Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Testing ESV

Cargado por

Arun Prakash100%(1)100% encontró este documento útil (1 voto)

559 vistas2 páginas1) The document provides instructions for annually testing the tightness of emergency stop valves (ESVs) against steam supply on a turbine.

2) The test is automatically performed by the turbine controller when ordered by the operator, and supervises rotor speed for 5 minutes while an ESV is closed and a control valve is open.

3) If rotor speed increases more than 10% within 5 minutes or if the control valve does not reach its ordered position within 30 seconds, the test fails and the turbine will trip.

Descripción original:

Derechos de autor

© Attribution Non-Commercial (BY-NC)

Formatos disponibles

TXT, PDF, TXT o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documento1) The document provides instructions for annually testing the tightness of emergency stop valves (ESVs) against steam supply on a turbine.

2) The test is automatically performed by the turbine controller when ordered by the operator, and supervises rotor speed for 5 minutes while an ESV is closed and a control valve is open.

3) If rotor speed increases more than 10% within 5 minutes or if the control valve does not reach its ordered position within 30 seconds, the test fails and the turbine will trip.

Copyright:

Attribution Non-Commercial (BY-NC)

Formatos disponibles

Descargue como TXT, PDF, TXT o lea en línea desde Scribd

100%(1)100% encontró este documento útil (1 voto)

559 vistas2 páginasTesting ESV

Cargado por

Arun Prakash1) The document provides instructions for annually testing the tightness of emergency stop valves (ESVs) against steam supply on a turbine.

2) The test is automatically performed by the turbine controller when ordered by the operator, and supervises rotor speed for 5 minutes while an ESV is closed and a control valve is open.

3) If rotor speed increases more than 10% within 5 minutes or if the control valve does not reach its ordered position within 30 seconds, the test fails and the turbine will trip.

Copyright:

Attribution Non-Commercial (BY-NC)

Formatos disponibles

Descargue como TXT, PDF, TXT o lea en línea desde Scribd

Está en la página 1de 2

Testing of Emergency Stop Valve

Instruction for testing of the emergency stop valve tightness

Each emergency stop valve (ESV) shall be tested regarding tightness against stea

m supply

once a year or when the servo and the valve have been disassembled. The test is

automatically performed by the turbine controller when ordered by the operator.

The

turbine rotor speed will be supervised during 5 minutes, while the ESV is closed

and one

control valve is open.

Conditions for test

· The turbine shall be on turning gear

· The steam pressure upstream the ESV shall be above 35 % of rated pressur

e

· Turbine trip shall be reset

· All ESV and CV shall be in closed position

· No other tightness test must be activated

· If there is a shut-off valve installed in the exhaust pipe, this valve m

ust be in open

position.

Test procedure

· If the conditions for test are not fulfilled, test "Blocked" will be ind

icated.

· Check the rotor speed and the control valve position during the test.

· Select "ESV Tightness test" ON from the safety test display at the opera

tor station.

One of the inlet control valves will automatically open to 50% a

t a rate of 2% per

second and the rotor speed will be supervised.

Test "Active" will be indicated.

The test can be manually interrupted before test is completed by

selecting test

"Reset".

· If the control valve reaches ordered position within 30 seconds and if s

peed increase is

less than 10% after 5 minutes, the following is automatically performed:

The control valve will be automatically closed again and the tes

t will be

Test "OK" will be indicated for 30 seconds.

· If a speed increase above 10% is obtained in 5 minutes or if the control

valve does not

reach ordered position within 30 seconds, the following is automatically

performed:

"Turbine Controller trip" will be released and the control valve

will be

immediately closed.

The test will be automatically reset.

Test "Failed" will be indicated for 30 seconds.

Failed test

At an unsuccessful test, the turbine will trip and "tightness test failure" will

be indicated as

cause of trip. Tightness test failure is cleared by reset of the turbine trip me

mory.

If the test failed due to speed increase more than 10%, the ESV is leaking too m

uch. The

ESV should then be opened/closed a couple of times, in heated condition, followe

d by a

new tightness test. If this does not help, the valve must be repaired.

WARNING! Do not start the turbine with a leaky ESV. It may become impossible to

stop

the turbine.

If the test failed due to slow control valve opening, check the function of the

control valve. automatically reset.

También podría gustarte

- B Me Engine Engine PreparingDocumento6 páginasB Me Engine Engine PreparingПетрAún no hay calificaciones

- Weekly Fire Pump InspectionDocumento6 páginasWeekly Fire Pump InspectionShabaaz Mohammed AbdulAún no hay calificaciones

- ATTDocumento3 páginasATTforu_kkkAún no hay calificaciones

- Gov1 Sim 23.12.06Documento25 páginasGov1 Sim 23.12.06SamAún no hay calificaciones

- PROCEDURES FOR OIL LEVEL, LEAK AND PRESSURE CHECKSDocumento6 páginasPROCEDURES FOR OIL LEVEL, LEAK AND PRESSURE CHECKSD VI MIAún no hay calificaciones

- ATT Stop and Control Valves-WriteupDocumento3 páginasATT Stop and Control Valves-WriteupErwin Fernandes GurningAún no hay calificaciones

- Testing and Commissioning of Fire PumpsDocumento4 páginasTesting and Commissioning of Fire PumpsDong Vanra100% (1)

- Automatic Turbine Testing (Att) : PMI-Noida 1Documento12 páginasAutomatic Turbine Testing (Att) : PMI-Noida 1rajan_me083100% (1)

- Load Rejection TestDocumento3 páginasLoad Rejection TestRaju SkAún no hay calificaciones

- ATT Stop and Control Valves-WriteupDocumento3 páginasATT Stop and Control Valves-WriteupVijay MahantAún no hay calificaciones

- Xmas Tree Integrity 6Documento4 páginasXmas Tree Integrity 6Vlassis SarantinosAún no hay calificaciones

- 160m Hyd TroubleshootDocumento8 páginas160m Hyd TroubleshootDaniel Rhasty-ghee AhmanorAún no hay calificaciones

- Senr3193 Hydrostatic TransmissionDocumento48 páginasSenr3193 Hydrostatic TransmissionMoicano P SánchezAún no hay calificaciones

- Automatic Isolation Valves Test ProceduresDocumento4 páginasAutomatic Isolation Valves Test ProceduresRahul ChandrawarAún no hay calificaciones

- JWZ Type Double Side Valve Test BedDocumento6 páginasJWZ Type Double Side Valve Test Bedjromero_rpgAún no hay calificaciones

- Standard Operating Procedure-Standard Maintenace ProcedureDocumento11 páginasStandard Operating Procedure-Standard Maintenace ProcedureVikram JitAún no hay calificaciones

- Vacuum System Testing & Commissioning GuideDocumento5 páginasVacuum System Testing & Commissioning GuideDong VanraAún no hay calificaciones

- Manipulator Elements Sergejs BoikoDocumento14 páginasManipulator Elements Sergejs BoikoСергей БойкоAún no hay calificaciones

- GAS UTILITY SERVICES REGULATOR INSPECTIONDocumento59 páginasGAS UTILITY SERVICES REGULATOR INSPECTIONsaahasitha 14Aún no hay calificaciones

- Plastech Manual LTU6000 enDocumento34 páginasPlastech Manual LTU6000 enCesar PomposoAún no hay calificaciones

- JLA Safety Valve Test BenchDocumento4 páginasJLA Safety Valve Test Benchjromero_rpgAún no hay calificaciones

- Dielectric Oil Testing KitDocumento2 páginasDielectric Oil Testing KitMohammed Imran100% (1)

- Group 2 Operational Checks and TroubleshootingDocumento11 páginasGroup 2 Operational Checks and TroubleshootingPriscila RodriguesAún no hay calificaciones

- Differences Between Manual Start and Remote-Auto Start of An EngineDocumento9 páginasDifferences Between Manual Start and Remote-Auto Start of An Engineart estacioAún no hay calificaciones

- Teste A Las Bombas, RevisionesDocumento2 páginasTeste A Las Bombas, RevisionesMario PazAún no hay calificaciones

- GROUP 2 CHECKS AND TROUBLESHOOTINGDocumento8 páginasGROUP 2 CHECKS AND TROUBLESHOOTINGthierrylindoAún no hay calificaciones

- Group 2 Operational Checks and TroubleshootingDocumento7 páginasGroup 2 Operational Checks and TroubleshootingPriscila RodriguesAún no hay calificaciones

- Elmar Pannel - BP ColombiaDocumento6 páginasElmar Pannel - BP ColombiaFelipe Augusto Diaz SuazaAún no hay calificaciones

- Pruebas y Ajustes DIRECCION 428BDocumento19 páginasPruebas y Ajustes DIRECCION 428BRamiro MillazAún no hay calificaciones

- Calibration Relief Valve ExcavatorDocumento36 páginasCalibration Relief Valve Excavatorcriman4550% (2)

- Turbine Startup ProcedureDocumento8 páginasTurbine Startup ProcedureBrijesh Srivastav0% (1)

- Installation and OperationDocumento9 páginasInstallation and Operationabdullatif_asAún no hay calificaciones

- Emergency generator testingDocumento4 páginasEmergency generator testingnarendra_katdareAún no hay calificaciones

- P&IDDocumento7 páginasP&IDTagabo AliAún no hay calificaciones

- Ship Departure Checklist For Engine Department: What To Do When A Ship Leaves A Port?Documento2 páginasShip Departure Checklist For Engine Department: What To Do When A Ship Leaves A Port?SurajitSarkarAún no hay calificaciones

- Volvo Penta Overheat DiagnosisDocumento15 páginasVolvo Penta Overheat DiagnosisJohn Morgan100% (1)

- JourneyDocumento194 páginasJourneyjuan carlos garciaAún no hay calificaciones

- Nissan Reset EcuDocumento3 páginasNissan Reset Ecuesquisof100% (1)

- 1988 Jeep Cherokee Cruise Control SystemDocumento11 páginas1988 Jeep Cherokee Cruise Control Systemjoker63000Aún no hay calificaciones

- NOTE See The Testing Tables For Detailed Instructions and Sign-Off For The Valve Line-Up ActivitiesDocumento1 páginaNOTE See The Testing Tables For Detailed Instructions and Sign-Off For The Valve Line-Up ActivitiessudiceAún no hay calificaciones

- DEH ControlDocumento30 páginasDEH Controlsambhu100% (1)

- Direct and Reverse Action of Control ValaveDocumento1 páginaDirect and Reverse Action of Control ValaveKyrie AbayaAún no hay calificaciones

- Model N18-4.9 (470 ) 18Mw Condensing Steam TurbineDocumento20 páginasModel N18-4.9 (470 ) 18Mw Condensing Steam TurbineFajarnurjamanAún no hay calificaciones

- Testing of Loco and Rake - 0Documento21 páginasTesting of Loco and Rake - 0SSE.C&W TIGAún no hay calificaciones

- Electrohydraulic camless engine controlDocumento10 páginasElectrohydraulic camless engine controlManojkumar ManoAún no hay calificaciones

- Group 2 Operational Checks and TroubleshootingDocumento8 páginasGroup 2 Operational Checks and TroubleshootingPriscila RodriguesAún no hay calificaciones

- Injection Actuation PressureDocumento20 páginasInjection Actuation Pressureabdelrhmangbr8682% (11)

- Intake Valve Actuation System Oil Pressure CircuitDocumento6 páginasIntake Valve Actuation System Oil Pressure CircuitWalterAún no hay calificaciones

- CAD Control Systems ManualDocumento27 páginasCAD Control Systems Manualnds2006sAún no hay calificaciones

- 1 System Description LP3-RLU - 13.02.2006 New NHP5Documento9 páginas1 System Description LP3-RLU - 13.02.2006 New NHP5Andrei ZahaAún no hay calificaciones

- Ldu 11Documento17 páginasLdu 11tvbm100Aún no hay calificaciones

- 03 Start, Stop and OperationDocumento8 páginas03 Start, Stop and Operationhmandioussama1Aún no hay calificaciones

- Bam 800 T004 - Nozzle Flow Testing GuidelinesDocumento11 páginasBam 800 T004 - Nozzle Flow Testing Guidelinesapi-3752216100% (1)

- Wellsite Pressure TestDocumento5 páginasWellsite Pressure TestBambang PermanaAún no hay calificaciones

- Weekly Fire Pump Inspection Test ProceduresDocumento3 páginasWeekly Fire Pump Inspection Test ProceduresJay T. YongAún no hay calificaciones

- Road Test: Test Four-Selector in Overdrive (4Th Gear)Documento2 páginasRoad Test: Test Four-Selector in Overdrive (4Th Gear)Engine Tuning UpAún no hay calificaciones

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SDe EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SAún no hay calificaciones

- Using The Point List View Technical NoteDocumento1 páginaUsing The Point List View Technical NoteArun PrakashAún no hay calificaciones

- Time Code ConvertersDocumento2 páginasTime Code ConvertersArun PrakashAún no hay calificaciones

- Motorised Operated Valve TorqueDocumento1 páginaMotorised Operated Valve TorqueArun PrakashAún no hay calificaciones

- MOV TemplateDocumento1 páginaMOV TemplateArun PrakashAún no hay calificaciones

- Time Code ConvertersDocumento2 páginasTime Code ConvertersArun PrakashAún no hay calificaciones

- Fault Location PrinciplesDocumento13 páginasFault Location PrinciplesArun Prakash100% (1)

- MOV TemplateDocumento1 páginaMOV TemplateArun PrakashAún no hay calificaciones

- SAMA AppdataDocumento1 páginaSAMA AppdataArun PrakashAún no hay calificaciones

- IEC101 Profile Checklist Datalist 6.23Documento26 páginasIEC101 Profile Checklist Datalist 6.23insan_soft6498Aún no hay calificaciones

- Hts541060g9at00 Mpb3paxgg0vxzm.Documento1 páginaHts541060g9at00 Mpb3paxgg0vxzm.Arun PrakashAún no hay calificaciones

- Leave Policy For - : ST ST STDocumento5 páginasLeave Policy For - : ST ST STDivyanshi SrivastavaAún no hay calificaciones

- Hts541060g9at00 Mpb3paxgg0vxzm.Documento1 páginaHts541060g9at00 Mpb3paxgg0vxzm.Arun PrakashAún no hay calificaciones

- Dell OptiPlex 745 Technical SpecificationsDocumento6 páginasDell OptiPlex 745 Technical SpecificationsThomas Grant50% (2)

- Calculation of The CRC16 Using CDocumento2 páginasCalculation of The CRC16 Using CArun PrakashAún no hay calificaciones

- Communicate REF 542 Relays VAMPDocumento1 páginaCommunicate REF 542 Relays VAMPArun PrakashAún no hay calificaciones

- VPN Connection DifferencesDocumento3 páginasVPN Connection DifferencesArun PrakashAún no hay calificaciones

- Hts541060g9at00 Mpb3paxgg0vxzm.Documento1 páginaHts541060g9at00 Mpb3paxgg0vxzm.Arun PrakashAún no hay calificaciones

- OK To Board-Visa On ArrivalDocumento1 páginaOK To Board-Visa On ArrivalArun Prakash100% (1)

- Vibration Diagnostic GuideDocumento2 páginasVibration Diagnostic GuideIzali Nizar100% (1)

- Hot Runner Technology PeterUngerDocumento245 páginasHot Runner Technology PeterUngerRiot DangerAún no hay calificaciones

- Presentasi Ec Clean (Kemenkes 03112020)Documento28 páginasPresentasi Ec Clean (Kemenkes 03112020)WarnoAún no hay calificaciones

- Chains and Sprockets: Inverted ToothDocumento32 páginasChains and Sprockets: Inverted ToothU.vijaya SarathiAún no hay calificaciones

- DURIT Thermal-CoatingsDocumento8 páginasDURIT Thermal-CoatingsMatheusAún no hay calificaciones

- Dimensional Analysis and SimilarityDocumento21 páginasDimensional Analysis and SimilaritySonali GungoosinghAún no hay calificaciones

- ESAB ExtractPage15-16cDocumento9 páginasESAB ExtractPage15-16cDries VandezandeAún no hay calificaciones

- Chapter 1Documento47 páginasChapter 1Hahshskakaga50% (2)

- TJ Diagnostic CodesDocumento3 páginasTJ Diagnostic Codeschristopheserv100% (1)

- Boiler CourseDocumento146 páginasBoiler Courseknx175100% (9)

- PNLD Ii: Pneumatic No-Loss DrainDocumento2 páginasPNLD Ii: Pneumatic No-Loss DrainSuresh NathAún no hay calificaciones

- Csi 2130 WP Triaxal AccelerometerDocumento13 páginasCsi 2130 WP Triaxal AccelerometerOrlando MarucaAún no hay calificaciones

- Catalog Echipamente ServiceDocumento10 páginasCatalog Echipamente ServiceCosmyn IpsilatAún no hay calificaciones

- Application and Operating History of Moderate-Speed Api 618 Reciprocating CompressorsDocumento10 páginasApplication and Operating History of Moderate-Speed Api 618 Reciprocating CompressorsTrịnh Đức HạnhAún no hay calificaciones

- Wall Hung Electric BoilerDocumento2 páginasWall Hung Electric BoilerDaxom NavidensAún no hay calificaciones

- TS 02 PDFDocumento5 páginasTS 02 PDFemmanuel rodriguezAún no hay calificaciones

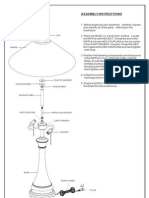

- Assembly Instructions: FinialDocumento1 páginaAssembly Instructions: Finialdayshift5Aún no hay calificaciones

- Chapt 02Documento144 páginasChapt 02Tony LoweAún no hay calificaciones

- J 616Documento4 páginasJ 616UsAmaImtiAz0% (1)

- Dulles International Airport, Virginia.: Eero SaarinenDocumento29 páginasDulles International Airport, Virginia.: Eero SaarinenAlaaalola55 YAHOOAún no hay calificaciones

- Beam Design Detail Report: Material and Design DataDocumento33 páginasBeam Design Detail Report: Material and Design DataazwanAún no hay calificaciones

- Karim Ahmed Fahmy 200330237 Lab 6 Investigation of The Variation in Refrigerator Coefficient of Performance For Various Evaporating TemperaturesDocumento4 páginasKarim Ahmed Fahmy 200330237 Lab 6 Investigation of The Variation in Refrigerator Coefficient of Performance For Various Evaporating TemperaturesKristin OlsonAún no hay calificaciones

- FCI 70-2-2006 PreDocumento1 páginaFCI 70-2-2006 PreIkhsan LyAún no hay calificaciones

- VAV Terminal UnitsDocumento15 páginasVAV Terminal Unitsckyee88Aún no hay calificaciones

- QW 482Documento2 páginasQW 482Ramu NallathambiAún no hay calificaciones

- KS3 Physics: Forces and Their EffectsDocumento18 páginasKS3 Physics: Forces and Their EffectsCinara RahimovaAún no hay calificaciones

- D Sars 0017924Documento7 páginasD Sars 0017924Richardo JuarezAún no hay calificaciones

- 1 Dimensional Details of Friction Slab and Crash Barrier ADocumento3 páginas1 Dimensional Details of Friction Slab and Crash Barrier AAlok vermaAún no hay calificaciones

- An Experimental Study of Electricity Generation Using A HorizontalDocumento5 páginasAn Experimental Study of Electricity Generation Using A HorizontalMariano MarcosAún no hay calificaciones

- Convection Tutorial Sheet 3Documento4 páginasConvection Tutorial Sheet 3Charlotte BAún no hay calificaciones

- IF Commercial Ironer Feeder Folder Brochure PDFDocumento2 páginasIF Commercial Ironer Feeder Folder Brochure PDFAl AdcockAún no hay calificaciones