Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Wa0001

Cargado por

Dilin DineshTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Wa0001

Cargado por

Dilin DineshCopyright:

Formatos disponibles

1

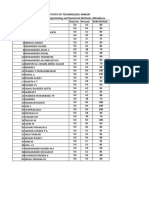

List of Experiments

Experiments Page N0

1) A Transportation problem using Excel Solver……………………………………………………….03

2) An Assignment Problem using Excel Solver………………………………………………………….07

3) A Transportation problem using LINGO……………………………………………………………..…11

4) An Assignment Problem using LINGO…………………………………………………………………..14

5) Bisection Method C program………………………………………………………………………………….17

6) Runge-Kutta method-C program…………………………………………………………………………...19

7) Stress Analysis of cantilever beam using solid works……………………………………..….…..21

8) Flow Analysis using Solid Works……………………………………………………………………....…..23

Computational Lab Record Malabar Institute of Technology, Anjarakandy

2

Computational Lab Record Malabar Institute of Technology, Anjarakandy

3

Experiment No: Date:

A TRANSPORTATION PROBLEM USING EXCEL SOLVER

Aim:

To solve a transportation problem using Microsoft Excel Solver.

Problem Description:

A company has three cement factories F1, F2 and F3 which supply cement to four projects

sites locatedin towns 1, 2, 3 and 4. Each plant can supply 6,1,10 truckloads of cements daily

respectively and the daily cement requirements of the projects are respectively 7,5,3,2

truckloads. The transportation costsper truck load of cement (inhundreds of rupees) from

each plant to each project site are as follows:

Project 1 Project 2 Project 3 Project 4

Factory 1 2 3 11 7

Factory 2 1 0 6 1

Factory 3 5 8 15 9

Procedure:

1) Open Microsoft Excel.

2) If the solver add-in is not enabled in your office suit enable it by going to

File>Options>Add-ins>Manage> Excel Add-ins> Solver Add-in.

3) Restart the Microsoft Excel.

4) Create the cost matrix in Excel sheet as shown in the figure.

5) Create the solution matrix as shown in figure

Computational Lab Record Malabar Institute of Technology, Anjarakandy

4

6) Goto Data> Solver and set solver parameters.

Set target cell :Select the objective function cell

Equal To : Min

By Changing Cells : Select the solution matrix cells

Subject to constraints : Add demand and supply constraints

7) Set options as assume ‘Linear model’ and assume ‘Non negative’

8) Solve and generate the answer.

Computational Lab Record Malabar Institute of Technology, Anjarakandy

5

Results:

Microsoft Excel 14.0 Answer Report

Worksheet: [TRANSPORTATION.xlsx]Sheet1

Report Created: 03-09-2014 14:28:25

Result: Solver found a solution. All Constraints and optimality conditions are satisfied.

Solver Engine

Engine: Simplex LP

Solution Time: 0.016 Seconds.

Iterations: 10 Subproblems: 0

Solver Options

Max Time Unlimited, Iterations Unlimited, Precision 0.000001, Use Automatic Scaling

Max Subproblems Unlimited, Max Integer Sols Unlimited, Integer Tolerance 1%, Assume NonNegative

Objective Cell (Min)

Cell Name Original Value Final Value

$G$15 Supply 100 100

Variable Cells

Cell Name Original Value Final Value Integer

$C$12 Factory 2 Project 1 0 0 Contin

$D$12 Factory 2 Project 2 5 5 Contin

$E$12 Factory 2 Project 3 1 1 Contin

$F$12 Factory 2 Project 4 0 0 Contin

$C$13 Factory 3 Project 1 0 0 Contin

$D$13 Factory 3 Project 2 0 0 Contin

$E$13 Factory 3 Project 3 1 1 Contin

Computational Lab Record Malabar Institute of Technology, Anjarakandy

6

$F$13 Factory 3 Project 4 0 0 Contin

$C$14 Factory 4 Project 1 7 7 Contin

$D$14 Factory 4 Project 2 0 0 Contin

$E$14 Factory 4 Project 3 1 1 Contin

$F$14 Factory 4 Project 4 2 2 Contin

Constraints

Cell Name Cell Value Formula Status Slack

$C$15 Project 1 7 $C$15=$C$7 Binding 0

$D$15 Project 2 5 $D$15=$D$7 Binding 0

$E$15 Project 3 3 $E$15=$E$7 Binding 0

$F$15 Project 4 2 $F$15=$F$7 Binding 0

$G$12 Factory 2 Supply 6 $G$12=$G$4 Binding 0

$G$13 Factory 3 Supply 1 $G$13=$G$5 Binding 0

$G$14 Factory 4 Supply 10 $G$14=$G$6 Binding 0

Computational Lab Record Malabar Institute of Technology, Anjarakandy

7

Experiment No: Date:

AN ASSIGNMENT PROBLEM USING EXCEL SOLVER

Aim:

To solve an assignment problem using Microsoft Excel Solver.

Problem Description:

Four jobs are to be done on four different machines. The cost (in rupees) of producing ‘i’th

job on ‘j’th machine is given below.

Machine 1 Machine 2 Machine 3 Machine 4

Jobs 1 15 11 13 15

Jobs 2 17 12 12 13

Jobs 3 14 15 10 14

Jobs 4 16 13 11 17

Procedure:

1) Open Microsoft Excel.

2) If the solver add-in is not enabled in your office suit enable it by going to

File>Options>Add-ins>Manage> Excel Add-ins> Solver Add-in.

3) Restart the Microsoft Excel.

4) Create the cost matrix in Excel sheet as shown in the figure.

5) Create the solution matrix as shown in figure

Computational Lab Record Malabar Institute of Technology, Anjarakandy

8

6) Goto Data> Solver and set solver parameters.

Set objective : Select the objective function cell

To : Min

By Changing Variable Cells : Select the solution matrix cells

Subject to constraints : Add demand and supply constraints

7) Solve.

Computational Lab Record Malabar Institute of Technology, Anjarakandy

9

Results:

Microsoft Excel 14.0 Answer Report

Worksheet: [TRANSPORTATION.xlsx]Sheet2

Report Created: 20-08-2014 14:45:03

Result: Solver found a solution. All Constraints and optimality conditions are satisfied.

Solver Engine

Engine: GRG Nonlinear

Solution Time: 0.156 Seconds.

Iterations: 10 Subproblems: 0

Solver Options

Max Time Unlimited, Iterations Unlimited, Precision 0.000001, Use Automatic Scaling

Convergence 0.0001, Population Size 100, Random Seed 0, Derivatives Forward, Require Bounds

Max Subproblems Unlimited, Max Integer Sols Unlimited, Integer Tolerance 1%, Assume NonNegative

Objective Cell (Min)

Original

Cell Name Value Final Value

$G$17 0 49

Variable Cells

Original

Cell Name Value Final Value Integer

$C$13 Jobs 1 Machine 1 0 0 Contin

$D$13 Jobs 1 Machine 2 0 1 Contin

$E$13 Jobs 1 Machine 3 0 0 Contin

Computational Lab Record Malabar Institute of Technology, Anjarakandy

10

$F$13 Jobs 1 Machine 4 0 0 Contin

$C$14 Jobs 2 Machine 1 0 0 Contin

$D$14 Jobs 2 Machine 2 0 0 Contin

$E$14 Jobs 2 Machine 3 0 0 Contin

$F$14 Jobs 2 Machine 4 0 1 Contin

$C$15 Jobs 3 Machine 1 0 1 Contin

$D$15 Jobs 3 Machine 2 0 0 Contin

$E$15 Jobs 3 Machine 3 0 0 Contin

$F$15 Jobs 3 Machine 4 0 0 Contin

$C$16 Jobs 4 Machine 1 0 0 Contin

$D$16 Jobs 4 Machine 2 0 0 Contin

$E$16 Jobs 4 Machine 3 0 1 Contin

$F$16 Jobs 4 Machine 4 0 0 Contin

Constraints

Cell Name Cell Value Formula Status Slack

$C$17 Machine 1 1 $C$17=$C$19 Binding 0

$D$17 Machine 2 1 $D$17=$D$19 Binding 0

$E$17 Machine 3 1 $E$17=$E$19 Binding 0

$F$17 Machine 4 1 $F$17=$F$19 Binding 0

$G$13 Jobs 1 1 $G$13=$I$13 Binding 0

$G$14 Jobs 2 1 $G$14=$I$14 Binding 0

$G$15 Jobs 3 1 $G$15=$I$15 Binding 0

$G$16 Jobs 4 1 $G$16=$I$16 Binding 0

Computational Lab Record Malabar Institute of Technology, Anjarakandy

11

Experiment No: Date:

A TRANSPORTATION PROBLEM USING LINGO

Aim:

To solve a transportation problem, using lingo optimization software.

Problem Description

A company has three cement factories F1, F2 and F3 which supply cement to four projects

sites locatedin towns 1, 2, 3 and 4. Each plant can supply 6,1,10 truckloads of cements daily

respectively and the daily cement requirements of the projects are respectively 7,5,3,2

truckloads. The transportation costsper truck load of cement (inhundreds of rupees) from

each plant to each project site are as follows:

Project 1 Project 2 Project 3 Project 4

Factory 1 2 3 11 7

Factory 2 1 0 6 1

Factory 3 5 8 15 9

Lingo Model

SETS:

FACTORY: SUPPLY;

WAREHOUSE: DEMAND;

SHIPLINKS (FACTORY, WAREHOUSE): COST,VOLUME;

ENDSETS

DATA:

FACTORY=F1..F3;

WAREHOUSE=W1,W2,W3,W4;

SUPPLY=6 1 10;

DEMAND=7 5 3 2;

COST= 2 3 11 7

1 0 6 1

5 8 15 9;

ENDDATA

!Objective Function;

MIN= @SUM(SHIPLINKS(I,J):COST(I,J)*VOLUME(I,J));

!Demand Constraint;

@FOR(WAREHOUSE(J):@SUM(FACTORY(I):VOLUME(I,J))= DEMAND(J));

Computational Lab Record Malabar Institute of Technology, Anjarakandy

12

!Supply Constraint;

@FOR(FACTORY(I):@SUM(WAREHOUSE(J):VOLUME(I,J))= SUPPLY(I));

Results:

Global optimal solution found.

Objective value: 100.0000

Infeasibilities: 0.000000

Total solver iterations: 10

Elapsed runtime seconds: 0.08

Model Class: LP

Total variables: 12

Nonlinear variables: 0

Integer variables: 0

Total constraints: 8

Nonlinear constraints: 0

Total nonzeros: 35

Nonlinear nonzeros: 0

Variable Value

Reduced Cost

SUPPLY( F1) 6.000000 0.000000

SUPPLY( F2) 1.000000 0.000000

SUPPLY( F3) 10.00000 0.000000

DEMAND( W1) 7.000000 0.000000

DEMAND( W2) 5.000000 0.000000

DEMAND( W3) 3.000000 0.000000

DEMAND( W4) 2.000000 0.000000

COST( F1, W1) 2.000000 0.000000

COST( F1, W2) 3.000000 0.000000

COST( F1, W3) 11.00000 0.000000

COST( F1, W4) 7.000000 0.000000

COST( F2, W1) 1.000000 0.000000

COST( F2, W2) 0.000000 0.000000

COST( F2, W3) 6.000000 0.000000

COST( F2, W4) 1.000000 0.000000

COST( F3, W1) 5.000000 0.000000

COST( F3, W2) 8.000000 0.000000

COST( F3, W3) 15.00000 0.000000

COST( F3, W4) 9.000000 0.000000

VOLUME( F1, W1) 0.000000 1.000000

VOLUME( F1, W2) 5.000000 0.000000

VOLUME( F1, W3) 1.000000 0.000000

VOLUME( F1, W4) 0.000000 2.000000

VOLUME( F2, W1) 0.000000 5.000000

VOLUME( F2, W2) 0.000000 2.000000

VOLUME( F2, W3) 1.000000 0.000000

VOLUME( F2, W4) 0.000000 1.000000

Computational Lab Record Malabar Institute of Technology, Anjarakandy

13

VOLUME( F3, W1) 7.000000 0.000000

VOLUME( F3, W2) 0.000000 1.000000

VOLUME( F3, W3) 1.000000 0.000000

VOLUME( F3, W4) 2.000000 0.000000

Row Slack or Surplus

Dual Price

1 100.0000

-1.000000

2 0.000000

4.000000

3 0.000000

2.000000

4 0.000000

-6.000000

5 0.000000

0.000000

6 0.000000

-5.000000

7 0.000000

0.000000

8 0.000000

-9.000000

Computational Lab Record Malabar Institute of Technology, Anjarakandy

14

Experiment No: Date:

AN ASSIGNMENT PROBLEM USING LINGO

Aim:

To solve an assignment problem using lingo.

Problem Description

Four jobs are to be done on four different machines. The cost (in rupees) of producing ‘i’th

job on ‘j’th machine is given below.

Machine 1 Machine 2 Machine 3 Machine 4

Jobs 1 15 11 13 15

Jobs 2 17 12 12 13

Jobs 3 14 15 10 14

Jobs 4 16 13 11 17

Lingo Model:

SETS:

MACHINE:REQ;

JOBS:ASSIGN;

ALLOCATIONS(MACHINE,JOBS):COST, ALLOC;

ENDSETS

DATA:

MACHINE=M1..M4;

REQ=1 1 1 1;

JOBS=JOBS1..JOBS4;

ASSIGN=1 1 1 1;

COST= 15 11 13 15

17 12 12 13

14 15 10 14

16 13 11 17;

ENDDATA

!Objetive function;

MIN= @SUM(ALLOCATIONS(I,J): COST(I,J)*ALLOC(I,J));

!Constraints;

@FOR(MACHINE(I):@SUM(JOBS(J):ALLOC(I,J))=1);

@FOR(JOBS(J):@SUM(MACHINE(I):ALLOC(I,J))=1);

Computational Lab Record Malabar Institute of Technology, Anjarakandy

15

Results:

Global optimal solution found.

Objective value: 49.00000

Infeasibilities: 0.000000

Total solver iterations: 7

Elapsed runtime seconds: 0.06

Model Class: LP

Total variables: 16

Nonlinear variables: 0

Integer variables: 0

Total constraints: 9

Nonlinear constraints: 0

Total nonzeros: 48

Nonlinear nonzeros: 0

Variable Value

Reduced Cost

REQ( M1) 1.000000 0.000000

REQ( M2) 1.000000 0.000000

REQ( M3) 1.000000 0.000000

REQ( M4) 1.000000 0.000000

ASSIGN( JOBS1) 1.000000 0.000000

ASSIGN( JOBS2) 1.000000 0.000000

ASSIGN( JOBS3) 1.000000 0.000000

ASSIGN( JOBS4) 1.000000 0.000000

COST( M1, JOBS1) 15.00000 0.000000

COST( M1, JOBS2) 11.00000 0.000000

COST( M1, JOBS3) 13.00000 0.000000

COST( M1, JOBS4) 15.00000 0.000000

COST( M2, JOBS1) 17.00000 0.000000

COST( M2, JOBS2) 12.00000 0.000000

COST( M2, JOBS3) 12.00000 0.000000

COST( M2, JOBS4) 13.00000 0.000000

COST( M3, JOBS1) 14.00000 0.000000

COST( M3, JOBS2) 15.00000 0.000000

COST( M3, JOBS3) 10.00000 0.000000

COST( M3, JOBS4) 14.00000 0.000000

COST( M4, JOBS1) 16.00000 0.000000

COST( M4, JOBS2) 13.00000 0.000000

COST( M4, JOBS3) 11.00000 0.000000

COST( M4, JOBS4) 17.00000 0.000000

ALLOC( M1, JOBS1) 0.000000 0.000000

ALLOC( M1, JOBS2) 1.000000 0.000000

ALLOC( M1, JOBS3) 0.000000 2.000000

ALLOC( M1, JOBS4) 0.000000 3.000000

ALLOC( M2, JOBS1) 0.000000 1.000000

Computational Lab Record Malabar Institute of Technology, Anjarakandy

16

ALLOC( M2, JOBS2) 0.000000 0.000000

ALLOC( M2, JOBS3) 0.000000 0.000000

ALLOC( M2, JOBS4) 1.000000 0.000000

ALLOC( M3, JOBS1) 1.000000 0.000000

ALLOC( M3, JOBS2) 0.000000 5.000000

ALLOC( M3, JOBS3) 0.000000 0.000000

ALLOC( M3, JOBS4) 0.000000 3.000000

ALLOC( M4, JOBS1) 0.000000 1.000000

ALLOC( M4, JOBS2) 0.000000 2.000000

ALLOC( M4, JOBS3) 1.000000 0.000000

ALLOC( M4, JOBS4) 0.000000 5.000000

Row Slack or Surplus

Dual Price

1 49.00000

-1.000000

2 0.000000

-11.00000

3 0.000000

-12.00000

4 0.000000

-10.00000

5 0.000000

-11.00000

6 0.000000

-4.000000

7 0.000000

0.000000

8 0.000000

0.000000

9 0.000000

-1.000000

Computational Lab Record Malabar Institute of Technology, Anjarakandy

17

Experiment No: Date:

BISECTION METHOD-C PROGRAM

Aim:

To write a program to find the root of an equation using bisecton method.

Problem description:

Find the roots of the equation f(x)=x3 –x-1 lying between 1 and 2, using bisection method.

Procedure:

1) Choose two real numbers x0 and x1 such that f(x0)f(x1)<0

2) Set x2=(x0+x1)/2

3) i) if f(x0)f(x2)<0, the root lies in the interval (x0,x2). Then set x1=x2 and go to the

step 2 above.

4) ii) if f(x0)f(x2) >0, the root lies in the interval (x2,x1). Then set x0=x2 and go to the

step 2 above.

iii) if f(x0)f(x2)=0, it means that x2 is a root of the equation f(x)=0 and the

computation may be terminated

Program

#include<conio.h>

#include<math.h>

#define ESP 0.001

float F(float x)

{

float y=(x*x*x)-x-1;

return(y);

}

void main()

{

int i=1;

float x0,x1,x2;

double f1=0,f2=0,f0=0,t;

printf("\n Enter the value of x0:");

scanf("%f",&x0);

printf("\n Enter the value of x1:");

scanf("%f",&x1);

do

{

x2=(x0+x1)/2;

f0=F(x0);

f1=F(x1);

f2=F(x2);

printf("\n %d %f %f %f %1f %1f %1f",i,x0,x1,x2,f0,f1,f2);

if(f0*f2<0)

{

x1=x2;

Computational Lab Record Malabar Institute of Technology, Anjarakandy

18

}

else

{

x0=x2;

}

i++;

}

while(fabs(f2)>ESP);

printf("\nf2=%f\n",fabs(f2));

printf("\n \n Approx root=%f",x2);

}

Result:

Computational Lab Record Malabar Institute of Technology, Anjarakandy

19

Experiment No: Date:

RUNGE-KUTTA METHOD-C PROGRAM

Aim:

To write a program to find the solution of given differential equation using second

orderRunge-Kutta method.

Problem Description:

Given dy/dx= y-x where y(0)=2, find y(0.1) and y(0.1).

Procedure:

The solution of a differential equation is given by the following formula

y1=y0 +1/2(k1+k2 )

k1 =hf(x0, y0)

k2 =hf(x0 +h, y0 +k1)

1) Obtain the values of ‘x0’,’yo’ and ‘h’

2) Calculate k1 using equation k1 =hf(x0, y0)

3) Calculate k2 using equation k2 =hf(x0 +h, y0 +k1)

4) Calculate y1 using y1=y0 +1/2(k1+k2 ), which is the required solution of differential

equation.

Program:

#include<stdio.h>

#include <math.h>

#include<conio.h>

#define F(x,y) (y)-(x)

void main()

{

double y0,x0,y1,n,h,f,f1,k1,k2;

int j;

clrscr();

printf("\nEnter the value of x0: ");

scanf("%lf",&x0);

printf("\nEnter the value of y0: ");

scanf("%lf",&y0);

printf("\nEnter the value of h: ");

scanf("%lf",&h);

printf("\nEnter the value of last point: ");

scanf("%lf",&n);

for(; x0<n; x0=x0+h)

Computational Lab Record Malabar Institute of Technology, Anjarakandy

20

{

f=F(x0,y0);

k1 = h * f;

f1 = F(x0+h,y0+k1);

k2 = h * f1;

y1 = y0 + ( k1 + k2)/2;

printf("\n\n k1 = %.4lf ",k1);

printf("\n\n k2 = %.4lf ",k2);

printf("\n\n y(%.4lf) = %.3lf ",x0+h,y1);

y0=y1;

}

getch();

}

Results:

Computational Lab Record Malabar Institute of Technology, Anjarakandy

21

Experiment No: Date:

STRESS ANALYSIS OF CANTILEVER BEAM USING SOLID

WORKS

Aim:

To analyze a cantilever beam with uniformly distributed load

Problem definition:

Find the deflection and stress distribution of a cantilever beam of 100mm x50mm

x20mm dimensionscarrying UDL of 50N over its entire length.

Procedure:

1) Create part and save it

Cantilever beam of required dimensions

2) Insert SolidWorks simulation

Select options and click add ins

Select SolidWorks simulation and press ok

3) Select simulation

Click on study adviser and select new study

Select static analysis and click ok

Select apply material

Define material

Select Fixture advisor

Fix boundary conditions

Select external load

Define load

4) Calculations

Select create mesh

Define mesh parameters

Select Run

Solve it

Generate report

Computational Lab Record Malabar Institute of Technology, Anjarakandy

22

Results:

Material Properties

Model Reference Properties Components

Name: Alloy Steel SolidBody 1(Boss-

Model type: Linear Elastic Isotropic Extrude1)(canti)

Default failure Max von Mises Stress

criterion:

Yield strength: 6.20422e+008 N/m^2

Tensile strength: 7.23826e+008 N/m^2

Elastic modulus: 2.1e+011 N/m^2

Poisson's ratio: 0.28

Mass density: 7700 kg/m^3

Shear modulus: 7.9e+010 N/m^2

Thermal expansion 1.3e-005 /Kelvin

coefficient:

Curve Data:N/A

Loads and Fixtures

Fixture name Fixture Image Fixture Details

Entities: 1 face(s)

Type: Fixed Geometry

Fixed-1

Resultant Forces

Components X Y Z Resultant

Reaction force(N) 0.000480652 50.0008 0.00148129 50.0008

Reaction Moment(N-m) 0 0 0 0

Load name Load Image Load Details

Entities: 1 face(s)

Type: Apply normal force

Value: 50 N

Force-1

Computational Lab Record Malabar Institute of Technology, Anjarakandy

23

Name Type Min Max

Stress1 VON: von Mises Stress 70.5563 N/m^2 901359 N/m^2

Node: 43498 Node: 972

canti-Study 1-Stress-Stress1

Name Type Min Max

Displacement1 URES: Resultant Displacement 0 mm 0.000911411 mm

Node: 1 Node: 1251

Computational Lab Record Malabar Institute of Technology, Anjarakandy

24

Name Type Min Max

canti-Study 1-Displacement-Displacement1

Name Type Min Max

Strain1 ESTRN: Equivalent Strain 3.2131e-010 3.08931e-006

Element: 20070 Element: 21340

Cantilever -Study 1-Strain-Strain1

Computational Lab Record Malabar Institute of Technology, Anjarakandy

25

Experiment No Date

FLOW ANALYSIS USING SOLID WORKS

Aim:

To create a pipe section and obtain velocity distribution of the fluid flowing through it

using SolidWorksFlowexpress.

Problem Description:

Velocity distribution of fluid flowing through a pipe of internal diameter 52 cm and 1m

length and inlet pressure 150kPa and outlet pressure 100kPa is to be generated.

Procedure:

1. Create part and save it

Pipe section of required dimensions

Two lids with required diameter

2. Assemble the parts

Select new

Select assembly

Select ok

3. Insert components

Mate the components, selecting proper mating conditions

Lock the lids and pipe

Obtain the sectional view

Save the assembly

4. Select evaluate

Select flowexpress analysis wizard

Define fluid

Select inlet boundary conditions

Select inlet surfaces, pressure , temperature etc

Select outlet boundary conditions

Select outlet surface, pressure, temperature

5. Calculations

Select solve and check the play button

Computational Lab Record Malabar Institute of Technology, Anjarakandy

26

6. View on Results

7. Generate the Flowexpress report which will be available in Word doc

Results:

A pipe section is created and the velocity distribution of fluid flowing through pipe is

obtained.

Fig 8.1 FloXpress Simulation

SolidWorksFloXpress Report

Model

Model Name: C:\Users\it\Desktop\New flow\Assem1.SLDASM

Fluid

Water

Environment Pressure 1

Type Environment Pressure

Faces <0>@lids-2

Value Environment Pressure: 150325.00 Pa

Temperature: 293.20 K

Environment Pressure 1

Type Environment Pressure

Computational Lab Record Malabar Institute of Technology, Anjarakandy

27

Faces <1>@lids-1

Value Environment Pressure: 101325.00 Pa

Temperature: 293.20 K

Results

Name Unit Value

Maximum Velocity m/s 9.875

Computational Lab Record Malabar Institute of Technology, Anjarakandy

También podría gustarte

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5795)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (895)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2104)

- Sepharial - The Science of Foreknowledge Cd13 Id 1928069166 Size603Documento114 páginasSepharial - The Science of Foreknowledge Cd13 Id 1928069166 Size603makarandmone100% (9)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- 07 Anti CollisionDocumento39 páginas07 Anti CollisionEmersonJParedes100% (2)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- Seismic PetrophysicsDocumento17 páginasSeismic PetrophysicsShahid Ur RehmanAún no hay calificaciones

- Sfa-5 10Documento23 páginasSfa-5 10Allen RosonAún no hay calificaciones

- Dynamic Behaviour of Transformer Winding Under Short-CircuitsDocumento164 páginasDynamic Behaviour of Transformer Winding Under Short-CircuitsHelen Dora CalayAún no hay calificaciones

- New Insights Into The Removal of Calcium SulfateDocumento10 páginasNew Insights Into The Removal of Calcium SulfatetsanshineAún no hay calificaciones

- Teaching Plan: Introduction: Fluids and Continuum, Physical Properties of Fluids, Density, Specific WeightDocumento5 páginasTeaching Plan: Introduction: Fluids and Continuum, Physical Properties of Fluids, Density, Specific WeightDilin DineshAún no hay calificaciones

- Course File Me - 110 Mechanical Workshop S1 EeeDocumento2 páginasCourse File Me - 110 Mechanical Workshop S1 EeeDilin DineshAún no hay calificaciones

- s5 Lab Me 2Documento10 páginass5 Lab Me 2Dilin DineshAún no hay calificaciones

- Course Diary: Malabar Institute of TechnologyDocumento2 páginasCourse Diary: Malabar Institute of TechnologyDilin DineshAún no hay calificaciones

- Malabar Institute of Technology, KnnurDocumento1 páginaMalabar Institute of Technology, KnnurDilin DineshAún no hay calificaciones

- Mechanics of Machinery Question BankDocumento1 páginaMechanics of Machinery Question BankDilin DineshAún no hay calificaciones

- Teaching Plan: Me 308 Computer Aided Design & AnalysisDocumento4 páginasTeaching Plan: Me 308 Computer Aided Design & AnalysisDilin DineshAún no hay calificaciones

- APJ Abdul Kalam Technological University: Course Name FeeDocumento1 páginaAPJ Abdul Kalam Technological University: Course Name FeeDilin DineshAún no hay calificaciones

- Machine1 Machine2 Machine3 Machine4 Job1 2 3 11 7 Job2 1 0 6 1 Job3 5 8 15 9 Job4 7 5 3 2Documento1 páginaMachine1 Machine2 Machine3 Machine4 Job1 2 3 11 7 Job2 1 0 6 1 Job3 5 8 15 9 Job4 7 5 3 2Dilin DineshAún no hay calificaciones

- Conventional and Model Based Test AnalysisDocumento21 páginasConventional and Model Based Test AnalysisHalil İbrahim KüplüAún no hay calificaciones

- Literature ReviewDocumento4 páginasLiterature ReviewParthipan JayaramAún no hay calificaciones

- Production Engineering Reference Books For GATEDocumento3 páginasProduction Engineering Reference Books For GATEkavi_soniiAún no hay calificaciones

- Taylor Patterns For Discrete Arrays: Alfred T. VilleneuveDocumento5 páginasTaylor Patterns For Discrete Arrays: Alfred T. VilleneuveKorbi SchramlAún no hay calificaciones

- Total StationDocumento7 páginasTotal Stationfaizankhan23Aún no hay calificaciones

- Chapter 1Documento69 páginasChapter 1AlifNRAún no hay calificaciones

- Pressure SlidesDocumento43 páginasPressure SlidesBjorn Low100% (1)

- Cell Biology Cell Structures and Their FunctionsDocumento30 páginasCell Biology Cell Structures and Their FunctionsMing Shahir SalehAún no hay calificaciones

- Lab 3 Determination of Equilibrium Constant For A Chemical ReactionDocumento4 páginasLab 3 Determination of Equilibrium Constant For A Chemical ReactionMarlette RaveloAún no hay calificaciones

- Experimental Aerodynamic Analysis of Delta WingDocumento8 páginasExperimental Aerodynamic Analysis of Delta WingShiva UAún no hay calificaciones

- SM Notes 1 by Civildatas - Blogspot.inDocumento154 páginasSM Notes 1 by Civildatas - Blogspot.inutsav_koshtiAún no hay calificaciones

- Mark Scheme (Results) January 2007: GCE Mathematics Core Mathematics C3 (6665)Documento7 páginasMark Scheme (Results) January 2007: GCE Mathematics Core Mathematics C3 (6665)Fahema ShafiAún no hay calificaciones

- ABB IRB 2400 SpecificatiiDocumento2 páginasABB IRB 2400 Specificatiialin.butunoi865Aún no hay calificaciones

- Omae2009 79047Documento6 páginasOmae2009 79047Mehdi Ghoddosi100% (1)

- Journal-Analysis of Semi Circular-Arch Truses Using I-DeasDocumento7 páginasJournal-Analysis of Semi Circular-Arch Truses Using I-DeascurrjekAún no hay calificaciones

- Finite Difference - WikipediaDocumento9 páginasFinite Difference - WikipediaJelena PapovicAún no hay calificaciones

- Are The Sequences of Bus and Earthquake Arrivals Poisson?: Application Example 6Documento12 páginasAre The Sequences of Bus and Earthquake Arrivals Poisson?: Application Example 6Dr. Ir. R. Didin Kusdian, MT.Aún no hay calificaciones

- 7 Infrared, Thermochemistry, UV-Vis, and NMRDocumento3 páginas7 Infrared, Thermochemistry, UV-Vis, and NMRfateixeira77Aún no hay calificaciones

- MercerizationDocumento2 páginasMercerizationLohit MohapatraAún no hay calificaciones

- Behavior and Analysis of A Curved and Skewed I-Girder BridgeDocumento17 páginasBehavior and Analysis of A Curved and Skewed I-Girder BridgeaapennsylvaniaAún no hay calificaciones

- PCAB List of Licensed Contractors For CFY 2018-2019 As of 10 Sep 2018 - WebDocumento3 páginasPCAB List of Licensed Contractors For CFY 2018-2019 As of 10 Sep 2018 - WebChris AnnAún no hay calificaciones

- 4.1 Gravity Force LabDocumento4 páginas4.1 Gravity Force LabT. Danielle Dockery100% (1)

- Comparison of Digestion Methods For Determination of PB (II), CR (VI) and CD (II) Contents in Some Ethiopia Spices Using Atomic Absorption SpectrosDocumento12 páginasComparison of Digestion Methods For Determination of PB (II), CR (VI) and CD (II) Contents in Some Ethiopia Spices Using Atomic Absorption SpectrosijasrjournalAún no hay calificaciones

- Master's Thesis - Quaternion-Based Control For Aggressive Trajectory Tracking With A Micro-Quadrotor UAVDocumento113 páginasMaster's Thesis - Quaternion-Based Control For Aggressive Trajectory Tracking With A Micro-Quadrotor UAVMarcus LimaAún no hay calificaciones