Documentos de Académico

Documentos de Profesional

Documentos de Cultura

en

Cargado por

Raphael Lino0 calificaciones0% encontró este documento útil (0 votos)

30 vistas2 páginasen

Título original

10501 En

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF, TXT o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoen

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

30 vistas2 páginasen

Cargado por

Raphael Linoen

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

Está en la página 1de 2

Belt Drive of Gear Unit

10501EN.doc 21.12.1999

V-BELT DRIVE OF GEAR UNIT

1. General 2.5 Installation of taper bushings (5210, 5212)

The V-belt drive is supplied as an optional accessory 2.5.1 Remove the protective grease from the

to gear units. For details, see Fig. 1. The V-belt drive is bushings and pulley hub. Insert the bushing

available as follows: in the hub and make sure that the holes are

- complete v-belt drive assembly (including pulleys, aligned.

V-belts tapered bushings, motor bracket and the 2.5.2 Apply grease to the fixing screws and screw

belt guard). them in position. The thread is in the pulley

- motor bracket and belt guard (including motor hub.

bracket, screws and belt guard). 2.5.3 Clean the shaft and insert the pulley and

- motor supplied only when ordered. sleeve.

All the versions (excluding V-belt guard only) will be 2.5.4 Tighten the screws.

supplied fully assembled on the gear unit. 2.5.5 Knock the sleeve lightly and relighten the

Any combination of the above options will also be screws. Repeat this a couple of times.

supplied. 2.5.6 Check the screws for tightness at least every

3000 hours.

2. Installation 2.5.7 Fill the pull holes with grease to prevent the

Installation sequence: ingress of dirt.

2.1 Mount the motor bracket (5112, 5110) to the gear. 2.6 Draw the V-belts (5218) over the pulleys and

tension the belts by means of the adjustment

2.2 Mount the motor onto the bracket.

screws in the motor bracket. When tightening the

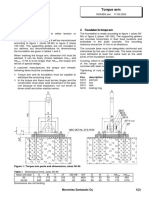

2.3 Fix the belt guard rear plate (5260) to the gear unit V-belts, make sure that the pulleys are aligned

motor bracket by means of fixings (pre-tightening). accurately enough. Use a steel liner to check

When mounting the rear plate, note the desired alignment as shown in Fig. 2. Make sure that the

direction of opening of the door. See note, Fig.1 ruler makes contact at four points. The maximum

permissible error of angle is 1mm per 1000mm

2.4 Mount the pulleys (5214, 5216) on the motor and span of the V-belt. Tension the V-belts according

gear shafts (as close to the shoulder as possible). to Table 1. This is the only way to ensure

maximum power transmission efficiency and to

prevent excessive loads on the gear and motor

shafts.

V-belt tension adjustm ent

Note! If the guard upper fixing (5262) is attached to the upper plate of the motor

bracket (5110), it must be loosened before adjusting the v-belt tension.

Fig. 1 Fig. 2

Moventas Santasalo Oy 1(2)

Belt Drive of Gear Unit

10501EN.doc 21.12.1999

Table 1. V-belt tightening.

3. Limitations

V-belt Smaller Force required to displace the V-

The following limitations for the use of V-belt drives

profile pulley belt by 16mm per one meter of

shall apply:

span length

d1 [mm] Newton (N) 3.1 V-belt speed

SPZ 56 - 95 13 - 20 The V-belt speed determined by the manufacturer

100 - 140 20 - 25 of cast-iron V-belt pulleys is:

SPA 80 - 132 25 - 35

140 - 200 35 - 45 vhmax = 35 m/s

SPB 112 - 224 45 - 65

236 - 315 65 - 85 3.2 Usually, a V-belt drive requires no extra

SPC 224 - 355 85 - 115 inspections, if the ambient temperature does not

375 - 560 115 - 150 exceed 70C. V-belt drives used at temperatures

exceeding 70C should be checked regularly at

Check the V-belt tension as follows (using a V-belt least every 1500 hours.

tension meter):

2.6.1 Measure the length of the V-belt span

(= free V-belt length).

2.6.2 Measure the perpendicular force causing a

16mm sag per one metre of V-belt.

2.6.3 Compare the measured values with those

listed in Table 1.

A new V-belt must be tensioned to the higher value

because it stretches in use. All V-belts should be

retensioned every 3000 hours.

2.7 Tighten the locking screws for the motor rack and

the belt guard rear plate.

2.8 Mount the belt guard lid using the hinge pins and

lock the pins.

Moventas Santasalo Oy 2(2)

También podría gustarte

- Awwa Hdpe PDFDocumento37 páginasAwwa Hdpe PDFRaphael LinoAún no hay calificaciones

- 5 - Equivalencia de Normas PERNOSDocumento1 página5 - Equivalencia de Normas PERNOSRaphael LinoAún no hay calificaciones

- Lubricants in Industrial Gears: Ath Lubrication Plash Lubrication Rease Lubrication Ressure Feed LubricationDocumento9 páginasLubricants in Industrial Gears: Ath Lubrication Plash Lubrication Rease Lubrication Ressure Feed LubricationRaphael LinoAún no hay calificaciones

- Assembly Report: Gear Unit: Manuf. Number: DriveDocumento1 páginaAssembly Report: Gear Unit: Manuf. Number: DriveRaphael LinoAún no hay calificaciones

- Mdi 110en PDFDocumento2 páginasMdi 110en PDFRaphael LinoAún no hay calificaciones

- Pressure lubrication unit connectionsDocumento2 páginasPressure lubrication unit connectionsRaphael LinoAún no hay calificaciones

- enDocumento2 páginasenRaphael LinoAún no hay calificaciones

- L3206en PDFDocumento2 páginasL3206en PDFRaphael LinoAún no hay calificaciones

- MDI 120EN - Safety GuideDocumento6 páginasMDI 120EN - Safety GuideRaphael LinoAún no hay calificaciones

- Corrosion Protection and StorageDocumento3 páginasCorrosion Protection and StorageRaphael LinoAún no hay calificaciones

- Use and Maintenance of Gear UnitDocumento4 páginasUse and Maintenance of Gear UnitRaphael LinoAún no hay calificaciones

- Use and Maintenance of Gear UnitDocumento4 páginasUse and Maintenance of Gear UnitRaphael LinoAún no hay calificaciones

- Corrosion Protection and StorageDocumento3 páginasCorrosion Protection and StorageRaphael LinoAún no hay calificaciones

- MDI 165EN - InstallingDocumento5 páginasMDI 165EN - InstallingRaphael LinoAún no hay calificaciones

- M062210 Tech SpecDocumento1 páginaM062210 Tech SpecRaphael LinoAún no hay calificaciones

- Mdi 110enDocumento2 páginasMdi 110enRaphael LinoAún no hay calificaciones

- M062210 Part ListDocumento4 páginasM062210 Part ListRaphael LinoAún no hay calificaciones

- MDI 120EN - Safety GuideDocumento6 páginasMDI 120EN - Safety GuideRaphael LinoAún no hay calificaciones

- M062210 - Manual Cover SheetDocumento1 páginaM062210 - Manual Cover SheetRaphael LinoAún no hay calificaciones

- L3206en PDFDocumento2 páginasL3206en PDFRaphael LinoAún no hay calificaciones

- Visual Differential Pressure Indicator: Type FPC V 10 VMDocumento1 páginaVisual Differential Pressure Indicator: Type FPC V 10 VMRaphael LinoAún no hay calificaciones

- L3206ENDocumento2 páginasL3206ENRaphael LinoAún no hay calificaciones

- enDocumento2 páginasenRaphael LinoAún no hay calificaciones

- 2577910.dimensional DrawingDocumento1 página2577910.dimensional DrawingRaphael LinoAún no hay calificaciones

- Safety Valve Durgo: 2. Ensure The Valve FunctionsDocumento1 páginaSafety Valve Durgo: 2. Ensure The Valve FunctionsRaphael LinoAún no hay calificaciones

- Astm A105Documento1 páginaAstm A105Raphael LinoAún no hay calificaciones

- enDocumento1 páginaenRaphael LinoAún no hay calificaciones

- enDocumento2 páginasenRaphael Lino100% (1)

- Shaft Driven Pump Operation DirectionsDocumento1 páginaShaft Driven Pump Operation DirectionsRaphael LinoAún no hay calificaciones

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (119)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2099)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- PC v00Documento108 páginasPC v00AgusBetaAún no hay calificaciones

- TR Rice Machinery Operations NC IIDocumento65 páginasTR Rice Machinery Operations NC IIApple Monderin100% (4)

- Wheel Horse Pulley Driven Generac Portable Generator Owners ManualDocumento22 páginasWheel Horse Pulley Driven Generac Portable Generator Owners ManualKevins Small Engine and Tractor ServiceAún no hay calificaciones

- Pascall - Catalogue - CAPCODocumento28 páginasPascall - Catalogue - CAPCOBelialShaun0% (1)

- Assembly Manual 2.4r2 HighcontrastDocumento293 páginasAssembly Manual 2.4r2 HighcontrastGeorge DonosaAún no hay calificaciones

- Catalogo de Piezas Español 644jDocumento700 páginasCatalogo de Piezas Español 644jELIZBANAún no hay calificaciones

- 700rcsj DVJ Manual Rev0410Documento24 páginas700rcsj DVJ Manual Rev0410Cono MetaAún no hay calificaciones

- Chapter 2 SolutionDocumento4 páginasChapter 2 SolutionEngr ShabirAún no hay calificaciones

- Mechanical BeltsDocumento9 páginasMechanical BeltstorresgiovanniAún no hay calificaciones

- Chp8 Parametric Design PDFDocumento34 páginasChp8 Parametric Design PDFThanhNguyenAún no hay calificaciones

- GS2912 Caterpillar 3508 GeneratorSet Build SheetDocumento3 páginasGS2912 Caterpillar 3508 GeneratorSet Build SheetLuis Emilio Santana DiazAún no hay calificaciones

- 00 - MAR - IND9D57 - DS - EN SMDocumento2 páginas00 - MAR - IND9D57 - DS - EN SMErick MelendezAún no hay calificaciones

- 1507556580atuadores Lineares Mecanicos Serie KDocumento17 páginas1507556580atuadores Lineares Mecanicos Serie KThomas JanjonAún no hay calificaciones

- FagDocumento198 páginasFagHamza NoumanAún no hay calificaciones

- Side Wall ConveyorDocumento47 páginasSide Wall ConveyorAnonymous BuAlxgBa0% (1)

- Price List A60HDocumento6 páginasPrice List A60HMaintenance PlannerAún no hay calificaciones

- Service Manual 3464E100-037DOC032 Edition August 2014Documento71 páginasService Manual 3464E100-037DOC032 Edition August 2014MAXAún no hay calificaciones

- Preventive Maintenance Checklist for Medical Imaging EquipmentDocumento24 páginasPreventive Maintenance Checklist for Medical Imaging EquipmentfortroniAún no hay calificaciones

- Installation and Maintenance Manual For: Dings Self-Cleaning Electro Overhead MagnetsDocumento21 páginasInstallation and Maintenance Manual For: Dings Self-Cleaning Electro Overhead MagnetsGarcia MarcosAún no hay calificaciones

- Null 3Documento4 páginasNull 3Yajnadatta PattanayakAún no hay calificaciones

- General Purpose 3-Phase Induction Motors: Product CatalogueDocumento36 páginasGeneral Purpose 3-Phase Induction Motors: Product CataloguezdrahalAún no hay calificaciones

- Prototype Grading Cereal CorpsDocumento16 páginasPrototype Grading Cereal Corpstaufiq hidAún no hay calificaciones

- Preliminaries Solution To Plate 1 (Shafting)Documento11 páginasPreliminaries Solution To Plate 1 (Shafting)PandaAún no hay calificaciones

- Drill Press: Operating Instructions and Parts ManualDocumento52 páginasDrill Press: Operating Instructions and Parts Manualhcblosbulliciosos hcblosbulliciososAún no hay calificaciones

- Fin Fan CoolersDocumento14 páginasFin Fan Coolersmohamedyoussef1Aún no hay calificaciones

- Maintenance Schedule FormatDocumento18 páginasMaintenance Schedule FormatAntoni100% (1)

- 990 Dumbwaiter and Magicart Parts GuideDocumento24 páginas990 Dumbwaiter and Magicart Parts GuidePutTank-inA-mallAún no hay calificaciones

- Double-Head Draw Frame SB-D 22: AdvantagesDocumento24 páginasDouble-Head Draw Frame SB-D 22: AdvantagesMuhammad Farooq KokabAún no hay calificaciones

- AHU Instalation Manual YorkDocumento36 páginasAHU Instalation Manual YorkBangto Yibsip50% (2)

- Chute Design Considerations For Feeding and TransferDocumento17 páginasChute Design Considerations For Feeding and TransferJose ArteagaAún no hay calificaciones