Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Resistance welding dos and don'ts guide

Cargado por

Joel BrasilBorgesDescripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Resistance welding dos and don'ts guide

Cargado por

Joel BrasilBorgesCopyright:

Formatos disponibles

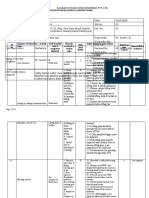

RESISTANCE WELDING DO’S AND DON’TS

Phone: 888-654-9353 Fax: 937-253-2324 Production Engineering Sales Co.

DO’S AND DON’TS FOR RESISTANCE WELDING ELECTRODES

DO’S DON’TS

1. Use the proper electrode material for the job 1. Never use unidentified electrodes or electrode

you are doing. materials.

2. Use standard electrodes wherever possible.

2. Avoid special, offset or irregular tips when the job

3. Use the most suitable tip diameter for the

can be done with a standard straight tip.

thickness of stock being welded.

4. Use open sight drains to observe more 3. Don’t use small tips on heavy gauge welding jobs

readily the water flow through the holders. or large tips on small work.

5. Connect the water inlet hose to the proper 4. Don’t forget to turn on the cooling water full force

holder inlet so that the water flows through the

before starting to weld.

center cooling tube first.

5. Never use water hose that will not fit the holder

6. Internally cool the spot welding tips with cool

water flowing at a rate of at least 1/2 gallon water connection nipples snugly.

per minute through each tip. 6. Do not allow water connections to become leaky,

7. Be sure the internal water cooling tube of the clogged or broken.

holder projects into the tip water hole to

7. Avoid using holders with leaking or deformed

within 1/4" of the tip hole bottom.

tapers.

8. Adjust the internal water cooling tube of the

8. Never use electrode holders that do not have an

holder to the proper height when changing to

a different length tip. adjustable internal water cooling tube.

9. Be sure top of adjustable water cooling tube in 9. Do not permit adjustable water tube to be “frozen”

holders is cut at an angle so as to avoid by accumulation of deposits. A few drops of oil

jamming tip down and shutting water off. periodically will keep the tube free.

10. Place a thin film of cup grease on the tip 10. Do not allow electrodes to remain idle in tapered

taper prior to inserting in the holder, to make

holder seats for extended periods.

it easier to remove.

11. Don’t use pipe wrenches or similar tools in

11. Use ejector type holders for easy removal of tips

and to avoid damage to tip tapers. removing electrodes.

12. Keep the tip taper and holder taper clean, smooth 12. Avoid using white lead or similar compounds to

and free of foreign deposits. seal a leaking taper.

13. Dress spot welding electrodes frequently to 13. Never permit a spot welding tip to mushroom

maintain the quality of the welds. enough to make dressing difficult.

14. Dress electrodes in a lathe to their original

14. Never dress electrodes with a coarse file.

contour whenever possible.

15. Don’t pound on the holder or tip with a steel

15. Use a rawhide or rubber mallet for striking holder

or tips in aligning operations. hammer in aligning the welder arms.

16. Provide flood cooling on both sides of the seam 16. Avoid the use of seam welder wheels too thin to

welding wheel. stand the heat or pressure of your job.

17. Use properly designed knurling wheels to maintain

17. Do not permit seam welding wheel to run off the

proper seam welding wheel shape.

corners of the work being welded.

www.resistanceweldsupplies.com 79

También podría gustarte

- SOP of Angle GrindingDocumento6 páginasSOP of Angle GrindingINFAún no hay calificaciones

- JSA Formet New Blasting & PaintingDocumento5 páginasJSA Formet New Blasting & Paintingsakthi venkatAún no hay calificaciones

- Rohan Builders (India) PVT - LTD: Concreting Rbipl MR - Vilas Kadam / MR - Sunil Shinde Main Plant and Road WorkDocumento3 páginasRohan Builders (India) PVT - LTD: Concreting Rbipl MR - Vilas Kadam / MR - Sunil Shinde Main Plant and Road WorkAbhaySngh100% (1)

- Risk Assessment-KioskDocumento3 páginasRisk Assessment-Kioskmubeen hassanAún no hay calificaciones

- JSA TOWER ERECTIONDocumento1 páginaJSA TOWER ERECTIONChristo Stiocal DjAún no hay calificaciones

- Data Page 100MS500-230-37-2pDocumento1 páginaData Page 100MS500-230-37-2pfjdk SmithAún no hay calificaciones

- JSA-03 Shed DismantlingDocumento3 páginasJSA-03 Shed DismantlingSwaroop Cherry0% (1)

- Risk Assessment Tables GuidanceDocumento6 páginasRisk Assessment Tables GuidanceBhargav BbvsAún no hay calificaciones

- Standard Operating Procedure For HSDDocumento3 páginasStandard Operating Procedure For HSDisjglfdskAún no hay calificaciones

- Basic Safety Instructions For All Employees Visiting or Working in The Construction of The HgpepDocumento42 páginasBasic Safety Instructions For All Employees Visiting or Working in The Construction of The Hgpepmalik jahanAún no hay calificaciones

- M.O.S DismantlingDocumento18 páginasM.O.S DismantlingAhmed Khaled100% (1)

- Jsa Bearing Replacement-OverhaulingDocumento2 páginasJsa Bearing Replacement-Overhaulingashish engineeringAún no hay calificaciones

- ScaffoldingDocumento16 páginasScaffoldingHSEAún no hay calificaciones

- Excavation Method StatementDocumento4 páginasExcavation Method StatementAnonymous 3eHGEDbxAún no hay calificaciones

- Cable Laying Safety MeasuresDocumento5 páginasCable Laying Safety MeasuresDwitikrushna RoutAún no hay calificaciones

- Fire Fighting Line MethodDocumento4 páginasFire Fighting Line MethodAbdul Rehman Sheikh100% (1)

- Breaker Machine Safety ChecklistDocumento1 páginaBreaker Machine Safety ChecklistNair R RakeshAún no hay calificaciones

- JHA For Work PermitDocumento1 páginaJHA For Work PermitShahid RazaAún no hay calificaciones

- JSA NO 3-Pile CapDocumento8 páginasJSA NO 3-Pile Capknabpsho50% (2)

- Stand Operating For Maintenance of HOUSE KEEPING AND CLEANING Sop No.-Kpo / BND / Sinter Plant / Sop - 00Documento3 páginasStand Operating For Maintenance of HOUSE KEEPING AND CLEANING Sop No.-Kpo / BND / Sinter Plant / Sop - 00Dwitikrushna Rout100% (1)

- How Chin Engineering: Job Safety AnalysisDocumento5 páginasHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdAún no hay calificaciones

- HOT WORK PERMIT Cutting & Grinding of GRP PipesDocumento1 páginaHOT WORK PERMIT Cutting & Grinding of GRP Pipesadil khanAún no hay calificaciones

- PT-03 JSA Dismantling of Slip Form (22-05-09)Documento10 páginasPT-03 JSA Dismantling of Slip Form (22-05-09)M Waqas HabibAún no hay calificaciones

- Tower Erection Method StatementDocumento2 páginasTower Erection Method StatementsoubhagyaAún no hay calificaciones

- 07 Method Sytatement For Drilling MachineDocumento5 páginas07 Method Sytatement For Drilling MachineNishar Balkavade100% (1)

- HIRA For Steam Drum ErectionDocumento18 páginasHIRA For Steam Drum ErectionNagendra Kumar SinghAún no hay calificaciones

- Aerial Lift Operations 10.01.16 FinalDocumento7 páginasAerial Lift Operations 10.01.16 FinalMohamed KadryAún no hay calificaciones

- 07 - TDS - Masterflow 520Documento3 páginas07 - TDS - Masterflow 520Alexi ALfred H. TagoAún no hay calificaciones

- Caretaker Risk Assessment - Working at HeightDocumento8 páginasCaretaker Risk Assessment - Working at HeightLina MarcelaAún no hay calificaciones

- Pentens PU-300 Grouting Product Data SheetDocumento2 páginasPentens PU-300 Grouting Product Data SheetS EfendiAún no hay calificaciones

- SOPDocumento8 páginasSOPAilyn MercadoAún no hay calificaciones

- Mansoon Sop & ChecklistDocumento3 páginasMansoon Sop & ChecklistRoselyn SharronAún no hay calificaciones

- Safe Work Method For Hydro TestDocumento1 páginaSafe Work Method For Hydro TestEswar RaoAún no hay calificaciones

- Rigging JSA RiggerDocumento12 páginasRigging JSA RiggeraQiLGunawanAún no hay calificaciones

- Jsa Fan Coil Unites MaintenanceDocumento5 páginasJsa Fan Coil Unites MaintenanceASLAM MULANIAún no hay calificaciones

- Fire Prevention PlanDocumento25 páginasFire Prevention PlanEMILYN DEPOLLOAún no hay calificaciones

- JHA For Installation 2 Inch Nozzle..Documento6 páginasJHA For Installation 2 Inch Nozzle..arnolhari100% (1)

- Asian Paints - Prem Gloss EnamelDocumento1 páginaAsian Paints - Prem Gloss EnamelwilliumstAún no hay calificaciones

- Operating A Telescoping Aerial Boom LiftDocumento1 páginaOperating A Telescoping Aerial Boom LiftTFattahAún no hay calificaciones

- Doku - Pub Risk-AssessmentDocumento10 páginasDoku - Pub Risk-AssessmentUlviyye ElesgerovaAún no hay calificaciones

- Jha Crane OperationsDocumento2 páginasJha Crane OperationsJaycee Bareng Pagador100% (1)

- Plywood Material Safety Data Sheet For MR Plywood PDFDocumento4 páginasPlywood Material Safety Data Sheet For MR Plywood PDFNirvana NircisAún no hay calificaciones

- 06 Steel Structure Erection PESB 01 PDFDocumento5 páginas06 Steel Structure Erection PESB 01 PDFShureendran Muniandy RajanAún no hay calificaciones

- SWP 02 - Use of Mobile ScaffoldDocumento4 páginasSWP 02 - Use of Mobile ScaffoldGerald Wong NttAún no hay calificaciones

- Concrete Mixer Safety ChecklistDocumento1 páginaConcrete Mixer Safety ChecklistSafety Man Shop100% (1)

- Temporary Electrical Safety ProcedureDocumento9 páginasTemporary Electrical Safety ProcedurejaimonjoyAún no hay calificaciones

- Jsa Ducting Rev 00Documento1 páginaJsa Ducting Rev 00SRR HSE Department, Sandvik Project,Aún no hay calificaciones

- Updated JSA For SAPMTofficeDocumento30 páginasUpdated JSA For SAPMTofficeShaikh Abu bakarAún no hay calificaciones

- Erection Method Statement - Birla White (Gotan)Documento15 páginasErection Method Statement - Birla White (Gotan)SEPL SEPLAún no hay calificaciones

- SOP Grinding & CuttingDocumento3 páginasSOP Grinding & CuttingIMRANAún no hay calificaciones

- Job Safety Analysis for PCC WorkDocumento6 páginasJob Safety Analysis for PCC WorkCICON EngineersAún no hay calificaciones

- Job Hazard AnalysisDocumento3 páginasJob Hazard AnalysisBrain Dee Tech LtdAún no hay calificaciones

- Planning Lifting Operations Cosalt OriginalDocumento89 páginasPlanning Lifting Operations Cosalt Originalmohamed fahsAún no hay calificaciones

- ISC-JSA Grouting Works For Shared FenceDocumento4 páginasISC-JSA Grouting Works For Shared FenceSameer AlmahboubAún no hay calificaciones

- Carrier Light Commercial Air Conditioner Split UnitDocumento14 páginasCarrier Light Commercial Air Conditioner Split UnitABie ShallabyAún no hay calificaciones

- JHA (Excavation of IPS Rev. B)Documento4 páginasJHA (Excavation of IPS Rev. B)Armando AballeAún no hay calificaciones

- Resistance Welding Dos and Don'ts GuideDocumento1 páginaResistance Welding Dos and Don'ts GuideIkhwan HafizAún no hay calificaciones

- Electrode Maintenance For Resistance Spot WeldingDocumento3 páginasElectrode Maintenance For Resistance Spot Weldingottou812Aún no hay calificaciones

- Help On SolderingDocumento7 páginasHelp On SolderingmarcusolivusAún no hay calificaciones

- Dos & Donts in WeldingDocumento19 páginasDos & Donts in Weldingkumaraswamy.kAún no hay calificaciones

- Resistance WeldingDocumento5 páginasResistance WeldingJoel BrasilBorgesAún no hay calificaciones

- F 201504271430187023Documento4 páginasF 201504271430187023Joel BrasilBorgesAún no hay calificaciones

- PHB 5 PDFDocumento22 páginasPHB 5 PDFestephan82Aún no hay calificaciones

- WeldingDocumento16 páginasWeldinghadeAún no hay calificaciones

- Far Son 2003Documento8 páginasFar Son 2003Joel BrasilBorgesAún no hay calificaciones

- Pei Wu PHDDocumento171 páginasPei Wu PHDJoel BrasilBorgesAún no hay calificaciones

- Motoman XRC 2001 Control With Auto AxcessDocumento24 páginasMotoman XRC 2001 Control With Auto AxcessEduardo Castillo ZuñigaAún no hay calificaciones

- AWS Standards Complete List 0503Documento4 páginasAWS Standards Complete List 0503Ron GoolsbyAún no hay calificaciones

- Weldhelp MatrixDocumento1 páginaWeldhelp MatrixJoel BrasilBorgesAún no hay calificaciones

- WeldingDocumento16 páginasWeldinghadeAún no hay calificaciones

- Microtip Minimizing Weld SplashDocumento2 páginasMicrotip Minimizing Weld SplashJoel BrasilBorgesAún no hay calificaciones

- Miller SSW Spot WelderDocumento4 páginasMiller SSW Spot WelderJoel BrasilBorgesAún no hay calificaciones

- Electrode Material SelectionDocumento1 páginaElectrode Material SelectionJoel BrasilBorgesAún no hay calificaciones

- Microstructure and Mechanical Properties of Resistance Spot Welded Advanced High Strength SteelsDocumento9 páginasMicrostructure and Mechanical Properties of Resistance Spot Welded Advanced High Strength SteelsJoel BrasilBorgesAún no hay calificaciones

- S PDFDocumento32 páginasS PDFJoel BrasilBorgesAún no hay calificaciones

- WT1 IntroDocumento3 páginasWT1 IntroJoel BrasilBorgesAún no hay calificaciones

- WeldingDocumento16 páginasWeldinghadeAún no hay calificaciones

- Design Guidelines - Spot Welding ChapterDocumento11 páginasDesign Guidelines - Spot Welding ChapterJoel BrasilBorgesAún no hay calificaciones

- Resistance Spot Welding of Martensitic Stainless Steel (Ss420) - Part IDocumento12 páginasResistance Spot Welding of Martensitic Stainless Steel (Ss420) - Part IJoel BrasilBorgesAún no hay calificaciones

- Welding NormsDocumento14 páginasWelding NormsimupathanAún no hay calificaciones

- Spot Weld Tensile Testing MachineDocumento3 páginasSpot Weld Tensile Testing MachineJoel BrasilBorgesAún no hay calificaciones

- Projection Design & EquipmentDocumento11 páginasProjection Design & EquipmentJoel BrasilBorgesAún no hay calificaciones

- Welding NormsDocumento14 páginasWelding NormsimupathanAún no hay calificaciones

- Numerical Study of Electrode Geometry Effects On Resistance Spot WeldingDocumento10 páginasNumerical Study of Electrode Geometry Effects On Resistance Spot WeldingJoel BrasilBorgesAún no hay calificaciones

- Resistance WeldingDocumento5 páginasResistance WeldingJoel BrasilBorgesAún no hay calificaciones

- Pod Raj 2008Documento11 páginasPod Raj 2008Joel BrasilBorgesAún no hay calificaciones

- Pod Raj 2008Documento11 páginasPod Raj 2008Joel BrasilBorgesAún no hay calificaciones

- Projection Welding - Balance Heat and Extend Electrode LifeDocumento4 páginasProjection Welding - Balance Heat and Extend Electrode LifeJoel BrasilBorgesAún no hay calificaciones

- Application Data SheetDocumento4 páginasApplication Data SheetJoel BrasilBorgesAún no hay calificaciones

- Resistance Welding - Amada Miyachi CoDocumento5 páginasResistance Welding - Amada Miyachi CoJoel BrasilBorgesAún no hay calificaciones

- Kendriya vidyalaya reading comprehension and grammar questionsDocumento7 páginasKendriya vidyalaya reading comprehension and grammar questionsRaam sivaAún no hay calificaciones

- Electrical Machines Multiple Choice Questions - Mcqs - QuizDocumento10 páginasElectrical Machines Multiple Choice Questions - Mcqs - Quiztooba mukhtarAún no hay calificaciones

- Measuring and calculating dimensions for pipes, plates, cylinders and moreDocumento100 páginasMeasuring and calculating dimensions for pipes, plates, cylinders and moreGarcia MaybelleAún no hay calificaciones

- BS en 12201 5 2011Documento20 páginasBS en 12201 5 2011fatjon31100% (4)

- 366 Community Service IdeasDocumento5 páginas366 Community Service IdeasAhmetYılmazVuralAún no hay calificaciones

- Kuffner Final PresentationDocumento16 páginasKuffner Final PresentationSamaa GamalAún no hay calificaciones

- Advanced Composite Materials Design EngineeringDocumento19 páginasAdvanced Composite Materials Design EngineeringpanyamnrAún no hay calificaciones

- 2290 PDFDocumento222 páginas2290 PDFmittupatel190785Aún no hay calificaciones

- Basic Principles of Local GovernmentDocumento72 páginasBasic Principles of Local GovernmentAnne Camille SongAún no hay calificaciones

- Semen RetentionDocumento3 páginasSemen RetentionMattAún no hay calificaciones

- Technote Torsional VibrationDocumento2 páginasTechnote Torsional Vibrationrob mooijAún no hay calificaciones

- BiologyDocumento21 páginasBiologyHrituraj banikAún no hay calificaciones

- Dahua Pfa130 e Korisnicko Uputstvo EngleskiDocumento5 páginasDahua Pfa130 e Korisnicko Uputstvo EngleskiSaša CucakAún no hay calificaciones

- Diagram "From-To" Pada Optimasi Tata Letak Berorientasi Proses (Process Layout)Documento17 páginasDiagram "From-To" Pada Optimasi Tata Letak Berorientasi Proses (Process Layout)Febrian Satrio WicaksonoAún no hay calificaciones

- Power Tube Biasing Operation Manual 15-01-08Documento2 páginasPower Tube Biasing Operation Manual 15-01-08MitchAún no hay calificaciones

- Termites and Microbial Biological Control StrategiesDocumento30 páginasTermites and Microbial Biological Control StrategiesMuhammad QasimAún no hay calificaciones

- Tec Relay 52GDocumento3 páginasTec Relay 52Gimmer nainggolanAún no hay calificaciones

- Business PlanDocumento63 páginasBusiness PlanKristine BalanayAún no hay calificaciones

- Ethics Module 2 - NotesDocumento1 páginaEthics Module 2 - Notesanon_137579236Aún no hay calificaciones

- Causes of DyspneaDocumento9 páginasCauses of DyspneaHanis Afiqah Violet MeowAún no hay calificaciones

- Com Statement (HT APFC22 - 02)Documento2 páginasCom Statement (HT APFC22 - 02)SOUMENAún no hay calificaciones

- II Unit - End EffectorsDocumento49 páginasII Unit - End EffectorsGnanasekarAún no hay calificaciones

- Ebook Drugs and The Neuroscience of Behavior An Introduction To Psychopharmacology 2Nd Edition Prus Test Bank Full Chapter PDFDocumento62 páginasEbook Drugs and The Neuroscience of Behavior An Introduction To Psychopharmacology 2Nd Edition Prus Test Bank Full Chapter PDFeffigiesbuffoonmwve9100% (10)

- PDLAMMPS - made easy: An introductionDocumento8 páginasPDLAMMPS - made easy: An introductionSaeed AbdAún no hay calificaciones

- Weber Grills - FinalDocumento12 páginasWeber Grills - FinalDIVYANSHU SHEKHARAún no hay calificaciones

- Schroedindiger Eqn and Applications3Documento4 páginasSchroedindiger Eqn and Applications3kanchankonwarAún no hay calificaciones

- Deforestation Management System Using Force and SoundDocumento4 páginasDeforestation Management System Using Force and SoundManeesh SvsAún no hay calificaciones

- Cosmic Freedom: David MolineauxDocumento2 páginasCosmic Freedom: David Molineauxsalomon46Aún no hay calificaciones

- Ampersand MenuDocumento5 páginasAmpersand MenuJozefAún no hay calificaciones

- Welcome To International Journal of Engineering Research and Development (IJERD)Documento9 páginasWelcome To International Journal of Engineering Research and Development (IJERD)IJERDAún no hay calificaciones