún no hay calificaciones

- Site Acceptance Testing For New Insatllation Activtiy: Sector Addition TDD SRA N FDD 2G Sector AdditionDocumento20 páginasSite Acceptance Testing For New Insatllation Activtiy: Sector Addition TDD SRA N FDD 2G Sector AdditionkrishkarnAún no hay calificaciones

- Checklist Ver3 - For Engg. DeputationDocumento6 páginasChecklist Ver3 - For Engg. Deputationveera chaitanyaAún no hay calificaciones

- RF Planning Instroduce V1.0Documento22 páginasRF Planning Instroduce V1.0Khang TrầnAún no hay calificaciones

- 08 GULN ZXRAN Base Station TroubleshootingDocumento39 páginas08 GULN ZXRAN Base Station Troubleshootinga2227 jglAún no hay calificaciones

- JLN-652 Installation Manual PDFDocumento52 páginasJLN-652 Installation Manual PDFal nakheel electronicsAún no hay calificaciones

- VTU Important SyllabusDocumento115 páginasVTU Important SyllabusDan HawkAún no hay calificaciones

- Electrical - Diagramm Bell Piston ProverDocumento42 páginasElectrical - Diagramm Bell Piston ProverBragutaAlexandruAún no hay calificaciones

- Experiment 1 WLF Water Flow MeasurementDocumento4 páginasExperiment 1 WLF Water Flow MeasurementKH200 73NG LIHUAAún no hay calificaciones

- A Multi Phase Harmonic Load Flow Solution TechniqueDocumento9 páginasA Multi Phase Harmonic Load Flow Solution TechniquerameshpampanaAún no hay calificaciones

- Bose Companion 5 Satellite Speaker Connector ReplaDocumento33 páginasBose Companion 5 Satellite Speaker Connector ReplamanojAún no hay calificaciones

- HM 71 T4 (A2:6) 2,2kW 25º: General DataDocumento4 páginasHM 71 T4 (A2:6) 2,2kW 25º: General Dataaqil khanAún no hay calificaciones

- Machine Condition Monitoring: Best Practice CatalogDocumento19 páginasMachine Condition Monitoring: Best Practice CatalogMarco Bertoldi100% (1)

- Electric Field To Gauss LawDocumento24 páginasElectric Field To Gauss LawMarl Allen ReyesAún no hay calificaciones

- BeoSound Ouverture EnglishDocumento44 páginasBeoSound Ouverture EnglishBenji PriceAún no hay calificaciones

- Simulation of 300 MVA Transformer Energization in New Substation 400/110 KV ''Ernestinovo'' Using ATP-EMTPDocumento10 páginasSimulation of 300 MVA Transformer Energization in New Substation 400/110 KV ''Ernestinovo'' Using ATP-EMTPgilbertomjcAún no hay calificaciones

- Zoom 606Documento21 páginasZoom 606washington.guitarAún no hay calificaciones

- En - ku990r Svc Eng - 080611 Не Нужные Водяные ЗнакиDocumento225 páginasEn - ku990r Svc Eng - 080611 Не Нужные Водяные ЗнакиMaxAllgeruAún no hay calificaciones

- Balanza SpiderDocumento333 páginasBalanza SpiderMadison MadisonAún no hay calificaciones

- Computer Engineering: Computer Engineering Electronic Devices For Ubiquitous Computing OptionDocumento2 páginasComputer Engineering: Computer Engineering Electronic Devices For Ubiquitous Computing OptionAbiy BerheAún no hay calificaciones

- Krein, Philip T. - Elements of Power Electronics-Oxford University Press (1998) PDFDocumento747 páginasKrein, Philip T. - Elements of Power Electronics-Oxford University Press (1998) PDFMohammad Samer88% (8)

- Telecommunication & Computer Networks: Introduction To Information and Communication TechnologyDocumento17 páginasTelecommunication & Computer Networks: Introduction To Information and Communication TechnologySaba SaherAún no hay calificaciones

- 12 VG 40Documento1 página12 VG 40yogeshroshanAún no hay calificaciones

- 4364 Ie3 Fs 90 180 MM Manual enDocumento34 páginas4364 Ie3 Fs 90 180 MM Manual enSilviu TichieruAún no hay calificaciones

- Reactive Power Compensation Using Capacitor BanksDocumento82 páginasReactive Power Compensation Using Capacitor BanksJustus Onderi MomanyiAún no hay calificaciones

- US200 User ManualDocumento145 páginasUS200 User ManualMoogii MonhAún no hay calificaciones

- M 05 BIST0504Documento90 páginasM 05 BIST0504Darshan HarishAún no hay calificaciones

- APFC Panel 23.06.23Documento11 páginasAPFC Panel 23.06.23rambhool singh ChohanAún no hay calificaciones

- APsystems Microinverter YC600 Y For USA User Manual - Rev1.3 - 2018 8 20Documento26 páginasAPsystems Microinverter YC600 Y For USA User Manual - Rev1.3 - 2018 8 20Diego LimaAún no hay calificaciones

- Cj-Hdr216a Hdr416a Quick Start Guide v1.0.0Documento54 páginasCj-Hdr216a Hdr416a Quick Start Guide v1.0.0Bsm GwapuAún no hay calificaciones

- MCCB & AcbDocumento42 páginasMCCB & AcbSandeep MenonAún no hay calificaciones

- Hartke A35 Manuel Utilisateur en 40765 PDFDocumento16 páginasHartke A35 Manuel Utilisateur en 40765 PDFjackniainaAún no hay calificaciones

- PHILIPPINE ELECTRONICS CODE BOOK 2 Chapter 3 and 4Documento4 páginasPHILIPPINE ELECTRONICS CODE BOOK 2 Chapter 3 and 4Jerome Carlo Villanueva100% (1)

- HSSN AssignmentDocumento23 páginasHSSN AssignmentChungMing LingAún no hay calificaciones

- Patent Search & Analysis Report (PSAR)Documento4 páginasPatent Search & Analysis Report (PSAR)mickyvirusAún no hay calificaciones

- Ijest10 02 12 191Documento4 páginasIjest10 02 12 191wwahib2Aún no hay calificaciones