Documentos de Académico

Documentos de Profesional

Documentos de Cultura

AN0103 On-Board SPI Programming DediProg Tool (Designer Version)

Cargado por

client10001 dvr10002Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

AN0103 On-Board SPI Programming DediProg Tool (Designer Version)

Cargado por

client10001 dvr10002Copyright:

Formatos disponibles

A

Apppplliiccaattiioonn N

Noottee:: A

ANN00110033 O

Onn BBooaarrdd SSPPII PPrrooggrraam

mmmiinngg D

DeeddiiPPrroogg IInncc..

4F., No.7, Ln. 143, Xinming Rd., Neihu Dist., Taipei City 114, Taiwan

Application Note: AN0103

On-Board SPI programming with

DediProg tools: Designer version

DediProg Page 1/25 December 09

A

Apppplliiccaattiioonn N

Noottee:: A

ANN00110033 O

Onn BBooaarrdd SSPPII PPrrooggrraam

mmmiinngg D

DeeddiiPPrroogg IInncc..

Table of content:

1. Introduction ....................................................................................3

1.1. Motherboard BIOS memory specific requirements ......................3

1.2. DediProg solutions ........................................................................4

1.3. SF100 ISP programmer features overview ...................................6

1.3.1. SF100 and SF300 Programmer .............................................................. 7

1.3.2. SF100 Programmer Power Design......................................................... 7

1.3.3. SF100 Connection to Motherboard: with ISP Cable ............................. 9

2. Design your motherboard for the In-system-programming ....10

2.1. What are the benefits for your company? ...................................10

2.2. In-system-programming methods ...............................................11

2.3. Update the Bios memory when “Power ON and Power OFF” ...13

2.3.1. Reference Schematic 1 ......................................................................... 14

2.3.2. Reference Schematic 2 ......................................................................... 15

2.4. Update the Bios memory only when “Power ON” .....................17

2.4.1. Reference Schematic 3:........................................................................ 17

2.4.2. Reference Schematic 4 ......................................................................... 18

2.5. Update the Bios memory only when chipset releases the SPI bus

19

2.5.1. Reference Schematic 5 ......................................................................... 20

2.6. Conclusion...................................................................................21

3. Backup Boot Flash design ............................................................22

3.1. What are the benefits for your company? ...................................22

3.2. Design the motherboard for the BBF method .............................23

3.3. Conclusion...................................................................................25

Important notice:

This document is provided as is. No responsibility is assumed for errors that might

appear. DediProg reserves the right to make any changes to the product and/or the

manual at any time without notice.

DediProg Page 2/25 December 09

A

Apppplliiccaattiioonn N

Noottee:: A

ANN00110033 O

Onn BBooaarrdd SSPPII PPrrooggrraam

mmmiinngg D

DeeddiiPPrroogg IInncc..

1. Introduction

1.1. Motherboard BIOS memory specific

requirements

Unlike other Applications using Serial Flash, motherboards have to be compliant with

a large amount of different and new peripherals: Bios codes need continuous

modifications during development and some update in the field.

An incorrect Bios selection or flawed manipulation, performed usually by

inexperienced users, can corrupt the memory content and prevent the computer from

being able to reboot: the motherboard would then need to be sent through a repairing

channel to change the memory. For these reasons, motherboard makers have to take

these constraints into account when designing the boards.

The past solution commonly used was to solder a socket on each motherboard

produced, to remove manually the corrupted memory and replace it by a new one with

the correct BIOS. The cumulative cost of this method over a number of years,

considering the cost of each socket implemented on the millions of motherboards

produced can easily lead us to conclude that this solution is not the optimal choice.

Additional solutions would be to solder a backup memory on the motherboard to boot

from it in case of main Bios corruptions. The cost of this solution is also quite

significant.

To reduce motherboard cost, some manufacturers solder the flash memory on board

but this adds to the cost and complexity of engineering Bios update or future repairs

of the motherboard.

The small size of the Serial Flash increases the difficulty to find cheap and reliable

sockets. The socket solution becomes now a risky solution:

- Increase the cost

- Increase the failure rate due to quality problem (SMT contact weakness,

oxidation, degradation of the high speed SPI signals, insertion error..)

- Reduce dangerously the number of suppliers for the DIP solution

DediProg Page 3/25 December 09

A

Apppplliiccaattiioonn N

Noottee:: A

ANN00110033 O

Onn BBooaarrdd SSPPII PPrrooggrraam

mmmiinngg D

DeeddiiPPrroogg IInncc..

1.2. DediProg solutions

DediProg team is working closely with motherboard makers, Chipset makers and

Serial Flash suppliers to offer the best solutions that fit each of your needs. These

solutions are adapted to satisfy each motherboard conditions.

A) In System Programming solution (ISP)

Features: update your Main Bios memories soldered on your motherboard by using

our low cost programmer: SF100 and SF300. When connected to the motherboard,

the SF100 programmer can control the Serial Flash to read or update its content.

Advantages:

- Very fast update (10sec / 30 sec)

- Flexible update as it only requires the naked motherboard (convenient for

development, production, storage area update or repairing channel)

Requirement:

- Some Chipsets need isolations for their SPI outputs protections.

Fig 1: In System Programming update

DediProg Page 4/25 December 09

A

Apppplliiccaattiioonn N

Noottee:: A

ANN00110033 O

Onn BBooaarrdd SSPPII PPrrooggrraam

mmmiinngg D

DeeddiiPPrroogg IInncc..

B) Backup Boot Flash solution (BBF)

Features: Our Backup Boot Flash disables the Main bios memory when connected to

the motherboard. Then the Chipset can boot from our Backup Boot Flash with the

appropriated Bios code and update the main memory by using the Flash utility tool.

Advantage:

- Low Cost

- Work with most of the market motherboard without hardware modification

- If coupled to our SF100 programmer, our Backup Boot Flash can be used as a

“Serial Flash Emulator” (convenient for Bios development)

Requirement:

- Need to perform a Boot of the motherboard:

Î Longer updating time versus ISP method

Î Requires a complete computer environment for boot

(ATX power, processor, monitor..)

Fig 2: Backup Boot Flash method

For more information, refer to our BBF dedicated documents in section 3.

DediProg Page 5/25 December 09

A

Apppplliiccaattiioonn N

Noottee:: A

ANN00110033 O

Onn BBooaarrdd SSPPII PPrrooggrraam

mmmiinngg D

DeeddiiPPrroogg IInncc..

1.3. SF100 ISP programmer features

overview

The SF100 ISP programmer has been developed and designed to provide a high

performance for the lowest cost that fits to the Bios development needs and solve the

repair issues of motherboard applications.

The SF100 ISP programmer is dedicated for Serial flash only, to optimize the

hardware and software performance and minimize the cost.

Why do you need to pay for memory support you don’t need?

With the SF100 ISP programmer, your motherboard will not only benefit from the

cost reduction due to the Serial Flash memory but also from the cost reduction

due to the socket removal.

Actually, the SF100 ISP programmer has been designed to update the Serial Flash

soldered directly on Board via an inexpensive Header connector on the SPI bus,

removing the need for a socket. The corrupted memory no longer needs to be

physically removed and replaced by a new one but simply updated just by connecting

the Programmer to the motherboard connector.

The SF100 ISP programmer has been designed by taking into account all the different

environments of the motherboard, from the development to the final user and repair

channel.

Like:

- Motherboard powered / not powered

- Additional Computer available / not available

- Expert engineers / inexperienced or not technical operators

- Single update (repairing channel) / High throughput (production)

As most of the Bios update needed for development requires partial change in the

memory, the SF100 software offers a “Smart update” to Erase, program and verify

only the sectors with differences (new Bios versus previous Bios). The “Smart

Update” feature reduces significantly the bios update time to few seconds only.

DediProg Page 6/25 December 09

A

Apppplliiccaattiioonn N

Noottee:: A

ANN00110033 O

Onn BBooaarrdd SSPPII PPrrooggrraam

mmmiinngg D

DeeddiiPPrroogg IInncc..

1.3.1. SF100 and SF300 Programmer

The SF100 programmer can be used in USB modes:

USB mode:

The programmer is connected to the host computer via the USB bus.

The memory management is controlled from the DediProg tool.

This mode is very convenient, friendly and gives access to a large amount of

features to be used by the experts (design, software, hardware, product, test or

quality engineers). It also offers an automatic mode that can easily be used by

inexperienced operators.

User can freely select between a friendly Window Graphic User Interface

(GUI) or a convenient Dos Command Line.

The SF300 programmer offers an additional mode, the stand Alone, that can be

manually selected by a switch.

Stand Alone mode:

The programmer is a stand-alone device that doesn’t need to be connected to a

computer. This mode is very convenient to reduce the cost of production line

programming (no computer needed) or to execute repetitive actions on

memories. It also allows non-technical personnel to easily perform repeated

command sequences.

The operations are started by clicking a button on the programmer.

In this mode, a Flash Card is used as a master reference to copy the code to the

motherboard memory.

1.3.2. SF100 Programmer Power Design

A convenient, flexible and low cost power management designed for

motherboard:

The BIOS memory soldered on the motherboard can be either powered by the

programmer (if motherboard is OFF during the update) or powered by the

motherboard (if motherboard is ON during the update).

A smart management system to protect the motherboard:

Our programmer has been optimised to provide safe management of the

memory supply and signals to limit the impact of the ISP method on the

application.

¾ The memory Vcc is managed safely by the programmer to supply the target

motherboard memory only when needed and is switched OFF when operations

are completed.

DediProg Page 7/25 December 09

A

Apppplliiccaattiioonn N

Noottee:: A

ANN00110033 O

Onn BBooaarrdd SSPPII PPrrooggrraam

mmmiinngg D

DeeddiiPPrroogg IInncc..

¾ The SPI signals are also applied only when needed and are switched in High

Impedance when operations are completed.

¾ All the ISP pins are protected with ESD high performance protection devices to

discharge the Electrostatics charge before the connection to protect the

application.

Advantages:

¾ The programmer is plugged on the application board with Vcc OFF and SPI

signals have High Impedance to block inrush currents.

¾ Motherboard can work with the programmer connected without any functional

interference (helpful for Bios development).

DediProg Page 8/25 December 09

A

Apppplliiccaattiioonn N

Noottee:: A

ANN00110033 O

Onn BBooaarrdd SSPPII PPrrooggrraam

mmmiinngg D

DeeddiiPPrroogg IInncc..

1.3.3. SF100 Connection to Motherboard: with ISP

Cable

The motherboard requires a 4X2 pin Header straight type with 2.54mm pitch. It is

used for the SF100 programmer to control the application memory, and if necessary:

power the memory and reset the application chipset. The ISP cable will be wired

accordingly.

Figure 3: DediProg SF100 Programmer to Motherboard with standard connection

Motherboard

Red wire: SPI Programmer

Header

(T i )

1 Vcc GND 2

3 CS CLK 4

SF100

ISP Cable 5 MISO MOSI 6

7 Empty I/O3 8

Programmer

Mistake Proof pin

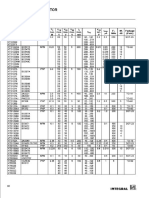

Tab 1: Description of the signals:

Pin Name of signal Description

1, 2 Vcc, Gnd Vcc supplied from the programmer to the Serial Flash

3, 4, 5, 6 CS1, CLK, MISO, MOSI SPI signals

5 Vcc Vcc is used to supply the application memory

8 IO3 used to reset the Chipset or switch off the Mosfet

7 Mistake proof pin Prevent from wrong connection

Figure 4: Motherboard ISP connector (not standard)

DediProg Page 9/25 December 09

A

Apppplliiccaattiioonn N

Noottee:: A

ANN00110033 O

Onn BBooaarrdd SSPPII PPrrooggrraam

mmmiinngg D

DeeddiiPPrroogg IInncc..

2. Design your motherboard for the In-

system-programming

2.1. What are the benefits for your company?

After investing in a few low cost SF100 programmers for Bios development,

production lines and repairing channels, your company will benefit from the

following advantages:

¾ Large COST REDUCTION on millions of motherboards over a long

period of time by removing all the sockets or backup memories from the

board.

¾ High performance: DediProg programmers are dedicated and optimized for

Serial Flash speed.

¾ High flexibility of code update: Bios development, Program in the

production line, update before shipment with the last Bios version, on field

storage area or on repairing channel.

¾ Improve Reliability: No problems from faulty mechanical contacts due to the

socket or problem due to human manipulation of the memory.

¾ Time saving: No need to manipulate the memory or boot on back-up memory,

just connect the programmer.

¾ Perform a short Failure analysis: to generate statistic reports on corruptions

and take corrective actions to improve your product reliability.

The ISP (In System Programming) is particularly appreciated for its update flexibility

and performance:

¾ In development:

- Easy to update or read the memory on board (no need to unsolder parts).

- Fast update thanks to the Smart update feature

¾ In production:

- Easy to implement and no technical expertise required

- Safer: programming after the memory manipulation (soldering, test)

- Flexible: update at the last time in production line or in storage area with the

last code revision or according to the last ordering

- Performance: the DediProg ISP method uses a Fast and direct connection to

the memory via the SPI bus optimised for the Serial flash speed (not limited

by a slow interface).

- SF100 can be used for ICT programming and can be controlled by tester

using our CML or .dll.

- SF100 can be used for ISP mass production programming by using our

production software (Multi-Programmer).

DediProg Page 10/25 December 09

A

Apppplliiccaattiioonn N

Noottee:: A

ANN00110033 O

Onn BBooaarrdd SSPPII PPrrooggrraam

mmmiinngg D

DeeddiiPPrroogg IInncc..

¾ In Field or repairing channel:

- Easy and Fast Bios update in case of Bios corruption.

- No technical expertise required: Click or press button

- Time saving: just connect the programmer with the motherboard OFF

- Perform a failure analysis before updating the Bios memory: to generate

statistic reports and to take corrective actions to decrease failure rates.

- Improve motherboard reliability: no problem of contact on socket or

human manipulation so finally, less return on repairing.

2.2. In-system-programming methods

When considering the methods to be selected for Bios update, the R&D engineers will

have to take into consideration the need from their Bios team requirements but also

from all the parties that will be finally involved in the motherboard development,

manufacturing, programming and repairing. The choice implemented will then have

to be clear enough for all the different actors despite the different motherboard models

or Chipset suppliers.

DediProg team will help you to have a clear overview about all the solutions

according to the chipset suppliers and select the optimized one. Our team will also

help you to generate one document where all updating steps will be described simply,

helping non expert or non technical employees to perform the bios update according

to the models. Please download the application note AN0106 "On board SPI

programming with DediProg tools: End user version" and contact us for

adaptation to your portfolio.

For your Motherboard Design, we have categorized three different updating

methods. Designers can select one of them which fit the most of your needs

according to the chipset capabilities:

Important: In this document, “Chipset” includes all the application controllers who

drive the Serial Flash: Southbridge, Super I/O, Embedded Controller etc..

Chipset capabilities:

Condition 1: If not powered, the Chipset is tolerant to the SPI signals

on its SPI IO through 100 Ohm Serial Resistor.

Condition 2: SPI outputs are in High Impedance when the Chipset is reset.

Condition 3: When motherboard is in Stand By mode (supplied but not turned ON),

the chipset and memories are supplied and the chipset release the SPI

bus in high Impedance.

Condition 4: When motherboard has finished booting, the chipset release the SPI bus

in high Impedance.

DediProg Page 11/25 December 09

A

Apppplliiccaattiioonn N

Noottee:: A

ANN00110033 O

Onn BBooaarrdd SSPPII PPrrooggrraam

mmmiinngg D

DeeddiiPPrroogg IInncc..

Updating Methods:

1) Update the Bios memory when “Power ON and power OFF”

This solution offers to the final user the same updating method what ever the hardware,

chipset or motherboard conditions.

Method Name: “Universal ON/OFF”

If the chipset fulfill the “Condition 1 and 2”

Î Designers can implement the “schematic 1”

If the chipset doesn’t fulfill the “Condition 1 and 2”

Î Designers can implement the “schematic 2”

2) Update the Bios memory only when “Power ON”

This solution offers to the final user the same updating method what ever the hardware,

chipset but only with motherboard turned ON.

Method Name: “Universal ON”

If the chipset fulfill the “Condition 2”

Î Designers can implement the “schematic 3”

If the chipset doesn’t fulfill the “Condition 2”

Î Designers can implement the “schematic 4”

3) Update the Bios memory only when Chipset releases the SPI bus

This solution offers to the final user the same updating method but requires from him to setup

the motherboard in a specific updating mode.

Method Name: “Universal HZ”

If the chipset and motherboard fulfill the “Condition 3”

Î Designers can implement the “schematic 5”

If the chipset doesn’t fulfill the “Condition 3”

Î Designers can implement the “schematic 2” if memory is not supplied

Î Designers can implement the “schematic 4” if memory is supplied

If the chipset fulfill the “Condition 4”

Î Designers can implement the “schematic 5”

If the chipset doesn’t fulfill the “Condition 4”

Î Designers can implement the “schematic 4” if memory is supplied

Designers can select one of these three methods to be applied on all their

motherboards projects and adapt the hardware schematics according to the

chipset capabilities. In this case, the Bios memories can be updated exactly with

the same method for all the different projects.

DediProg Page 12/25 December 09

A

Apppplliiccaattiioonn N

Noottee:: A

ANN00110033 O

Onn BBooaarrdd SSPPII PPrrooggrraam

mmmiinngg D

DeeddiiPPrroogg IInncc..

2.3. Update the Bios memory when “Power

ON and Power OFF”

Method name: “Universal ON/OFF”

The memory can be updated with the same method what ever the Chipset

suppliers or motherboard conditions.

These designs are recommended by DediProg as it will offer a simple, flexible and

safe method to update all the motherboards with the same tools and by the same way.

Same method means same way to update the Bios at the user point of view but the

design can be different according to the chipset used.

This is also the most convenient way to program the memory in production line or

update the corrupted content in repairing channel or storage area. Actually, when the

board is received, the operators just have to connect the programmer on the

motherboard connector and start the update on the naked motherboard. Fast, simple

and convenient, this method does not require to connect the motherboard to ATX

power supply or to connect peripherals to perform a boot.

Update with motherboard not supplied (OFF):

The SF100 programmer has been developed and designed to update the Bios memory

with the Motherboard OFF (not supplied). The programmer can supply the bios

memory via the pin Vcc of the ISP programmer but in this case, an isolation

component (diode or Mosfet) must be inserted on the Vcc line to avoid supplying the

entire motherboard with the 3V.

¾ With a Diode:

The memory will be supplied through the diode when the motherboard is ON. The

diode must be selected with a low threshold drop down to keep the serial Flash

supply compliant with the memory supplier specification (Often 2.7V/3.6V). When

the motherboard is OFF and memory supplied by the programmer, the diode will

prevent the rest of the motherboard to be supplied with the programmer Vcc.

¾ With a N Mosfet:

When the motherboard is supplied, the MOSFET is ON. The Serial Flash memory

is then powered by the motherboard.

When the motherboard is not powered, the MOSFET is OFF. The motherboard is

then protected from the programmer Vcc.

When compared to the Diode solution, the Mosfet isolation has the advantage to

reduce the drop down of the memory Vcc when motherboard is ON thanks to it is

small Ron value. It is usually recommended to drive it with the highest voltage

(+5V/12V) to reduce the Ron.

Remark: The Mosfet must be connected carefully according to the parasitic diode

effect when not powered. The diode effect must prevent the current leakage from

the ISP Vcc to the Motherboard (contact our support team for more information).

DediProg Page 13/25 December 09

A

Apppplliiccaattiioonn N

Noottee:: A

ANN00110033 O

Onn BBooaarrdd SSPPII PPrrooggrraam

mmmiinngg D

DeeddiiPPrroogg IInncc..

Update with motherboard supplied (ON):

The IO3 signal from the SF100 programmer is used to isolate or reset the Chipset and

avoid conflict on the SPI bus during the update.

2.3.1. Reference Schematic 1

Chipset requirement: Chipset must fulfill conditions 1 and 2

- Condition 1: If not powered, the Chipset is tolerant to the SPI signals

on its SPI IO through 100 Ohm Serial Resistor.

- Condition 2: SPI outputs are in High Impedance when the Chipset is reset.

Fig 5: reference Schematic 1

a) Updating conditions: All

- Motherboard OFF (naked motherboard not supplied)

- Motherboard ON

b) How does it work?

- Motherboard OFF: As the Chipset is tolerant to the SPI signal on its SPI IO even if

not supplied, the programmer can control the SPI bus to update the serial Flash

without damaging the Chipset. The Serial resistors on the SPI bus will also help to

limit the current injected in the Chipset IO. In this mode, the programmer will supply

the serial Flash but not the motherboard thanks to the Mosfet isolation on the Vcc line

(Q5).

- Motherboard ON: The programmer has been designed to be transparent for the

motherboard even if connected. When the update is requested by the user, the

programmer drives automatically the IO3 signal low to reset the Chipset and switch

its SPI outputs on High impedance. Then the programmer can drive the SPI bus safely

to update the Serial Flash. After update, the programmer switches its outputs in High

impedance and release the Reset signal so the motherboard can boot on the new Bios

version.

DediProg Page 14/25 December 09

A

Apppplliiccaattiioonn N

Noottee:: A

ANN00110033 O

Onn BBooaarrdd SSPPII PPrrooggrraam

mmmiinngg D

DeeddiiPPrroogg IInncc..

c) Hardware Requirements:

- One N Mosfet

- Four Serial resistors (the SPI bus parasitic capacitance must be minimized by

placing the Chipset, Serial Flash and ISP connector as close as possible)

- One pin header connector (can be 2.54mm or 1.27mm)

Remark: The Serial resistors (R1 to R4) are also useful to filter the under and

overshoot of the fast SPI signals. The CS pull up resistor (R5) deselects the memory

when chipset does not drive the bus and protect the memory from noise.

2.3.2. Reference Schematic 2

Chipset requirement:

Î no conditions required (work with all the chipsets)

For Cost reduction reasons, DediProg recommended to use the schematic 1 if the

Chipset is compliant with the “condition 1 and 2”. If not, designers can implement

the reference schematic 2.

This schematic is compliant with all South bridges such as Intel ICH7, ICH8, ICH9,

etc..

As these Chipsets are not tolerant to SPI signal when Chipset is not supplied (High

current injected) or because the SPI outputs are not switched in High impedance when

the Chipset is reset, designers must implement some isolations on the SPI bus to

protect the Chipset during the update with motherboard OFF or avoid any conflict

with the programmer during the update with motherboard ON.

Fig 6: Isolations needed when SPI signals from an external programmer

DediProg Page 15/25 December 09

A

Apppplliiccaattiioonn N

Noottee:: A

ANN00110033 O

Onn BBooaarrdd SSPPII PPrrooggrraam

mmmiinngg D

DeeddiiPPrroogg IInncc..

Fig 7: Reference Schematic 2

Remark: The Mosfet must be connected carefully according to the parasitic diode

effect when not supplied. The diode effect must prevent the current leakage from the

ISP connector to the Chipset.

Fig 8: Mosfet on the board

a) Updating conditions: All

- Motherboard OFF (naked motherboard not supplied)

- Motherboard ON

b) How does it work?

- Motherboard OFF: When the Motherboard is not supplied, the MOSFET are open

and ensure a perfect isolation for the programmer. In this mode, the programmer will

supply the serial Flash but not the motherboard thanks to the Mosfet isolation on the

Vcc line.

- Motherboard ON: When the motherboard is supplied, the MOSFET are closed and

ensure a perfect communication between the Chipset and the Serial Flash (small Ron

if driven by 5V or 12V). The programmer has been designed to be transparent for the

motherboard even if connected. When the update is requested by the user, the

programmer drives automatically the IO3 signal low to switch OFF and open the

MOSFET. Then the programmer can drive the SPI bus safely to update the Serial

Flash as they are isolated from the Chipset. After update, the programmer switches its

outputs in High impedance and release the IO3 signal so the MOSFET are closed and

the Chipset can boot on the new Bios version.

DediProg Page 16/25 December 09

A

Apppplliiccaattiioonn N

Noottee:: A

ANN00110033 O

Onn BBooaarrdd SSPPII PPrrooggrraam

mmmiinngg D

DeeddiiPPrroogg IInncc..

c) Hardware requirements:

- Five N Mosfet

- One Serial resistor

- One pin header connector (can be 2.54mm or 1.27mm)

Conclusion:

If you implement the schematic 1 when the Chipset fulfill the Condition 1 and 2 and

the schematic 2 when the Chipset doesn’t fulfill the Condition 1 and 2 then all your

motherboards will be compliant with our “Universal ON/OFF” method and will be

optimized for cost reduction. The users (Bios engineer, R&D, operators in production

or repairing) will be able to implement a unique and simple way to update the bios

what ever the motherboard model, the Chipset used or the Motherboard conditions.

2.4. Update the Bios memory only when

“Power ON”

Method name: “Universal ON”

The memory can be updated with the same method what ever the Chipset

suppliers but only with the motherboard supplied (ON).

These designs offer a simple, flexible and safe method to update all the motherboards

with the same tools and by the same way (motherboard ON).

Same method means same way to update the Bios at the user point of view but the

design can be different according to the chipset used.

2.4.1. Reference Schematic 3:

Chipset condition:

- Condition 2: SPI outputs are in High Impedance when the Chipset is reset.

This schematic 3 is a simplification of the schematic 1 (fig 5) limited to the

update with motherboard ON only to reduce the number of MOSFET.

Fig 9: Reference Schematic 3

DediProg Page 17/25 December 09

A

Apppplliiccaattiioonn N

Noottee:: A

ANN00110033 O

Onn BBooaarrdd SSPPII PPrrooggrraam

mmmiinngg D

DeeddiiPPrroogg IInncc..

a) Updating conditions:

- Motherboard ON only

b) How does it work?

In this case, the Serial flash is supplied by the motherboard during the update, so the

Vcc doesn’t need to be connected to the programmer and the Vcc Mosfet isolation is

not needed. The IO3 resets the Chipset during the memory update to release the SPI

bus in High Impedance.

c) Hardware Requirements:

- Four Serial resistors (the SPI bus parasitic capacitance must be minimized by

placing the Chipset, Serial Flash and ISP connector as close as possible)

- One pin header connector (can be 2.54mm or 1.27mm)

Remark: The Serial resistors (R1 to R4) are also useful to filter the under and

overshoot of the fast SPI signals. The CS pull up resistor (R5) deselects the memory

when chipset does not drive the bus and protect it from noise.

2.4.2. Reference Schematic 4

Chipset condition:

Î no conditions required (work with all the chipsets)

This schematic 4 is a simplification of the schematic 2 (fig 7) limited to the

update with motherboard ON only to reduce the number of MOSFET. It is

applicable to all the Chipset suppliers including Intel ICH7, ICH8, ICH9..

For Cost reduction reasons, DediProg recommended to use the schematic 3 if the

Chipset is compliant with the “condition 2”. If not, designers can implement the

reference schematic 4.

Fig 10: Reference Schematic 4

DediProg Page 18/25 December 09

A

Apppplliiccaattiioonn N

Noottee:: A

ANN00110033 O

Onn BBooaarrdd SSPPII PPrrooggrraam

mmmiinngg D

DeeddiiPPrroogg IInncc..

a) Updating conditions:

- Motherboard ON only

b) How does it work?

In this case, the Serial flash is supplied by the motherboard during the update, so the

Vcc doesn’t need to be connected to the programmer and the Vcc Mosfet isolation is

not needed. Three Mosfets are needed to isolate the Chipset outputs (CS, CLK and

MOSI) during the serial flash update to avoid conflict with the programmer. The IO3

is needed to switch the MOSFET OFF. The MISO signal doesn’t need to be isolated

as it is a Soutbridge input (no possible conflict).

Remark: on the schematic of figure 8, the MISO Mosfet (Q4) is needed to protect the

Chipset when update is performed with motherboard OFF (Chipset not supplied) and

avoid current injection in the Chipset input buffer.

c) Hardware requirements:

- Three N Mosfet

- One Serial resistor

- One pin header connector (can be 2.54mm or 1.27mm)

Remark: The Mosfet must be connected carefully according to the parasitic diode

effect when not supplied. The diode effect must prevent the current leakage from the

ISP connector to the Chipset.

Conclusion:

If you implement the schematic 3 when the Chipset fulfill the Condition 2 and the

schematic 4 when the Chipset doesn’t fulfill the Condition 2 then all your

motherboards will be compliant with our “Universal ON” method and will be

optimized for cost reduction. The users (Bios engineer, R&D, operators in production

or repairing) will be able to implement a unique and simple way to update the bios

what ever the motherboard model, the Chipset used but only with the Motherboard

ON.

2.5. Update the Bios memory only when

chipset releases the SPI bus

Method name: “Universal HZ”

Designers can decide to select a specific time when the Chipset releases

automatically the bus in High Impedance to perform the update.

- Chipset condition 3: When motherboard is in Stand By mode (supplied but not

turned ON), the chipset and memories are supplied and the chipset release the SPI bus

in high Impedance.

Remark: Designers need to be sure that in Stand By mode, the motherboard will

supply the Chipset and the Serial Flash memory (3.3V) and that the Chipset releases

the SPI bus in high impedance.

DediProg Page 19/25 December 09

A

Apppplliiccaattiioonn N

Noottee:: A

ANN00110033 O

Onn BBooaarrdd SSPPII PPrrooggrraam

mmmiinngg D

DeeddiiPPrroogg IInncc..

- Chipset condition 4: When motherboard has finished booting, the chipset

release the SPI bus in high Impedance.

Remark: Designers need to be sure that after have booted, the Chipset will not try to

access the serial Flash during the ISP update

In this case, DediProg recommends to provide a clear dedicated document where all

the methods are clearly detailed according to the motherboard models. This document

(motherboard maker specific) will then be useful for the final user that will attempt to

update the Bios memory in these different conditions.

Download the Application AN0106 "On-Board SPI programming with DediProg

tools: End user version" and contact our DediProg technical team to adapt it to your

specific motherboard portfolio and update conditions.

If the chipset and motherboard fulfill the “Condition 3”

Î Designers can implement the “schematic 5” and user can update

the memory during the motherboard Stand by mode.

If the chipset doesn’t fulfill the “Condition 3”

Î Designers can implement the “schematic 2” if memory is not supplied

Î Designers can implement the “schematic 4” if memory is supplied

If the chipset fulfill the “Condition 4”

Î Designers can implement the “schematic 5” and user can update

the memory after the motherboard boot.

If the chipset doesn’t fulfill the “Condition 4”

Î Designers can implement the “schematic 4” if memory is supplied

2.5.1. Reference Schematic 5

Fig 11: Schematic 5

a) Updating conditions:

- Motherboard supplied but update only during Stand By mode or after boot.

b) How does it work?

We select the appropriate time when the Chipset is in waiting mode so, does not try to

access the memory and does not drive the SPI bus (SPI is in High Impedance).

DediProg Page 20/25 December 09

A

Apppplliiccaattiioonn N

Noottee:: A

ANN00110033 O

Onn BBooaarrdd SSPPII PPrrooggrraam

mmmiinngg D

DeeddiiPPrroogg IInncc..

c) Hardware requirements:

- Four Serial resistors (the SPI bus parasitic capacitance must be minimized by

placing the Chipset, Serial Flash and ISP connector as close as possible)

- One pin header connector (can be 2.54mm or 1.27mm)

Remark: The Serial resistors (R1 to R4) are also useful to filter the under and

overshoot of the fast SPI signals. They are also a protection in case, the Chipset

attempt to access the Serial Flash during the ISP update. The CS pull up resistor (R5)

deselects the memory when chipset does not drive the bus and protect it from noise.

2.6. Conclusion

We recommend to the motherboard makers to select one of these updating methods

in order to rationalize their solutions and offer to all the actors involved on the

motherboard chain ONE UNIQUE METHOD to update all your motherboards

portfolio and make it simple and convenient.

¾ “Universal ON/OFF” method

¾ “Universal ON” method

¾ “Universal HZ” method

If for cost reason, you decide to select different updating methods according to your

chipset capabilities then we recommend you to provide a documentation to explain

clearly the updating conditions according to the motherboard models.

DediProg team has generated a Generic Application Note to explain step by step the

Bios updating process to the field operators. This Application note can be easily

adapted to your solutions portfolio.

Please Download the AN0106 "On-Board SPI programming with DediProg tools:

End user version" and contact us for your specific adaptation.

DediProg Page 21/25 December 09

A

Apppplliiccaattiioonn N

Noottee:: A

ANN00110033 O

Onn BBooaarrdd SSPPII PPrrooggrraam

mmmiinngg D

DeeddiiPPrroogg IInncc..

3. Backup Boot Flash design

3.1. What are the benefits for your company?

The DediProg Backup Boot Flash tool can be differentiate from the In System

Programming method on the fact that it will not be used to update directly the Serial

Flash on board but ingenuously oblige the computer to work on a backup memory.

This tool is very convenient for Bios development and for repairing in case, the ISP

method cannot be supported by the motherboard.

Fig 12: Backup Boot Flash tool

Convenient for the Bios development:

Bios team don’t need to unsolder the part from the board to update the bios. With Our

Backup Boot Flash tool, all the Bios trials and development could be done from the

Serial Flash inserted in our tool socket. The Backup Serial Flash can been easily

changed (different densities or suppliers) and even easily updated by connecting our

SF100 programmer as below:

Fig 13: Backup Boot Flash tool connected on programmer

DediProg Page 22/25 December 09

A

Apppplliiccaattiioonn N

Noottee:: A

ANN00110033 O

Onn BBooaarrdd SSPPII PPrrooggrraam

mmmiinngg D

DeeddiiPPrroogg IInncc..

Useful for the Bios repairing if ISP method is not supported:

When the Bios of the motherboard is corrupted, the computer is not able to boot

anymore. When connected on the motherboard, the DediProg Backup Boot tool will

disable automatically the Main Serial Flash soldered on board so that chipset will boot

on the backup Serial Flash inserted in the socket. After the motherboard boot

completion, operator must disconnect the BBF tool from the motherboard to enable

the main Serial Flash again and use the Flash Utility tool (usually provided by the

Chipset maker, bios maker or motherboard maker) to update its Bios content and

repair it.

The DediProg Backup Boot Flash tool can be connected on the motherboard pin

header as below:

Fig 14: Backup Boot Flash connection on the motherboard connector

3.2. Design the motherboard for the BBF

method

The Backup Boot Flash method does not require complex design:

¾ Connect the Hold Pin to the Vcc through a Pull up resistor

Most of the market motherboards already fulfill this condition.

¾ Select the method to connect the BBF tool on the motherboard

1) A Standard BBF pin header on the motherboard

The Standard BBF Pin header (8 pins 2.54mm pitch) has the equivalent pin-out

than the SO8 Serial flash pin out.

DediProg Page 23/25 December 09

A

Apppplliiccaattiioonn N

Noottee:: A

ANN00110033 O

Onn BBooaarrdd SSPPII PPrrooggrraam

mmmiinngg D

DeeddiiPPrroogg IInncc..

Table 2: 1 CS VCC 2

3 MISO Hold 4

5 x CLK 6

7 GND MOSI 8

Remark: the pin 5 can be used as a mistake proof pin to prevent

from wrong connection.

Figure 15: Standard connector for the BBF method

2) Replace the Main Serial Flash by a SMT Straight 1.27mm pin Header

This solution is very convenient for Bios development. The main Serial Flash is

unsoldered from motherboard and our SMT Straight 1.27mm Pin header is

soldered on its SO8 footprint. The Backup Boot Flash tool can then be connected

for a perfect stability (no impact on the production version).

Figure 16: SMT Straight 1.27mm pin Header

3) Connect the BBF on the Serial Flash Package:

Our SO Test Clip can be used to connect the Backup Boot Flash tool directly

on the pins of the Serial Flash soldered on the board (SO8N, SO8W or SO16

packages only). This connection must be carefully handle to avoid wrong

connection or unstable connection.

This solution can be used if the motherboard has not been designed to support

the ISP or BBF connectors.

DediProg recommends to use soldered connector when ever is possible.

DediProg Page 24/25 December 09

A

Apppplliiccaattiioonn N

Noottee:: A

ANN00110033 O

Onn BBooaarrdd SSPPII PPrrooggrraam

mmmiinngg D

DeeddiiPPrroogg IInncc..

Fig 17: Backup Boot Flash connection on the Serial Flash package

3.3. Conclusion

The Backup Boot Flash method can be easily implemented without any complex

hardware modification and even used in most of the motherboard without any

modification but you have to remember that this method will not be the best

choice for all the parties involved in the bios management (production, repairing)

versus the ISP method.

Actually, The Backup Boot Flash method needs a Boot of the motherboard so:

- Requires the complete computer booting environment (ATX power, processor,

monitor, Keyboard, mousse, RAM..).

- Requires the Flash utility tool (dos or window version)

- Requires more time to complete the Bios update versus the ISP method

DediProg Technology Co. Ltd.

4F., No.7, Ln. 143, Xinming Rd., Neihu Dist., Taipei City 114, Taiwan

Email for technical support: support@dediprog.com

Email for Sale information: sales@dediprog.com

www.DediProg.com

Information furnished above is believed to be accurate and reliable. However,

DediProg assumes no responsibility for the consequences of use of such information

or for any infringement of patents or other rights of third parties which may result

from its use. Specifications mentioned in this publication are subject to change

without notice.

This publication supersedes and replaces all information previously supplied.

All rights reserved

Printed in Taiwan.

DediProg Page 25/25 December 09

También podría gustarte

- 40002137B Pic18f27q84 PDFDocumento49 páginas40002137B Pic18f27q84 PDFAu GroupsAún no hay calificaciones

- Soyo - MB - SY 5VA0 A5 22Documento37 páginasSoyo - MB - SY 5VA0 A5 22MarnixAún no hay calificaciones

- Acer Veriton N260, N260G - ServiceManDocumento99 páginasAcer Veriton N260, N260G - ServiceManJonathan LongAún no hay calificaciones

- Daktronics Sign ManualDocumento143 páginasDaktronics Sign Manualkejowe28Aún no hay calificaciones

- Fuji Frontier 330-340-350-370-390 - Di Print-Data Writing Service Software Ver.5.0 First Edition Rulit Net 158097Documento171 páginasFuji Frontier 330-340-350-370-390 - Di Print-Data Writing Service Software Ver.5.0 First Edition Rulit Net 158097gribl79% (14)

- M 100 Hardware GuideDocumento30 páginasM 100 Hardware GuideRadi PratamaAún no hay calificaciones

- Mcu An 500015 e v11 8fx LPC Flash OperationDocumento33 páginasMcu An 500015 e v11 8fx LPC Flash OperationRagulan ThennarasuAún no hay calificaciones

- Manual Soyo 5EASDocumento43 páginasManual Soyo 5EASAnonymous RCPxaonfv0% (1)

- plt-03099 A.5 - Omnikey SW Dev Guide 0Documento62 páginasplt-03099 A.5 - Omnikey SW Dev Guide 0Juan ZentenoAún no hay calificaciones

- Diebold Nixdorf BEETLE XSDocumento33 páginasDiebold Nixdorf BEETLE XSOferty Firm / SklepówAún no hay calificaciones

- Modeling Preemphasis Using IbisDocumento22 páginasModeling Preemphasis Using IbisonafetsAún no hay calificaciones

- Maintenance and Service Guide - Compaq 800 - Presarior3000Documento148 páginasMaintenance and Service Guide - Compaq 800 - Presarior3000kelkelkelkelAún no hay calificaciones

- FSB800 - DDR400 (PC3200)Documento96 páginasFSB800 - DDR400 (PC3200)nivaldo de oliveira Oliveira100% (1)

- H8Dgi H8Dgi-F H8Dg6 H8Dg6-F: User'S ManualDocumento82 páginasH8Dgi H8Dgi-F H8Dg6 H8Dg6-F: User'S ManualOofAún no hay calificaciones

- Travelmate C100: Service GuideDocumento114 páginasTravelmate C100: Service Guidemarito72Aún no hay calificaciones

- cPCI-6965 50-15068-1000 101 enDocumento116 páginascPCI-6965 50-15068-1000 101 enBuka jayaAún no hay calificaciones

- KINO PV D5253 D4253 - UMN - v1.02Documento139 páginasKINO PV D5253 D4253 - UMN - v1.02Rafael SoaresAún no hay calificaciones

- Microatx Electrical Design Suggestions: Design Guide Revision 1.1 July 2018Documento25 páginasMicroatx Electrical Design Suggestions: Design Guide Revision 1.1 July 2018mastermindizAún no hay calificaciones

- JDM2 Based PIC ProgrammerDocumento9 páginasJDM2 Based PIC Programmerقرين لطفيAún no hay calificaciones

- Running From Flash Spra958hDocumento40 páginasRunning From Flash Spra958hsomethingfornowAún no hay calificaciones

- Service Manual: FY8-13FX-000Documento90 páginasService Manual: FY8-13FX-000remote controlAún no hay calificaciones

- Smart 5 Boot Block Flash Memory Family 2, 4, 8 MBIT: Advance InformationDocumento39 páginasSmart 5 Boot Block Flash Memory Family 2, 4, 8 MBIT: Advance InformationPEIDELUO PEREIRAAún no hay calificaciones

- MNL 0684Documento88 páginasMNL 0684apple appleAún no hay calificaciones

- Manual Placa Mãe GA-X79-UP4Documento100 páginasManual Placa Mãe GA-X79-UP4Luis E. SoaresAún no hay calificaciones

- Ic25n020atda04 Travelstar 20 GB Hard DriveDocumento220 páginasIc25n020atda04 Travelstar 20 GB Hard DriveromluxlightingAún no hay calificaciones

- ASUS A53SV ManualDocumento110 páginasASUS A53SV ManualKee LeongAún no hay calificaciones

- 269 3206 DatasheetzDocumento264 páginas269 3206 DatasheetzGiovanni LorchaAún no hay calificaciones

- PDS-16002 JMS578 Datasheet (Rev. 1.01)Documento23 páginasPDS-16002 JMS578 Datasheet (Rev. 1.01)kok86845Aún no hay calificaciones

- S29Gl-P Mirrorbit Flash FamilyDocumento71 páginasS29Gl-P Mirrorbit Flash FamilyedgarlibanioAún no hay calificaciones

- Nning From Internal Flash PDFDocumento45 páginasNning From Internal Flash PDFChu Minh ThắngAún no hay calificaciones

- OME44372H VR3020 LivePlayer V4Documento92 páginasOME44372H VR3020 LivePlayer V4Eugenia Espinoza VeraAún no hay calificaciones

- dsk6416 TechRefDocumento56 páginasdsk6416 TechRefAizaz Hussain ShahAún no hay calificaciones

- Product Specification: (V) Preliminary Specifications Final SpecificationsDocumento27 páginasProduct Specification: (V) Preliminary Specifications Final Specificationsamir baroughAún no hay calificaciones

- Spansion FlashDocumento34 páginasSpansion FlashVenkanna YapalaAún no hay calificaciones

- Digital Photo Printer: Dpp-Ex7Documento296 páginasDigital Photo Printer: Dpp-Ex7CLPHtheoryAún no hay calificaciones

- CIP3 PluginDocumento18 páginasCIP3 PluginNVK CTPAún no hay calificaciones

- AML8613 A/V Processor User Guide DatasheetDocumento25 páginasAML8613 A/V Processor User Guide DatasheetMile MartinovAún no hay calificaciones

- Infineon-Motor Control Shield With IFX007T For Arduino-UserManual-V02 00-EnDocumento15 páginasInfineon-Motor Control Shield With IFX007T For Arduino-UserManual-V02 00-EnMR. VAIBHAVSINGH VARMAAún no hay calificaciones

- 6-Slot Node IPC ChassisDocumento19 páginas6-Slot Node IPC ChassisPablo De ArribaAún no hay calificaciones

- B121ew09 V2Documento37 páginasB121ew09 V2nuevacuent904Aún no hay calificaciones

- Technical Reference Manual (TRM) : Psoc Mixed Signal ArrayDocumento542 páginasTechnical Reference Manual (TRM) : Psoc Mixed Signal ArrayArie LitbakAún no hay calificaciones

- VR 3020 Liveplayer v4 Om Eng 44372fDocumento89 páginasVR 3020 Liveplayer v4 Om Eng 44372fgAún no hay calificaciones

- PC 102851 ML 1 PC7302 - Quick - Start - GuideDocumento11 páginasPC 102851 ML 1 PC7302 - Quick - Start - GuideAlex HuAún no hay calificaciones

- Technical Manual IMS: Integrated Management System IMSDocumento16 páginasTechnical Manual IMS: Integrated Management System IMS徐玉坤Aún no hay calificaciones

- IC203 - Field Service - Bizhub PRO 920Documento30 páginasIC203 - Field Service - Bizhub PRO 920Hugo Luis EscalanteAún no hay calificaciones

- Digsi Manual CFC b2 v0487 enDocumento206 páginasDigsi Manual CFC b2 v0487 enHector Fabio Florez LondoñoAún no hay calificaciones

- Omnikey Soft DeveDocumento96 páginasOmnikey Soft DeveTim Kanyutu Murunga100% (1)

- 8) SRP Well Report Generator 014 PDFDocumento21 páginas8) SRP Well Report Generator 014 PDFjuanc964Aún no hay calificaciones

- Ps HardwareDocumento50 páginasPs HardwareJaja JajagfAún no hay calificaciones

- SP601 Hardware User GuideDocumento52 páginasSP601 Hardware User GuideToastysterAún no hay calificaciones

- Samsung MX d850Documento56 páginasSamsung MX d850Garotinho Latino AmericanoAún no hay calificaciones

- ZedBoard HW UG v1 1 PDFDocumento38 páginasZedBoard HW UG v1 1 PDFHammad Ur RehmanAún no hay calificaciones

- Miu X5 enDocumento77 páginasMiu X5 enIsaac MtzAún no hay calificaciones

- D2619-N BIOS Setup Utility For PRIMERGY RX300 S6 and TX300 S6Documento68 páginasD2619-N BIOS Setup Utility For PRIMERGY RX300 S6 and TX300 S6Programmatore UnoAún no hay calificaciones

- KINO-QM770 UMN v1.02Documento164 páginasKINO-QM770 UMN v1.02ThienAún no hay calificaciones

- PIC Microcontroller Projects in C: Basic to AdvancedDe EverandPIC Microcontroller Projects in C: Basic to AdvancedCalificación: 5 de 5 estrellas5/5 (10)

- PIC32 Microcontrollers and the Digilent Chipkit: Introductory to Advanced ProjectsDe EverandPIC32 Microcontrollers and the Digilent Chipkit: Introductory to Advanced ProjectsCalificación: 5 de 5 estrellas5/5 (1)

- PIC Microcontrollers: An Introduction to MicroelectronicsDe EverandPIC Microcontrollers: An Introduction to MicroelectronicsCalificación: 5 de 5 estrellas5/5 (1)

- Designing Embedded Systems with 32-Bit PIC Microcontrollers and MikroCDe EverandDesigning Embedded Systems with 32-Bit PIC Microcontrollers and MikroCCalificación: 5 de 5 estrellas5/5 (2)

- Embedded DSP Processor Design: Application Specific Instruction Set ProcessorsDe EverandEmbedded DSP Processor Design: Application Specific Instruction Set ProcessorsAún no hay calificaciones

- Calculate power needs for an EX8208 switchDocumento5 páginasCalculate power needs for an EX8208 switchbrightanvilAún no hay calificaciones

- Technical Data Sheet - SDCDocumento4 páginasTechnical Data Sheet - SDCnailulfalah17Aún no hay calificaciones

- Trench Angle: A Key Design Factor For A Deep Trench Superjunction MOSFETDocumento6 páginasTrench Angle: A Key Design Factor For A Deep Trench Superjunction MOSFETCazimir BostanAún no hay calificaciones

- ECE 334-Lecture 30-nMOS - Inverter-DepletionloadDocumento7 páginasECE 334-Lecture 30-nMOS - Inverter-DepletionloadBretuoba Nana Yaw YeboahAún no hay calificaciones

- Translay MBCIDocumento36 páginasTranslay MBCIRock123y0% (1)

- Laser Security SystemDocumento18 páginasLaser Security SystemDipin Preet Singh100% (2)

- Orosz-Ussr Russian Semiconductor Cross-ReferenceDocumento8 páginasOrosz-Ussr Russian Semiconductor Cross-ReferenceNikolett GyalogAún no hay calificaciones

- LED 3mm Red PDFDocumento4 páginasLED 3mm Red PDFEra O Que FaltavaAún no hay calificaciones

- Manual Microstep MD2U MD20 enDocumento1 páginaManual Microstep MD2U MD20 enJose M RojasAún no hay calificaciones

- TTC 5200Documento5 páginasTTC 5200Jose M PeresAún no hay calificaciones

- Presentation On Vocational Training at NSPCL, BHILAIDocumento22 páginasPresentation On Vocational Training at NSPCL, BHILAISanKhanAún no hay calificaciones

- System On Chips Soc'S & Multiprocessor System On Chips MpsocsDocumento42 páginasSystem On Chips Soc'S & Multiprocessor System On Chips MpsocsAli AhmadAún no hay calificaciones

- BTECH SEVENTH SEM EXAMDocumento3 páginasBTECH SEVENTH SEM EXAMAjuuAún no hay calificaciones

- Tektronik 212 Scope Maintenance ManualDocumento83 páginasTektronik 212 Scope Maintenance ManualEduardo EscalanteAún no hay calificaciones

- Glucometry Setup Using Lm358Documento4 páginasGlucometry Setup Using Lm358mpraj88Aún no hay calificaciones

- Product data sheet for ATS48C41Q soft starter: characteristics, specifications, dimensionsDocumento5 páginasProduct data sheet for ATS48C41Q soft starter: characteristics, specifications, dimensionsLmf DanielAún no hay calificaciones

- Analyze small signal parameters of CC amplifierDocumento5 páginasAnalyze small signal parameters of CC amplifierAafaqIqbalAún no hay calificaciones

- LEON3 SPARC Processor, The Past Present and FutureDocumento41 páginasLEON3 SPARC Processor, The Past Present and FutureBonnie ThompsonAún no hay calificaciones

- Een 202 Lab 8 ReportDocumento5 páginasEen 202 Lab 8 Reportapi-296881750Aún no hay calificaciones

- Terumo Sarns Modular Perfusion System 8000Documento2 páginasTerumo Sarns Modular Perfusion System 8000guaji15950% (2)

- BisturiDocumento42 páginasBisturiajcneto82Aún no hay calificaciones

- IndexDocumento167 páginasIndexahmadpoly100% (1)

- CBSE Class 12 Physics Board Exam 2019: Most Important Topics and DerivationsDocumento8 páginasCBSE Class 12 Physics Board Exam 2019: Most Important Topics and DerivationsSahil SainiAún no hay calificaciones

- BECT Semiconductor Devices Circuits 211208 193735Documento151 páginasBECT Semiconductor Devices Circuits 211208 193735Prasann KatiyarAún no hay calificaciones

- Electronic Door Lock1Documento26 páginasElectronic Door Lock1smahesh_1980Aún no hay calificaciones

- Panasonic Dmc-Lx5pu Service ManualDocumento75 páginasPanasonic Dmc-Lx5pu Service ManualABUTALEB_535364936Aún no hay calificaciones

- Piezoelectric Actuators and Sensors LectureDocumento32 páginasPiezoelectric Actuators and Sensors LecturetitiminetAún no hay calificaciones

- Gps Signal AmplifierDocumento5 páginasGps Signal AmplifierAadal ArasuAún no hay calificaciones

- EDA Open Source Tools WikiDocumento13 páginasEDA Open Source Tools WikiNitin PatelAún no hay calificaciones

- HT855PF Service ManualDocumento69 páginasHT855PF Service ManualGarlapati TrinadhAún no hay calificaciones