Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Experimental Analysis of The Operation of A Solar Adsorption Refrigerator Under Sahelian Climatic Conditions: Case of Burkina Faso

Cargado por

IJAERS JOURNALTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Experimental Analysis of The Operation of A Solar Adsorption Refrigerator Under Sahelian Climatic Conditions: Case of Burkina Faso

Cargado por

IJAERS JOURNALCopyright:

Formatos disponibles

International Journal of Advanced Engineering Research and Science (IJAERS) [Vol-4, Issue-11, Nov- 2017]

https://dx.doi.org/10.22161/ijaers.4.11.22 ISSN: 2349-6495(P) | 2456-1908(O)

Experimental analysis of the operation of a solar

adsorption refrigerator under Sahelian climatic

conditions: case of Burkina Faso

Guy Christian Tubreoumya1,2,3, Eloi Salmwend Tiendrebeogo1, Ousmane Coulibaly1,

Issoufou Ouarma1,Kayaba Haro1, Charles Didace Konseibo3, Alfa Oumar Dissa1,

Belkacem Zeghmati2

Laboratoire de Physique et de Chimie de lEnvironnement (L.P.C.E), Universit Ouaga I, Pr Joseph KI ZERBO,

1

Ouagadougou, Burkina Faso.

2

LAboratoire de Mathematiqueset PhySique (LA.M.P.S), Universite de Perpignan Via Domitia (UPVD), Perpignan, France

3

Centre Ecologique Albert Schweitzer (CEAS), Ouagadougou, Burkina Faso

AbstractThis work is an experimental analysis of the addition, they use refrigerants that have no effect on the

operation of a solar adsorption refrigerator designed for environment such as water [3-5], methanol [6-8] and

the conservation of pharmaceutical products. The ammonia [9]. As a result, several researchers have

experiment consisted to measure incident solar radiation focused their work on its machines because they have

on the collector-adsorber, temperature of all the several advantages and the different demands of cold

components of the collector-adsorber, of the condenser, coincide in most of the time with the availability of the

the evaporator and the storage tank. Experimental results sun [10-15].

indicated that the maximum temperature of the front face In this article, the solar adsorption refrigerator using the

of the absorbent plate varied from 70 C to 80 C and zeolite-water pair is presented, described and tested under

that of the condenser varied from 45 C to 53 C. The the climatic conditions of Yako, Burkina Faso. The main

minimum temperature reached by the evaporator was + 4 objective of this study is to evaluate the behavior and

C. With a total energy received of about 19 MJ/m2, this overall performance of the prototype. Therefore, in the

solar adsorption refrigeration device can provide a first part of our work, the operating principle and design

SCOP ranging from 0.09 to 0.185. These results criteria are described. Then, the experimental results of a

demonstrate the technical feasibility of the prototype few days of operation are presented.

solar adsorption refrigerator that we have experimented.

KeywordsSolar energy; Refrigeration; Adsorption; II. OPERATIONAL PHASES OF THE SOLAR

Experimentation; Zeolite / Water. ADSORPTION REFRIGERATOR

A solar refrigerating adsorption machine operates in a

I. INTRODUCTION cycle. It consists in a flat plate collector containing the

The conservation of food and pharmaceutical products is zeolite/water mixture and plays a role of capturing and

a real problem in some regions of Burkina Faso. These releasing the heat. It is connected to a condenser and an

different regions are not connected to the national evaporator. The principle of operation of these machines

electricity grid. This problem results from the lack of is based on the phenomena of adsorption- desorption of a

electrical energy to cover the whole country. However, gas (water vapor) in a solid (zeolite). This chemical

Burkina Faso has a very important solar potentiel with an reaction is exo or endothermic according to its direction

average irradiation between 5.5 kWh.m-2.day-1 and of unwinding. The basic adsorption cycle for refrigeration

6.5kWh.m-2.day-1and an annual sunshine duration of 3000 consists of four processes represented in Fig. 1. In the

hours running up to and 3500 hours [1]. Thus, solar first one 12, the adsorbent is heated by solar energy until

adsorption refrigeration machines are an alternative to the pressure reaches a level that enables desorption of

meet this energy problem. In fact, solar adsorption refrigerant (state 2). During process 23 addition of heat

refrigeration units operate without moving parts and do from solar energy results in desorption of vapor

not require another source of energy out of solar energy. refrigerant, which condenses in an air-cooled condenser.

The technology of these machines is simple, maintenance At state 3, when the adsorbent rises up to its maximum

is easy and the materials used, are recyclable [2]. In temperature, solar irradiance starts to decrease. The

www.ijaers.com Page | 148

International Journal of Advanced Engineering Research and Science (IJAERS) [Vol-4, Issue-11, Nov- 2017]

https://dx.doi.org/10.22161/ijaers.4.11.22 ISSN: 2349-6495(P) | 2456-1908(O)

collector, cut off from the condenser, drops in

temperature. Cooling of the adsorbent provokes a drop of

pressure in the collector (process 34). Meanwhile, the

liquid refrigerant is transferred into the evaporator. When

the pressure reaches the value of the pressure at the

evaporator temperature, the collector is connected to the

evaporator (state 4). The adsorbent continues to decrease

in temperature and pumps the liquid refrigerant, which

evaporates and extracts out heat from the evaporator

(process 41) generating a cooling process inside the

chamber. The cycle is said intermittent because the

evaporationcooling process happens only during the

night.

III. IMPLEMENTATION OF THE

PROTOTYPE Fig. 2. Photography of solar adsorption refrigerator

The prototype of the solar adsorption refrigeration

machine that we have experimented is installed in Yako, a 3.1 The collector-adsorber

village located in the province of Passor, about 100 km The collector-adsorber is an essential element of the solar

far from Ouagadougou (Burkina Faso). It is located adsorption refrigerator. It is a parallelepipedic box of 1m2

between latitudes 12 90 and 12 96 North and between surface and 20 cm high, closed on its upper face by a 5

longitudes -2 17 and -2 26 west. This prototype mm thick glass cover. The side faces and the back face

consists of a collector-adsorber, a condenser and a are insulated by 10 cm thick of layer of glass wool. The

refrigerating enclosed containing the evaporator (Figure adsorber, enclosed in the housing, is composed of:

2). The adsorbent / adsorbate pair used is the zeolite / 8 cm of 32 kg of zeolite in contact with thirteen (13)

water pair. fins provide heat transfer between the front face and

the inside of the adsorber.

a channel of rectangular section 2 cm high, arranged

between the zeolite bed and the back plate of the

adsorber with a grid to allow the water vapor

desorbed from the bed of zeolite of flow to the

condenser through the flexible tube.

The front face of the adsorber, intended to receive the

solar flux, was previously coated with a black paint of

low emissivity allowing good absorption of solar

radiation. The absorbed solar flux is converted into heat

for heating the adsorbent (the zeolite). The collector-

adsorber assembly has a tilt angle of 13 to the horizontal

(Fig.3).

3.2 The condenser

The condenser consists of an aluminum tube 65 cm long,

5 mm thick and 10 cm in diameter. It has 52 fins spaced

15 cm apart. Each aluminum fin has a square shape of 20

Fig.1. Theoretical cycle of an adsorption machine

cm of coast and thickness 1 mm. The total exchange area

of the condenser is 3.5 m2. The condenser is cooled by

natural convection generated by the difference between

the temperature of the outer face of the condenser wall

and that of the ambient air. It is positioned in the solar

refrigeration plant so that the condensate flows through

one of the orifices easily under the effect of gravity

towards the evaporator.

www.ijaers.com Page | 149

International Journal of Advanced Engineering Research and Science (IJAERS) [Vol-4, Issue-11, Nov- 2017]

https://dx.doi.org/10.22161/ijaers.4.11.22 ISSN: 2349-6495(P) | 2456-1908(O)

3.3 The evaporator condenser, ...). We did not introduce a thermocouple

It is installed in a thermally insulated cold chamber with inside the adsorber for the sake of sealing. These

internal dimensions 50x50x30 cm. It consists of a thermocouples are connected to a data logger of the Midi

parallelepiped tank whose walls are insulated with 20 cm Logger GL220A type thus allowing the acquisition of

thick of layer of glass wool. It has two tubes 25 mm in measurements with an accuracy of 0, 5 C (Fig.5). In

diameter allowing the passage of water vapor during addition, we measured the overall illumination on the

adsorption. The total exchange area of the evaporator is inclined plane of the adsorber sensor with a KIMO brand

0.7 m2. A part of the evaporator contains a sufficient

solarimeter ( 0.38 W / m 2 C ). Measurements were

quantity of distilled water which does not participate in

done all the day long with a timestep of fifteen (15)

the cycle of the refrigerating machine. It is constantly

minutes.

present to form a mass of ice that serves as cold storage

for the day and the periods without sun. The storage of

cold latent form allows a constant evaporator temperature

and very low.

3.4 Connecting accessories

The different components of the experimental prototype

(the collector-adsorber, the condenser and the evaporator)

are connected by connecting accessories namely: the

flexible tube and the valves(Fig.4).

Fig.4. Detailed photograph of the condenseur and the

refrigerating enclosure

V. EXPRIMENTAL RESULTS AND

DISCUSSION

5.1 Evolution of solar irradiance and ambient

temperature

Figs.6-8 present the hourly evolution of the ambient

temperature and solar irradiance measured during the

different days of experiments. We found that the global

solar irradiance increases from 6:00 h and reaches a

maximum value around 12:00 h,then gradually decreases

Fig.3. Detailed photograph of the collector-adsorber.

until the end of the day. The maximum value of solar

irradiance varies between 750 and 830 W / m2. Moreover

IV. MEASUREMENT PROCEDURE

for the days considered, we observe a difference in the

To verify and evaluate the performance of our

shape of evolution during the day of solar irradiance. This

experimental device in a more realistic way, we tested it

difference is due to the passage of clouds and the

in the weather conditions of a city in Burkina Faso. This

environment of the experimental site (the shadow of the

experimental study is based mainly on the measurements,

building). The maximum value of the recorded ambient

over time, of the temperature of the components of the

temperature was approximately 38 C and the minimum

collector-adsorber, the condenser, the evaporator and the

value was 21 C.

solar flux incident on the inclined plane of the collector-

adsorber. The various tests on the solar refrigerator took

place in Yako (Burkina Faso). We used (08) eight type K

thermocouples placed on the various compartments of the

refrigerator (glass, front and back side of the adsorber,

www.ijaers.com Page | 150

International Journal of Advanced Engineering Research and Science (IJAERS) [Vol-4, Issue-11, Nov- 2017]

https://dx.doi.org/10.22161/ijaers.4.11.22 ISSN: 2349-6495(P) | 2456-1908(O)

Fig.8. Evolution of solar irradiance and ambient

Fig.5. Acquisition of experimental data. temperature for 04/08/2016

Gn

5.2 Evolution of the temperature of the various

Tamb

components of the collector-adsorber

800 38

The hourlyevolution of the temperature of the various

700 36 components of the collector-adsorber (glass, front and

34 back of the absorbent plate, zeolite) are shown in Figs .9-

600

32

11. Initially, the temperature of each of the components

500 matches the ambient temperature, then they follow during

30

the day the same shape as that of the of solar irradiance.

Tamb (C)

Gn (W/m )

2

400

28

The hourly evolutions of the temperature of the front (Tp-

300 26 av) and back (Tp-ar) of the absorbent plate show that they

200 24

reach a maximum value at 12:00 h,corresponding to the

maximum solar irradiation of the day of 15/12/ 2016.

22

100 Thus, the maximum temperature of the front face of the

20

0

absorbent plat is of the order of 80 C and 40C for the

18 back face. The temperature of the zeolite is assumed

07:39:39 09:19:39 10:59:39 12:39:39 14:19:39 15:59:39 17:39:39 19:19:39

equal to the average of the temperatures of the front and

Time

back of the absorbent plate. Its maximum value is

therefore 60 C.

Fig.6.Evolution of solar irradiance and ambient

temperature for 12/15/2016

Fig.9. Evolution of the temperature of the various

Fig.7. Evolution of solar irradiance and ambient components of the collector-adsorber for 15/12/2016

temperature for 14/12/2016.

www.ijaers.com Page | 151

International Journal of Advanced Engineering Research and Science (IJAERS) [Vol-4, Issue-11, Nov- 2017]

https://dx.doi.org/10.22161/ijaers.4.11.22 ISSN: 2349-6495(P) | 2456-1908(O)

the temperature of the condenser decreases along with the

reduction of solar irradiance. It follows that the flow rate

of the desorbed water vapor decreases with time, which

causes a decrease in the temperature of the condenser. At

approximately 16:00 h, the hourly evolution of the

condenser temperature is similar to that of the ambient

temperature.

Fig.10.Hourly evolution of the temperature of the various

components of the collector-adsorber during the day of

14/12/2016

Fig.12 Evolution of the condenser and ambient

temperature for 15/12/2016

50

Tcd

45

Tamb

40

Temperature (C)

35

30

Fig.11. Evolution of the temperature of the various

25

components of the collector-adsorber for 04/08/2016

5.3 Evolution of the condenser temperature 20

Figs. 12-14 show the hourlyevolution of the condenser

05:09:3906:49:3908:29:3910:09:3911:49:3913:29:3915:09:3916:49:3918:29:39

temperature during the different days of experimentation.

Time

It should be noted that the temperature of the condenser is

equal to the ambient temperature up to 9h. Then, it

Fig.13 Evolution of the condenser and ambient

gradually increases over time until the maximum

temperature for 14/12/2016

difference with the ambient temperature is equal to 17 C

(15/12/2016). This increase of the temperature results

mainly from the amount of heat released during the water

vapor condensation on the walls of the condenser. The

amount of water vapor desorbed is all the more important

that the difference between the temperature of the

condenser and that of the ambient is large. After 12:00 h,

www.ijaers.com Page | 152

International Journal of Advanced Engineering Research and Science (IJAERS) [Vol-4, Issue-11, Nov- 2017]

https://dx.doi.org/10.22161/ijaers.4.11.22 ISSN: 2349-6495(P) | 2456-1908(O)

Fig.15 Evolution of the evaporator and the storage tank

temperatures for 14/12/2016

Fig.14 Evolution of the condenser and ambient

temperature for 04/08/2016

5.4 Evolution of the evaporator and the storage tank

temperature

We have shown in Fig. 15-17 the hourly evolution of the

evaporator (Tev) and the storage tank (Tst) temperatures.

We note that the hourly evolution for these two

temperatures, during the test days, is similar between

18:00 h to 6:00 h. During this period, the amount of cold

is produced by the evaporation of water at low pressure.

The high adsorption capacity of the zeolite makes it

possible to adsorb large amounts of water vapor, which

allows the continuation of the vaporization of the water

and thus the production of cold in the refrigerating

enclosure.

The evaporator tempearture and that of the storage tank Fig.16 Evolution of the evaporator and the storage tank

begin to decrease from 18:00 h until reaching a temperatures for 15/12/2016

temperature about +4C at about 6:00 h. However, during

the day, the evaporator tempearture and that of the storage

tank gradually increase until reaching maximum values of

22C (14/12/2016). This increase of the temperature is

partly due to the infiltration of air into the refrigerating

enclosure and also the energy losses and the climatic

conditions.

Fig.17 Evolution of the evaporator and the storage tank

temperatures for 04/08/2016

www.ijaers.com Page | 153

International Journal of Advanced Engineering Research and Science (IJAERS) [Vol-4, Issue-11, Nov- 2017]

https://dx.doi.org/10.22161/ijaers.4.11.22 ISSN: 2349-6495(P) | 2456-1908(O)

VI. PERFORMANCE OF ADSORPTION Qf produced at the evaporator. Thus, we used the

REFRIGERATION SYSTEM correlation of Errougani, A. (2007) [19] to estimate the

The thermal performance of the solar adsorption

mass of cycled condensate ( mad ) as a function of the

refrigerator is characterized by the solar performance

coefficient (SCOP). This coefficient is the ratio between ambient temperature and the incident daily solar

the amount of the cooling production to the heat input irradiation. This correlation is given by equation (3.3):

Gn (3.3)

log mad 2, 44859*log

more precisely the total solar energy captured by the

4, 0886

collector-adsorber during a day. Tamb

Qf Where Gn is kJ / m2 and Tamb in (K).

SCOP tss (3.1)

A .Gn.dt

tsr

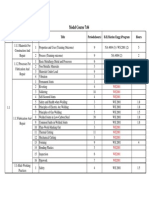

s Table 3.1 gives the solar performance coefficient (SCOP)

estimates for the different days of experimentation. The

Where As is the collecting surface and Gn is the solar experimental SCOP of our solar adsorption refrigeration

irradiation system varies between 0.09 to 0.185 and the total energy

Qf received by the adsorber-collector varies between 15 and

is the amount of cold product at the evaporator :

19 MJ. The low SCOP value obtained can be explained

Q f mad . L Tev Cpl Tcd Tev (3.2) by the small amount of cold produced due to the small

amount of adsorbed refrigerant compared to the solar

The prototype that we have experimented is not equipped

thermal energy received by the adsorber collector.

with a device for measuring the cycled condensate mass

during a cycle of operation of the solar adsorption

refrigerator. This quantity is an important parameter

because it allows the calculation of the amount of cold

Table.1: Coefficient of performance of the solar adsorption refrigerator.

Solar radiation Amount of cold Evaporator Condenser

Day energy (MJ) produced(MJ) temperature (C) temperature (C) SCOP

Max Min Max Min

03/08/2016 15,519 1,40 16 11 47 26 0,09

04/08/2016 21,86 2,21 14 9,5 44 28 0,101

05/08/2016 18,15 1.87 18 8 42 25 0,103

11/12/2016 15,77 2,69 16 11 47 26 0,171

12/12/2016 15,12 2,40 14 9,5 44 28 0,158

13/12/2016 19.66 3.30 18 8 42 25 0,167

14/12/2016 21,32 3,78 21 12 45 21 0,177

15/12/2016 19,60 3,63 15 4 52 20 0,185

16/12/2016 19,66 3,30 16 6 49 23 0,167

Table.2: Comparison SCOP of some solar refrigerator adsorption system

adsorbent/adsorbate SCOP Total energy received

Present experimental study Zeolithe/water 0.09-0.185 15-20 MJ/m2

Hildbrand et al. (2004) Silicagel/ water 0.12-0.23 > 20 MJ/m2.

Philippe Dind et al. (2005) Silicagel/ water 0.19 Artificial sunshine

A.Boubakri et al. (1992) AC/methanol 0.12 19.54 MJ/m2

Hildbrand et al. (2005) AC/methanol 0.09-0.13 19-25 J/m2

We compared the obtainedresults with those of the technical feasibility of the solar adsorption refrigerator

literature (Table 3.2). We found that these values are of prototype that we used.

the same order of magnitude as in the literature [16-18]

using the zeolite-water or silica gel-water pair. This VII. CONCLUSION

validates our experimental protocol and demonstrates the In this paper, an experimental solar adsorption

refrigerator, using the zeolite/water pair, is presented.

www.ijaers.com Page | 154

International Journal of Advanced Engineering Research and Science (IJAERS) [Vol-4, Issue-11, Nov- 2017]

https://dx.doi.org/10.22161/ijaers.4.11.22 ISSN: 2349-6495(P) | 2456-1908(O)

Designed for the conservation of pharmaceutical Applied Sciences, 21, 155-169.

products, several experimental tests have been carried out https://doi.org/10.4314/gjpas.v21i2.8

in order to test the reliability of the solar adsorption [2] A. Chikouche, Using solar energy for refrigeration

refrigeration system. Thus, the hourly evolution of the purposes in Algeria, chez 4th JIIRCRAC

temperature of the different components of the system Proceeding, 2012.

was presented and discussed: [3] Marlinda, A. Uyun, T. Miyazaki, Y. Ueda et A.

The maximum value of solar irradiance varies Akisawa, Performance analysis of a double-effect

between 750 and 830 W / m2. Tthe maximum value adsorption refrigeration cycle with a silica gel/water

of the recorded ambient temperature was working pair, Energies, pp. 3,17041720., 2010.

approximately 38 C and the minimum value was 21 [4] Tubreoumya, G.C., Dissa, A.O., Tiendrebeogo, E.S.,

C. Chesneau, X., Compaore, A., Haro, K., Konseibo,

The maximum temperature of the front face of the C.D., Zeghmati, B. and Koulidiati, J. (2017)

absorbent plat is of the order of 80 C and that of the Contribution to the Modeling of a Solar Adsorption

back face is 40C. The temperature of the zeolite is Refrigerator under the Climatic Conditions of

maximum value is therefore 60 C. Burkina Faso. Energy and PowerEngineering, 9,

The temperature of the condenser reaches a 119-135. https://doi.org/10.4236/epe.2017.92010

maximum temperature of 52 C and that of the [5] Allouhi, A., Kousksou, T., Jamil, A. and Zeraouli,

evaporator, a minimum temperature of 4 C. Y. (2014) Modeling of a ThermalAdsorber Powered

The SCOP of the solar adsorption refrigeration system by Solar Energy for Refrigeration Applications.

varies between 0.09 to 0.185 and the total energy received Energy, 75, 589-596.

by the adsorber-collector varies between 15 and 19 MJ. https://doi.org/10.1016/j.energy.2014.08.022

Acknowledgements [6] H. Hassan, A. Mohamad et H. Al-Ansary,

The authors are grateful to the University Agency of the Development of a continuously operating solar-

Francophonie (AUF) and the French Embassy (SCAC) driven adsorption cooling system: Thermodynamic

for financial support which allowed the realization of this analysis and parametric study. Appl. Therm. Eng, pp.

work. 48, 332341, 2012.

Nomenclature http://dx.doi.org/10.1016/j.applthermaleng.2012.04.

Cp Specific heat (J/kg.K) 040

Gn Solar radiation (W/m2) [7] Boubakri, A., Guilleminot, J. and Meunier, F. (2000)

m mass (kg) Adsorptive Solar Powered Ice Maker: Experiments

Qf Cold production (J) and Model. Solar Energy, 69, 249-263.

q Water concentration inside the https://doi.org/10.1016/S0038-092X(00)00063-3

zolithe (kg/kg) [8] Lemmini, F. and Errougani, A. (2007)

A Area (m2) Experimentation of a Solar Adsorption Refrigerator

L(T) Latent heat of vaporization (J/kg) in Morocco. Renewable Energy, 32, 2629-2641.

T Temprature (K) https://doi.org/10.1016/j.renene.2007.01.004

P Pressure (Pa) [9] M. Louajari, A. Mimet et A. Ouammi, Study of the

Indexes effect of finned tube adsorber on theperformance of

amb ambient solar driven adsorption cooling machine using

zeo zeolite activated carbon-ammonia pair.Appl. Energy , pp.

ev evaporator 88, 690698., 2011.

cd condenser http://dx.doi.org/10.1016/j.apenergy.2010.08.032

v glass [10] Muhammad, U., Atsushi, A. and Yuki, U. (2014)

p plaque Performance Evaluation of a SolarAdsorption

st storage Refrigeration System with a Wing Type Compound

t Time (s) Parabolic Concentrator. Energies, 7, 1448-1466.

g generation https://doi.org/10.3390/en7031448

ad adsorbent [11] Bakkas, M., Mada, M. and Tahri, M. (2001)

Modelisation et Simulation du Transfert de Chaleur

REFERENCES et de Masse a l'Interieur d'un Reacteur de Charbon

[1] Ousmane, M., Dianda, B., Kam, S., Konfe, A., Ky, Actif Reagissant avec de lAmmoniac Couple a un

T. and Bathiebo, D. (2015) Experimental Study in Caloduc Annulaire a Eau. Revue des Energies

Natural Convection. Global Journal of Pure and Renouvelables, 19-24.

www.ijaers.com Page | 155

International Journal of Advanced Engineering Research and Science (IJAERS) [Vol-4, Issue-11, Nov- 2017]

https://dx.doi.org/10.22161/ijaers.4.11.22 ISSN: 2349-6495(P) | 2456-1908(O)

[12] Allouhi, A., Kousksou, T., Jamil, A., El Rhafiki, T.,

Mourad, Y. and Zeraouli, Y.(2015) Optimal

Working Pairs for Solar Adsorption Cooling

Applications. Energy,79, 235-247.

https://doi.org/10.1016/j.energy.2014.11.010

[13] Leite, A.D.M. (2000) Performance of a New Solid

Adsorption Ice Maker with SolarEnergy

Regeneration. Energy Conversion and Management,

41, 1625-1647.

https://doi.org/10.1016/S0196-8904(00)00011-X

[14] Guilleminot, J.M.F. (1987) Heat and Mass Transfer

in a Non Isothermal Fixed BedSolid Adsorbent

Reactor a Uniform Pressure-Non Uniform

Temperature. International Journal of Heat and Mass

Transfer, 30, 1595-1606.

https://doi.org/10.1016/0017-9310(87)90304-8

[15] Mimet, A. (1991) Etude theorique et experimentale

dune machine frigorifique a adsorption dammoniac

sur charbon actif. These de Doctorat, FPMs, Mons.

[16] Boubakri, A., Arsalane, M., Yous, B., Alimoussa,

L., Pons, M., Meunier, F., Guilleminot, J. (1992).

Experimental study of adsorptive solar powered ice

makers in Agadir (Morocco)-1.Performance in

actual site. Renew. Energ.(2 (1), 7-13.), 2 (1), 7-13.

[17] Dind, P., Catherine., H., Cherbuin, O., Mayor, J.

(2005). La rfrigration solaire adsorption. HES-

SO: Projet Gerbert Rf Stiftung.

[18] Hildbrand, C., Dind, P., Pons, M., Buchter, F.

(2004). A new solar powerd adsorption refrigerator

with high performance. Solar Energy, vol 77,

pp.311-

318https://doi.org/10.1016/j.solener.2004.05.007

[19] Errougani, A. (2007). Fabrication et experimentation

dun refrigerateur solaire a adsorption utilisant le

couple charbon actif- methanol. Agdal: Universit

Mohammed V.

www.ijaers.com Page | 156

También podría gustarte

- Climatic Rhythms and Prevalence of Malaria in The Municipality of Sinende in Northern BeninDocumento8 páginasClimatic Rhythms and Prevalence of Malaria in The Municipality of Sinende in Northern BeninIJAERS JOURNALAún no hay calificaciones

- Facing Dengue and Malaria As A Public Health Challenge in BrazilDocumento6 páginasFacing Dengue and Malaria As A Public Health Challenge in BrazilIJAERS JOURNALAún no hay calificaciones

- Beef Cattle Farmers' Economic Behavior in The Minahasa Tenggara Regency, IndonesiaDocumento7 páginasBeef Cattle Farmers' Economic Behavior in The Minahasa Tenggara Regency, IndonesiaIJAERS JOURNALAún no hay calificaciones

- Analysis of The Thermal Behavior of Masonry Concrete Block With Internal Natural Element CoatingDocumento11 páginasAnalysis of The Thermal Behavior of Masonry Concrete Block With Internal Natural Element CoatingIJAERS JOURNALAún no hay calificaciones

- Business Logistics and The Relationship With Organizational SuccessDocumento4 páginasBusiness Logistics and The Relationship With Organizational SuccessIJAERS JOURNALAún no hay calificaciones

- Impacts On The Mental Health of Professionals in A Prisonal System in Alagoas During The Covid-19 PandemicDocumento7 páginasImpacts On The Mental Health of Professionals in A Prisonal System in Alagoas During The Covid-19 PandemicIJAERS JOURNALAún no hay calificaciones

- Enhancing Cybersecurity: The Power of Artificial Intelligence in Threat Detection and PreventionDocumento6 páginasEnhancing Cybersecurity: The Power of Artificial Intelligence in Threat Detection and PreventionIJAERS JOURNALAún no hay calificaciones

- The Economic Impact of Coronavirus Disease (COVID-19) : A Study On Tourism Indicators in The Kingdom of Saudi ArabiaDocumento4 páginasThe Economic Impact of Coronavirus Disease (COVID-19) : A Study On Tourism Indicators in The Kingdom of Saudi ArabiaIJAERS JOURNALAún no hay calificaciones

- Childhood/ Pediatric Cancer: Nursing Care in Oncopediatrics With A Central Focus On HumanizationDocumento12 páginasChildhood/ Pediatric Cancer: Nursing Care in Oncopediatrics With A Central Focus On HumanizationIJAERS JOURNALAún no hay calificaciones

- Constructed Wetlands: Technology For Removing Drug Concentration From WaterDocumento12 páginasConstructed Wetlands: Technology For Removing Drug Concentration From WaterIJAERS JOURNALAún no hay calificaciones

- Breastfeeding and Factors Associated With The Prevention of Childhood Obesity: An Integrative Literature ReviewDocumento16 páginasBreastfeeding and Factors Associated With The Prevention of Childhood Obesity: An Integrative Literature ReviewIJAERS JOURNALAún no hay calificaciones

- Associativism As Strategy of Reaching Territorial Rights, Programs, Projects and Public Policies of Rural Development: The Case of The São Francisco Do Mainã Community, Manaus, AMDocumento9 páginasAssociativism As Strategy of Reaching Territorial Rights, Programs, Projects and Public Policies of Rural Development: The Case of The São Francisco Do Mainã Community, Manaus, AMIJAERS JOURNALAún no hay calificaciones

- Study of The Extraction Process of The Pleurotus Citrinopileatus Mushroom and Evaluation of The Biological Activity of The ExtractDocumento8 páginasStudy of The Extraction Process of The Pleurotus Citrinopileatus Mushroom and Evaluation of The Biological Activity of The ExtractIJAERS JOURNALAún no hay calificaciones

- The Economic Impact of Coronavirus Disease (COVID-19) : A Study On Tourism Indicators in The Kingdom of Saudi ArabiaDocumento4 páginasThe Economic Impact of Coronavirus Disease (COVID-19) : A Study On Tourism Indicators in The Kingdom of Saudi ArabiaIJAERS JOURNALAún no hay calificaciones

- Water Quality Assessment Using GIS Based Multi-Criteria Evaluation (MCE) and Analytical Hierarchy Process (AHP) Methods in Yenagoa Bayelsa State, NigeriaDocumento11 páginasWater Quality Assessment Using GIS Based Multi-Criteria Evaluation (MCE) and Analytical Hierarchy Process (AHP) Methods in Yenagoa Bayelsa State, NigeriaIJAERS JOURNALAún no hay calificaciones

- Design and Building of Servo Motor Portable Coconut Peller MachineDocumento5 páginasDesign and Building of Servo Motor Portable Coconut Peller MachineIJAERS JOURNALAún no hay calificaciones

- Humanization in Undergraduate Medical Education: The Brazilian Learner's PerspectiveDocumento12 páginasHumanization in Undergraduate Medical Education: The Brazilian Learner's PerspectiveIJAERS JOURNALAún no hay calificaciones

- Mining and Its Impacts On Environment and Health With Special Reference To Ballari District, Karnataka, IndiaDocumento7 páginasMining and Its Impacts On Environment and Health With Special Reference To Ballari District, Karnataka, IndiaIJAERS JOURNALAún no hay calificaciones

- Komla Uwolowudu Amegna: International Journal of Advanced Engineering Research and Science (IJAERS)Documento9 páginasKomla Uwolowudu Amegna: International Journal of Advanced Engineering Research and Science (IJAERS)IJAERS JOURNALAún no hay calificaciones

- Morphometric Analysis of The Ekole River As A Consequence of Climate Change: A Case Study in Yenagoa, Bayelsa State, NigeriaDocumento9 páginasMorphometric Analysis of The Ekole River As A Consequence of Climate Change: A Case Study in Yenagoa, Bayelsa State, NigeriaIJAERS JOURNALAún no hay calificaciones

- The Psychologist's Role in The Process of Listening To Children Victims of Sexual Violence in Legal ProceedingsDocumento8 páginasThe Psychologist's Role in The Process of Listening To Children Victims of Sexual Violence in Legal ProceedingsIJAERS JOURNALAún no hay calificaciones

- Process Sequence Optimization and Structural Analysis of Nanoscale Heterostructure Using Compound Semiconductors AlAsSb/In0.59Ga0.41As/GaAs0.53Sb0.47Documento5 páginasProcess Sequence Optimization and Structural Analysis of Nanoscale Heterostructure Using Compound Semiconductors AlAsSb/In0.59Ga0.41As/GaAs0.53Sb0.47IJAERS JOURNALAún no hay calificaciones

- Multiprofessional Care For A Patient With Gestational DiabetesDocumento12 páginasMultiprofessional Care For A Patient With Gestational DiabetesIJAERS JOURNALAún no hay calificaciones

- VCO Rancidity Analysis Refers To Fermentation Time That Produced by Gradual Heating MethodDocumento6 páginasVCO Rancidity Analysis Refers To Fermentation Time That Produced by Gradual Heating MethodIJAERS JOURNAL100% (1)

- Morphometric Analysis of The Ekole River As A Consequence of Climate Change: A Case Study in Yenagoa, Bayelsa State, NigeriaDocumento9 páginasMorphometric Analysis of The Ekole River As A Consequence of Climate Change: A Case Study in Yenagoa, Bayelsa State, NigeriaIJAERS JOURNALAún no hay calificaciones

- Sociodemographic and Clinical Profile of Women With Uterine Cervical Cancer Attended in An Oncological Hospital in The State of Acre, BrazilDocumento9 páginasSociodemographic and Clinical Profile of Women With Uterine Cervical Cancer Attended in An Oncological Hospital in The State of Acre, BrazilIJAERS JOURNALAún no hay calificaciones

- Does Blended Learning Approach Affect Madrasa Students English Writing Errors? A Comparative StudyDocumento12 páginasDoes Blended Learning Approach Affect Madrasa Students English Writing Errors? A Comparative StudyIJAERS JOURNALAún no hay calificaciones

- Assessment of The Risk of Cardiovascular Diseases and Its Relationship With Heart Rate Variability in Physically Active and Sedentary IndividualsDocumento13 páginasAssessment of The Risk of Cardiovascular Diseases and Its Relationship With Heart Rate Variability in Physically Active and Sedentary IndividualsIJAERS JOURNALAún no hay calificaciones

- Association of Bacterial Vaginosis To Atypia in Squamous Cells of The CervixDocumento15 páginasAssociation of Bacterial Vaginosis To Atypia in Squamous Cells of The CervixIJAERS JOURNALAún no hay calificaciones

- Modeling of Geological and Geophysical Data, Onshore Field of Potiguar Basin, Northeastern BrazilDocumento5 páginasModeling of Geological and Geophysical Data, Onshore Field of Potiguar Basin, Northeastern BrazilIJAERS JOURNALAún no hay calificaciones

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2219)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (119)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2099)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- Cold Chain in The ShipCOLD CHAIN IN THE SHIPPING INDUSTRYping IndustryDocumento15 páginasCold Chain in The ShipCOLD CHAIN IN THE SHIPPING INDUSTRYping IndustryAnkush SinghAún no hay calificaciones

- As NZS 1677.2-1998 Refrigerating Systems Safety Requirements For Fixed ApplicationsDocumento8 páginasAs NZS 1677.2-1998 Refrigerating Systems Safety Requirements For Fixed ApplicationsSAI Global - APAC0% (1)

- Slides - PowerDocumento349 páginasSlides - Powernathaniel villanuevaAún no hay calificaciones

- Correction of Service Manual Si-18 M-11011Documento18 páginasCorrection of Service Manual Si-18 M-11011Ahmed AzadAún no hay calificaciones

- Ceccato cdx100 cdx180 Manual PDFDocumento10 páginasCeccato cdx100 cdx180 Manual PDFpeterpunk75100% (1)

- Catalogue FREECOLD EN 2020Documento12 páginasCatalogue FREECOLD EN 2020Belly Yan DewantaraAún no hay calificaciones

- Removal of Carbon Dioxide From Natural Gas For LNG ProductionDocumento74 páginasRemoval of Carbon Dioxide From Natural Gas For LNG Productiontaufany99Aún no hay calificaciones

- THERMAL ENGINEERING GAS POWER CYCLESDocumento17 páginasTHERMAL ENGINEERING GAS POWER CYCLESprasanthprpAún no hay calificaciones

- Design of Cooling TowerDocumento4 páginasDesign of Cooling TowerHadis ShojaeiAún no hay calificaciones

- Coolpack SoftwareDocumento2 páginasCoolpack Softwarepatilabhay376Aún no hay calificaciones

- GFG-2011 Buyers Gu PDFDocumento16 páginasGFG-2011 Buyers Gu PDFDejan BošnjakAún no hay calificaciones

- Bulletin 114 REV032014 PDFDocumento20 páginasBulletin 114 REV032014 PDFmul yadiAún no hay calificaciones

- 6.thermal EngineeringDocumento7 páginas6.thermal EngineeringprasanthprpAún no hay calificaciones

- Trane Classic Absorption Single-Stage Hot Water or Steam-Fired Absorption Chillers 112 To 465 TonsDocumento2 páginasTrane Classic Absorption Single-Stage Hot Water or Steam-Fired Absorption Chillers 112 To 465 TonsAhmed AzadAún no hay calificaciones

- Refrigeration Dryer CD-seriesDocumento8 páginasRefrigeration Dryer CD-series1hamdijaAún no hay calificaciones

- Alfa Laval Brazed Heat ExchangersDocumento20 páginasAlfa Laval Brazed Heat ExchangersCelso FernandesAún no hay calificaciones

- Section 109 Land Reforms Act - 1961Documento3 páginasSection 109 Land Reforms Act - 1961maheshmrplegalisAún no hay calificaciones

- Vol-1, Issue-5Documento7 páginasVol-1, Issue-5Ijrei JournalAún no hay calificaciones

- Consider A Two-Stage Cascade Refrigeration System .Documento5 páginasConsider A Two-Stage Cascade Refrigeration System .NaufalAún no hay calificaciones

- Sroc 04Documento44 páginasSroc 04ambuenaflorAún no hay calificaciones

- Ammonia Storage Decommissioning PDFDocumento19 páginasAmmonia Storage Decommissioning PDFDAYAMOY APL100% (1)

- Libert PDX-S User ManualDocumento86 páginasLibert PDX-S User ManualTờ Rí50% (2)

- MHOD District Cooling - Arup 29-09-2011Documento52 páginasMHOD District Cooling - Arup 29-09-2011Mrityunjay MallikAún no hay calificaciones

- Thermo Scientific Revco UxF40086DDocumento2 páginasThermo Scientific Revco UxF40086DdouglaslinoAún no hay calificaciones

- DX System Vs Ammonia AbsorptionDocumento33 páginasDX System Vs Ammonia AbsorptionFahim I. SiddiquiAún no hay calificaciones

- Heat Pump - Refrigeration and LiquefactionDocumento72 páginasHeat Pump - Refrigeration and LiquefactionhananAún no hay calificaciones

- Module II - Application of ThermodynamicsDocumento22 páginasModule II - Application of Thermodynamicsbalaji08Aún no hay calificaciones

- Pre-Insulated Plastic Pipe Systems OverviewDocumento18 páginasPre-Insulated Plastic Pipe Systems OverviewRebecca TerryAún no hay calificaciones

- Imo (7 04Documento21 páginasImo (7 04drthuhanAún no hay calificaciones

- Compressor Manual P 251511 Om Ssp1 GBR 3-A4Documento82 páginasCompressor Manual P 251511 Om Ssp1 GBR 3-A4PRKrauseAún no hay calificaciones