Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Zinc Spray Bright Grade

Cargado por

Anwar MohiuddinDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Zinc Spray Bright Grade

Cargado por

Anwar MohiuddinCopyright:

Formatos disponibles

Technical Datasheet

Zinc Spray bright grade Create Date: 06.06.2016 - Page 1/1

Pretreatment of the surface

Clean and degrease surfaces with WEICON Cleaner S.

Processing

Shake can before use until the mixing ball can be heard clearly. Spray

on evenly and crosswise at room temperature (approx. 20C) and at

about 25 cm distance from the surface. Dust-dry after approx. 15

minutes, fully hardened after approx. 10-12 hours.

Storage

Pressurized container: protect from sunlight and do not expose to

temperatures exceeding +50C.

Note

The specifications and recommendations given in this technical data

sheet must not be seen as guaranteed product characteristics. They

are based on our laboratory tests and on practical experience. Since

individual application conditions are beyond our knowledge, control and

long-term cathodic corrosion protection responsibility, this information is provided without any obligation.

Zinc Spray bright grade is approved by the German TV and provides We do guarantee the continuously high quality of our products.

a longlasting cathodic corrosion protection to all metal surfaces. It has However, own adequate laboratory and practical tests to find out if the

a bright colour shade matched to hot galvanization. product in question meets the requested properties are recommended.

A claim cannot be derived from them. The user bears the only

The spray forms a fast-drying, adherent protective layer of microfine responsibility for non-appropriate or other than specified applications.

zinc flakes. The zinc flakes form a resistant protective layer, even

under extreme weather and environmental conditions. Health and Safety

When using WEICON products, the physical, safety technical,

Zinc Spray bright grade can be used for the coating of welded joints toxicological and ecological data and regulations in our EC safety data

and drilled holes, as a conductive intermediate layer for spot welding sheets (www.weicon.com) must be observed.

and everywhere where metal must be protected against corrosion.

ISSA: 53.402.07

IMPA: 45 08 12

Technical data

Colour RAL 9006, "Fresh hot-dip galvanisation"

Application Indoors and outdoors

Binding agent Modified Alkyd resin

Pigment Flaky zinc and aluminium pigments

Pigment purity about 99,9 Zn / approx. 99,5 Al

Percentage of metal in dry film ca. 70 %

Content 400 ml

Specific weight 1,0 - 1,2 g/cm

Recommended primer Zinc Spray

Processing temperature +5 to +35, optimum temperature from +18 to + 25 C

Consumption at 1.5 cross coats ca. 150 ml/m

Layer thickness at 1.5 cross coats ca. 20-40 m

dust dry after ca. 15 Min.

Hardened after ca. 12 h

paintable ca. 24 h

Abrasion-resistant abrasion-resistant

Cross cutting DIN 53151 / ISO 2409 Cross cut characteristic value GT 0 to

GT 1

Salt spraying test ISO 9227 >240 h

Mandrel bend test DIN EN ISO 1519 no hair cracking

Top coating not required

Temperature resistance after complete hardening about -50 to +300 C

Storage stability 24 months

También podría gustarte

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- Quality CircleDocumento33 páginasQuality CircleSudeesh SudevanAún no hay calificaciones

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2099)

- EMMS SpecificationsDocumento18 páginasEMMS SpecificationsAnonymous dJtVwACc100% (2)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (73)

- Method Statement For Bolting SystemDocumento6 páginasMethod Statement For Bolting SystemAnwar Mohiuddin100% (1)

- Heavy Equipment Inspection ChecklistDocumento1 páginaHeavy Equipment Inspection ChecklistMyco Cris RomasantaAún no hay calificaciones

- Air Handling 02Documento20 páginasAir Handling 02Anwar MohiuddinAún no hay calificaciones

- Homo Sapiens ActivityDocumento8 páginasHomo Sapiens ActivityJhon Leamarch BaliguatAún no hay calificaciones

- Risk AssesmentDocumento6 páginasRisk AssesmentAnwar Mohiuddin0% (1)

- Method Statement For Cmu Block WorkDocumento8 páginasMethod Statement For Cmu Block WorkAnwar MohiuddinAún no hay calificaciones

- Method Statement For Cmu Block WorkDocumento8 páginasMethod Statement For Cmu Block WorkAnwar MohiuddinAún no hay calificaciones

- Little Book of Effective WritingDocumento44 páginasLittle Book of Effective Writingshalashvili100% (1)

- The Rich Hues of Purple Murex DyeDocumento44 páginasThe Rich Hues of Purple Murex DyeYiğit KılıçAún no hay calificaciones

- Indian Institute OF Management, BangaloreDocumento20 páginasIndian Institute OF Management, BangaloreGagandeep SinghAún no hay calificaciones

- Class Flanges Bolt Torque LoadsDocumento2 páginasClass Flanges Bolt Torque LoadsAulia RahmanAún no hay calificaciones

- Method Statement For Antibacterial PaintDocumento7 páginasMethod Statement For Antibacterial PaintAnwar MohiuddinAún no hay calificaciones

- Method Statement For Antibacterial PaintDocumento7 páginasMethod Statement For Antibacterial PaintAnwar MohiuddinAún no hay calificaciones

- Static Pressure Cal. (KG-MECH)Documento3 páginasStatic Pressure Cal. (KG-MECH)Anwar MohiuddinAún no hay calificaciones

- Hos-Sqm-Mos-009-01 Method Statement For Earthwork - CRSDocumento1 páginaHos-Sqm-Mos-009-01 Method Statement For Earthwork - CRSAnwar MohiuddinAún no hay calificaciones

- Under Ground Utilities HazardsDocumento1 páginaUnder Ground Utilities HazardsAnwar MohiuddinAún no hay calificaciones

- STAIRCASEDocumento10 páginasSTAIRCASEAnwar MohiuddinAún no hay calificaciones

- Investment Contract of AgreementDocumento1 páginaInvestment Contract of AgreementAnwar MohiuddinAún no hay calificaciones

- Welding & Cutting HazardsDocumento1 páginaWelding & Cutting HazardsAnwar MohiuddinAún no hay calificaciones

- Hos-Pmt-Pro-001-01 Document and Communication Codification ProcedureDocumento7 páginasHos-Pmt-Pro-001-01 Document and Communication Codification ProcedureAnwar MohiuddinAún no hay calificaciones

- Hos-Sqm-Mos-008-00 Method Statement For Cmu Block Work - CRSDocumento1 páginaHos-Sqm-Mos-008-00 Method Statement For Cmu Block Work - CRSAnwar MohiuddinAún no hay calificaciones

- Fire Prevention ChecklistDocumento1 páginaFire Prevention ChecklistAnwar MohiuddinAún no hay calificaciones

- Ultimate Load Test For GRG DomeDocumento11 páginasUltimate Load Test For GRG DomeAnwar MohiuddinAún no hay calificaciones

- 100 Bed Hospital Isolation Material DamageDocumento1 página100 Bed Hospital Isolation Material DamageAnwar MohiuddinAún no hay calificaciones

- Saep 13 PDFDocumento23 páginasSaep 13 PDFAnwar MohiuddinAún no hay calificaciones

- Air Conditioning System Presentation 160419174932Documento28 páginasAir Conditioning System Presentation 160419174932selvaAún no hay calificaciones

- PipingDocumento1 páginaPipingAnwar MohiuddinAún no hay calificaciones

- Sha'ban & Shabe Baraat - UrduDocumento6 páginasSha'ban & Shabe Baraat - UrduAnwar MohiuddinAún no hay calificaciones

- Extract Pages From Standard ASTM A370Documento3 páginasExtract Pages From Standard ASTM A370Anwar MohiuddinAún no hay calificaciones

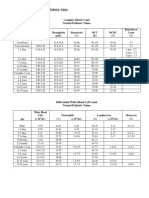

- 30a2131 Complete Blood Count Normal Pediatric Values PDFDocumento1 página30a2131 Complete Blood Count Normal Pediatric Values PDFReziel Basilan Manalo100% (2)

- Weld DefectsDocumento16 páginasWeld DefectsAnwar MohiuddinAún no hay calificaciones

- PT 1Documento4 páginasPT 1Anwar MohiuddinAún no hay calificaciones

- Linguistics: Chapter 1 - 10Documento41 páginasLinguistics: Chapter 1 - 10Ahmad A. JawadAún no hay calificaciones

- Caribbean Examinations Council Caribbean Secondary Certificate of Education Guidelines For On-Site Moderation SciencesDocumento9 páginasCaribbean Examinations Council Caribbean Secondary Certificate of Education Guidelines For On-Site Moderation SciencesjokerAún no hay calificaciones

- Java MCQ QuestionsDocumento11 páginasJava MCQ QuestionsPineappleAún no hay calificaciones

- Agricultural Sciences P1 Nov 2015 Memo EngDocumento9 páginasAgricultural Sciences P1 Nov 2015 Memo EngAbubakr IsmailAún no hay calificaciones

- R4 User GuideDocumento48 páginasR4 User GuideAaron SmithAún no hay calificaciones

- Executive Education Portfolio Soft Copy-INSEADDocumento58 páginasExecutive Education Portfolio Soft Copy-INSEADОля КусраеваAún no hay calificaciones

- Donaldson 004117 PDFDocumento6 páginasDonaldson 004117 PDFNSAún no hay calificaciones

- VARCDocumento52 páginasVARCCharlie GoyalAún no hay calificaciones

- Summer Internship Project-NishantDocumento80 páginasSummer Internship Project-Nishantnishant singhAún no hay calificaciones

- Class 9th Chemistry Unit#4 Structure of MoleculesDocumento8 páginasClass 9th Chemistry Unit#4 Structure of MoleculesIrfanullahAún no hay calificaciones

- Osora Nzeribe ResumeDocumento5 páginasOsora Nzeribe ResumeHARSHAAún no hay calificaciones

- The Slave Trade and The British Empire An Audit of Commemoration in WalesDocumento133 páginasThe Slave Trade and The British Empire An Audit of Commemoration in WaleslegoarkeologAún no hay calificaciones

- Practical LPM-122Documento31 páginasPractical LPM-122anon_251667476Aún no hay calificaciones

- 277Documento18 páginas277Rosy Andrea NicolasAún no hay calificaciones

- All MeterialsDocumento236 páginasAll MeterialsTamzid AhmedAún no hay calificaciones

- Legal Research MethodsDocumento10 páginasLegal Research MethodsCol Amit KumarAún no hay calificaciones

- Prof. Michael Murray - Some Differential Geometry ExercisesDocumento4 páginasProf. Michael Murray - Some Differential Geometry ExercisesAnonymous 9rJe2lOskxAún no hay calificaciones

- Ne 01 20 09 2018Documento436 páginasNe 01 20 09 2018VaradrajAún no hay calificaciones

- Fiery Training 1Documento346 páginasFiery Training 1shamilbasayevAún no hay calificaciones

- Mesopotamia CivilizationDocumento56 páginasMesopotamia CivilizationYashika TharwaniAún no hay calificaciones

- Daughters of The Storm by Kim Wilkins - Chapter SamplerDocumento32 páginasDaughters of The Storm by Kim Wilkins - Chapter SamplerHarlequinAustraliaAún no hay calificaciones

- Main Hoon Na - WikipediaDocumento8 páginasMain Hoon Na - WikipediaHusain ChandAún no hay calificaciones

- A.2.3. Passive Transport Systems MCQsDocumento3 páginasA.2.3. Passive Transport Systems MCQsPalanisamy SelvamaniAún no hay calificaciones

- W1inse6220 PDFDocumento11 páginasW1inse6220 PDFpicalaAún no hay calificaciones