Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Bending Forming Bus Conductor

Cargado por

martinpellsDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Bending Forming Bus Conductor

Cargado por

martinpellsCopyright:

Formatos disponibles

Bus Conductors

Bus Conductors

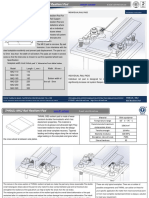

Bending & Forming Bus Conductor

Aluminum bus conductors can be formed by the same Flatwise Bends for Rectangular Bus

procedures and practices that are used for other metals. Type of Thickness Radius

Alloy and Temper

The most important factors governing to consider when Bar in min.1

bending bus conductor are: Extruded 6101-T6 0.125-0.375 2 x thickness

1. The ductility of the conductor Extruded 6101-T6 0.376-0.500 2 1/2 x thickness

2. The size and shape of the conductor Extruded 6101-T61 0.125-0.500 1 x thickness

3. The method of bending Extruded 6101-T61 0.501-0.749 2 x thickness

4. The bending equipment used Extruded 6101-T61 0.750-1.000 3 x thickness

Extruded 6101-T61 1.001-1.625 4 x thickness

A metal must be ductile enough to allow stretching and

Extruded 6101-T63 0.125-0.375 1 x thickness

compression to take place. Elongation alone is not a

Extruded 6101-T63 0.376-0.500 1 1/2 x thickness

complete criterion for ductility. The ration of yield strength

Extruded 6101-T63 0.501-1.000 2 1/2 x thickness

to tensile strength must also be taken into account. A

Extruded 6101-T64 0.125-0.750 1 x thickness

combination of a high elongation value and a low ratio

Extruded 6101-T64 0.751-1.00 2 1/2 x thickness

of yield strength to tensile strength provides the most

Extruded 6101-T65 0.125-0.500 1 x thickness

satisfactory ductility.

Extruded 6101-T65 0.501-0.749 2 x thickness

The size and the shape of the bus conductor is another

1. Applicable to widths up through 6 inches in the T6, T61, T63 and T65 tempers and to

factor that must be taken into consideration. For example, widths up through 12 inches for all other listed tempers. Blend radii for greater widths

in case of a tube, the sharpness of a bend depends not are subject to inquiry.

only on the diameter of the tube, but also on the ratio of

wall thickness to the diameter. When making edgewise

bends of rectangular bar, tests have shown that the radius

(in terms of width of the bar) around which a bar can be

bent satisfactorily depends not only on the ductility of the

car but also on its ratio of width to thickness.

Extruded, rolled, and sawed-plated bus bars can be bent

flatwise at room temperature through an angle of 90

degrees to minimum inside radii.

Tubular conductors made alloys 6063-T6 and 6061-T6

are often bent to form turns and offsets In these cases,

specifications should require seamless pipe made by holow

ingot process (ASTM B241). Ideally, the ratio of tensile

yield to tensile ultimate should not exceed 0.85. It is vital

to specify that severe forming will be encountered and

optimum heat treatments are required.

For substations, inside radii of five to seven times the

nominal pipe size for ASA schedules 40 and 80 pipe of

6063-T6 and 6061-T6 alloys should produce satisfactory

results with conventional bending tools.

www.AFLglobal.com or 800-890-8878 2011, AFL, all rights reserved. 02.15.11

Specifications are subject to change without notice.

625

También podría gustarte

- VSL SlabDocumento12 páginasVSL SlabhazemAún no hay calificaciones

- Datasheet Strenx 100 XFDocumento2 páginasDatasheet Strenx 100 XFLuis Alberto BelmonteAún no hay calificaciones

- Fiberglass Bridge and Boardwalk Systems: Presented by Dustin TroutmanDocumento36 páginasFiberglass Bridge and Boardwalk Systems: Presented by Dustin Troutmanaandueza_1Aún no hay calificaciones

- Okicat07 StoodyDocumento12 páginasOkicat07 StoodyGianfranco CopelloAún no hay calificaciones

- Sheet MetalDocumento60 páginasSheet MetalAnonymous tQhtrPbAún no hay calificaciones

- Crgo Aksteels Tran CorDocumento38 páginasCrgo Aksteels Tran CoripraoAún no hay calificaciones

- 50% Break LoadDocumento2 páginas50% Break LoadOleksandr ChernovAún no hay calificaciones

- Shearing and Slitting Steel Sheet and StreepDocumento8 páginasShearing and Slitting Steel Sheet and StreepgrtunaAún no hay calificaciones

- Hitchiner-Quick Facts and General TolerancesDocumento2 páginasHitchiner-Quick Facts and General Tolerancesjavo01280% (1)

- Steel One Linear NotesDocumento102 páginasSteel One Linear NotesUtkarsh KumarAún no hay calificaciones

- Design and Fabrication of Stair Climber TrolleyDocumento21 páginasDesign and Fabrication of Stair Climber TrolleyAnonymous 1mMOyt9zAún no hay calificaciones

- Steel SpecificationsDocumento18 páginasSteel SpecificationssurenderbuddhaAún no hay calificaciones

- Shut-Down Maintenance and Pending Job List: (Lime Stone Crusher & Raw Mil Section) Month: November-2017Documento15 páginasShut-Down Maintenance and Pending Job List: (Lime Stone Crusher & Raw Mil Section) Month: November-2017vinodsnAún no hay calificaciones

- Be Final Year ProjectDocumento17 páginasBe Final Year ProjectMALLIKARJUN KATAREAún no hay calificaciones

- Crane Rail Pads MK2Documento2 páginasCrane Rail Pads MK2Mukty BaktiarAún no hay calificaciones

- 30mnb5 Specificationa IneternationalDocumento3 páginas30mnb5 Specificationa IneternationalMohammed AliAún no hay calificaciones

- Stoody 104TJ SAW005Documento1 páginaStoody 104TJ SAW005Juaros LeonAún no hay calificaciones

- Stoody 105Documento1 páginaStoody 105JUAN DAVID ESPITIAAún no hay calificaciones

- CatalougeDocumento15 páginasCatalougeBarbara OrtigozaAún no hay calificaciones

- LT0359 6Documento12 páginasLT0359 6Jhampier Sánchez ZambranoAún no hay calificaciones

- Aslan 400: Carbon Fiber Reinforced Polymer (CFRP) Laminates Physical / Mechanical PropertiesDocumento1 páginaAslan 400: Carbon Fiber Reinforced Polymer (CFRP) Laminates Physical / Mechanical PropertiesnandinipriyatAún no hay calificaciones

- What Exactly is Rolling? The Process and Key FactsDocumento39 páginasWhat Exactly is Rolling? The Process and Key FactsAshish12312Aún no hay calificaciones

- Catalogue Linear Motion SolutionsDocumento16 páginasCatalogue Linear Motion SolutionsofanAún no hay calificaciones

- Steel Fibres: Shotcrete ApplicationsDocumento8 páginasSteel Fibres: Shotcrete ApplicationsMade JumiartaAún no hay calificaciones

- Porcelain Long Rod Insulator Specification-WBSETCLDocumento13 páginasPorcelain Long Rod Insulator Specification-WBSETCLSutirtha ChakrabortyAún no hay calificaciones

- Tin Mill Products, Black Plate Electrolytic Chromium-Coated, Single and Double ReducedDocumento8 páginasTin Mill Products, Black Plate Electrolytic Chromium-Coated, Single and Double ReducedsamehAún no hay calificaciones

- Carlite: ® Grain Oriented Electrical SteelsDocumento41 páginasCarlite: ® Grain Oriented Electrical SteelsVelkinPorllesAún no hay calificaciones

- Astm A-657Documento7 páginasAstm A-657Tri-Sure More Than ClosuresAún no hay calificaciones

- General CapabilitiesDocumento1 páginaGeneral CapabilitiesBenito LópezAún no hay calificaciones

- FL4011 Dode 1090 T PDFDocumento2 páginasFL4011 Dode 1090 T PDFJuan Pablo Palma PizarroAún no hay calificaciones

- 3.2.3 X-U Universal Knurled Shank Fasteners 3.2.3.1 Product DescriptionDocumento3 páginas3.2.3 X-U Universal Knurled Shank Fasteners 3.2.3.1 Product Descriptionrmsa17Aún no hay calificaciones

- Substation BusConductorsDocumento26 páginasSubstation BusConductorsPramod MahariaAún no hay calificaciones

- NEW Spec Long Rod InsulatorDocumento25 páginasNEW Spec Long Rod InsulatorbinodeAún no hay calificaciones

- Acoplamientos para EjesDocumento15 páginasAcoplamientos para EjesCapacitacion TodocatAún no hay calificaciones

- Wires FinalDocumento120 páginasWires FinalarshabharataAún no hay calificaciones

- Behaviour of Steel Fibre Reinforced Conc PDFDocumento4 páginasBehaviour of Steel Fibre Reinforced Conc PDFBenharzallah KrobbaAún no hay calificaciones

- 06 - Weidmuller - Pe and Ie BusbarDocumento3 páginas06 - Weidmuller - Pe and Ie BusbarharisAún no hay calificaciones

- Acousteel Brochure Digital FINALDocumento8 páginasAcousteel Brochure Digital FINALfahadullahAún no hay calificaciones

- Binder1 PDFDocumento26 páginasBinder1 PDFTejas DesaiAún no hay calificaciones

- Structural FabricationDocumento46 páginasStructural FabricationmithileshAún no hay calificaciones

- Irjet V5i5220Documento4 páginasIrjet V5i5220afaq AhmadAún no hay calificaciones

- Indispensable: Spindles, Rings & TravellersDocumento20 páginasIndispensable: Spindles, Rings & TravellersNeelakandan DAún no hay calificaciones

- 14B Overhead SwitchesDocumento28 páginas14B Overhead SwitchesRhiannon HaynesAún no hay calificaciones

- Kraft PaperDocumento2 páginasKraft PaperEko SusantoAún no hay calificaciones

- DefinitionDocumento4 páginasDefinitiondaveadeAún no hay calificaciones

- APS ThinsulatorsDocumento3 páginasAPS ThinsulatorsBobbie RuckAún no hay calificaciones

- Litz Wire BrochureDocumento7 páginasLitz Wire BrochurefdAún no hay calificaciones

- Lead Screw Nut Product GuideDocumento32 páginasLead Screw Nut Product GuideGanesh JadhavAún no hay calificaciones

- Steel Fibers PDFDocumento73 páginasSteel Fibers PDFjoseAún no hay calificaciones

- Ispat Industries Limited, Kalmeshwar - Nagpur (India) : Specification For Cold Rolled Steel Sheets & CoilsDocumento4 páginasIspat Industries Limited, Kalmeshwar - Nagpur (India) : Specification For Cold Rolled Steel Sheets & CoilsAbhi Sheoran100% (2)

- Ak Carlite Lite 042413Documento46 páginasAk Carlite Lite 042413ecaph244Aún no hay calificaciones

- An DL001Documento12 páginasAn DL001maggamAún no hay calificaciones

- Machining Operations - (MF F316) - 19, 20Documento17 páginasMachining Operations - (MF F316) - 19, 20Kislay TiwaryAún no hay calificaciones

- Fichetechnique-White-Metal Anglais Site 2Documento1 páginaFichetechnique-White-Metal Anglais Site 2sourajpatelAún no hay calificaciones

- ISPAT INDUSTRIES SPECIFICATION FOR COLD ROLLED STEELDocumento1 páginaISPAT INDUSTRIES SPECIFICATION FOR COLD ROLLED STEELVinoth ShankarAún no hay calificaciones

- Belting Correia de BorrachaDocumento54 páginasBelting Correia de BorrachaFilype NascimentoAún no hay calificaciones

- Alloy 34MnB5Documento2 páginasAlloy 34MnB5Javo RodriguezAún no hay calificaciones

- Carlite: Grain Oriented Electrical SteelsDocumento27 páginasCarlite: Grain Oriented Electrical SteelsRichard SyAún no hay calificaciones

- Quenched and Tempered Steels: Chemical Composition Available DimensionsDocumento2 páginasQuenched and Tempered Steels: Chemical Composition Available DimensionsAndreAún no hay calificaciones

- Classic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersDe EverandClassic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersCalificación: 3.5 de 5 estrellas3.5/5 (2)

- B2 302 2014Documento15 páginasB2 302 2014martinpellsAún no hay calificaciones

- MODERNIZING SOLAR POWER WITH STRING INVERTERSDocumento16 páginasMODERNIZING SOLAR POWER WITH STRING INVERTERSmartinpellsAún no hay calificaciones

- Champs Electriques Et Magnetiques Engendres Par Les Reseaux de TransportDocumento139 páginasChamps Electriques Et Magnetiques Engendres Par Les Reseaux de TransportJohnAún no hay calificaciones

- Elt 024 3Documento32 páginasElt 024 3martinpellsAún no hay calificaciones

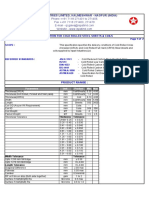

- Xiang-An Torch Switching Station 1HC0126418AADocumento2 páginasXiang-An Torch Switching Station 1HC0126418AAmartinpellsAún no hay calificaciones

- 02 WholeDocumento239 páginas02 WholemartinpellsAún no hay calificaciones

- NREL - Photovoltaic System Cost Benchmark - 68925Documento73 páginasNREL - Photovoltaic System Cost Benchmark - 68925martinpellsAún no hay calificaciones

- Deflection Values of Aluminum PipeDocumento2 páginasDeflection Values of Aluminum PipemartinpellsAún no hay calificaciones

- Wisniewski Jozef Using 10 2012Documento9 páginasWisniewski Jozef Using 10 2012martinpellsAún no hay calificaciones

- 3 Design of Grid Connect PVDocumento51 páginas3 Design of Grid Connect PVRaja Sekhar BatchuAún no hay calificaciones

- Elt 121 2Documento9 páginasElt 121 2martinpellsAún no hay calificaciones

- Philips Discharge Lamp PDFDocumento21 páginasPhilips Discharge Lamp PDFmartinpellsAún no hay calificaciones

- New 94, 95 and 97 Series sockets with push-in technologyDocumento2 páginasNew 94, 95 and 97 Series sockets with push-in technologymartinpellsAún no hay calificaciones

- Elt 024 3Documento32 páginasElt 024 3martinpellsAún no hay calificaciones

- Sam Webinars 2015 Parametric StatisticalDocumento16 páginasSam Webinars 2015 Parametric StatisticalmartinpellsAún no hay calificaciones

- Solar Energy Can Provide Valuable Capacity To Utilities and Power System OperatorsDocumento2 páginasSolar Energy Can Provide Valuable Capacity To Utilities and Power System OperatorsSunil SinghAún no hay calificaciones

- br604 PDFDocumento5 páginasbr604 PDFmartinpellsAún no hay calificaciones

- ELK-04 145 Flyer 1HDX580104 en 0315 PDFDocumento2 páginasELK-04 145 Flyer 1HDX580104 en 0315 PDFmartinpellsAún no hay calificaciones

- En 280PP 60 J4Documento2 páginasEn 280PP 60 J4martinpellsAún no hay calificaciones

- NREL CasaDocumento3 páginasNREL CasamartinpellsAún no hay calificaciones

- Welding Aluminum Bus To Aluminum ConnectorsDocumento2 páginasWelding Aluminum Bus To Aluminum ConnectorsmartinpellsAún no hay calificaciones

- Philips Discharge Lamp PDFDocumento21 páginasPhilips Discharge Lamp PDFmartinpellsAún no hay calificaciones

- 09 PV Sam Pvsyst Performance Yield ComparisonDocumento19 páginas09 PV Sam Pvsyst Performance Yield Comparisonrajuwithualways100% (1)

- NREL CasaDocumento3 páginasNREL CasamartinpellsAún no hay calificaciones

- 6V 4 OpzS 200 vented stationary batteries technical dataDocumento12 páginas6V 4 OpzS 200 vented stationary batteries technical datamartinpellsAún no hay calificaciones

- Barras Celdas Siemens Pages From Ha - 25!22!03 - B-Vers - enDocumento2 páginasBarras Celdas Siemens Pages From Ha - 25!22!03 - B-Vers - enmartinpellsAún no hay calificaciones

- Barras Celdas Siemens Pages From Ha - 25!22!03 - B-Vers - enDocumento2 páginasBarras Celdas Siemens Pages From Ha - 25!22!03 - B-Vers - enmartinpellsAún no hay calificaciones

- AECD Part1 Compressed PDFDocumento183 páginasAECD Part1 Compressed PDFmartinpellsAún no hay calificaciones

- Sag and ConductorsDocumento60 páginasSag and Conductorsmadhes14Aún no hay calificaciones

- Srihari Katari 11 Jan 2022Documento50 páginasSrihari Katari 11 Jan 2022Abhishek DevarajAún no hay calificaciones

- Chapter 8 - Miscellaneous Practices: Bht-All-SpmDocumento58 páginasChapter 8 - Miscellaneous Practices: Bht-All-SpmAnwar HossainAún no hay calificaciones

- Tensile Test UpvcDocumento3 páginasTensile Test UpvcAloka Karunarathne0% (1)

- MVIP Catalog - 2013 - r2 - WsDocumento34 páginasMVIP Catalog - 2013 - r2 - WsjjescuderoAún no hay calificaciones

- Ruidp Isor 2022Documento762 páginasRuidp Isor 2022Ankit ChaudharyAún no hay calificaciones

- MSS SP 136 Ductile Iron Swing Check Valves 2007 PDFDocumento14 páginasMSS SP 136 Ductile Iron Swing Check Valves 2007 PDFJavierfox98100% (1)

- BROC Poroscope HV5-20-40 932-004 En-UkDocumento8 páginasBROC Poroscope HV5-20-40 932-004 En-UkPP043Aún no hay calificaciones

- Welding Positions - 4 Main Types - Weld GuruDocumento19 páginasWelding Positions - 4 Main Types - Weld GuruFarid Ahmed Khwaja100% (1)

- Vibration Standards For Different Countries PDFDocumento7 páginasVibration Standards For Different Countries PDFokt_lyaAún no hay calificaciones

- Ramfill RsDocumento2 páginasRamfill RsMAT-LIONAún no hay calificaciones

- Msis 12 Chapter 11 Rev 1.01 PDFDocumento46 páginasMsis 12 Chapter 11 Rev 1.01 PDFMohamed SalemAún no hay calificaciones

- Technical Specifications: Rotary Blasthole DrillDocumento8 páginasTechnical Specifications: Rotary Blasthole DrillenricoAún no hay calificaciones

- Exxon IP 10-9-1 Mechanical AgitatorsDocumento7 páginasExxon IP 10-9-1 Mechanical AgitatorsGilvan SilvaAún no hay calificaciones

- And Owner'S Manual: Installation InstructionsDocumento48 páginasAnd Owner'S Manual: Installation InstructionsBondanAún no hay calificaciones

- Astm f1548 1994Documento6 páginasAstm f1548 1994dharlanuctcomAún no hay calificaciones

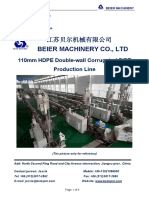

- BEIER MACHINERY 110MM PIPE PRODUCTIONDocumento9 páginasBEIER MACHINERY 110MM PIPE PRODUCTIONAdoniyas Abayneh Negash100% (1)

- ANSI Pipe Marking Standards GuideDocumento2 páginasANSI Pipe Marking Standards GuideSupawat RangsiwongAún no hay calificaciones

- Durapipe ABS Pipe CatalogueDocumento72 páginasDurapipe ABS Pipe CatalogueBaefikar Yaar100% (1)

- ATA-18 - Material PRs - Acid Section 10.02.18Documento11 páginasATA-18 - Material PRs - Acid Section 10.02.18gullipalli srinivasa raoAún no hay calificaciones

- American Standard ATT00257 CatalogDocumento670 páginasAmerican Standard ATT00257 Catalogalien2083Aún no hay calificaciones

- Exchanger Book 1Documento20 páginasExchanger Book 1Will SmithAún no hay calificaciones

- Pipeline Maintenance and RepairDocumento50 páginasPipeline Maintenance and RepairSandra PrasetyoAún no hay calificaciones

- SS525 2006Documento72 páginasSS525 2006Vun FangAún no hay calificaciones

- Astm A 234Documento8 páginasAstm A 234acolombelAún no hay calificaciones

- PPI - Handbook of Polyethylene Pipe (2nd ED)Documento626 páginasPPI - Handbook of Polyethylene Pipe (2nd ED)card89100% (5)

- SprinklerBrochures Schedule10 40Documento4 páginasSprinklerBrochures Schedule10 40Keshia Murillo PinnockAún no hay calificaciones

- En 10305-1Documento33 páginasEn 10305-1cataldocataldoAún no hay calificaciones

- Geotechnical Anchors ApprovalDocumento29 páginasGeotechnical Anchors ApprovalLuis MarcosAún no hay calificaciones

- Ir 07 01 PDFDocumento128 páginasIr 07 01 PDFfmboy700Aún no hay calificaciones

- Lesson 21 RP-576 New2Documento64 páginasLesson 21 RP-576 New2gopu100% (1)