Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Amercoat 68hs - Ingles 2015

Cargado por

Peter CallánDescripción original:

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Amercoat 68hs - Ingles 2015

Cargado por

Peter CallánCopyright:

Formatos disponibles

PRODUCT DATA SHEET July 23, 2015 (Revision of June 26, 2015)

AMERCOAT 68 HS

DESCRIPTION

Three-component, zinc rich epoxy

PRINCIPAL CHARACTERISTICS

>80% zinc in dry film

Provides outstanding corrosion resistance

Fast dry times for rapid topcoating

AMERCOAT 861 accelerator can be used for low temperature curing

COLOR AND GLOSS LEVEL

Reddish gray

Flat

Note: Green color will be made-to-order

BASIC DATA AT 68F (20C)

Data for mixed product

Number of components Three

Volume solids 70 2%

VOC (Supplied) max. 2.4 lb/US gal (approx. 288 g/l)

Temperature resistance (Continous) To 400F (204C)

Recommended dry film thickness 2.0 - 5.0 mils (50 - 125 m) depending on system

Theoretical spreading rate 561 ft/US gal for 2.0 mils (14.0 m/l for 50 m)

Shelf life Base: at least 24 months when stored cool and dry

Hardener: at least 24 months when stored cool and dry

Powder: at least 24 months when stored cool and dry

Notes:

- See ADDITIONAL DATA Overcoating intervals

- See ADDITIONAL DATA Curing time

- Color will drift at elevated temperatures

- Continous temperature resistance should be less than 5% of the time, and maximum 24 hours

RECOMMENDED SUBSTRATE CONDITIONS AND TEMPERATURES

Coating performance is proportional to the degree of surface preparation. All previous coats must dry and free of

contaminants

Ref. P039 Page 1/6

PRODUCT DATA SHEET July 23, 2015 (Revision of June 26, 2015)

AMERCOAT 68 HS

Steel

Abrasive blast with an angular abrasive to an SSPC SP-6 or higher. Achieve a surface profile of 1.0 3.0 mils (25 75 m)

Higher surface profiles up to 5 mils (125 m) are acceptable, but the product must be applied in a thickness great enough to

achieve a minimum of 2.5 mils (65 m) dry film thickness

Apply this product as soon as possible to prevent blasted surface from rusting.

Keep moisture, oil, grease and other organic matter off surface before coating

For touch up and repair, power tool cleaning in accordance with SSPC SP-11 is acceptable

Substrate temperature and application conditions

Surface temperature during application should be between 40F (4C) and 120F (49C)

With accelerator: Surface temperature during application should be between 32F (0C) and 100F (38C)

Surface temperature during application should be at least 5F (3C) above dew point

Relative humidity during application and curing should not exceed 85%

Notes:

- Extreme caution should be taken to ensure there is no ice on the surface in cold weather

- Product can be applied without accelerator at surface and air temperatures down to 40F. Material temperature must be maintained at 60

to 90F at the time of application. Due to the long curing time at this temperatures when accelerator is not used, it is recommended that

temperatures above 50F are expected within 12 hours of application. Coated surfaces should be protected from moisture until dry

through time is reached.

- If abrasive blast preparation is not possible, use SSPC-SP11, power tool cleaning to bare metal (ISO-St3)

SYSTEM SPECIFICATION

Primers: Direct to metal, can be used to touch up inorganic zincs such as DIMETCOTE 9-SERIES

Topcoats: AMERSHIELD, PSX 700, AMERCOAT 450 H, AMERLOCK 2/400, AMERCOAT 385, AMERCOAT 370, AMERCOAT

Epoxies, PITTGUARD Epoxies, DURATHANE DTM, PITTHANE ULTRA

SECONDARY SURFACE PREPARATION

During storage and construction, contamination of the prefabrication primer should be limited

Mix as packaged

Pre-mix base component with a pneumatic air mixer at moderate speeds to homogenize the container. Add hardener to

base and agitate with a power mixer for 1-2 minutes until completely dispersed. Add powder component slowly under

agitation until fully mixed. Strain the mixture from one container to another through a 30 mesh filter/strainer to remove any

undispersed lumps

Pot life

9 hours at 70F (21C)

Note: See ADDITIONAL DATA Pot life

Ref. P039 Page 2/6

PRODUCT DATA SHEET July 23, 2015 (Revision of June 26, 2015)

AMERCOAT 68 HS

Application

Area should be sheltered from airborne particulates and pollutants

Ensure good ventilation during application and curing

Provide shelter to prevent wind from affecting spray patterns

Material temperature

Material temperature during application should be between 50F (10C) and 90F (32C)

Air spray

A moisture and oil trap in the main line is essential. Product is sensitive to moisture contamination

Separate air and fluid pressure regulators and a moisture and oil trap in the main air supply line are recommended.

Use standard conventional equipment

Recommended thinner

THINNER 21-06 (AMERCOAT 65) (xylene)), THINNER 21-25 (AMERCOAT 101) (recommended for > 90F (32C))

Volume of thinner

0 - 10%

Nozzle orifice

Approx. 0.070 in (1.8 mm)

Airless spray

45:1 pump or larger

Recommended thinner

THINNER 21-06 (AMERCOAT 65) (xylene)), THINNER 21-25 (AMERCOAT 101) (recommended for > 90F (32C))

Nozzle orifice

Approx. 0.43 0.53 mm (0.017 0.021 in)

Brush/roller

Use a high-quality natural-bristle brush. Brush application is only recommended for small touch-up and/or repair areas.

Roller application is not recommended

Ensure the brush/roller is well-loaded to avoid air entrainment. Level air bubbles with a brush. Multiple coats may be

necessary to achieve adequate film build

Recommended thinner

AMERCOAT 65 (xylene), AMERCOAT 101 (recommended for > 90F (32C))

Ref. P039 Page 3/6

PRODUCT DATA SHEET July 23, 2015 (Revision of June 26, 2015)

AMERCOAT 68 HS

Cleaning solvent

Amercoat 12 Cleaner (Thinner 90-58) or Amercoat 65 Thinner (Thinner 21-06)

Note: All application equipment must be cleaned immediately after use

ADDITIONAL DATA

Overcoating interval for DFT up to 3.0 mils (75 m)

Overcoating with... Interval 32F (0C) 50F (10C) 70F (21C) 90F (32C)

various two-pack epoxy Minimum N/A 6 hours 2 hours 1 hour

and polyurethane coatings Maximum Unlimited Unlimited Unlimited Unlimited

Note: Surface must be power washed as needed to remove all surface contaminants including zinc salts. Surface must be clean

and dry

Overcoating interval with AMERCOAT 861 accelerator for DFT up to 3.0 mils (75 m)

Overcoating with... Interval 40F (4C) 50F (10C) 70F (21C) 90F (32C)

various two-pack epoxy Minimum 18 hours 4 hours 1.5 hours 45 minutes

and polyurethane coatings

Maximum Unlimited Unlimited Unlimited Unlimited

Notes:

- Surface must be power washed as needed to remove all surface contaminants including zinc salts. Surface must be clean and dry

- With force cure capabilities (oven temperatures of 140F (60C) to 180F (82C)), product can be overcoated after 5-15 minutes. Allow 5-

10 minutes flash off prior to heating past 120F (49C). Addition of AMERCOAT 861 accelerator is recommended for this procedure.

Curing time for DFT up to 3.0 mils (75 m)

Substrate temperature Dry to touch Dry to handle

40F (4C) 6 hours 3 days

50F (10C) 90 minutes 36 hours

70F (21C) 30 minutes 8 hours

90F (32C) 15 minutes 4 hours

curing time for DFT up to 3.0 mils with Amercoat 861 Accelerator

Substrate temperature Dry to touch Dry to handle

32F (0C) 6 hours 4 days

50F (10C) 1 hour 16 hours

70F (21C) 20 minutes 4 hours

90F (32C) 10 minutes 1.5 hours

Ref. P039 Page 4/6

PRODUCT DATA SHEET July 23, 2015 (Revision of June 26, 2015)

AMERCOAT 68 HS

Pot life (at application viscosity)

Mixed product temperature Pot life

50F (10C) 24 hours

70F (21C) 16 hours

90F (32C) 8 hours

Pot life (at application viscosity) with AMERCOAT 861

accelerator

Mixed product temperature Pot life

50F (10C) 16 hours

70F (21C) 9 hours

90F (32C) 5 hours

Product Qualifications

RCSC Class B slip coefficient for high strength bolted connections

SSPC Paint 20, Type II, Level 2

Zinc dust meets ASTM D520 type 2 standards

SAFETY PRECAUTIONS

For paint and recommended thinners see INFORMATION SHEETS 1430, 1431 and relevant Material Safety Data Sheets

This is a solvent-borne paint and care should be taken to avoid inhalation of spray mist or vapor, as well as contact between

the wet paint and exposed skin or eyes

WORLDWIDE AVAILABILITY

It is always the aim of PPG Protective and Marine Coatings to supply the same product on a worldwide basis. However, slight

modification of the product is sometimes necessary to comply with local or national rules/circumstances. Under these

circumstances an alternative product data sheet is used.

REFERENCES

CONVERSION TABLES INFORMATION SHEET 1410

EXPLANATION TO PRODUCT DATA SHEETS INFORMATION SHEET 1411

SAFETY INDICATIONS INFORMATION SHEET 1430

SAFETY IN CONFINED SPACES AND HEALTH SAFETY, EXPLOSION HAZARD INFORMATION SHEET 1431

TOXIC HAZARD

Ref. P039 Page 5/6

PRODUCT DATA SHEET July 23, 2015 (Revision of June 26, 2015)

AMERCOAT 68 HS

WARRANTY

PPG warrants (i) its title to the product, (ii) that the quality of the product conforms to PPGs specifications for such product in effect at the time of manufacture and (iii) that the product shall be delivered free of the rightful claim of any

third person for infringement of any U.S. patent covering the product. THESE ARE THE ONLY WARRANTIES THAT PPG MAKES AND ALL OTHER EXPRESS OR IMPLIED WARRANTIES, UNDER STATUTE OR ARISING OTHERWISE IN

LAW, FROM A COURSE OF DEALING OR USAGE OF TRADE, INCLUDING WITHOUT LIMITATION, ANY OTHER WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE OR USE, ARE DISCLAIMED BY PPG. Any claim under this

warranty must be made by Buyer to PPG in writing within five (5) days of Buyers discovery of the claimed defect, but in no event later than the expiration of the applicable shelf life of the product, or one year from the date of the

delivery of the product to the Buyer, whichever is earlier. Buyers failure to notify PPG of such non-conformance as required herein shall bar Buyer from recovery under this warranty.

LIMITATIONS OF LIABILITY

IN NO EVENT WILL PPG BE LIABLE UNDER ANY THEORY OF RECOVERY (WHETHER BASED ON NEGLIGENCE OF ANY KIND, STRICT LIABILITY OR TORT) FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES IN ANY WAY RELATED TO, ARISING FROM, OR RESULTING FROM ANY USE MADE OF THE PRODUCT. The information in this sheet is intended for guidance only and is based upon laboratory tests that PPG believes to

be reliable. PPG may modify the information contained herein at any time as a result of practical experience and continuous product development. All recommendations or suggestions relating to the use of the PPG product, whether in

technical documentation, or in response to a specific inquiry, or otherwise, are based on data, which to the best of PPGs knowledge, is reliable. The product and related information is designed for users having the requisite knowledge

and industrial skills in the industry and it is the end-users responsibility to determine the suitability of the product for its own particular use and it shall be deemed that Buyer has done so, as its sole discretion and risk. PPG has no

control over either the quality or condition of the substrate, or the many factors affecting the use and application of the product. Therefore, PPG does not accept any liability arising from any loss, injury or damage resulting from such

use or the contents of this information (unless there are written agreements stating otherwise). Variations in the application environment, changes in procedures of use, or extrapolation of data may cause unsatisfactory results. This

sheet supersedes all previous versions and it is the Buyers responsibility to ensure that this information is current prior to using the product. Current sheets for all PPG Protective & Marine Coatings Products are maintained at

www.ppgpmc.com. The English text of this sheet shall prevail over any translation thereof.

Packaging: Available in 1-gallon and 4-gallon kits

Product code Description

AT68HS-A Reddish Gray Base

AT68HS-5 Green Base

AT68HS-B Hardener

AT68HS-P Zinc Powder

The PPG Logo, Bringing innovation to the surface., and all other trademarks herein are property of the PPG group of companies.

Ref. P039 Page 6/6

También podría gustarte

- 7570 SigmaZinc 170 Sigmazinc 9 (January 2014)Documento6 páginas7570 SigmaZinc 170 Sigmazinc 9 (January 2014)Akhtar AnsariAún no hay calificaciones

- Hempadur Avantguard 750 1736g - Product DatasheetDocumento2 páginasHempadur Avantguard 750 1736g - Product DatasheetWisnu Wardhana0% (1)

- A002511 Rev 34Documento9 páginasA002511 Rev 34Bruno AbudAún no hay calificaciones

- Mip - Chain Va.754Documento16 páginasMip - Chain Va.754Jiggy JickAún no hay calificaciones

- AI Hempel's Galvosil 15700 EnglishDocumento7 páginasAI Hempel's Galvosil 15700 EnglishvitharvanAún no hay calificaciones

- SES Amercoat Dimetcote 9Documento4 páginasSES Amercoat Dimetcote 9kamalkashAún no hay calificaciones

- API 6A Licensing Information Form 20190510Documento1 páginaAPI 6A Licensing Information Form 20190510Guillermo Aponte RiañoAún no hay calificaciones

- Sigmaprime 700Documento7 páginasSigmaprime 700Trịnh Minh KhoaAún no hay calificaciones

- Norsok Systems No7 August 2022Documento3 páginasNorsok Systems No7 August 2022angelito bernalAún no hay calificaciones

- 4.2.1 HVA Adhesive Anchor: Anchoring SystemsDocumento15 páginas4.2.1 HVA Adhesive Anchor: Anchoring SystemsechavarriAún no hay calificaciones

- Con-011 Instruction For Painting Work Rev.0Documento11 páginasCon-011 Instruction For Painting Work Rev.0monchai_626Aún no hay calificaciones

- CPVC ChecklistDocumento1 páginaCPVC Checklistchakravarthi kanugulaAún no hay calificaciones

- Sigmadur 550Documento9 páginasSigmadur 550indcoatingsAún no hay calificaciones

- Interseal 670HDocumento2 páginasInterseal 670Hmadmax_mfpAún no hay calificaciones

- Hempadur Quattro 17634: Product Characteristics Product SafetyDocumento4 páginasHempadur Quattro 17634: Product Characteristics Product Safetyulul100% (1)

- Fenomastic Hygiene Emulsion SilkDocumento4 páginasFenomastic Hygiene Emulsion Silkمحمد عزتAún no hay calificaciones

- Vinyl Ester-Glass Flake PaintDocumento4 páginasVinyl Ester-Glass Flake PaintSimbu ArasanAún no hay calificaciones

- Project Title - ID: Activity NameDocumento5 páginasProject Title - ID: Activity NameRiaz MohammedAún no hay calificaciones

- Coke Crusher - Lubrication Pumps Run in TestDocumento26 páginasCoke Crusher - Lubrication Pumps Run in TestsayedAún no hay calificaciones

- 14 Procedure For Shop and Field PaintingDocumento24 páginas14 Procedure For Shop and Field PaintingdnbinhAún no hay calificaciones

- Astm A179 PDFDocumento1 páginaAstm A179 PDFgaminAún no hay calificaciones

- A F E S: Process Piping 670.200Documento17 páginasA F E S: Process Piping 670.200puwarin najaAún no hay calificaciones

- 8-12-8 Fabrication of Piping PDFDocumento7 páginas8-12-8 Fabrication of Piping PDFasif rahimAún no hay calificaciones

- Scope: Painting ProcedureDocumento2 páginasScope: Painting Procedureคุณพ่อน้อง บิ๊กบอสAún no hay calificaciones

- Chemical Tank LiningDocumento16 páginasChemical Tank LiningChonTicha'100% (1)

- Asme 1325-18 (2007)Documento1 páginaAsme 1325-18 (2007)Matthew TaylorAún no hay calificaciones

- Painting Maual For Power Sector ErectionDocumento32 páginasPainting Maual For Power Sector Erectionnagarathinam82Aún no hay calificaciones

- 000 A Ee 0230028 513 R0Documento13 páginas000 A Ee 0230028 513 R0onur gunesAún no hay calificaciones

- Dimecote 9 Inorganic Zinc Silicate CoatingDocumento4 páginasDimecote 9 Inorganic Zinc Silicate Coatingabdulgafoor54Aún no hay calificaciones

- Standard Specification FOR Pipeline Internal CoatingDocumento2 páginasStandard Specification FOR Pipeline Internal CoatingRanjan KumarAún no hay calificaciones

- Prorox WM 960 Sa PDFDocumento1 páginaProrox WM 960 Sa PDFr afriantoAún no hay calificaciones

- Hempel Product Data SheetDocumento6 páginasHempel Product Data SheetHendri Arief SetyawanAún no hay calificaciones

- Blasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateDocumento3 páginasBlasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateLOPA THANDARAún no hay calificaciones

- Repair Procedure For Carbon Steel: Rev No: 00 Date Rev: 17 Dec 2008 Page No: 1 of 6Documento6 páginasRepair Procedure For Carbon Steel: Rev No: 00 Date Rev: 17 Dec 2008 Page No: 1 of 6mohd as shahiddin jafriAún no hay calificaciones

- Daily Painting Report System P 01ndDocumento49 páginasDaily Painting Report System P 01ndArung IdAún no hay calificaciones

- Swagelok Magnehelic Gauge InstructionsDocumento4 páginasSwagelok Magnehelic Gauge InstructionsAnonymous vF4wgBTdSbAún no hay calificaciones

- S0442 GPS L XXX SP 0005 - 0 - Specification For Piping Fabrication and InstallationDocumento42 páginasS0442 GPS L XXX SP 0005 - 0 - Specification For Piping Fabrication and InstallationThành TrịnhAún no hay calificaciones

- Product Data: Hempadur Multi-Strength 35530Documento2 páginasProduct Data: Hempadur Multi-Strength 35530Vijayaraj KumarAún no hay calificaciones

- WPS - 2Documento3 páginasWPS - 2aleventAún no hay calificaciones

- WPS & SmawDocumento12 páginasWPS & Smawnuke apriyaniAún no hay calificaciones

- Belzona 1391 Dta SheetDocumento4 páginasBelzona 1391 Dta SheetMuthuKumarAún no hay calificaciones

- Data Sheet Proguard CN 200 A.SDocumento3 páginasData Sheet Proguard CN 200 A.SAlexir Thatayaone NdovieAún no hay calificaciones

- Sae Air81d PDFDocumento12 páginasSae Air81d PDFfarhad pashaei mehrAún no hay calificaciones

- ASTM D4541 and ISO 4624: ?/sup InstrumentsDocumento2 páginasASTM D4541 and ISO 4624: ?/sup InstrumentsTeguh SilaAún no hay calificaciones

- Instruction Manual Enardo 2000 2500 Series Emergency Pressure Relief Vents North America Only en 122600 3Documento8 páginasInstruction Manual Enardo 2000 2500 Series Emergency Pressure Relief Vents North America Only en 122600 3Ramon GarciaAún no hay calificaciones

- dpvc-09 Petrobras PDFDocumento47 páginasdpvc-09 Petrobras PDFBilly TanAún no hay calificaciones

- PDF Iso 3834 Checklist 1 CompressDocumento12 páginasPDF Iso 3834 Checklist 1 CompressViệt VũAún no hay calificaciones

- Approved Itp-Dss - 28 Sep 2016Documento4 páginasApproved Itp-Dss - 28 Sep 2016Selvakumar SubramanianAún no hay calificaciones

- INS T 004, Tol - OvalityDocumento4 páginasINS T 004, Tol - OvalityDeepakAún no hay calificaciones

- ENG-DUQM-101 - Painting Procedure - Rev 3.Documento269 páginasENG-DUQM-101 - Painting Procedure - Rev 3.Shiva RajAún no hay calificaciones

- Daily Consumed Productive Hours: Job No: MRT-FRM-304-109 Responsible Engineer: Saif Ullah KhanDocumento4 páginasDaily Consumed Productive Hours: Job No: MRT-FRM-304-109 Responsible Engineer: Saif Ullah KhanSUKhanAún no hay calificaciones

- Eadips Manual Engl PDFDocumento390 páginasEadips Manual Engl PDFbkarabasevicAún no hay calificaciones

- Sigmashield 880 GF - ISO 23040-1Documento1 páginaSigmashield 880 GF - ISO 23040-1Saravan KumarAún no hay calificaciones

- EFCO Maschinenbau India Private Limited: Job Card - Isolation ValveDocumento2 páginasEFCO Maschinenbau India Private Limited: Job Card - Isolation ValveDebasis Pattnaik DebaAún no hay calificaciones

- 800D SeriesDocumento3 páginas800D Seriesvkeie0206Aún no hay calificaciones

- Sl-Elt-Pr-Wps1-4107-C2-S1-Welder QualificationDocumento15 páginasSl-Elt-Pr-Wps1-4107-C2-S1-Welder Qualificationsaeed ghafooriAún no hay calificaciones

- FSK-E290-006-A4-0 Quality Control Plan (QC Plan)Documento4 páginasFSK-E290-006-A4-0 Quality Control Plan (QC Plan)Amir Reza RashidfarokhiAún no hay calificaciones

- Amercoat 68hsvocDocumento6 páginasAmercoat 68hsvocVijay KumarAún no hay calificaciones

- Amercoat 68HSDocumento7 páginasAmercoat 68HSVijay KumarAún no hay calificaciones

- Amercoat 68 HsDocumento7 páginasAmercoat 68 HsdharamgurnaniAún no hay calificaciones

- Learnlight - CardsDocumento3 páginasLearnlight - CardsPeter CallánAún no hay calificaciones

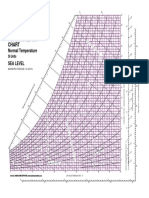

- Psychrometric ChartDocumento1 páginaPsychrometric ChartPeter CallánAún no hay calificaciones

- Performance Test Report - Novaguard 890 PDFDocumento2 páginasPerformance Test Report - Novaguard 890 PDFPeter Callán100% (1)

- Caso HistoricoDocumento2 páginasCaso HistoricoPeter CallánAún no hay calificaciones

- Ed About Brushless MotorsDocumento7 páginasEd About Brushless MotorsAddo AdhiyaksaAún no hay calificaciones

- NISHANTH C G FOURESS REPORTDocumento20 páginasNISHANTH C G FOURESS REPORTNithish ChandrashekarAún no hay calificaciones

- Short Introduction of Sizing / Warping / WeavingDocumento14 páginasShort Introduction of Sizing / Warping / WeavingAmir YasinAún no hay calificaciones

- Project ReportDocumento63 páginasProject ReportPramit ChhabraAún no hay calificaciones

- Introduction To Production Planning and ControlDocumento28 páginasIntroduction To Production Planning and ControlDr. Mahmoud Abbas Mahmoud Al-NaimiAún no hay calificaciones

- Village of Fredonia Inspection Report 2015Documento16 páginasVillage of Fredonia Inspection Report 2015WGRZ-TV100% (1)

- ISO 8501-3 Prep PDFDocumento6 páginasISO 8501-3 Prep PDFAdnan HussainAún no hay calificaciones

- ZF-Ecomat and Ecomat 2Documento38 páginasZF-Ecomat and Ecomat 2duongpndng80% (5)

- Válvulas de Alívio NaucoDocumento12 páginasVálvulas de Alívio NaucoBruno CoutoAún no hay calificaciones

- S80 - Sales Borchure EnglishDocumento2 páginasS80 - Sales Borchure Englishevilnemesis133Aún no hay calificaciones

- HWH Joystick-Controlled 200/210 Series Leveling SystemDocumento40 páginasHWH Joystick-Controlled 200/210 Series Leveling SystemEdward Tillman100% (3)

- Krishna Engineering College Department of Mechanical EngineeringDocumento4 páginasKrishna Engineering College Department of Mechanical EngineeringVivek BajpaiAún no hay calificaciones

- 5R110W Assembly PDFDocumento16 páginas5R110W Assembly PDFLuis VelazquezAún no hay calificaciones

- BR PDFDocumento240 páginasBR PDFMisha KulibaevAún no hay calificaciones

- Catalog Wirsbo Pex PlumbingDocumento6 páginasCatalog Wirsbo Pex PlumbingJas BoldexAún no hay calificaciones

- RE18306-01 - 2018-12 - Gruppo 05Documento82 páginasRE18306-01 - 2018-12 - Gruppo 05Giovanni TrinidadAún no hay calificaciones

- Qw-483 Procedure Qualification Records (PQR: Groove Design of Test Coupon Base Metals (Qw-403) Filler Metals (Qw-404)Documento2 páginasQw-483 Procedure Qualification Records (PQR: Groove Design of Test Coupon Base Metals (Qw-403) Filler Metals (Qw-404)Parminder SinghAún no hay calificaciones

- Release Bearing Noise With Pedal UpDocumento2 páginasRelease Bearing Noise With Pedal UpKB JongAún no hay calificaciones

- Chapter 4 - Plasticity of SoilDocumento15 páginasChapter 4 - Plasticity of SoilHussein EssaAún no hay calificaciones

- DevelopmentsDocumento8 páginasDevelopmentsPaige RobsonAún no hay calificaciones

- Plant FibreDocumento5 páginasPlant FibreNur Hafizah MukhtarAún no hay calificaciones

- M015710 04e PDFDocumento211 páginasM015710 04e PDFTaz UddinAún no hay calificaciones

- Home ScienceDocumento3 páginasHome ScienceCricket ClutchAún no hay calificaciones

- 60 W-Universal Input/90 W-230 Vac Input PWM Switching RegulatorsDocumento14 páginas60 W-Universal Input/90 W-230 Vac Input PWM Switching RegulatorsIBSDIALLO0% (1)

- Robitic WeldingDocumento23 páginasRobitic Weldingkhaled osmanAún no hay calificaciones

- 2022 Brochure - Bomanite Polished ConcreteDocumento4 páginas2022 Brochure - Bomanite Polished ConcreteGemma LamosteAún no hay calificaciones

- Steel Members DesignDocumento195 páginasSteel Members DesignStephen JamesAún no hay calificaciones

- KDocumento18 páginasKredaAún no hay calificaciones

- ICAM Schedule V6Documento25 páginasICAM Schedule V6Vimal KekAún no hay calificaciones

- Stepwise Analysis of Gasification Reactions With Aspen Plus and CPFDDocumento12 páginasStepwise Analysis of Gasification Reactions With Aspen Plus and CPFDabcd123Aún no hay calificaciones