Documentos de Académico

Documentos de Profesional

Documentos de Cultura

HFIC

Cargado por

walkerbho0 calificaciones0% encontró este documento útil (0 votos)

111 vistas2 páginasFluoride Ion Cleaning

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF, TXT o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoFluoride Ion Cleaning

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

111 vistas2 páginasHFIC

Cargado por

walkerbhoFluoride Ion Cleaning

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

Está en la página 1de 2

FLUORIDE ION CLEANING

AS A PREBRAZE PROCESS

A special prebraze cleaning Some base metals and compo- capable of removing these deeply

process called fluoride ion

cleaning was developed

S nents, such as stainless steels and

Co- and Ni-base superalloys

used in land-based and aero-

space turbine blades and vanes, re-

imbedded oxides. FIC is a process

that can prepare gas-turbine compo-

nents for braze repair by removing

oxides present on parts that have been

to remove complex Ti and quire special methods to prepare the in service. Once the oxides have been

Al oxides from superalloys surface prior to brazing. These removed, the surface and cracks

used in gas turbines methods include vacuum cleaning, hy- can be braze repaired with excellent

drogen partial pressure cleaning, and results.

because conventional fluoride ion cleaning (FIC). Conven-

cleaning processes like tional processes such as hydrogen What is FIC?

cleaning were effective for a wide Fluoride ion cleaning, synonymous

hydrogen cleaning range of stainless steels, cobalt- and with hydrogen fluoride (HF) ion

(bright annealing) are nickel-base alloys. However, hy- cleaning, has been proven to be a

unable to remove them for drogen is not very effective on alloys highly effective process for the removal

containing significant amounts of alu- of deeply embedded oxides from

effective brazing. minum and titanium. These two superalloys containing significant

metals severely oxidize to form com- amounts of aluminum and titanium.

plex spinels on hardware surfaces It was developed by a major jet-engine

Robert Kornfeld that penetrate deeply into existing manufacturer as a cost effective repair

Hi-Tech Furnace Systems Inc. cracks. process for nickel-base airfoil compo-

Shelby Township, Mich. Only cleaning methods using the nents such as turbine blades and

fluoride-ion technique are currently vanes. Today it is widely used to pre-

Bell type furnace used for fluoride ion cleaning of aerospace parts prior to brazing

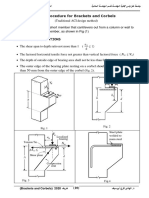

IGT nozzles ready for fluoride ion cleaning in bell type furnace. Typical fixtures for bell type furnace system.

38 HEAT TREATING PROGRESS MAY/JUNE 2006

Photomicrograph illustrates

general alloy depletion along the surface

with areas of deeper localized depletion.

Sample is IN-713 nickel-base

superalloy material.

For more information:

Robert E. Kornfeld is president, Hi-Tech Furnace Systems Inc.,

50685 wing Dr., Shelby Township, MI 48315; tel: 586-566-0600; fax:

586-566-9253; e-mail: rkornfeld@hi-techfurnace.com; Internet:

www.hi-techfurnace.com.

pare cobalt- and nickel-base superal-

loys for braze repair/activated diffu-

sion healing (ADH) on jet engines and

industrial gas turbines.

FIC is a vacuum/thermal/chemical

process that operates in a pressure and

temperature range of 100 torr (133

mbar) to atmospheric and 1750 to

1900F (955 to 1040C), respectively,

using HF (anhydrous hydrogen fluo-

ride) gas, which must be precisely me-

tered during the process. FIC utilizing

HF gas offers a more precise and con-

sistent alternative to other more

complex techniques. The process

attacks deeply imbedded oxides

(surface and cracks) through the fol-

lowing reactions:

6 HF + Al2O3 > 2 AlF3 + 3 H2O

4 HF + TiO2 > TiF4 + 2 H2O

6 HF + Cr2O3 > 2 CrF2 + F2 + 3 H2O

Vacuum/partial pressure increases

effectiveness for removal of oxides

from cracks and inside of cooling pas-

sages. HF gas is forced into voids and

cracks, and lower pressure helps boil

off oxides illustrated by the reactions:

6 HF + 2Al > 2AlF3 + 3H2

8 HF + 2Ti > 2TiF4 + 4H2

The depletion reaction is a function

of temperature, concentration of HF,

and alloy composition. Surface deple-

tion of Ti and Al also occurs.

FIC is a cost-effective, repeatable

process. The generation of HF is inde-

pendent of the part process tempera-

ture and is not a secondary reaction.

HF concentration, cleaning time, pres-

sure and temperature are independent

process variables. In addition, the

process offers reliable off-gas manage-

ment, and process residuals are

neutralized for easy disposal.

HEAT TREATING PROGRESS MAY/JUNE 2006 39

También podría gustarte

- EAF and Secondary Dust CharacterisationDocumento8 páginasEAF and Secondary Dust CharacterisationJorge MadiasAún no hay calificaciones

- Thermodynamic and Kinetic Aspects of Secondary Steelmaking ProcessesDocumento37 páginasThermodynamic and Kinetic Aspects of Secondary Steelmaking ProcessesHASSAN MUSHTAQAún no hay calificaciones

- Reducing Dioxin Emissions in Electric Steel Mills PDFDocumento4 páginasReducing Dioxin Emissions in Electric Steel Mills PDFJames DuAún no hay calificaciones

- Direct Reduction and Smelting Processes - IMPORTANTDocumento40 páginasDirect Reduction and Smelting Processes - IMPORTANTffgfgfgffgAún no hay calificaciones

- 0229 RedlDocumento8 páginas0229 Redlasad.ittibaAún no hay calificaciones

- Resources, Conservation & Recycling: ReviewDocumento17 páginasResources, Conservation & Recycling: ReviewKatia UrearAún no hay calificaciones

- Nitriding CLIN Process HEFDocumento6 páginasNitriding CLIN Process HEFsreedhar srinivasanAún no hay calificaciones

- EAF DustTreatment ByNewProcessDocumento11 páginasEAF DustTreatment ByNewProcessAlsultan AlsultanAún no hay calificaciones

- Improving Repair Qualitv of Turbine Nozzles Using SA650 Braze AlloyDocumento8 páginasImproving Repair Qualitv of Turbine Nozzles Using SA650 Braze AlloywalkerbhoAún no hay calificaciones

- CAPE Chemistry Module 3Documento18 páginasCAPE Chemistry Module 3mcphersonsheroniAún no hay calificaciones

- Prospects For Coal-Based Direct Reduction Process: Haruyasu MICHISHITA, Hidetoshi TANAKADocumento8 páginasProspects For Coal-Based Direct Reduction Process: Haruyasu MICHISHITA, Hidetoshi TANAKAsikeme4327nic58.comAún no hay calificaciones

- Kho Swinbourne10 Mpm188 EAFDocumento9 páginasKho Swinbourne10 Mpm188 EAFalilounahdisteAún no hay calificaciones

- Smelting Potential of Hismelt Technology For High-Phosphorus Iron Ore and IlmeniteDocumento5 páginasSmelting Potential of Hismelt Technology For High-Phosphorus Iron Ore and IlmeniteamrohAún no hay calificaciones

- PPBB01-Kelompok 7-Rotary Hearth FurnaceDocumento25 páginasPPBB01-Kelompok 7-Rotary Hearth FurnaceFikriAún no hay calificaciones

- CBloch ACC CommissioningDocumento28 páginasCBloch ACC CommissioningManuel PerezAún no hay calificaciones

- EAF DustTreatment ByNewProcessDocumento11 páginasEAF DustTreatment ByNewProcessAgustine Setiawan100% (1)

- Proceso Finex y CorexDocumento15 páginasProceso Finex y CorexAnthony AlvarezAún no hay calificaciones

- Study of Fluxless Soldering Using Formic Acid Vapor - IEEE Trans On Adv PKG, Nov 1999Documento10 páginasStudy of Fluxless Soldering Using Formic Acid Vapor - IEEE Trans On Adv PKG, Nov 1999pelenius100% (1)

- Kho Swinbourne10 mpm188 EAFDocumento9 páginasKho Swinbourne10 mpm188 EAFRICCO LauwisAún no hay calificaciones

- HTTP Hbia - Org Technical Openpdf - CFM Filename DRProcess 2001-2DRDocumento9 páginasHTTP Hbia - Org Technical Openpdf - CFM Filename DRProcess 2001-2DRpdiconpAún no hay calificaciones

- Productive Recycling of BOF Sludge in Integrated PlantDocumento5 páginasProductive Recycling of BOF Sludge in Integrated PlantJorge MadiasAún no hay calificaciones

- Copper Smelting and Converting: Past and Present Chilean DevelopmentsDocumento11 páginasCopper Smelting and Converting: Past and Present Chilean DevelopmentsMARCELO HINOJOSA HERNANDEZAún no hay calificaciones

- Nitro Car Buri ZingDocumento9 páginasNitro Car Buri ZingJesus Alberto Perez AlvarezAún no hay calificaciones

- High Efficiency N-Type PERT and PERL Solar CellsDocumento4 páginasHigh Efficiency N-Type PERT and PERL Solar CellshakimkorichiAún no hay calificaciones

- Alternative Routes To Iron MakingDocumento8 páginasAlternative Routes To Iron MakingMohd AyazAún no hay calificaciones

- Control Corrosion Factors in Ammonia and Urea PlantsDocumento13 páginasControl Corrosion Factors in Ammonia and Urea PlantsLiu YangtzeAún no hay calificaciones

- Future Coils For Ethylene FurnacesDocumento2 páginasFuture Coils For Ethylene FurnacesAli DarvishiAún no hay calificaciones

- Mitigating Coke Formation Hydrocarbon Engineering July2014 PDFDocumento3 páginasMitigating Coke Formation Hydrocarbon Engineering July2014 PDFghasem_726990287Aún no hay calificaciones

- influence-and-control-of-gases-and-blends-during-sintering-of-carbon-steel-partsDocumento12 páginasinfluence-and-control-of-gases-and-blends-during-sintering-of-carbon-steel-partsHossein Hosseini RadAún no hay calificaciones

- 08 - FGD by Ammonia Scrubbing in CFB Power PlantDocumento4 páginas08 - FGD by Ammonia Scrubbing in CFB Power PlantNishantAún no hay calificaciones

- HP 01 2020 Tip Linde Graf tcm17-585707Documento3 páginasHP 01 2020 Tip Linde Graf tcm17-585707puri16Aún no hay calificaciones

- Improve Metallurgical Properties and Increase Productlvlty Using Ion NitridingDocumento4 páginasImprove Metallurgical Properties and Increase Productlvlty Using Ion NitridingsleonAún no hay calificaciones

- Copper Cementation From The Waste Effluents of Primary Copper IndustryDocumento6 páginasCopper Cementation From The Waste Effluents of Primary Copper IndustryIoannis KapageridisAún no hay calificaciones

- ASM Hand Book, Volchapter 1. 2003. An Introduion To Nitriding ASM InternationalDocumento14 páginasASM Hand Book, Volchapter 1. 2003. An Introduion To Nitriding ASM Internationalrpr 04121997Aún no hay calificaciones

- Abbott ASV 2009Documento7 páginasAbbott ASV 2009juanpablo bohorquez ricoAún no hay calificaciones

- Rec. de ZNDocumento8 páginasRec. de ZNedwin quintanillaAún no hay calificaciones

- Direct Reduction and Smelting ProcessesDocumento40 páginasDirect Reduction and Smelting ProcessesAfza NurhakimAún no hay calificaciones

- Controlling SO2 emissions without corroding the bottom lineDocumento8 páginasControlling SO2 emissions without corroding the bottom lineLisbeth Roos RoosAún no hay calificaciones

- 4331 Eap 1117080Documento6 páginas4331 Eap 1117080Farah Talib Al-sudaniAún no hay calificaciones

- Reducing NOx Emissions from Cement Kiln PlantsDocumento9 páginasReducing NOx Emissions from Cement Kiln PlantsKristínaAún no hay calificaciones

- An Overview On Designing An Environmental Friendly Electrode Manufacturing Process (EFEMP)Documento7 páginasAn Overview On Designing An Environmental Friendly Electrode Manufacturing Process (EFEMP)jai2009Aún no hay calificaciones

- Cleanliness of Low Carbon Aluminum-Killed Steels During Secondary Refining ProcessesDocumento17 páginasCleanliness of Low Carbon Aluminum-Killed Steels During Secondary Refining ProcessesPhuNguyenVanAún no hay calificaciones

- Vanadium Recovery As Fev From Petroleum Fly ASH: Y. Xiao, C. R. Mambote, H. Jalkanen, Y. Yang and R. BoomDocumento10 páginasVanadium Recovery As Fev From Petroleum Fly ASH: Y. Xiao, C. R. Mambote, H. Jalkanen, Y. Yang and R. BoomnikitaambeAún no hay calificaciones

- Sponge Iron ManufacturingDocumento14 páginasSponge Iron Manufacturingapi-2604165367% (3)

- Furnace Technology Argon PurgingDocumento7 páginasFurnace Technology Argon Purgingvasanthi100% (1)

- 19.1.7 A New Approach To Migrant Iron Control in Industrial and Power Generation Steam SystemsDocumento19 páginas19.1.7 A New Approach To Migrant Iron Control in Industrial and Power Generation Steam SystemsJose Luis Frias ColoradoAún no hay calificaciones

- BrilumDocumento4 páginasBrilumkhanqaderi786Aún no hay calificaciones

- Brazing: Selection Brazing Processes and Filler MetalsDocumento14 páginasBrazing: Selection Brazing Processes and Filler MetalsMarcionilo NeriAún no hay calificaciones

- BerelimDocumento5 páginasBerelimalirezayusufyarAún no hay calificaciones

- Article Chemical Engineering July 2017 Activated Carbon Fundamentals and New ApplicationsDocumento10 páginasArticle Chemical Engineering July 2017 Activated Carbon Fundamentals and New ApplicationsHonguito WebAún no hay calificaciones

- FUNDAMENTALS OF ZINC RECOVERY FROM METALLURGICAL Wastes in The Enviroplas Process PDFDocumento14 páginasFUNDAMENTALS OF ZINC RECOVERY FROM METALLURGICAL Wastes in The Enviroplas Process PDFManojlovic Vaso100% (1)

- 3.engine Exhaust SystemDocumento8 páginas3.engine Exhaust SystempspadaAún no hay calificaciones

- New immersion tin generation combining organic metal and tin for printed circuit boardsDocumento4 páginasNew immersion tin generation combining organic metal and tin for printed circuit boardsAnh Mai NgôAún no hay calificaciones

- Ferronickel Smelting Plant Electric Furnace Off-Gas Utilization To Save EnergyDocumento4 páginasFerronickel Smelting Plant Electric Furnace Off-Gas Utilization To Save Energyasad.ittibaAún no hay calificaciones

- Nitro - CarburizingDocumento9 páginasNitro - CarburizingRajaSekarsajjaAún no hay calificaciones

- The Linde Solinox Process: Gypsum-Free Flue-Gas DesulphurizationDocumento8 páginasThe Linde Solinox Process: Gypsum-Free Flue-Gas DesulphurizationDũng LêAún no hay calificaciones

- The Chemistry of Iron, Cobalt and Nickel: Comprehensive Inorganic ChemistryDe EverandThe Chemistry of Iron, Cobalt and Nickel: Comprehensive Inorganic ChemistryAún no hay calificaciones

- Materials Technology in Steam Reforming Processes: Proceedings of the Materials Technology Symposium Held on October 21-22, 1964, Organised by the Agricultural Division, Imperial Chemical Industries Ltd.De EverandMaterials Technology in Steam Reforming Processes: Proceedings of the Materials Technology Symposium Held on October 21-22, 1964, Organised by the Agricultural Division, Imperial Chemical Industries Ltd.C. EdeleanuCalificación: 5 de 5 estrellas5/5 (1)

- Extractive Metallurgy 3: Processing Operations and RoutesDe EverandExtractive Metallurgy 3: Processing Operations and RoutesAún no hay calificaciones

- Evaluation of Uncertainty in Determining Average Grain Size by ASTM E112 StandardDocumento9 páginasEvaluation of Uncertainty in Determining Average Grain Size by ASTM E112 StandardwalkerbhoAún no hay calificaciones

- Principles Solidification: "Calculation and Applications Phase Equilibria"Documento33 páginasPrinciples Solidification: "Calculation and Applications Phase Equilibria"Amit Ranjan KumarAún no hay calificaciones

- Improving Repair Qualitv of Turbine Nozzles Using SA650 Braze AlloyDocumento8 páginasImproving Repair Qualitv of Turbine Nozzles Using SA650 Braze AlloywalkerbhoAún no hay calificaciones

- Struers Application Note - Metallographic Preparation of TitaniumDocumento6 páginasStruers Application Note - Metallographic Preparation of TitaniumCan ERTANAún no hay calificaciones

- Effect of Si Addition As A Grain RefinerDocumento12 páginasEffect of Si Addition As A Grain RefinerwalkerbhoAún no hay calificaciones

- SIHARD 2243 Steel: Designation by StandardsDocumento3 páginasSIHARD 2243 Steel: Designation by StandardswalkerbhoAún no hay calificaciones

- Diagrammi Di StatoDocumento1 páginaDiagrammi Di StatowalkerbhoAún no hay calificaciones

- Evaluation of Uncertainty in Determining Average Grain Size by ASTM E112 StandardDocumento9 páginasEvaluation of Uncertainty in Determining Average Grain Size by ASTM E112 StandardwalkerbhoAún no hay calificaciones

- Niobium To Stainless Steel Braze Transition DevelopmentDocumento3 páginasNiobium To Stainless Steel Braze Transition DevelopmentwalkerbhoAún no hay calificaciones

- Wide Gap Brazing When Parts Don't Fit Together Well For BrazingDocumento2 páginasWide Gap Brazing When Parts Don't Fit Together Well For BrazingwalkerbhoAún no hay calificaciones

- Microstructure Analysis of Selected Platinum Alloys: by Paolo BattainiDocumento10 páginasMicrostructure Analysis of Selected Platinum Alloys: by Paolo BattainirezaeibehrouzAún no hay calificaciones

- Mechanical Preparation of MaterialsDocumento11 páginasMechanical Preparation of MaterialswalkerbhoAún no hay calificaciones

- s41598 018 20386 1Documento10 páginass41598 018 20386 1walkerbhoAún no hay calificaciones

- Hot Mounting Resins Guide Speed, Protection & QualityDocumento6 páginasHot Mounting Resins Guide Speed, Protection & QualitywalkerbhoAún no hay calificaciones

- NIS ElementsDocumento245 páginasNIS ElementswalkerbhoAún no hay calificaciones

- Al 7075Documento11 páginasAl 7075walkerbhoAún no hay calificaciones

- TextureDocumento29 páginasTexturedebjit123Aún no hay calificaciones

- C 6 Ra 28464 GDocumento9 páginasC 6 Ra 28464 GwalkerbhoAún no hay calificaciones

- GB Grade EmatiiDocumento2 páginasGB Grade EmatiiwalkerbhoAún no hay calificaciones

- Matrix IIDocumento5 páginasMatrix IIwalkerbhoAún no hay calificaciones

- Ti Metastable DiagramDocumento1 páginaTi Metastable DiagramwalkerbhoAún no hay calificaciones

- Matrix IIDocumento5 páginasMatrix IIwalkerbhoAún no hay calificaciones

- Conv. Durezza TitanioDocumento37 páginasConv. Durezza TitaniowalkerbhoAún no hay calificaciones

- ASTM E2658 Standard Practices For Verification of Speed For Material Tetsign MachinesDocumento10 páginasASTM E2658 Standard Practices For Verification of Speed For Material Tetsign MachineswalkerbhoAún no hay calificaciones

- It A Specifications Book 2005Documento45 páginasIt A Specifications Book 2005walkerbhoAún no hay calificaciones

- Conv. Durezza TitanioDocumento37 páginasConv. Durezza TitaniowalkerbhoAún no hay calificaciones

- Vickers Hardness CalculatorDocumento2 páginasVickers Hardness CalculatorwalkerbhoAún no hay calificaciones

- Calculation of The Crosshead Velocity Required To Achieve A Specified Stress Rate or An Estimated Strain RateDocumento9 páginasCalculation of The Crosshead Velocity Required To Achieve A Specified Stress Rate or An Estimated Strain Ratemp87_ing100% (1)

- MA200 Instruction Manual PDFDocumento107 páginasMA200 Instruction Manual PDFwalkerbhoAún no hay calificaciones

- Tensile Test For Metallic Materials Using Strain Rate Control and Stress Rate ControlDocumento11 páginasTensile Test For Metallic Materials Using Strain Rate Control and Stress Rate ControlwalkerbhoAún no hay calificaciones

- IS Code of Cement & ConcreteDocumento8 páginasIS Code of Cement & ConcreteKuldeep UpadhyayAún no hay calificaciones

- SWAGELOK-prise Échantillon en BouteillesDocumento8 páginasSWAGELOK-prise Échantillon en BouteillesmarsulexAún no hay calificaciones

- Green Building Materials Guide: Characteristics, Selection & CategoriesDocumento23 páginasGreen Building Materials Guide: Characteristics, Selection & Categoriessusmita sethiAún no hay calificaciones

- Cold Rooms Amp Insulated Panels TSSCDocumento32 páginasCold Rooms Amp Insulated Panels TSSCZar KhariAún no hay calificaciones

- Fisa Tehnica Robineti Sertar R55Documento2 páginasFisa Tehnica Robineti Sertar R55Petrisor FilipAún no hay calificaciones

- STR Myanmar Co., LTD Mgs Kitchen Project 7/6/2020Documento5 páginasSTR Myanmar Co., LTD Mgs Kitchen Project 7/6/2020Myanmar Ding Ming XinAún no hay calificaciones

- Sluice Valve With ISI MarkDocumento3 páginasSluice Valve With ISI Markatul.mankarAún no hay calificaciones

- Ebook Solvent Cement Guide PDF V3Documento17 páginasEbook Solvent Cement Guide PDF V3hjgkhgAún no hay calificaciones

- Coast Aluminum Catalog, 2021 (8120) 77a8Documento204 páginasCoast Aluminum Catalog, 2021 (8120) 77a8jose.mora-oldAún no hay calificaciones

- Weight and dimensions of water-filled steel and PVC pipesDocumento11 páginasWeight and dimensions of water-filled steel and PVC pipesmoh. rusli bahtiarAún no hay calificaciones

- Data Sheet BISALLOY 500-STEELDocumento1 páginaData Sheet BISALLOY 500-STEELFery FebryantoAún no hay calificaciones

- Highly stressed die forgings technical termsDocumento22 páginasHighly stressed die forgings technical termsLeo AislanAún no hay calificaciones

- McMaster - About Plastics Doc 8574KACDocumento3 páginasMcMaster - About Plastics Doc 8574KACkristechnikAún no hay calificaciones

- Cap Boiler ManualDocumento43 páginasCap Boiler Manualdnageshm4n244100% (1)

- Brackets and Corbels ACI 318 L # 1Documento7 páginasBrackets and Corbels ACI 318 L # 1soran azizAún no hay calificaciones

- Chapter 2 - CompositesDocumento42 páginasChapter 2 - CompositesAmmar SafwtAún no hay calificaciones

- BQ Pintu & JendelaDocumento13 páginasBQ Pintu & Jendelahasan albanaAún no hay calificaciones

- Project Cost 18 Feb 2015Documento137 páginasProject Cost 18 Feb 2015SarinAún no hay calificaciones

- Boiler Maintenance Gyanendra Sharma NPTI DelhiDocumento38 páginasBoiler Maintenance Gyanendra Sharma NPTI DelhiNPTI100% (1)

- 2021-22 Asia Line Book FaucetDocumento172 páginas2021-22 Asia Line Book FaucetThảo PhươngAún no hay calificaciones

- ASTM D3754 Tuberia de Fibra de VIdirio para Sistemas Industriales y A PresiónDocumento14 páginasASTM D3754 Tuberia de Fibra de VIdirio para Sistemas Industriales y A PresiónalexagoAún no hay calificaciones

- Alltek: An Internal Finish For Walls & Ceilings, Designed To Replace Gypsum Based PlasterDocumento3 páginasAlltek: An Internal Finish For Walls & Ceilings, Designed To Replace Gypsum Based PlasterTinasheAún no hay calificaciones

- Chemistry Project MannyDocumento12 páginasChemistry Project Mannyabhishekhembrom89Aún no hay calificaciones

- 3 Week AheadDocumento2 páginas3 Week AheadAlessandro Del BorgiaAún no hay calificaciones

- Revere Concept 175w-250w Mercury Series Bulletin 1966Documento2 páginasRevere Concept 175w-250w Mercury Series Bulletin 1966Alan MastersAún no hay calificaciones

- YA-SY18: Tin/Ticn-Coated HSS-PM (Powder Metallurgy) TAPSDocumento12 páginasYA-SY18: Tin/Ticn-Coated HSS-PM (Powder Metallurgy) TAPSpo truongAún no hay calificaciones

- Alucoworld E CatalogueDocumento22 páginasAlucoworld E CatalogueRicardo Miguel Ayllon CamachoAún no hay calificaciones

- S235, S275, S355 Structural Steel Grades GuideDocumento5 páginasS235, S275, S355 Structural Steel Grades GuideGopi KrishnanAún no hay calificaciones

- Data Sheet Soundsoak Walls PDFDocumento2 páginasData Sheet Soundsoak Walls PDFSameera LakmalAún no hay calificaciones

- 33 05 23.16 Pipe JackingDocumento3 páginas33 05 23.16 Pipe JackingisaacalvareztejanoAún no hay calificaciones