Documentos de Académico

Documentos de Profesional

Documentos de Cultura

004 005 D PDF

Cargado por

Rangga Prasetya BaitullahTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

004 005 D PDF

Cargado por

Rangga Prasetya BaitullahCopyright:

Formatos disponibles

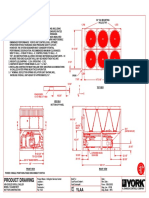

004_Layout 2 7/16/12 10:56 AM Page 4

Series

Magnehelic Differential Pressure Gages

PRESSURE

2000

Indicate Positive, Negative or Differential, Accurate within 2% RoHS

.025 (.64) SPACE CREATED BY 3 (3) 6-32 X 3/16 (4.76) DEEP HOLES

SPACER PADS WHEN SURFACE RUBBER PRESSURE RELIEF EQUALLY SPACED ON A 4-1/8

MOUNTED. DO NOT OBSTRUCT. PLUG WILL UNSEAT ITSELF (104.78) BOLT CIRCLE FOR

PROVIDES PATH FOR RELIEF OF WHEN GAGE IS PANEL MOUNTING

OVERPRESSURE. 17/32 OVERPRESSURIZED 1/8 FEMALE NPT

(13.49) HIGH PRESSURE

1/8 FEMALE CONNECTION

NPT HIGH

PRESSURE

CONNECTION

1-1/4 1-3/4

(31.75) (44.45)

1/8 FEMALE

NPT LOW

Differential Pressure Gages

4-1/2 PRESSURE

(114.3) CONNECTION

1/2

(12.70)

15/32 1/8 FEMALE NPT

4-3/4 (11.91) 11/16 LOW PRESSURE

(120.65) 7/16 (17.46) CONNECTION

1-11/16 (11.11)

(42.86)

17/32 4-3/4 (120.65) PANEL CUTOUT

(13.49) 1/8 FEMALE NPT

HIGH PRESSURE

CONNECTION

5

1-1/4 (127) 1-3/4

(31.75) (44.45)

4-47/64

4-1/2 (120.27)

(114.3)

1/2

(12.70)

5-1/2 15/32 1/8 FEMALE

(11.91) 11/16 NPT LOW

(139.70) 3/16 (17.46) PRESSURE

MOUNTING RING 2-17/32

(64.29) (4.76) CONNECTION

Select the Dwyer Magnehelic gage for high accuracy guaranteed within 2% of SPECIFICATIONS

full-scale and for the wide choice of 81 models available to suit your needs precisely. Using Service: Air and non-combustible, compatible gases (natural gas option available).

Dwyer's simple, frictionless Magnehelic gage movement, it quickly indicates low air or non- Note: May be used with hydrogen. Order a Buna-N diaphragm. Pressures must be

corrosive gas pressures either positive, negative (vacuum) or differential. The design less than 35 psi.

resists shock, vibration and over-pressures. No manometer fluid to evaporate, freeze or Wetted Materials: Consult factory.

cause toxic or leveling problems. It's inexpensive, too. Housing: Die cast aluminum case and bezel, with acrylic cover. Exterior finish is

The Magnehelic gage is the industry standard to measure fan and blower pressures, coated gray to withstand 168 hour salt spray corrosion test.

filter resistance, air velocity, furnace draft, pressure drop across orifice plates, liquid Accuracy: 2% of FS (3% on - 0, -100 Pa, -125 Pa, 10MM and 4% on - 00, -60

levels with bubbler systems and pressures in fluid amplifier or fluidic systems. It also Pa, -6MM ranges), throughout range at 70F (21.1C).

checks gas-air ratio controls and automatic valves, and monitors blood and respiratory Pressure Limits: -20 in Hg to 15 psig (-0.677 to 1.034 bar); MP option: 35 psig

pressures in medical care equipment. (2.41 bar); HP option: 80 psig (5.52 bar).

Overpressure: Relief plug opens at approximately 25 psig (1.72 bar), standard

Mounting gages only. See Overpressure Protection Note on next page.

A single case size is used for most models of Magnehelic gages. They can be flush Temperature Limits: 20 to 140F*

or surface mounted with standard hardware supplied. Although calibrated for vertical (-6.67 to 60C). -20F (-28C) with low temperature option.

position, many ranges above 1 may be used at any angle by simply re-zeroing. Size: 4 (101.6 mm) diameter dial face.

However, for maximum accuracy, they must be calibrated in the same position in Mounting Orientation: Diaphragm in vertical position. Consult factory for other

which they are used. These characteristics make Magnehelic gages ideal for both position orientations.

stationary and portable applications. A 4-9/16 hole is required for flush panel Process Connections: 1/8 female NPT duplicate high and low pressure taps -

mounting. Complete mounting and connection fittings, plus instructions, are one pair side and one pair back.

furnished with each instrument. See pages 6 and 7 for more information on mounting Weight: 1 lb 2 oz (510 g), MP & HP 2 lb 2 oz (963 g).

accessories. Standard Accessories: Two 1/8 NPT plugs for duplicate pressure taps, two 1/8

pipe thread to rubber tubing adapter, and three flush mounting adapters with

screws. (Mounting and snap ring retainer substituted for three adapters in MP &

HP gage accessories.)

Agency Approval: RoHS. Note:-SP models not RoHS approved.

For applications with high cycle rate within gage total pressure rating, next higher rating

is recommended. See Medium and High pressure options at lower left.

ACCESSORIES

Model A-432 Portable Kit

Combine carrying case with any Magnehelic gage of

Flush, Surface or Pipe Mounted standard range, except high pressure connection.

Includes 9 ft (2.7 m) of 3/16 ID rubber tubing,

standhang bracket and terminal tube with holder . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .$48.00

Model A-605 Air Filter Gage Accessory Kit

Adapts any standard Magnehelic gage for use as an

air filter gage. Includes aluminum surface mounting

bracket with screws, two 5 ft (1.5 m) lengths of 1/4

aluminum tubing two static pressure tips and two

molded plastic vent valves, integral compression

fittings on both tips and valves . . . . . . . . . . . . .35.00

Enclosure Mounted

A-605B Air Filter Gage Accessory Kit, Air filter kit with two plastic open/close

valves, two 4 steel static tips, plastic tubing and mounting flange . . . . . . . . .26.00

A-605C Air Filter Gage Accessory Kit, Air filter kit with two plastic open/close

valves, two plastic static tips, plastic tubing and mounting flange . . . . . . . . . .21.00

4 DWYER INSTRUMENTS, INC. | www.dwyer-inst.com

005_Layout 2 7/16/12 10:59 AM Page 5

Series

Magnehelic Gage Models & Ranges

PRESSURE

2000

Bezel provides flange for flush mounting in panel. O-ring seal for cover assures pressure integrity of case.

Clear plastic face is highly resistant to breakage. Provides OVERPRESSUREPROTECTION

undistorted viewing of pointer and scale. Blowout plug is comprised of a rubber plug on the rear which

functions as a relief valve by unseating and venting the gage

Precision litho-printed scale is accurate and easy to read. interior when over pressure reaches approximately 25 psig (1.7

bar).To provide a free path for pressure relief, there are four

Red tipped pointer of heat treated aluminum tubing is easy spacer pads which maintain 0.023 clearance when gage is

to see. It is rigidly mounted on the helix shaft. surface mounted. Do not obstruct the gap created by these pads.

Differential Pressure Gages

The blowout plug is not used on models above 180 of water

Pointer stops of molded rubber prevent pointer over-travel pressure, medium or high pressure models, or on gages which

without damage. require an elastomer other than silicone for the diaphragm.

The blowout plug should not be used as a system overpressure

Wishbone assembly provides mounting for helix, helix control. High supply pressures may still cause the gage to fail due

bearings and pointer shaft. to over pressurization, resulting in property damage or serious

injury. Good engineering practices should be utilized to prevent

Jeweled bearings are shock-resistant mounted; provide your system from exceeding the ratings or any component.

virtually friction-free motion for helix. Motion damped with

high viscosity silicone fluid. Die cast aluminum case is precision made and iridite-dipped to

withstand 168 hour salt spray corrosion test. Exterior finished in

Zero adjustment screw is conveniently located in the baked dark gray hammerloid. One case size is used for all

plastic cover, and is accessible without removing cover. standard pressure options, and for both surface and flush

O-ring seal provides pressure tightness. mounting.

Helix is precision made from an alloy of high magnetic Silicone rubber diaphragm with integrally molded O-ring is

permeability. Mounted in jeweled bearings, it turns freely, supported by front and rear plates. It is locked and sealed in

following the magnetic field to move the pointer across position with a sealing plate and retaining ring. Diaphragm motion

the scale. is restricted to prevent damage due to overpressures.

Calibrated range spring is flat spring steel. Small amplitude Samarium Cobalt magnet mounted at one end of range spring

of motion assures consistency and long life. It reacts to rotates helix without mechanical linkages.

pressure on diaphragm. Live length adjustable for calibration.

Dual Scale Air Velocity Units

Range Inches Range Range MM Range, For use with pitot tube

Model of Water Price Model PSI Price Model of Water Price Model kPa Price

Range in

2000-00N .05-0-.2 $77.45 2201 0-1 $67.95 2000-6MM 0-6 $73.00 2000-0.5KPA 0-0.5 $63.50

W.C./

2000-00 0-.25 73.00 2202 0-2 67.95 2000-10MM 0-10 63.50 2000-1KPA 0-1 63.50

Velocity

2000-0 0-.50 63.50 2203 0-3 67.95 2000-15MM 0-15 63.50 2000-1.5KPA 0-1.5 63.50

Model F.P.M. Price

2001 0-1.0 63.50 2204 0-4 67.95 2000-25MM 0-25 63.50 2000-2KPA 0-2 63.50

2000-00AV 0-.25/ $98.00

2002 0-2.0 63.50 2205 0-5 67.95 2000-30MM 0-30 63.50 2000-2.5KPA 0-2.5 63.50

300-2000

2003 0-3.0 63.50 2210* 0-10 169.45 2000-50MM 0-50 63.50 2000-3KPA 0-3 63.50

2000-0AV 0-.50/ 88.50

2004 0-4.0 63.50 2215* 0-15 169.45 2000-80MM 0-80 63.50 2000-4KPA 0-4 63.50

500-2800

2005 0-5.0 63.50 2220* 0-20 169.45 2000-100MM 0-100 63.50 2000-5KPA 0-5 63.50

2001AV 0-1.0/ 67.95

2006 0-6.0 63.50 2230** 0-30 242.00 2000-125MM 0-125 63.50 2000-8KPA 0-8 63.50

500-4000

2008 0-8.0 63.50 2000-150MM 0-150 63.50 2000-10KPA 0-10 63.50

2002AV 0-2.0/ 67.95

2010 0-10 63.50 Range, 2000-200MM 0-200 63.50 2000-15KPA 0-15 63.50

1000-5600

2012 0-12 63.50 CM of 2000-250MM 0-250 63.50 2000-20KPA 0-20 63.50

2005AV 0-5.0/ 67.95

2015 0-15 63.50 Model Water Price 2000-300MM 0-300 63.50 2000-25KPA 0-25 63.50

2000-8800

2020 0-20 63.50 2000-15CM 0-15 $63.50 Zero Center Ranges 2000-30KPA 0-30 63.50

Zero Center Ranges 2010AV 0-10/ 67.95

2025 0-25 63.50 2000-20CM 0-20 63.50 2300-6MM 3-0-3 $99.00

2300-1KPA .5-0-.5 $74.00 2000-12500

2030 0-30 63.50 2000-25CM 0-25 63.50 2300-10MM 5-0-5 74.00

2040 0-40 63.50 2000-50CM 0-50 63.50 2300-20MM 10-0-10 74.00 2300-2KPA 1-0-1 74.00

2050 0-50 63.50 2000-80CM 0-80 63.50 Model Range, Pa Price 2300-2.5KPA 1.25-0-1.25 74.00

2060 0-60 63.50 2000-100CM 0-100 63.50 2000-60NPA 10-0-50 $77.45 2300-3KPA 1.5-0-1.5 74.00

2080 0-80 63.50 2000-150CM 0-150 67.95 2000-60PA 0-60 73.00 Dual Scale English/Metric Models

2100 0-100 63.50 2000-200CM 0-200 67.95 2000-100PA 0-100 63.50 Range, Range,

2120 0-120 63.50 2000-250CM 0-250 67.95 2000-125PA 0-125 63.50 Model in w.c. Pa or kPa Price

2150 0-150 63.50 2000-300CM 0-300 67.95 2000-250PA 0-250 63.50 2000-00D 0-.25 0-62 Pa $73.00

2160 0-160 88.50 Zero Center Ranges 2000-300PA 0-300 63.50 2000-0D 0-0.5 0-125 Pa 67.95

2180* 0-180 190.00 2000-500PA 0-500 63.50 2001D 0-1.0 0-250 Pa 67.95

2250 * 0-250 190.00 2300-4CM 2-0-2 $78.45

2300-10CM 5-0-5 78.45 2000-750PA 0-750 63.50 2002D 0-2.0 0-500 Pa 67.95

Zero Center Ranges 2000-1000PA 0-1000 63.50 2003D 0-3.0 0-750 Pa 67.95

2300-30CM 15-0-15 78.45

2300-00 0.125-0-0.125 $74.00 Zero Center Ranges 2004D 0-4.0 0-1.0 kPa 67.95

2300-0 .25-0-.25 74.00 Model Range, Pa Price 2005D 0-5.0 0-1.25 kPa 67.95

2301 .5-0-.5 74.00 These ranges calibrated 2300-60PA 30-0-30 $74.00 2006D 0-6.0 0-1.5 kPa 67.95

2302 1-0-1 74.00 for vertical scale position. 2300-100PA 50-0-50 74.00 2008D 0-8.0 0-2.0 kPa 67.95

2304 2-0-2 74.00 Accuracy +/-3% 2300-120PA 60-0-60 74.00 2010D 0-10 0-2.5 kPa 67.95

2310 5-0-5 74.00 Accuracy +/-4% 2300-200PA 100-0-100 74.00 2015D 0-15 0-3.7 kPa 67.95

2320 10-0-10 74.00 *MP option standard 2300-250PA 125-0-125 74.00 2020D 0-20 0-5 kPa 88.50

2330 15-0-15 74.00 **HP option standard 2300-300PA 150-0-150 74.00 2025D 0-25 0-6.2 kPa 88.50

2300-500PA 250-0-250 74.00 2050D 0-50 0-12.4 kPa 88.50

2300-1000PA 500-0-500 74.00 2060D 0-60 0-15 kPa 88.50

VELOCITY AND VOLUMETRIC FLOW UNITS

Scales are available on the Magnehelic that read in velocity units (FPM, m/s) or volumetric flow units (SCFM, m3/s, m3/h). Stocked velocity units with dual range scales in inches

w.c. and feet per minute are shown above. For other ranges contact the factory.

When ordering volumetric flow scales please specify the maximum flow rate and its corresponding pressure. Example:0.5 in w.c. = 16,000 CFM.

ACCESSORIES A-310A 3-Way Vent Valves . . . . . . . . . . . . . .$16.50

A-321, Safety Relief Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34.00 In applications where pressure is continuous and the

A-448, 3-piece magnet kit for mounting Magnehelic gage directly to Magnehelic gage is connected by metal or plastic

magnetic surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10.75 tubing which cannot be easily removed, we suggest

A-135, Rubber gasket for panel mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.50 using Dwyer A-310A vent valves to connect gage.

Pressure can then be removed to check or re-zero the

gage.

CALL TO ORDER | 800/872-9141 5

También podría gustarte

- CPC Veh Int PDFDocumento1 páginaCPC Veh Int PDFalejandro sanchezAún no hay calificaciones

- Mcquay Chiller FundamentalsDocumento20 páginasMcquay Chiller FundamentalsSajith MenonAún no hay calificaciones

- TE32+MANUAL (FZ Transm) (041-060)Documento20 páginasTE32+MANUAL (FZ Transm) (041-060)Marco Guachun100% (1)

- Selecting Amines For Sweetening Units PDFDocumento9 páginasSelecting Amines For Sweetening Units PDFGui Do EspAún no hay calificaciones

- Mersen Process Technologies ProviderDocumento6 páginasMersen Process Technologies ProviderIbhar Santos MumentheyAún no hay calificaciones

- Oisd STD-226Documento75 páginasOisd STD-226sruhil82% (11)

- Iso 11114-1 1997Documento50 páginasIso 11114-1 1997shah harshitAún no hay calificaciones

- CH3080 Cyclone Separator Format ErrorDocumento19 páginasCH3080 Cyclone Separator Format ErrorMerlando Dany SAún no hay calificaciones

- Penlon Prima SP Anaesthesia Machine - User ManualDocumento140 páginasPenlon Prima SP Anaesthesia Machine - User Manualtallraj50% (2)

- Serie 2000Documento2 páginasSerie 2000Fredy MurilloAún no hay calificaciones

- Magnehelic Differential Pressure Gages: SolutionsDocumento2 páginasMagnehelic Differential Pressure Gages: Solutionsdaniel GasperinAún no hay calificaciones

- Series 2000 - Magnahelic Differential Pressure GaugeDocumento2 páginasSeries 2000 - Magnahelic Differential Pressure GaugeKoteswara RaoAún no hay calificaciones

- Magnehelic Differential Pressure Gages: Indicate Positive, Negative or Differential, Accurate Within 1%Documento4 páginasMagnehelic Differential Pressure Gages: Indicate Positive, Negative or Differential, Accurate Within 1%Johan VBAún no hay calificaciones

- Magnehelic Differential Pressure Gages: Indicate Positive, Negative or Differential, Accurate Within 1%Documento4 páginasMagnehelic Differential Pressure Gages: Indicate Positive, Negative or Differential, Accurate Within 1%RyanAún no hay calificaciones

- Dwyer 2000Documento4 páginasDwyer 2000Saravana KumarAún no hay calificaciones

- Dwyer 2300 250pa Pressure Gauge DatasheetDocumento2 páginasDwyer 2300 250pa Pressure Gauge DatasheetGorch Marroko100% (1)

- MAGNEHELICDocumento2 páginasMAGNEHELICCésar Arturo TorresAún no hay calificaciones

- Magnehelic-Gage Series 2000Documento2 páginasMagnehelic-Gage Series 2000Jonathan GanAún no hay calificaciones

- Purafil Side Access BulletinDocumento5 páginasPurafil Side Access BulletinPablo TorresAún no hay calificaciones

- Magnehelic Differential Pressure Gages: Indicate Positive, Negative or Differential, Accurate Within 2%Documento2 páginasMagnehelic Differential Pressure Gages: Indicate Positive, Negative or Differential, Accurate Within 2%SlametKhoerudinAún no hay calificaciones

- Magnehelic Series 2000 - CatDocumento2 páginasMagnehelic Series 2000 - CatFerdian AriestaAún no hay calificaciones

- Magnehelic Differential Pressure Gage: Bulletin A-27Documento2 páginasMagnehelic Differential Pressure Gage: Bulletin A-27Marco Antonio Rivera DoteroAún no hay calificaciones

- Fr. No.: +-+ - All Angles All Decimal Dimensions Standard Tolerances Unless Noted: 1 .005Documento1 páginaFr. No.: +-+ - All Angles All Decimal Dimensions Standard Tolerances Unless Noted: 1 .005César Arturo TorresAún no hay calificaciones

- Explosion-Proof Differential Pressure SwitchDocumento1 páginaExplosion-Proof Differential Pressure SwitchTadau EnergyAún no hay calificaciones

- CO Component Description: Discharge DelaysDocumento1 páginaCO Component Description: Discharge DelayskiuAún no hay calificaciones

- Dwyer MagnehelicmanualDocumento2 páginasDwyer MagnehelicmanualAndres GonzalesAún no hay calificaciones

- Digihelic 3 Differential Pressure Controllers: Digihelic Controller in Photohelic Gage, Square Root Output For FlowDocumento1 páginaDigihelic 3 Differential Pressure Controllers: Digihelic Controller in Photohelic Gage, Square Root Output For FlowAdriana Zarahi Velez HernandezAún no hay calificaciones

- Series 605 Magnehelic Differential Pressure Indicating Transmitter Specifications - Installation and Operating InstructionsDocumento4 páginasSeries 605 Magnehelic Differential Pressure Indicating Transmitter Specifications - Installation and Operating InstructionsAlberto Angel Mora ZavalaAún no hay calificaciones

- Series 605 Magnehelic Differential Pressure Indicating Transmitter Specifications - Installation and Operating InstructionsDocumento4 páginasSeries 605 Magnehelic Differential Pressure Indicating Transmitter Specifications - Installation and Operating InstructionsKrissthian EspitiaAún no hay calificaciones

- DA-DS CatDocumento2 páginasDA-DS Catsorin sorinAún no hay calificaciones

- Explosion-Proof Level Switches For Powder & Bulk SolidsDocumento2 páginasExplosion-Proof Level Switches For Powder & Bulk Solidsjalfaro021Aún no hay calificaciones

- Switch Nivel A Prueba de ExplosiónDocumento2 páginasSwitch Nivel A Prueba de ExplosiónHeiferk AbrilAún no hay calificaciones

- 1910 00 ManualDocumento4 páginas1910 00 ManualRusty AllenAún no hay calificaciones

- Certified: 3/23/2021 Garrett BinnsDocumento1 páginaCertified: 3/23/2021 Garrett Binnsjose luis rios guerraAún no hay calificaciones

- Dweyer Pressure SwitchDocumento1 páginaDweyer Pressure SwitchMuhamad PriyatnaAún no hay calificaciones

- Power Pack Detail Scale 1 / 6: KEF 6/4/2014 Universal Air & Gas Products Corp. 1140 Kingwood Ave Norfolk, Va 23502Documento1 páginaPower Pack Detail Scale 1 / 6: KEF 6/4/2014 Universal Air & Gas Products Corp. 1140 Kingwood Ave Norfolk, Va 23502juanAún no hay calificaciones

- Differential Pressure Transmitter: Same Size As Standard Magnehelic Differential Pressure GageDocumento1 páginaDifferential Pressure Transmitter: Same Size As Standard Magnehelic Differential Pressure GageJose Antonio Yupa MedinaAún no hay calificaciones

- Diaphragm Seal For DA Series Pressure Switch: PVC and FEP Construction For Corrosive ApplicationsDocumento1 páginaDiaphragm Seal For DA Series Pressure Switch: PVC and FEP Construction For Corrosive Applicationsluat1983Aún no hay calificaciones

- 23 Ridge-Hip (Floating) DetailDocumento1 página23 Ridge-Hip (Floating) DetailAhmed Saber NassarAún no hay calificaciones

- JETTA 96 Tierras A BateríaDocumento7 páginasJETTA 96 Tierras A BateríajcarlosahuatltAún no hay calificaciones

- Series DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsDocumento2 páginasSeries DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsJuan Carlos Chara VelazcoAún no hay calificaciones

- Ansul Design #007 Kidde Booth SystemDocumento8 páginasAnsul Design #007 Kidde Booth SystemJhoAún no hay calificaciones

- Engine Controls MAXIMA 2003Documento5 páginasEngine Controls MAXIMA 2003Rogelio ArenasAún no hay calificaciones

- 05322D01 - Airset Hazardous Duty 24VDCDocumento1 página05322D01 - Airset Hazardous Duty 24VDCnuraida hakikiAún no hay calificaciones

- FPS-004 R4Documento1 páginaFPS-004 R4chocostarfishAún no hay calificaciones

- All Dimensions Are in Inches (Millimeters)Documento1 páginaAll Dimensions Are in Inches (Millimeters)Atty AttyAún no hay calificaciones

- Fail Safe or TR RegulatorDocumento2 páginasFail Safe or TR RegulatorYeit HauAún no hay calificaciones

- 616kd 11 DatasheetDocumento1 página616kd 11 Datasheetramalho12andyAún no hay calificaciones

- ULS-1 Single Point Level SwitchesDocumento1 páginaULS-1 Single Point Level SwitchesAndre SoaresAún no hay calificaciones

- Josam: Slot Width 1/4" (Typ)Documento1 páginaJosam: Slot Width 1/4" (Typ)dumbestdummyAún no hay calificaciones

- As Sea20007e Ew 121 128 B As Ew 129Documento1 páginaAs Sea20007e Ew 121 128 B As Ew 129Juan RuizAún no hay calificaciones

- Kidde 81-871403-000Documento1 páginaKidde 81-871403-000pedrocardososAún no hay calificaciones

- Photohelic Pressure Switch/Gages: 3-In-One Indicating Gage, Lo-Limit and Hi-Limit ControlDocumento2 páginasPhotohelic Pressure Switch/Gages: 3-In-One Indicating Gage, Lo-Limit and Hi-Limit ControlAnonymous u0wETydFAún no hay calificaciones

- Transmissions (Transmission and Drivetrain) - ALLDATA RepairDocumento2 páginasTransmissions (Transmission and Drivetrain) - ALLDATA RepairEricson CabreraAún no hay calificaciones

- Mini-Size Flow Switches: Monitor Flow in 1/2 To 2 Pipe, Explosion-ProofDocumento2 páginasMini-Size Flow Switches: Monitor Flow in 1/2 To 2 Pipe, Explosion-Proofjp3863887Aún no hay calificaciones

- A4 Controles Del Motor 1Documento1 páginaA4 Controles Del Motor 1juan jose jimenez perezAún no hay calificaciones

- Anemometro Dwyer VT-200Documento1 páginaAnemometro Dwyer VT-200Israel Hernandez GomezAún no hay calificaciones

- 09 Season City-5Documento1 página09 Season City-5laphika153Aún no hay calificaciones

- Dwyer-1910-1-Product OverviewDocumento1 páginaDwyer-1910-1-Product OverviewRusty AllenAún no hay calificaciones

- ROSS Pneumatic Directional Control Valves 27 SeriesDocumento18 páginasROSS Pneumatic Directional Control Valves 27 SeriesQuy HoangAún no hay calificaciones

- Se-Pn-10 Panel Load Schedule - 10 (Cp-Fac-2)Documento1 páginaSe-Pn-10 Panel Load Schedule - 10 (Cp-Fac-2)Văn VươngAún no hay calificaciones

- Product Drawing: Power Entry 13 1/2" WIDE X 7" HIGHDocumento1 páginaProduct Drawing: Power Entry 13 1/2" WIDE X 7" HIGHsamersibaniAún no hay calificaciones

- Series DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsDocumento2 páginasSeries DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsJorge Renato Chirinos QuiñonezAún no hay calificaciones

- Continuous Level Transmitter: Customize To Fit Application, 316 SS or Buna-N FloatsDocumento1 páginaContinuous Level Transmitter: Customize To Fit Application, 316 SS or Buna-N FloatsMohamed HammamAún no hay calificaciones

- Simple Drip IrrigationDocumento2 páginasSimple Drip IrrigationHarry JouleAún no hay calificaciones

- Combo PurifierDocumento1 páginaCombo PurifierRangga Prasetya BaitullahAún no hay calificaciones

- Sby Filter ModelDocumento1 páginaSby Filter ModelRangga Prasetya BaitullahAún no hay calificaciones

- Carrier PDFDocumento44 páginasCarrier PDFRangga Prasetya BaitullahAún no hay calificaciones

- A T On: ParameDocumento1 páginaA T On: ParameRangga Prasetya BaitullahAún no hay calificaciones

- Parte 3 Piping Design Carrier HandBookDocumento2 páginasParte 3 Piping Design Carrier HandBookRangga Prasetya BaitullahAún no hay calificaciones

- Water Cooled Chiller: RefrigerantDocumento3 páginasWater Cooled Chiller: RefrigerantRangga Prasetya BaitullahAún no hay calificaciones

- ReadmeDocumento5 páginasReadmeRangga Prasetya BaitullahAún no hay calificaciones

- HelpDocumento1 páginaHelpĐào Huy ĐạtAún no hay calificaciones

- Refrigerant ChargeDocumento3 páginasRefrigerant ChargeRangga Prasetya BaitullahAún no hay calificaciones

- R ChargeDocumento3 páginasR ChargeRangga Prasetya BaitullahAún no hay calificaciones

- Refrigerant ChargeDocumento3 páginasRefrigerant ChargeRangga Prasetya BaitullahAún no hay calificaciones

- Blow Through vs. Draw ThroughDocumento1 páginaBlow Through vs. Draw ThroughAditya PatilAún no hay calificaciones

- 004 005 D PDFDocumento2 páginas004 005 D PDFRangga Prasetya BaitullahAún no hay calificaciones

- Chapter 2 Pure SubstanceDocumento52 páginasChapter 2 Pure SubstanceSyafiq AimanAún no hay calificaciones

- Topic 3 - RevisionDocumento33 páginasTopic 3 - RevisionYu Seung KimAún no hay calificaciones

- Troubleshooting Problem 5.1: Mass Balance With Recycle StreamsDocumento10 páginasTroubleshooting Problem 5.1: Mass Balance With Recycle Streamsmilton ochoaAún no hay calificaciones

- BP Vs BTH Eff: BTE BP Diesel B10 B20 B30Documento6 páginasBP Vs BTH Eff: BTE BP Diesel B10 B20 B30Babu JonnalagaddaAún no hay calificaciones

- Air Pollution Dispersion Modeling PDFDocumento6 páginasAir Pollution Dispersion Modeling PDFadcaAún no hay calificaciones

- RPM Rotary Gas MetersDocumento8 páginasRPM Rotary Gas MetersFranklin Villca RochaAún no hay calificaciones

- In SpitalDocumento68 páginasIn Spitalyes techAún no hay calificaciones

- Pneumatic Positioner: Control Valves Actuators AccessoriesDocumento6 páginasPneumatic Positioner: Control Valves Actuators AccessoriesBraj BhushanAún no hay calificaciones

- BPMG2013 - B - Quiz 4 - 256253Documento2 páginasBPMG2013 - B - Quiz 4 - 256253ctkhadeejaAún no hay calificaciones

- TermodinamicaDocumento3 páginasTermodinamicaDiianaBm50% (2)

- Jjmie: Experimental Study of Solar Powered Air Conditioning Unit Using Drop - in Hydro Carbon Mixture To Replace R-22Documento8 páginasJjmie: Experimental Study of Solar Powered Air Conditioning Unit Using Drop - in Hydro Carbon Mixture To Replace R-22أبو أسامة حمديAún no hay calificaciones

- Control ValveDocumento12 páginasControl ValvenerioalfonsoAún no hay calificaciones

- Mohammed Hama Honia Ali Aya SaadDocumento5 páginasMohammed Hama Honia Ali Aya SaadHonya Hemn AliAún no hay calificaciones

- What Are The Types of HRSGDocumento2 páginasWhat Are The Types of HRSGThiruvengadamAún no hay calificaciones

- Description of Primary and Enhanced Oil Recovery Implementation On Karazhanbas and Troll Oil and Gas FieldDocumento11 páginasDescription of Primary and Enhanced Oil Recovery Implementation On Karazhanbas and Troll Oil and Gas FieldТемирлан АльпиевAún no hay calificaciones

- Steam Tracing SpecificationDocumento14 páginasSteam Tracing SpecificationPankaj SahuAún no hay calificaciones

- Eternity T Installation GuideDocumento28 páginasEternity T Installation GuidepsicodeAún no hay calificaciones

- Tugas 2 SINPRODocumento5 páginasTugas 2 SINPROcitra maharaniAún no hay calificaciones

- 3558783Documento44 páginas3558783สิทธิไชย อรุณวํฒนชัยAún no hay calificaciones

- Fluid Mechanics I Lab - MENG 370L: Experiment 3: Venturi MeterDocumento20 páginasFluid Mechanics I Lab - MENG 370L: Experiment 3: Venturi MeterMahdi GharibAún no hay calificaciones

- Pump Operating RangeDocumento2 páginasPump Operating RangeNikesh100% (1)

- Hydraulics and PneumaticsDocumento12 páginasHydraulics and PneumaticsAmal_YaguAún no hay calificaciones

- Refrigerant Changeover Guide R22 R 407C PDFDocumento6 páginasRefrigerant Changeover Guide R22 R 407C PDFkuruvillaj2217Aún no hay calificaciones

- Corken SC Side Channel Pump EnglishDocumento40 páginasCorken SC Side Channel Pump EnglishEliecer PeñalbaAún no hay calificaciones