Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Compressor CSL 18 Max Single Stage 125 Psig

Cargado por

Joel Leandro Ibarra CoriaTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Compressor CSL 18 Max Single Stage 125 Psig

Cargado por

Joel Leandro Ibarra CoriaCopyright:

Formatos disponibles

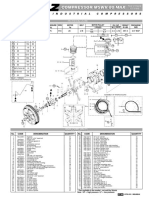

SINGLE STAGE

COMPRESSOR CSL 18 MAX 125 PSIG

C A S T I R O N I N D U S T R I A L C O M P R E S S O R S

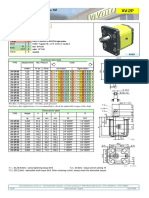

TECHNICAL DATA

FREE AIR DELIVERY MOTOR PULLEY

MODEL DISPLACEMENT MAX. PRESSURE cfm RPM BELT OIL CAP. WEIGHT INLET DISCHARGE

cfm psig 2 POLES in qt in lbs

40 psig 90 psig inch mm

CSL 18 MAX 18 125 16.5 13.5 1,190 1-A 4.2 108 0.54 40 1/2'' NPSC 1/2'' NPSC

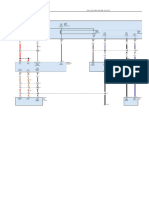

T1 1

23

27

2

24

3 25

26

DETAIL A

6

OPTIONAL

STANDARD

3

Parts Position Bolt ft.lb lbf.in N.m

8 UNC 5/16" x 2". 1/4"

Cylinder Head T1 21 255 29

type Allen

22

1 T2 Cylinder

T2 UNC 5/16" x 1" 12 149 17

Flywheel

Flange T3 UNC 1/4" x 3/4 6.7 80 9.3

3 21

Valve plate T4 M3 type Allen 1.4 17.6 2.0

20 Valve plate M4 type Allen 2.9 35 4.0

4 1 T5

Labyrinth cover T6 M5 type Allen 1.2 14.8 1.5

T3

TABLE 1 - TORQUE ESPECIFICATION

5 10

T6 13 14 15

3 1

1 T5 DETAIL A T2

16 17 18

7

9

19 15

11

12

7

T4

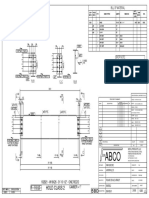

BARE PUMP PARTS

No. CODE DENOMINATION QTY. No. CODE DENOMINATION QTY.

1 830.1228-0/AT Bolt kit 01 15 830.1226-0/AT Crankshaft 01

2 709.1665-0 Aluminum cylinder head 01 16 019.0081-0 6305 Bearing 01

3 830.1225-0/NA/AT Gasket kit 01 17 709.1643-0 Flange 01

4 028.0364-0 Labyrinth cover elbow 01 18 023.0320-0 Oil seal 01

5 033.0095-0 Labyrinth cover 01 19 709.1350-0 Flywheel 01

6 809.1654-0 Valve plate 01 20 709.1653-0 Connecting rod 02

7 830.1227-0/AT Valve plate kit 01 21 016.0123-0 3 Piston 02

8 709.1641-0 Cylinder 01 22 830.1229-0/AT Ring kit (kit is for 1 cylinder) 02

9 830.0532-7 Oil plug 01 23 007.0157-0 Air filter 01

10 023.0368-0 Gasket labyrinth cover 01 24 60318003 Filter element 01

11 60250001 1/2 Oil level sight kit 01 25 809.1016-0 Air filter 01

12 003.0028-4 1/4" plug 01 26 007.0122-0 Filter element 01

13 709.1652-0 Crankase 01 27 023.0286-0/NA Washer 01

14 019.0080-0 6304 Bearing 01

TC 237 2006/APRIL 025.0576-0

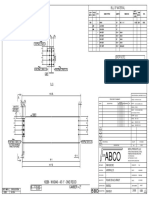

DIMENSIONS MAINTENANCE

WARNING

CSL 18 MAX Turn off power before servicing and be sure the air tank is unloaded. These

instructions are based on normal operating conditions. If the compressor is

located in an exceedingly dusty area, increase the frequency of all

inspections.

DAILY

E

- Inspect the compressor visually.

- Check oil level and add some if necessary, before turning the

compressor on.

- Drain moisture from the piping system.

G

F - Be sure there is no excessive or unusual vibration or noise.

H WEEKLY

C

- Remove and clean intake air filters; do not wash the filter element.

D I B - Check V-belts for tightness. Belt tension should be adjusted to allow

A approximately 3/8" to 1/2" (9 to 13 mm) deflection with normal thumb

pressure.

A B C D E F G H I - Clean cylinders externally, cylinder head, motor, fan blade, tubing, and tank.

mm 307 300 149.5 140.5 302 10 27 40.5 76 - Safety valve should be tested manually to see if it is working properly.

inch 12 11.8 5.9 5.5 12 0.4 1.06 1.6 2.9 MONTHLY

- Check entire system for air leakage around fittings, etc by using water and

soap lather.

INSTALLATION AND OPERATION INSTRUCTIONS - Check the pressure switch operation.

- Check for oil contamination and change it if necessary.

INSTALLATION AND LOCATION QUARTERLY

1. Installation: Install the compressor in a covered, well - Change the air filter element every 300 working hours or quarterly.

ventilated area, free of dust, toxic gases, humidity or any other (Whichever occurs first).

kind of pollution. The compressor should be located no closer - Fasten bolts and nuts as required. (See Table 1)

than 32" (800mm) from a wall or any other obstacle that could - Change oil more frequently if compressor is located in a very dirty

interfere with the air flow through the fan. This distance will environment.

also make maintenance easier. Place the compressor on a - WHILE RUNNING IN A PERIOD OF ABOUT 100 WORKING HOURS THE OIL

leveled surface. Rotation of the flywheel must be in the LEVEL SHOULD BE CAREFULLY CHECKED.

direction of the arrow cast into the flywheel. The maximum ANNUALLY

ambient temperature recommended while working is 104F or

- Test and calibrate the pressure switch, pressure gauge and safety valve

40C. If necessary, install an exhaust fan to guarantee fresh air

according to their own technical standards. These parts must be removed

and to dissipate heat.

from the tank and pump to be tested.

Before making the electrical connections, check oil level and

top-up lubricating oil. For type of oil, see table at the end of - Inspect and clean the suction and discharge valve(s) plate(s) every 1000 (one

these instructions. thousand) working hours (whichever occurs first), located between the

cylinder and its cover and, if necessary, replace it (them) according to the

2. Electrical connection: The country's valid electrical standards

operation conditions.

must be followed regarding Low Voltage Electrical Installation.

OPERATION LUBRICATION

1. Initial start procedure: Before turning on the compressor, - The first oil change should be made after 8 hours of operation.

check the crankcase oil level. It must be in the middle of the oil - The second oil change after 40 hours of operation.

level sight or oil level dipstick . As to the type of oil to be used - The third and following exchanges should be made after 200 hours of

and the recommended change intervals, check at "Lubrication" operation, or 60 (sixty) days, whichever occurs first.

and as to its volume, check the Technical Data Table. NOTE:

2. Start: Turn on the electrical start key and let your compressor Heavy Duty and multi-viscous oils are not adequate for Schulz air

run for about 10 (ten) minutes, what will keep the tank's internal compressor's lubrication. The same applies to oils that tend to emulsify.

pressure or compressed air around 20 psig. This will optimize a We recommend good industrial oil for air compressors, with rust and

homogeneous lubrication of the parts. oxidation inhibitors and high viscosity level (from 90 to 95), SAE or ISO, as

indicated in the table below:

LIMITED WARRANTY

RECOMMENDED LUBRICANT OILS FOR SCHULZ AIR PUMPS

All component parts on your SCHULZ compressor are

warranted to be free of defects in workmanship and material

for a period of one year. Transportation charges are AMBIENT TEMPERATURE 0F (0C)

0 0 0 0 0

responsibility of the purchaser. This warranty extends to the Below 32 F 32 F to 68 F 68 F to 104 F

original purchaser of the compressor only. Below 0 0C 0 0C to 20 0C 20 0C to 40 0C

There are no express warranties except as contained in this SAE 10W SAE 20W SAE 30

or or or

limited warranty statement and implied warranties, ISO 32 ISO 68 ISO 100

including those of merchantability and fitness for a particular

purpose, are limited to the period of warranty.

Our liability is limited solely to replacement of NOTE: Schulz reserves the right to make changes without prior notice.

nonconforming parts as set forth herein and does not include

any liability for any incidental, consequential, or other

damages of any kind. This warranty gives you specific legal

rights, and you may also have other rights that vary from DISTRIBUTOR

state to state.

Schulz of America, Inc.

3420 Novis Pointe

Acworth, GA 30101

Phone # (770) 529-4731 / 32

Fax # (770) 529-4733

sales@schulzamerica.com

www.schulzamerica.com

También podría gustarte

- Champion Spark Plugs for Proven PerformanceDocumento7 páginasChampion Spark Plugs for Proven PerformanceMGD040452100% (1)

- Cg-010-457-Boq-Ff - 08.10.15Documento33 páginasCg-010-457-Boq-Ff - 08.10.15Rajshekhar KategarAún no hay calificaciones

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDe EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceAún no hay calificaciones

- Doosan DX225LC PDFDocumento856 páginasDoosan DX225LC PDFHarlinton descalzi94% (16)

- Optimize Mercedes Benz ADM and PLD engine control unit schematicDocumento1 páginaOptimize Mercedes Benz ADM and PLD engine control unit schematicBassie91% (11)

- 1939-1964 Ford Tractor Specifications & DataDocumento12 páginas1939-1964 Ford Tractor Specifications & Datajleo250% (1)

- Control Loop 9Documento19 páginasControl Loop 9nmulyonoAún no hay calificaciones

- Production of Biodiesel From Zobo' (Hibiscus Sabdariffa L.) Seed OilDocumento50 páginasProduction of Biodiesel From Zobo' (Hibiscus Sabdariffa L.) Seed OilBimbo AdulojuAún no hay calificaciones

- 01 TQ EngineDocumento39 páginas01 TQ EngineHarlinton descalzi100% (2)

- Ss Platii NomDocumento12 páginasSs Platii NomForklift Systems IncorporatedAún no hay calificaciones

- Control Loop 13Documento15 páginasControl Loop 13nmulyonoAún no hay calificaciones

- Catalogo Lincoln Centro-Matic Automatic Lubrication Systems 2014Documento64 páginasCatalogo Lincoln Centro-Matic Automatic Lubrication Systems 2014Luis RuizAún no hay calificaciones

- A-Cilp LED circuit board schematicDocumento1 páginaA-Cilp LED circuit board schematicYuda Aditama100% (12)

- 2506a E15tag2Documento2 páginas2506a E15tag2Bambang Sigit Priyanto100% (1)

- Current Revision Approved: Upper Frame, 68SbsDocumento3 páginasCurrent Revision Approved: Upper Frame, 68Sbscapslive_001100% (1)

- 7029120023Documento1 página7029120023Roderick Pinto100% (1)

- APACHE / APACHE RTR/ RTR REF. / RTR EFI / NEW RTR REF. PARTS CATALOGUE CYLINDER HEAD ASSEMBLYDocumento74 páginasAPACHE / APACHE RTR/ RTR REF. / RTR EFI / NEW RTR REF. PARTS CATALOGUE CYLINDER HEAD ASSEMBLYLukesh Kumar100% (2)

- New Product Launch - CNG BikeDocumento17 páginasNew Product Launch - CNG BikeRishabh Chaudhary100% (1)

- MBE 926 ManualDocumento122 páginasMBE 926 ManualCharles Tooraen83% (12)

- GES-25 MKII - Free Fall Lifeboat: Enterprise No.: NO940411696Documento6 páginasGES-25 MKII - Free Fall Lifeboat: Enterprise No.: NO940411696Reinard BadenhorstAún no hay calificaciones

- Tuberia Astm A53 Grado A Grado BDocumento6 páginasTuberia Astm A53 Grado A Grado BMedardo Silva50% (2)

- 284 Parts Manual 1994Documento94 páginas284 Parts Manual 1994Jesus AguinagaAún no hay calificaciones

- Peugeot 206 Wiring Diagrams GuideDocumento19 páginasPeugeot 206 Wiring Diagrams GuideSUMINISTROS DVLAún no hay calificaciones

- Compressor MSL 15 Max Siingle StageDocumento2 páginasCompressor MSL 15 Max Siingle StageJoel Leandro Ibarra CoriaAún no hay calificaciones

- PART NUMBER PUMP INLETDocumento1 páginaPART NUMBER PUMP INLETPaško KelavaAún no hay calificaciones

- Bomba de gasolina grand cherokee 2011-2013Documento1 páginaBomba de gasolina grand cherokee 2011-2013Miguel SayagoAún no hay calificaciones

- All Piping Drawings Spec SheetsDocumento18 páginasAll Piping Drawings Spec Sheetsc.reidAún no hay calificaciones

- Hold Class 2: Bill of MaterialDocumento1 páginaHold Class 2: Bill of Materialai ambaraAún no hay calificaciones

- Maximizing signal reception with an adjustable LNA circuitDocumento1 páginaMaximizing signal reception with an adjustable LNA circuitALFONZO DANIELAún no hay calificaciones

- Current Revision Approved: Anti-Spin, 68H/SbsDocumento2 páginasCurrent Revision Approved: Anti-Spin, 68H/Sbscapslive_001Aún no hay calificaciones

- Bill of Material: 102B5 - W18X40 - 43'-1 1/2" - 4 REQ'D Camber 2"Documento1 páginaBill of Material: 102B5 - W18X40 - 43'-1 1/2" - 4 REQ'D Camber 2"ai ambaraAún no hay calificaciones

- COMPRESSOR MSL 10 ML TECHNICAL SPECIFICATIONSDocumento2 páginasCOMPRESSOR MSL 10 ML TECHNICAL SPECIFICATIONSdosorioa2Aún no hay calificaciones

- Va1027 0Documento1 páginaVa1027 0陆军Aún no hay calificaciones

- BILL OF MATERIALS FOR STEEL BEAM AND CONNECTIONSDocumento1 páginaBILL OF MATERIALS FOR STEEL BEAM AND CONNECTIONSai ambaraAún no hay calificaciones

- Bill of Material: 102B6 - W18X40 - 43'-1" - ONE REQ'D Camber 2"Documento1 páginaBill of Material: 102B6 - W18X40 - 43'-1" - ONE REQ'D Camber 2"ai ambaraAún no hay calificaciones

- Yash Cad PDF 9Documento1 páginaYash Cad PDF 9rashmi PhegadeAún no hay calificaciones

- xp207 - однонаправленныеDocumento2 páginasxp207 - однонаправленныеMichael AkhramovichAún no hay calificaciones

- PCM 2 Silverado 2009Documento2 páginasPCM 2 Silverado 2009Alejandro MerinoAún no hay calificaciones

- Pump Skid (With Boiler) - Rev-1 - Apr-15-2016Documento3 páginasPump Skid (With Boiler) - Rev-1 - Apr-15-2016Carlos EafAún no hay calificaciones

- SINGLE LINE DIAGRAM LOADLIST-lantai 2Documento1 páginaSINGLE LINE DIAGRAM LOADLIST-lantai 2Achmad Nuril AnwarAún no hay calificaciones

- Compressor MSL 40 Max Two Stages 175 PsigDocumento2 páginasCompressor MSL 40 Max Two Stages 175 PsigJoel Leandro Ibarra CoriaAún no hay calificaciones

- BILL OF MATERIALS FOR BEAM 102B21Documento1 páginaBILL OF MATERIALS FOR BEAM 102B21ai ambaraAún no hay calificaciones

- MC-23-6053 GadDocumento1 páginaMC-23-6053 Gadpramodptvpm_65797156Aún no hay calificaciones

- Zaenal Mutaqin Prof.H.Soemarto, M.Sie Sps PTK Upi 27-9-2018 19-9-2018Documento1 páginaZaenal Mutaqin Prof.H.Soemarto, M.Sie Sps PTK Upi 27-9-2018 19-9-2018Fauziah WahidaAún no hay calificaciones

- 7029120030Documento1 página7029120030Razvan UrsuAún no hay calificaciones

- MomentumDocumento19 páginasMomentumAlejandro MarinAún no hay calificaciones

- STD Hyd CylDocumento2 páginasSTD Hyd Cylparashar_tabibAún no hay calificaciones

- FMC 435 water pump diagram and part listDocumento1 páginaFMC 435 water pump diagram and part listGonzalo Hernández MelladoAún no hay calificaciones

- Regulator Valve Pressure KoomeyDocumento2 páginasRegulator Valve Pressure KoomeyJuan Sebastian Diaz CuadrosAún no hay calificaciones

- 1510 Scupper DrainDocumento1 página1510 Scupper DrainAfnanMuhammadAún no hay calificaciones

- 24 25 26 .l0l 27 316 Li LD Asm-Penduium Asm-Pendulum Adjust t5 PIN I6 IIDocumento1 página24 25 26 .l0l 27 316 Li LD Asm-Penduium Asm-Pendulum Adjust t5 PIN I6 IIanon_835518017Aún no hay calificaciones

- Omnirest Parts ListDocumento20 páginasOmnirest Parts ListjmezapAún no hay calificaciones

- North Rig 2Documento1 páginaNorth Rig 2avefenix666Aún no hay calificaciones

- Scalf00007766 (RFP) - T-Frame For Top Mount Chh-616Documento1 páginaScalf00007766 (RFP) - T-Frame For Top Mount Chh-616berkahharianAún no hay calificaciones

- JTEX shockman circuit analysisDocumento1 páginaJTEX shockman circuit analysisมนต์ชัย บุญธนลาภ100% (1)

- Motor Hidraulico XV2M 19CCDocumento2 páginasMotor Hidraulico XV2M 19CCmanutencao.servdrillAún no hay calificaciones

- Control Loop 11Documento17 páginasControl Loop 11nmulyonoAún no hay calificaciones

- Submersible Pumps GuideDocumento236 páginasSubmersible Pumps GuideSrie WidodoAún no hay calificaciones

- SMC MGPLDocumento5 páginasSMC MGPLwahyuAún no hay calificaciones

- TC0-Dual Plate Wafer Type Check Valve-CI-BSTDocumento1 páginaTC0-Dual Plate Wafer Type Check Valve-CI-BSTCV Carlitos Maju PratamaAún no hay calificaciones

- Cbna 13 4.2Documento35 páginasCbna 13 4.2DAVID ALFONSO CARABALLO PATIÑOAún no hay calificaciones

- 4-1 Sistema ElectricoDocumento3 páginas4-1 Sistema ElectricoMario HernandezAún no hay calificaciones

- Jayson Guansing Dwg-A3-Size - PDF 2Documento1 páginaJayson Guansing Dwg-A3-Size - PDF 2ADONIS PLATINOAún no hay calificaciones

- Harris PDFDocumento60 páginasHarris PDFNeyplayer FernandesAún no hay calificaciones

- Sales & Engineering Data: 20 - 120 6661T3-XXX-C THRU 6661U4-XXX-C 1-1/2'' Non-Metallic Diaphragm PumpDocumento2 páginasSales & Engineering Data: 20 - 120 6661T3-XXX-C THRU 6661U4-XXX-C 1-1/2'' Non-Metallic Diaphragm PumpFlorin Daniel AnghelAún no hay calificaciones

- 2017.10 Qan-Bypass Exh-L1-A3Documento1 página2017.10 Qan-Bypass Exh-L1-A3Kyaw MinAún no hay calificaciones

- Hold Class 2: Bill of MaterialDocumento1 páginaHold Class 2: Bill of Materialai ambaraAún no hay calificaciones

- MD1PE Integrated Lift Controller Gearless EN81 1 Pre WringDocumento18 páginasMD1PE Integrated Lift Controller Gearless EN81 1 Pre WringГариб МедAún no hay calificaciones

- Bull1524r0 L8543219Documento76 páginasBull1524r0 L8543219Benjamin HewittAún no hay calificaciones

- Prince Hydraulics - SPD1 Series Hydraulic Double Gear Pumps Offered by PRC Industrial SupplyDocumento2 páginasPrince Hydraulics - SPD1 Series Hydraulic Double Gear Pumps Offered by PRC Industrial SupplyPRC Industrial SupplyAún no hay calificaciones

- Registered Trademark of The Dupont Company. - Denotes O-Ring Code. See Chart AboveDocumento1 páginaRegistered Trademark of The Dupont Company. - Denotes O-Ring Code. See Chart AboveAtty AttyAún no hay calificaciones

- Technical specifications for MFI control systemDocumento1 páginaTechnical specifications for MFI control systemHuy Trần QuốcAún no hay calificaciones

- Clap CKTDocumento2 páginasClap CKTMunavir k100% (1)

- KD105 ManualDocumento22 páginasKD105 ManualJoel Leandro Ibarra CoriaAún no hay calificaciones

- MANUALcentralQ7 S 2017Documento7 páginasMANUALcentralQ7 S 2017Joel Leandro Ibarra CoriaAún no hay calificaciones

- Compressor MSW 60 Max Two Stages 175 PsigDocumento2 páginasCompressor MSW 60 Max Two Stages 175 PsigJoel Leandro Ibarra CoriaAún no hay calificaciones

- Manual Sc32.PDF Prenza Hidraulica GatesDocumento16 páginasManual Sc32.PDF Prenza Hidraulica GatesEsteban Sándiga GrandaAún no hay calificaciones

- Compressor MSV 20 SD Two Stages 175 PsigDocumento2 páginasCompressor MSV 20 SD Two Stages 175 PsigJoel Leandro Ibarra CoriaAún no hay calificaciones

- Compressor Msii 52 ML Single Stage 120 PsigDocumento2 páginasCompressor Msii 52 ML Single Stage 120 PsigJoel Leandro Ibarra CoriaAún no hay calificaciones

- COMPRESSOR MSWV 80 MAX TWO STAGE 175 PSIG TECHNICAL DATADocumento2 páginasCOMPRESSOR MSWV 80 MAX TWO STAGE 175 PSIG TECHNICAL DATAebebvetbAún no hay calificaciones

- SOLDADURADocumento25 páginasSOLDADURAJoel Leandro Ibarra CoriaAún no hay calificaciones

- Compressor MSL 40 Max Two Stages 175 PsigDocumento2 páginasCompressor MSL 40 Max Two Stages 175 PsigJoel Leandro Ibarra CoriaAún no hay calificaciones

- Compressor CSW 40 Max Two Stages 175 PsigDocumento2 páginasCompressor CSW 40 Max Two Stages 175 PsigJoel Leandro Ibarra CoriaAún no hay calificaciones

- Compressor MSL 40 Max Two Stages 175 PsigDocumento2 páginasCompressor MSL 40 Max Two Stages 175 PsigJoel Leandro Ibarra CoriaAún no hay calificaciones

- Thor 175 C Safe1Documento1 páginaThor 175 C Safe1Joel Leandro Ibarra CoriaAún no hay calificaciones

- Dimensions: 1 2 3 4 5 6 7 8 9 10 Grouser Height 11 Ground Clearance (SAE J1234) 432.5 MM 12 Boom Height - Tip ofDocumento1 páginaDimensions: 1 2 3 4 5 6 7 8 9 10 Grouser Height 11 Ground Clearance (SAE J1234) 432.5 MM 12 Boom Height - Tip ofJoel Leandro Ibarra CoriaAún no hay calificaciones

- Dinset/Gasline: Outlet Points For Industrial GasesDocumento2 páginasDinset/Gasline: Outlet Points For Industrial GasesJoel Leandro Ibarra CoriaAún no hay calificaciones

- ReleaseNotes PDFDocumento21 páginasReleaseNotes PDFFrancisco Jose Arista QuinteroAún no hay calificaciones

- PipelayerDocumento1 páginaPipelayerJoel Leandro Ibarra CoriaAún no hay calificaciones

- Dimensions: 1 2 3 4 5 6 7 8 9 10 Grouser Height 11 Ground Clearance (SAE J1234) 432.5 MM 12 Boom Height - Tip ofDocumento1 páginaDimensions: 1 2 3 4 5 6 7 8 9 10 Grouser Height 11 Ground Clearance (SAE J1234) 432.5 MM 12 Boom Height - Tip ofJoel Leandro Ibarra CoriaAún no hay calificaciones

- Dimensions: 1 2 3 4 5 6 7 8 9 10 Grouser Height 11 Ground Clearance (SAE J1234) 432.5 MM 12 Boom Height - Tip ofDocumento1 páginaDimensions: 1 2 3 4 5 6 7 8 9 10 Grouser Height 11 Ground Clearance (SAE J1234) 432.5 MM 12 Boom Height - Tip ofJoel Leandro Ibarra CoriaAún no hay calificaciones

- Dimensions: 1 2 3 4 5 6 7 8 9 10 Grouser Height 11 Ground Clearance (SAE J1234) 432.5 MM 12 Boom Height - Tip ofDocumento1 páginaDimensions: 1 2 3 4 5 6 7 8 9 10 Grouser Height 11 Ground Clearance (SAE J1234) 432.5 MM 12 Boom Height - Tip ofJoel Leandro Ibarra CoriaAún no hay calificaciones

- Lista de Articulos: 1 Electrodos Conarco GrupoDocumento8 páginasLista de Articulos: 1 Electrodos Conarco GrupoJoel Leandro Ibarra CoriaAún no hay calificaciones

- Teras Ariel 50M-5200BHP/65TSBP/AHT/OCEAN TOWING: Please Email Us atDocumento2 páginasTeras Ariel 50M-5200BHP/65TSBP/AHT/OCEAN TOWING: Please Email Us atKenRoczen CaesarAún no hay calificaciones

- 6、地泊泵站外输泵机组巡检检查表1Documento9 páginas6、地泊泵站外输泵机组巡检检查表1thura mgAún no hay calificaciones

- Jimny Wobble Service BulletinDocumento5 páginasJimny Wobble Service BulletinAna Vilma González CorralesAún no hay calificaciones

- GLTV3 Level SensorDocumento2 páginasGLTV3 Level Sensoreisman diazAún no hay calificaciones

- WAG process through horizontal wellsDocumento18 páginasWAG process through horizontal wellsarlenAún no hay calificaciones

- Compressor Section ComponentsDocumento13 páginasCompressor Section ComponentsÄbdur RáhmánAún no hay calificaciones

- D1503me3 PDFDocumento47 páginasD1503me3 PDFhristea marian100% (1)

- Chemical Forms of Ash-Forming Elements in Woody Biomass Fuels PDFDocumento13 páginasChemical Forms of Ash-Forming Elements in Woody Biomass Fuels PDFskakindAún no hay calificaciones

- Maracaibo BasinDocumento8 páginasMaracaibo BasinAdian AndrewsAún no hay calificaciones

- GEM SeriesDocumento180 páginasGEM SeriesZiyadawaliAún no hay calificaciones

- Viva QuestionsDocumento12 páginasViva QuestionsJayesh Tanwani50% (4)

- Pocket Guide ReactorsDocumento2 páginasPocket Guide ReactorsRanti WarfiAún no hay calificaciones

- Ingredients of Bituminous Mixes & Introduction To ModifiersDocumento69 páginasIngredients of Bituminous Mixes & Introduction To ModifiersjaffnaAún no hay calificaciones

- S270P New Tech Sheet ¿ ®Documento2 páginasS270P New Tech Sheet ¿ ®truong nguyenAún no hay calificaciones

- Power Plant InstrumentsDocumento4 páginasPower Plant InstrumentssseshaAún no hay calificaciones

- Directions:: T-501 Vertical Fixed Roof Residual Fuel Oil No. 6 Jimmy Peress Newark NJ Outdoor Storage TankDocumento8 páginasDirections:: T-501 Vertical Fixed Roof Residual Fuel Oil No. 6 Jimmy Peress Newark NJ Outdoor Storage TankAnonymous K3FaYFlAún no hay calificaciones