Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Korodur Copetti Floor PDF

Cargado por

Ibrahim Sahin0 calificaciones0% encontró este documento útil (0 votos)

128 vistas1 páginaKCF is a factory-produced, cementitious flooring material that provides a decorative design simulating marble optics. It is applied in two layers - first a bonding compound is applied to the concrete base, then the KCF dry mortar is applied and troweled smooth. The KCF hardens to be durable, water resistant, anti-slip, and easy to clean. It is produced by KORODUR Westphal Hartbeton GmbH & Co. KG and is suitable for commercial applications like shops, museums, and airports.

Descripción original:

Título original

Korodur Copetti Floor.pdf

Derechos de autor

© © All Rights Reserved

Formatos disponibles

PDF, TXT o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoKCF is a factory-produced, cementitious flooring material that provides a decorative design simulating marble optics. It is applied in two layers - first a bonding compound is applied to the concrete base, then the KCF dry mortar is applied and troweled smooth. The KCF hardens to be durable, water resistant, anti-slip, and easy to clean. It is produced by KORODUR Westphal Hartbeton GmbH & Co. KG and is suitable for commercial applications like shops, museums, and airports.

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

128 vistas1 páginaKorodur Copetti Floor PDF

Cargado por

Ibrahim SahinKCF is a factory-produced, cementitious flooring material that provides a decorative design simulating marble optics. It is applied in two layers - first a bonding compound is applied to the concrete base, then the KCF dry mortar is applied and troweled smooth. The KCF hardens to be durable, water resistant, anti-slip, and easy to clean. It is produced by KORODUR Westphal Hartbeton GmbH & Co. KG and is suitable for commercial applications like shops, museums, and airports.

Copyright:

© All Rights Reserved

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

Está en la página 1de 1

KCF KORODUR COPETTI FLOOR

KORODUR DESIGN FLOOR

IN MARBLE OPTICS

DESCRIPTION PROCESSING 2. On to separation or insulation

KCF a factory-produced, ready 1. On to set base concrete layer

to use, cementitious, extremely The base concrete, min. C 25/30 must be Cement screed, min. C 35/F5

decorative design floor. pre-treated by milling, shot-peening etc. (bond strength > 1,5 N/mm) in min.10 cm

KCF - in marble optics For permabond composite the surface thickness (DIN 18560, table 7, line 3.4.3)

KCF also coloured, see colour chart must be free from cracks, even, free as compensation layer, to be applied over

from loose and brittle particles and gauges, struck off aligned and mechanic-

ally compacted.

APPLICATION enrichments of finest mortar, rough

As soon as the cement screed has

KCF design floor for post-modern and open-pore. The evenness should be

acc. to DIN 18202, table 3, line 3. The sufficiently dried the KCF is applied ana-

architecture in sales rooms, boutiques, logously to the processing as described

exposition rooms, restaurants, bond strength must be min. 1,5 N/mm .

The pre-treated base concrete is under on to set base concrete (see item

lobbies, museums, office buildings,

airport terminals, subway and railway thoroughly pre-wetted, avoiding

stations as well as representational areas. puddles. On to the matt-damp surface the

AFTER-TREATMENT

KORODUR Bonding Compound HB 5 is After-treatment for 7 days with PE foil. To

to be applied following the system. achieve the intended shiny effect

PROPERTIES of the surface, the KCF floor after

heavy duty KCF-dry mortar to be mixed with approx. 21 days is cleaned pore-deep from

water-resistant, qualified in wet rooms 10 % water (referred to the mortar weight) any contamination and a first mainten-

anti-skid, non slip in plastic consistency and to be applied ance carried out. (see KORODUR

resistant against gasoline, mineral oil fresh-in-fresh on the still damp bonding cleaning and maintenance system).

resistant against solvents compound in a thickness of approx.

electrostatic non-chargeable 12 mm, struck off aligned and timely PRODUCTION

improved surface density ground and smoothed. The KCF- surface KORODUR Westphal Hartbeton

easy to clean must be repeatedly mechanically GmbH & Co. KG, works Wattenscheid

smoothed until a shiny structure is Certification: DIN EN ISO 9001:2000

TECHNICAL DATA achieved. At the end of the setting phase

grain size: 0-4 mm the surface has to be finally smoothed by

compressive strength: approx. 55 using power trowel until closure of pores. P A C K I N G / S T O R A G E

N/mm In case of need it can be partially re- 25 kg packaging /

tensile strength: approx. 7 moistened and smoothed again with store dry, like cement

N/mm power trowel to intensify the cloud

material consumption at layer thick- formation effect for the marble optics HINTS

ness of the surface. Acc. to the current stand of techniques,

of approx. 12 mm: approx. 28 possibly occurring hair line cracks cannot

kg/m completely be avoided. KCF contains cement

and has an alkaline reaction with moisture/wa-

water admixture: approx. 10 %

ter. Therefore protect hands and eyes. In case

referred to the mortar weight

of contact with eyes consult a doctor. We re-

Processing temperature: > 5 C commend to adapt the processing to the given

local conditions and we refer in this context to

our general terms of sale and delivery.

per July 2008

KORODUR International GmbH. www. korodur.de

Head Office: Bochum-Wattenscheid works:

Wernher-von-Braun-Str. 4 Hohensteinstr. 19

92224 Amberg 44866 Bochum

P.O. Box 1653, 92206 Amberg P.O. Box 60 02 48, 44842 Bochum

C0204/11

Phone: 09621-47590 Phone: 02327-94570

Telefax: 09621-32341 Telefax: 02327-321084

info@korodur.de wattenscheid@korodur.de

También podría gustarte

- KEIM Porosil-Leichtputz (Lightweight Render)Documento2 páginasKEIM Porosil-Leichtputz (Lightweight Render)gunelAún no hay calificaciones

- Koroplan DurDocumento1 páginaKoroplan DurIbrahim SahinAún no hay calificaciones

- FloArm Screed Eco Ver7Documento4 páginasFloArm Screed Eco Ver7imsAún no hay calificaciones

- Epoxy Repair Mortar TDS FloArm-ERM-Ver-6 24-01-2023Documento3 páginasEpoxy Repair Mortar TDS FloArm-ERM-Ver-6 24-01-2023Rajesh GiriAún no hay calificaciones

- Concresive 1020 Special v2 PDFDocumento2 páginasConcresive 1020 Special v2 PDFMohammad UmmerAún no hay calificaciones

- Renderoc TGDocumento2 páginasRenderoc TGMansoor Ali50% (2)

- Nafufill: Corrosion Protection Coat and Bond CoatDocumento2 páginasNafufill: Corrosion Protection Coat and Bond CoatRichard AmoahAún no hay calificaciones

- Emcoril Compact Top EN EN TDSDocumento2 páginasEmcoril Compact Top EN EN TDSParinex SRLAún no hay calificaciones

- Ds Medapoxy Sol SoupleDocumento2 páginasDs Medapoxy Sol SouplefaridAún no hay calificaciones

- Tufbuild HsDocumento2 páginasTufbuild HsWilfredoEnghoy0% (1)

- Fosroc Renderoc TG: Constructive SolutionsDocumento2 páginasFosroc Renderoc TG: Constructive SolutionsVincent JavateAún no hay calificaciones

- Polypoxy EN: High Build Phenol Novolac Epoxy Resin Based Protective CoatingDocumento2 páginasPolypoxy EN: High Build Phenol Novolac Epoxy Resin Based Protective CoatingVaittianathan MahavapillaiAún no hay calificaciones

- iKOTE CM 30R (TDS) 02-APRIL-2024Documento2 páginasiKOTE CM 30R (TDS) 02-APRIL-2024nguyen hoang AnhAún no hay calificaciones

- 3 - TarcoatDocumento8 páginas3 - Tarcoatkrishna KumarAún no hay calificaciones

- 6 2 3 6 3 Polybond Ac PDFDocumento2 páginas6 2 3 6 3 Polybond Ac PDFHtun ZarniAún no hay calificaciones

- RCT-ConRep FR MortarDocumento2 páginasRCT-ConRep FR MortarfahadAún no hay calificaciones

- Knauf Sheetrock Wetstop 10mm-13mm - Technical Datasheet - AustraliaDocumento2 páginasKnauf Sheetrock Wetstop 10mm-13mm - Technical Datasheet - AustraliaMatt WilliamsAún no hay calificaciones

- PSOW2 - MS For Waterproofing Dated 04.11.2023Documento5 páginasPSOW2 - MS For Waterproofing Dated 04.11.2023projectsAún no hay calificaciones

- MC-Color Flex Pure Data SheetDocumento2 páginasMC-Color Flex Pure Data SheetHenri DormoyAún no hay calificaciones

- Mc-Dur 1077 FGDocumento2 páginasMc-Dur 1077 FGTibelu'Aún no hay calificaciones

- RENDORC FC (FOSAM) Method Statement - CompressedDocumento27 páginasRENDORC FC (FOSAM) Method Statement - CompressedMohamed Reda Hussein SengarAún no hay calificaciones

- RAF026-SiKA QUARTZTOPDocumento11 páginasRAF026-SiKA QUARTZTOPEmil ElkinAún no hay calificaciones

- Renderoc HSDocumento2 páginasRenderoc HSMansoor AliAún no hay calificaciones

- Polyhard: Mineral Based Dry Shake Floor HardenerDocumento2 páginasPolyhard: Mineral Based Dry Shake Floor HardenerAlexi ALfred H. TagoAún no hay calificaciones

- Bonding Old-To-New Concrete, Epoxy Concrete BondingDocumento3 páginasBonding Old-To-New Concrete, Epoxy Concrete BondingShepherd NhangaAún no hay calificaciones

- Fosroc Nitocote CM210: Uses Standards ComplianceDocumento4 páginasFosroc Nitocote CM210: Uses Standards ComplianceSaif SAún no hay calificaciones

- 00 Flowcrete Uk Technical DataDocumento2 páginas00 Flowcrete Uk Technical DataCAITLIN AndrewAún no hay calificaciones

- Probuild PB200Documento2 páginasProbuild PB200osama mohAún no hay calificaciones

- TDS en Contite WS2 Rev 022 Nov 18Documento2 páginasTDS en Contite WS2 Rev 022 Nov 18Josip MedvedAún no hay calificaciones

- TDS Renderoc FC Saudi ArabiaDocumento3 páginasTDS Renderoc FC Saudi ArabiaMohammad ArslanAún no hay calificaciones

- Cikopoxy CF: Technical DataDocumento2 páginasCikopoxy CF: Technical DataM. KumaranAún no hay calificaciones

- Hempadur Fast Dry 17410 En-GbDocumento2 páginasHempadur Fast Dry 17410 En-GbTrịnh Minh KhoaAún no hay calificaciones

- Fosroc - UG Water Tank SpecsDocumento1 páginaFosroc - UG Water Tank SpecsShakil AkhterAún no hay calificaciones

- Polypoxy FC (S)Documento2 páginasPolypoxy FC (S)Alexi ALfred H. TagoAún no hay calificaciones

- Nanocrete FC Data Sheet: Specialist Construction Supplies For Repair, Maintenance, Building & InfrastructureDocumento5 páginasNanocrete FC Data Sheet: Specialist Construction Supplies For Repair, Maintenance, Building & InfrastructureVelmurugan BalasubramanianAún no hay calificaciones

- Fosroc Renderoc FC: Constructive SolutionsDocumento4 páginasFosroc Renderoc FC: Constructive Solutionsraahul_nAún no hay calificaciones

- Rheomix 131: Page 1 of 2Documento2 páginasRheomix 131: Page 1 of 2Ankita Baban Gavade100% (1)

- Renderoc HB40 NewDocumento5 páginasRenderoc HB40 NewJayvee G. DignosAún no hay calificaciones

- TDs - Emaco R101Documento3 páginasTDs - Emaco R101Venkata RaoAún no hay calificaciones

- Emaco S74: Shrinkage Controlled Micro-Concrete For All Types of Structural RepairsDocumento2 páginasEmaco S74: Shrinkage Controlled Micro-Concrete For All Types of Structural RepairsFrancois-Aún no hay calificaciones

- Fosroc System BOQDocumento12 páginasFosroc System BOQAsdf GhjkAún no hay calificaciones

- Abe DIY BookletDocumento89 páginasAbe DIY BookletPula ConsultantsAún no hay calificaciones

- TEC-030100.2-MET-DoR-002-Fosroc1A-Renderoc FC (Fairing Coat) (1 Component Polymer Modifyied CementitiousDocumento4 páginasTEC-030100.2-MET-DoR-002-Fosroc1A-Renderoc FC (Fairing Coat) (1 Component Polymer Modifyied CementitiousEli MatucadAún no hay calificaciones

- Sikatop®-107 Seal KH: Product Data SheetDocumento4 páginasSikatop®-107 Seal KH: Product Data SheetReab SimanthAún no hay calificaciones

- Renderoc FCDocumento4 páginasRenderoc FCMansoor AliAún no hay calificaciones

- Grinding Aids - SikaDocumento8 páginasGrinding Aids - SikaNam HuynhAún no hay calificaciones

- Boq R2 - 290914Documento25 páginasBoq R2 - 290914raviAún no hay calificaciones

- CIKOcem ScreedDocumento2 páginasCIKOcem Screedsales02Aún no hay calificaciones

- SikaTop Seal-107 Standard PB ENGDocumento4 páginasSikaTop Seal-107 Standard PB ENGJoshua WijayaAún no hay calificaciones

- Weber - Tec MC1Documento2 páginasWeber - Tec MC1rangarajan1989Aún no hay calificaciones

- PDS Optimum Flex 18 KG - 9 SQ.M PER GAL 1MMTHKDocumento2 páginasPDS Optimum Flex 18 KG - 9 SQ.M PER GAL 1MMTHKRoemaric AguasAún no hay calificaciones

- REMAFIX C A 2012-04-01-Eng PDFDocumento2 páginasREMAFIX C A 2012-04-01-Eng PDFMaximiliano Cares LetelierAún no hay calificaciones

- 10 Conbextra EP10Documento2 páginas10 Conbextra EP10ahmad wildaanAún no hay calificaciones

- Cemcoat PuttyDocumento2 páginasCemcoat Puttyosama mohAún no hay calificaciones

- Method Statement For RoofDocumento22 páginasMethod Statement For Roofahmed samirAún no hay calificaciones

- Renderoc HB25: Constructive SolutionsDocumento4 páginasRenderoc HB25: Constructive SolutionsDoby YuniardiAún no hay calificaciones

- Tds - Emaco Cp20Documento3 páginasTds - Emaco Cp20Venkata RaoAún no hay calificaciones

- Concresive 1020 Special v2Documento2 páginasConcresive 1020 Special v2kavi_prakash6992Aún no hay calificaciones

- UP210 Lime/cement Basecoat Render: Data Sheet Sept 2014Documento3 páginasUP210 Lime/cement Basecoat Render: Data Sheet Sept 2014Francesco FanaraAún no hay calificaciones

- Hot Dip GalvanizingDocumento4 páginasHot Dip GalvanizingIbrahim SahinAún no hay calificaciones

- Baumit Facade Insulating Board EPS-F: ProductDocumento6 páginasBaumit Facade Insulating Board EPS-F: ProductIbrahim SahinAún no hay calificaciones

- Asodur - D2: Schomburg SchomburgDocumento2 páginasAsodur - D2: Schomburg SchomburgIbrahim SahinAún no hay calificaciones

- T C D E G H I J K L A S D' R R' F P N M O B: Trafficable Fla Roof Trafficable Fla RoofDocumento1 páginaT C D E G H I J K L A S D' R R' F P N M O B: Trafficable Fla Roof Trafficable Fla RoofIbrahim SahinAún no hay calificaciones

- 09 - PEX20 Screed & Concrete FloorDocumento4 páginas09 - PEX20 Screed & Concrete FloorIbrahim SahinAún no hay calificaciones

- Technical Description ChapterTBDocumento8 páginasTechnical Description ChapterTBIbrahim SahinAún no hay calificaciones

- Guiderails Vertical ChapterCDocumento12 páginasGuiderails Vertical ChapterCIbrahim SahinAún no hay calificaciones

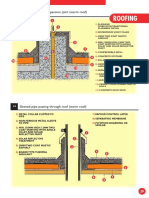

- Roofing p29Documento1 páginaRoofing p29Ibrahim SahinAún no hay calificaciones

- Examples of ApplicationDocumento12 páginasExamples of ApplicationIbrahim SahinAún no hay calificaciones

- Aluminium Ladders ChapterADocumento41 páginasAluminium Ladders ChapterAIbrahim SahinAún no hay calificaciones

- ManSafe For Industry (UK)Documento8 páginasManSafe For Industry (UK)Ibrahim SahinAún no hay calificaciones

- ABS Katalog EnglischDocumento17 páginasABS Katalog EnglischIbrahim SahinAún no hay calificaciones

- Fastening Sets: Nno Ech Arbeitsschutz GMBHDocumento1 páginaFastening Sets: Nno Ech Arbeitsschutz GMBHIbrahim SahinAún no hay calificaciones

- ABS Katalog EnglischDocumento17 páginasABS Katalog EnglischIbrahim SahinAún no hay calificaciones

- Safesite Corporate Brochure and O&M ManualDocumento98 páginasSafesite Corporate Brochure and O&M ManualIbrahim SahinAún no hay calificaciones

- Roofing p17 18Documento2 páginasRoofing p17 18Ibrahim SahinAún no hay calificaciones

- Roofing p28Documento1 páginaRoofing p28Ibrahim SahinAún no hay calificaciones

- Perma Track Details Sheet AllDocumento16 páginasPerma Track Details Sheet AllIbrahim SahinAún no hay calificaciones

- Esd Flooring Selection Chart: Carpet Tile Carpet Broadloom Vinyl Tile Vinyl Sheet Epoxy RubberDocumento1 páginaEsd Flooring Selection Chart: Carpet Tile Carpet Broadloom Vinyl Tile Vinyl Sheet Epoxy RubberIbrahim SahinAún no hay calificaciones

- Roofing p5 6Documento2 páginasRoofing p5 6Ibrahim SahinAún no hay calificaciones

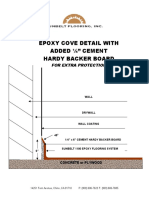

- Cove Base FRP Wall SystemDocumento1 páginaCove Base FRP Wall SystemIbrahim SahinAún no hay calificaciones

- Reducing Our Impact With Every StepDocumento6 páginasReducing Our Impact With Every StepIbrahim SahinAún no hay calificaciones

- IKO Green BrochureDocumento12 páginasIKO Green BrochureIbrahim SahinAún no hay calificaciones

- Standard Pigmented ColorsDocumento1 páginaStandard Pigmented ColorsIbrahim SahinAún no hay calificaciones

- Cove Base Detail With Hardy Backer Board.Documento1 páginaCove Base Detail With Hardy Backer Board.Ibrahim SahinAún no hay calificaciones

- Instrument TechnicianDocumento3 páginasInstrument TechnicianMahabula TypingAún no hay calificaciones

- An Introduction To Coolants PDFDocumento57 páginasAn Introduction To Coolants PDFPETER ADAMAún no hay calificaciones

- Presentation On FacebookDocumento39 páginasPresentation On FacebookShaswat SinghAún no hay calificaciones

- Premium Protection Synthetic Motor Oils (AMO & ARO)Documento2 páginasPremium Protection Synthetic Motor Oils (AMO & ARO)brian5786Aún no hay calificaciones

- Buying Solutions' Total Cost of Ownership (TCO) CalculatorDocumento93 páginasBuying Solutions' Total Cost of Ownership (TCO) Calculatorankitch123Aún no hay calificaciones

- U.S. Patent 4,064,781, Guitar Pick, Issued 1977.Documento3 páginasU.S. Patent 4,064,781, Guitar Pick, Issued 1977.Anonymous a7S1qyXAún no hay calificaciones

- A318/A319/A320/A321: Service BulletinDocumento22 páginasA318/A319/A320/A321: Service BulletinPradeep K sAún no hay calificaciones

- CYMTCC For Windows: User's Guide and Reference ManualDocumento290 páginasCYMTCC For Windows: User's Guide and Reference ManualJosselynGalloMuñozAún no hay calificaciones

- CR 55 AaaehqqeDocumento7 páginasCR 55 AaaehqqesigithvacAún no hay calificaciones

- Timetable Victoria Chichester PDFDocumento2 páginasTimetable Victoria Chichester PDFLizzie CosterAún no hay calificaciones

- HIDROMONTAŽA - We Change EverythingDocumento1 páginaHIDROMONTAŽA - We Change EverythingsamccoAún no hay calificaciones

- Section 02795 Porous Paving: Whole Building Design Guide Federal Green Construction Guide For SpecifiersDocumento6 páginasSection 02795 Porous Paving: Whole Building Design Guide Federal Green Construction Guide For SpecifiersAnonymous NMytbMiDAún no hay calificaciones

- Global Sources - 2010 June - Home ProductsDocumento212 páginasGlobal Sources - 2010 June - Home Productsdr_twiggyAún no hay calificaciones

- A White Paper On IExpense Features in R12Documento17 páginasA White Paper On IExpense Features in R12Balaji ShindeAún no hay calificaciones

- Catalogue SocorexDocumento40 páginasCatalogue Socorexdomitian88100% (1)

- Karcher Quotation List - 2023Documento12 páginasKarcher Quotation List - 2023veereshmyb28Aún no hay calificaciones

- Short Notes On Building ConstructionDocumento20 páginasShort Notes On Building Constructionlarnz0% (1)

- Kyabin Studio Pricelist 2021Documento18 páginasKyabin Studio Pricelist 2021BudiAún no hay calificaciones

- CM Line Catalog ENUDocumento68 páginasCM Line Catalog ENUdmugalloyAún no hay calificaciones

- EMT Tooth Saver Data SheetDocumento5 páginasEMT Tooth Saver Data SheetTerry FarmakisAún no hay calificaciones

- Naging: Case SelectingDocumento5 páginasNaging: Case SelectingPrabhakar RaiAún no hay calificaciones

- Vsphere Esxi Vcenter Server 50 Monitoring Performance GuideDocumento86 páginasVsphere Esxi Vcenter Server 50 Monitoring Performance GuideZeno JegamAún no hay calificaciones

- Oracle® Auto Service Request: Exadata Database Machine Quick Installation Guide Release 5.0Documento12 páginasOracle® Auto Service Request: Exadata Database Machine Quick Installation Guide Release 5.0ManifoldAún no hay calificaciones

- How To Import PRN Files in IdeaDocumento7 páginasHow To Import PRN Files in Ideainformation technology auditAún no hay calificaciones

- Vi35 San GuideDocumento43 páginasVi35 San Guideapi-3824328Aún no hay calificaciones

- Computer Science Ram PresentationDocumento11 páginasComputer Science Ram Presentationapi-268896185100% (3)

- Pd-Coated Wire Bonding Technology - Chip Design, Process Optimization, Production Qualification and Reliability Test For HIgh Reliability Semiconductor DevicesDocumento8 páginasPd-Coated Wire Bonding Technology - Chip Design, Process Optimization, Production Qualification and Reliability Test For HIgh Reliability Semiconductor Devicescrazyclown333100% (1)

- 12556/gorakhdham Exp Third Ac (3A)Documento2 páginas12556/gorakhdham Exp Third Ac (3A)Lovkesh GoyalAún no hay calificaciones

- Manual Bombas Pozo e ImpulsionDocumento112 páginasManual Bombas Pozo e ImpulsionFernando PuentesAún no hay calificaciones

- An Applied Guide to Water and Effluent Treatment Plant DesignDe EverandAn Applied Guide to Water and Effluent Treatment Plant DesignCalificación: 5 de 5 estrellas5/5 (4)

- Well Control for Completions and InterventionsDe EverandWell Control for Completions and InterventionsCalificación: 4 de 5 estrellas4/5 (10)

- Process Plant Equipment: Operation, Control, and ReliabilityDe EverandProcess Plant Equipment: Operation, Control, and ReliabilityCalificación: 5 de 5 estrellas5/5 (1)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersDe EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersAún no hay calificaciones

- Piping Engineering Leadership for Process Plant ProjectsDe EverandPiping Engineering Leadership for Process Plant ProjectsCalificación: 5 de 5 estrellas5/5 (1)

- Distillation Design and Control Using Aspen SimulationDe EverandDistillation Design and Control Using Aspen SimulationCalificación: 5 de 5 estrellas5/5 (2)

- Sodium Bicarbonate: Nature's Unique First Aid RemedyDe EverandSodium Bicarbonate: Nature's Unique First Aid RemedyCalificación: 5 de 5 estrellas5/5 (21)

- Guidelines for Chemical Process Quantitative Risk AnalysisDe EverandGuidelines for Chemical Process Quantitative Risk AnalysisCalificación: 5 de 5 estrellas5/5 (1)

- Lees' Process Safety Essentials: Hazard Identification, Assessment and ControlDe EverandLees' Process Safety Essentials: Hazard Identification, Assessment and ControlCalificación: 4 de 5 estrellas4/5 (4)

- Troubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersDe EverandTroubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersCalificación: 4.5 de 5 estrellas4.5/5 (2)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsDe EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsAún no hay calificaciones

- Understanding Distillation Using Column Profile MapsDe EverandUnderstanding Distillation Using Column Profile MapsAún no hay calificaciones

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsDe EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsAún no hay calificaciones

- The Perfumed Pages of History: A Textbook on Fragrance CreationDe EverandThe Perfumed Pages of History: A Textbook on Fragrance CreationCalificación: 4 de 5 estrellas4/5 (1)

- Fundamentals of Risk Management for Process Industry EngineersDe EverandFundamentals of Risk Management for Process Industry EngineersAún no hay calificaciones

- A New Approach to HAZOP of Complex Chemical ProcessesDe EverandA New Approach to HAZOP of Complex Chemical ProcessesAún no hay calificaciones

- Mastering Biochemistry: A Comprehensive Guide to ExcellenceDe EverandMastering Biochemistry: A Comprehensive Guide to ExcellenceAún no hay calificaciones

- Fun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksDe EverandFun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksAún no hay calificaciones

- Fun Facts about Carbon : Chemistry for Kids The Element Series | Children's Chemistry BooksDe EverandFun Facts about Carbon : Chemistry for Kids The Element Series | Children's Chemistry BooksAún no hay calificaciones

- Handbook of Cosmetic Science: An Introduction to Principles and ApplicationsDe EverandHandbook of Cosmetic Science: An Introduction to Principles and ApplicationsH. W. HibbottCalificación: 4 de 5 estrellas4/5 (6)

- Cathodic Protection: Industrial Solutions for Protecting Against CorrosionDe EverandCathodic Protection: Industrial Solutions for Protecting Against CorrosionAún no hay calificaciones

- High Pressure Phase Behaviour of Multicomponent Fluid MixturesDe EverandHigh Pressure Phase Behaviour of Multicomponent Fluid MixturesAún no hay calificaciones

- Bioinspired Materials Science and EngineeringDe EverandBioinspired Materials Science and EngineeringGuang YangAún no hay calificaciones