Documentos de Académico

Documentos de Profesional

Documentos de Cultura

LV Junction Repair Instructions - V3 (Draft)

Cargado por

nandhagopal2010Descripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

LV Junction Repair Instructions - V3 (Draft)

Cargado por

nandhagopal2010Copyright:

Formatos disponibles

TECHNICAL NOTE

Pages: 1 Datum

Subject LV JUNCTION REPAIR INSTRUCTIONS version 3 29/07/2016

To Installation personnel By RCE

Phase 1: PREPARATION & SAFETY

- Preparation:

a) Check whether a grinder with diamond blade can be used (spark and/or dust restrictions)

If necessary, cover switch boards and other sensible equipment with plastic sheeting or similar to avoid

precipitation of dust on sensitive equipment.

If necessary, provide a cover to avoid rain and water on the elements during and after removing the

junction.

b) Tools :

A diamond disc grinder reaching a depth of 30 mm is required

Concrete drills of 8 and 10 and 15 mm and length equivalent to the height of the busduct

Big chisel and small (8 mm) chisel and hammer

Clamps (wood or preferably steel) and threaded rods to secure the element on both sides of the junction.

This avoids splitting of the insulation close to the junction.

Phase 2: SAFETY

- Always wear gloves, goggles and adequate clothing (long sleeves) when using grinder

- Use respiratory protection

- If the system is situated at more than 1.5 m above ground suitable scaffolding must be provided

- Always make sure you work according local regulations (work permits, PPE, tooling, )

Low voltage junction repair instructions Page 1 | 10

Phase 3: understanding the geometry of the low voltage junction

Junction without resin

insulation isometric view

Pressure strips Phase Insulation

busduct insulation

busduct insulation

Section view of junction Junction insulation surface

+ Busduct insulation Busduct insulation surface

surface

+ junction insulation

17.5

37.5

surface

17.5

Junction insulation heigth

Conductor heigth

junction heigth

busduct heigth

element insulation width

Junction insulation width

Low voltage junction repair instructions Page 2 | 10

Side view of junction

Junction insulation heigth

busduct heigth

Low voltage junction repair instructions Page 3 | 10

Phase 4: Removal low voltage busduct junctions

This section explains how you should remove the insulation around the junction.

1 Make sure the junction is accessible from

all sides

2 Use a grinder with diamond disc and

sufficient grinding depth to make cuts in

all sides of the junctions.

For LA busduct type use the grinding

depths defined in annex 1

For LB busduct type use the grinding

depths defined in annex 2

Important: Cuts must remain 40 mm from

the extremities of the junction to preserve

insulation of the element itself. These

areas are indicated with .

For information: cuts with a depth of

19mm should be sufficient to get the job

done.

Low voltage junction repair instructions Page 4 | 10

3. Use a grinder with diamond disc and

sufficient grinding depth to make cuts in

all sides of the junctions.

For LA busduct type use the grinding

depths defined in annex 1

Area of metal pressure strips

For LB busduct type use the grinding

depths defined in annex 2

For information: cuts with a depth of

19mm should be sufficient to get the job

done.

4 Continue with the cutting all sides of the

junction insulation. For information: cuts

with a depth of 19mm should be sufficient

to get the job done.

5 Continue with the cutting all sides of the

junction insulation perpendicular to the

former cuts. For information: cuts with a

depth of 19mm should be sufficient to get

the job done.

Low voltage junction repair instructions Page 5 | 10

6 Use a big chisel and hammer to chip off

piece by piece of the insulation.

7 Once the position of pressure plates and

bolts is known, cut the bolts with the

diamond tool. After this, the laterals and

pressure plates can be removed.

Cut bolts Remove pressure plates

Remove outer junction

Remove pressure plates conductor and insulation

Both sides of the junction removed

Low voltage junction repair instructions Page 6 | 10

8 Once the exact position of junction plates

and conductors is known, the remainder

of the BIM insulation can be removed.

Drill holes in the spacing between

conductors to facilitate removal of BIM

insulation and junction plates between the

conductors.

Do not damage the busduct conductors !

Cut away the resin between Drill holes between element

element conductors conductors

Cut away the insulation Use small chisel & hammer

between elements to chip off the insulation

Use big chisel & hammer to push out the junction plates

between all element conductors

9 Finally remove the 40 mm remaining on

both sides taking care to have the clamps

in place. This to avoid splitting of the

busduct beyond the junction area.

Use clamps to avoid cracks

remove the 40 mm edges

in the elements while

removing the 40mm edges !

10 Be sure to remove all traces of insulation

in the contact area up to 75 mm of the

ends of the conductors to assure a good

75mm 75mm

electrical connection when replacing the

junction.

Use the scourer tape to remove oxidation

and resin in case copper conductors are

used.

remove remains of insulation in the 75mm areas for all element conductors

Low voltage junction repair instructions Page 7 | 10

Phase 5: Replacement of the junction by a new junction + resin mixture

See Installation manual modules F +G +H +I.

Phase 6: Junction resistance test + test report

See Installation manual Annex A + B to perform the test and fill in the test report. In case the junction resistance is

below the limit set by Eta-com, make sure the report is signed by the client and sent to Eta-com.

Low voltage junction repair instructions Page 8 | 10

Annex 1: grinding depths for LA type busducts

insulation

grinding grinding insulation thickness

Number of

conductor conductor depth depth top + thickness TOP + mould mould

LA conductors

thickness height sidewise bottom SIDE BOTTOM width height

[mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm]

LA04 3 4 40 < 47,5 < 37,5 47,5 37,5 139 115

LA04 3 5 40 < 46 < 37,5 46 37,5 139 115

LA04 3 6 40 < 44,5 < 37,5 44,5 37,5 139 115

LA08 3 4 80 < 47,5 < 37,5 47,5 37,5 139 155

LA08 3 5 80 < 46 < 37,5 46 37,5 139 155

LA08 3 6 80 < 44,5 < 37,5 44,5 37,5 139 155

LA12 3 4 120 < 47,5 < 37,5 47,5 37,5 139 195

LA12 3 5 120 < 46 < 37,5 46 37,5 139 195

LA12 3 6 120 < 44,5 < 37,5 44,5 37,5 139 195

LA16 3 4 160 < 47,5 < 37,5 47,5 37,5 139 235

LA16 3 5 160 < 46 < 37,5 46 37,5 139 235

LA16 3 6 160 < 44,5 < 37,5 44,5 37,5 139 235

LA20 3 4 200 < 52,5 < 37,5 52,5 37,5 149 275

LA20 3 5 200 < 51 < 37,5 51 37,5 149 275

LA20 3 6 200 < 49,5 < 37,5 49,5 37,5 149 275

LA04 4 4 40 < 40,5 < 37,5 40,5 37,5 139 115

LA04 4 5 40 < 38,5 < 37,5 38,5 37,5 139 115

LA04 4 6 40 < 36,5 < 37,5 36,5 37,5 139 115

LA08 4 4 80 < 40,5 < 37,5 40,5 37,5 139 155

LA08 4 5 80 < 38,5 < 37,5 38,5 37,5 139 155

LA08 4 6 80 < 36,5 < 37,5 36,5 37,5 139 155

LA12 4 4 120 < 40,5 < 37,5 40,5 37,5 139 195

LA12 4 5 120 < 38,5 < 37,5 38,5 37,5 139 195

LA12 4 6 120 < 36,5 < 37,5 36,5 37,5 139 195

LA16 4 4 160 < 40,5 < 37,5 40,5 37,5 139 235

LA16 4 5 160 < 38,5 < 37,5 38,5 37,5 139 235

LA16 4 6 160 < 36,5 < 37,5 36,5 37,5 139 235

LA20 4 4 200 < 45,5 < 37,5 45,5 37,5 149 275

LA20 4 5 200 < 43,5 < 37,5 43,5 37,5 149 275

LA20 4 6 200 < 41,5 < 37,5 41,5 37,5 149 275

LA04 5 4 40 < 33,5 < 37,5 33,5 37,5 139 115

LA04 5 5 40 < 31 < 37,5 31 37,5 139 115

LA04 5 6 40 < 28,5 < 37,5 28,5 37,5 139 115

LA08 5 4 80 < 33,5 < 37,5 33,5 37,5 139 155

LA08 5 5 80 < 31 < 37,5 31 37,5 139 155

LA08 5 6 80 < 28,5 < 37,5 28,5 37,5 139 155

LA12 5 4 120 < 33,5 < 37,5 33,5 37,5 139 195

LA12 5 5 120 < 31 < 37,5 31 37,5 139 195

LA12 5 6 120 < 28,5 < 37,5 28,5 37,5 139 195

LA16 5 4 160 < 33,5 < 37,5 33,5 37,5 139 235

LA16 5 5 160 < 31 < 37,5 31 37,5 139 235

LA16 5 6 160 < 28,5 < 37,5 28,5 37,5 139 235

LA20 5 4 200 < 38,5 < 37,5 38,5 37,5 149 275

LA20 5 5 200 < 36 < 37,5 36 37,5 149 275

LA20 5 6 200 < 33,5 < 37,5 33,5 37,5 149 275

Low voltage junction repair instructions Page 9 | 10

Annex 2: grinding depths for LB type busducts

insulation

grinding grinding insulation thickness

Number of

LB conductor conductor depth depth top + thickness TOP + mould mould

conductors

thickness height sidewise bottom SIDE BOTTOM width height

[mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm]

LB04 6 or 7 4 40 < 36,5 < 37,5 36,5 37,5 173 115

LB04 6 or 7 5 40 < 33 < 37,5 33 37,5 173 115

LB04 6 or 7 6 40 < 29,5 < 37,5 29,5 37,5 173 115

LB08 6 or 7 4 80 < 36,5 < 37,5 36,5 37,5 173 155

LB08 6 or 7 5 80 < 33 < 37,5 33 37,5 173 155

LB08 6 or 7 6 80 < 29,5 < 37,5 29,5 37,5 173 155

LB12 6 or 7 4 120 < 36,5 < 37,5 36,5 37,5 173 195

LB12 6 or 7 5 120 < 33 < 37,5 33 37,5 173 195

LB12 6 or 7 6 120 < 29,5 < 37,5 29,5 37,5 173 195

LB16 6 or 7 4 160 < 36,5 < 37,5 36,5 37,5 173 235

LB16 6 or 7 5 160 < 33 < 37,5 33 37,5 173 235

LB16 6 or 7 6 160 < 29,5 < 37,5 29,5 37,5 173 235

LB04 8 or 9 4 40 < 37,5 < 37,5 37,5 37,5 203 115

LB04 8 or 9 5 40 < 33 < 37,5 33 37,5 203 115

LB04 8 or 9 6 40 < 28,5 < 37,5 28,5 37,5 203 115

LB08 8 or 9 4 80 < 37,5 < 37,5 37,5 37,5 203 155

LB08 8 or 9 5 80 < 33 < 37,5 33 37,5 203 155

LB08 8 or 9 6 80 < 28,5 < 37,5 28,5 37,5 203 155

LB12 8 or 9 4 120 < 37,5 < 37,5 37,5 37,5 203 195

LB12 8 or 9 5 120 < 33 < 37,5 33 37,5 203 195

LB12 8 or 9 6 120 < 28,5 < 37,5 28,5 37,5 203 195

LB16 8 or 9 4 160 < 37,5 < 37,5 37,5 37,5 203 235

LB16 8 or 9 5 160 < 33 < 37,5 33 37,5 203 235

LB16 8 or 9 6 160 < 28,5 < 37,5 28,5 37,5 203 235

Low voltage junction repair instructions Page 10 | 10

También podría gustarte

- Manual de Instalación ReychemDocumento6 páginasManual de Instalación ReychemLuisAún no hay calificaciones

- LS Bus Duct System: WWW - Lsis.bizDocumento48 páginasLS Bus Duct System: WWW - Lsis.bizKao SophearakAún no hay calificaciones

- Turnout Operating Unit MK 2Documento5 páginasTurnout Operating Unit MK 2Li XinAún no hay calificaciones

- Installation instructions for SEIK 14, 24, 34 plug-in cable terminationsDocumento5 páginasInstallation instructions for SEIK 14, 24, 34 plug-in cable terminationsSonia Noval LlorianAún no hay calificaciones

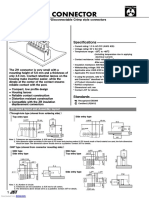

- Connector Connector: ZH Connector ZH ConnectorDocumento3 páginasConnector Connector: ZH Connector ZH ConnectorGreenoceanAún no hay calificaciones

- Kabel Tegangan MenengahDocumento18 páginasKabel Tegangan MenengahDwiki sevenfoldismAún no hay calificaciones

- Multi-blade Manual Balancing Damper Drive ArrangementDocumento3 páginasMulti-blade Manual Balancing Damper Drive ArrangementElmer Ramón Murillo MejiaAún no hay calificaciones

- Splicing Instruction For Trellex Steelcord Conveyor Belts: 1067 (42") ST 5700 14: 10 DIN XDocumento6 páginasSplicing Instruction For Trellex Steelcord Conveyor Belts: 1067 (42") ST 5700 14: 10 DIN XnicolasAún no hay calificaciones

- S 14 Steel 6 Connections 2Documento81 páginasS 14 Steel 6 Connections 2Md. Mahmudle HassanAún no hay calificaciones

- Connector: 2.5mm Pitch/disconnectable Crimp Style ConnectorsDocumento6 páginasConnector: 2.5mm Pitch/disconnectable Crimp Style ConnectorsDragos-Iulian NeacsuAún no hay calificaciones

- Connector: 2.5mm Pitch/disconnectable Crimp Style ConnectorsDocumento5 páginasConnector: 2.5mm Pitch/disconnectable Crimp Style Connectorssaiful rizalAún no hay calificaciones

- MV Cable TerminationDocumento16 páginasMV Cable TerminationsulemankhalidAún no hay calificaciones

- PCB Terminal Block - PT 1,5/ 2-5,0-H - 1935161: Key Commercial DataDocumento6 páginasPCB Terminal Block - PT 1,5/ 2-5,0-H - 1935161: Key Commercial DatauiddcguzAún no hay calificaciones

- Extract From The Online Catalog: Urtk/S-BenDocumento13 páginasExtract From The Online Catalog: Urtk/S-BenMaq QuinalhaAún no hay calificaciones

- Panta Flat WireDocumento25 páginasPanta Flat WireTechnoCommercial2 OfficeAún no hay calificaciones

- ANALYSIS OF RCC Girder - 20m SpanDocumento36 páginasANALYSIS OF RCC Girder - 20m SpanRaghums GOWDAAún no hay calificaciones

- 2002 Electrical Charcteristics of FinFET With Vertically Nonuniform Source Drain Doping ProfileDocumento2 páginas2002 Electrical Charcteristics of FinFET With Vertically Nonuniform Source Drain Doping ProfileeleenaamohapatraAún no hay calificaciones

- Instruction Guide Combiflex Crimping ToolDocumento2 páginasInstruction Guide Combiflex Crimping ToolAE,110 KV KanjikodeAún no hay calificaciones

- Solid Wall Pipe System Made With PP-MD According To DIN 14758Documento2 páginasSolid Wall Pipe System Made With PP-MD According To DIN 14758Carjan BogdanAún no hay calificaciones

- Nkt-06086 Katalog HochspannungsgarniturenDocumento20 páginasNkt-06086 Katalog Hochspannungsgarniturenrjk941-1Aún no hay calificaciones

- Quick Term III 3MDocumento11 páginasQuick Term III 3MGRUPO GENELCOAún no hay calificaciones

- Cables FIPEX BF MT 15 To 25 KV PDFDocumento3 páginasCables FIPEX BF MT 15 To 25 KV PDFISCENER SRLAún no hay calificaciones

- SOUTHERN CABLE 630mmsq Cu XLPEDocumento3 páginasSOUTHERN CABLE 630mmsq Cu XLPERozaimi GhazaliAún no hay calificaciones

- S.N. Name of Chapter / Subhead Page No.: Description Unit Rate With CI Cost Index For Idukki Item CodeDocumento51 páginasS.N. Name of Chapter / Subhead Page No.: Description Unit Rate With CI Cost Index For Idukki Item CodeTreesa ArchnanaAún no hay calificaciones

- Condenser MicrophoneDocumento11 páginasCondenser Microphoneverd leonardAún no hay calificaciones

- Axo BulkFlatCables - FlexlinkDocumento3 páginasAxo BulkFlatCables - FlexlinkRoad BlasterAún no hay calificaciones

- Deck Slab LSD (12.9m) - 14mDocumento17 páginasDeck Slab LSD (12.9m) - 14mGaurav SinghAún no hay calificaciones

- CSCP2.5T2Documento2 páginasCSCP2.5T2NileshAún no hay calificaciones

- General Guidelines InsulationDocumento56 páginasGeneral Guidelines InsulationPadmanaban SoundirarajanAún no hay calificaciones

- Euromold K158LR Separable Elbow Connectors Copper Wire Screen Cables Type A InstructionDocumento10 páginasEuromold K158LR Separable Elbow Connectors Copper Wire Screen Cables Type A InstructionMosa Elnaid ElnaidAún no hay calificaciones

- Euromold K158LR Separable Elbow Connectors Copper Wire Screen Cables Type A InstructionDocumento10 páginasEuromold K158LR Separable Elbow Connectors Copper Wire Screen Cables Type A InstructionMosa Elnaid ElnaidAún no hay calificaciones

- CBL-VDL 2016Documento2 páginasCBL-VDL 2016smilegirlAún no hay calificaciones

- MS For AC Pipe InsulationDocumento14 páginasMS For AC Pipe InsulationTruong Quoc Bao100% (1)

- 3.3 GTP - Brothers - 33kV 200A Off-Load Fused Isolator For Aux TransformerDocumento2 páginas3.3 GTP - Brothers - 33kV 200A Off-Load Fused Isolator For Aux Transformerjitendra prasadAún no hay calificaciones

- TE S Raychem Cable Accessories: Scan QR Codes and Get Video SupportDocumento8 páginasTE S Raychem Cable Accessories: Scan QR Codes and Get Video SupportHossam AlzubairyAún no hay calificaciones

- PTFR Brochure en 2019 02 Grid PTR 0234Documento8 páginasPTFR Brochure en 2019 02 Grid PTR 0234p m yadavAún no hay calificaciones

- DTS617/DTB617 Deadbreak Bolted Tee Connector: Power Systems Installation InstructionDocumento10 páginasDTS617/DTB617 Deadbreak Bolted Tee Connector: Power Systems Installation InstructionMuhammad Lathieful HaqAún no hay calificaciones

- UK 5 N BU terminal blockDocumento8 páginasUK 5 N BU terminal blockfragercitoAún no hay calificaciones

- Busbar Insulation PDFDocumento8 páginasBusbar Insulation PDFPipo KingAún no hay calificaciones

- Eaton 107186 BBA TP3 CU BAND en - 800ADocumento2 páginasEaton 107186 BBA TP3 CU BAND en - 800AAleksandar SekuloskiAún no hay calificaciones

- 15kV Outdoor Termination_KSU_500sq.mmDocumento5 páginas15kV Outdoor Termination_KSU_500sq.mmabd elmohsen saedAún no hay calificaciones

- DDFL4U Double Level Fuse Terminal BlockDocumento1 páginaDDFL4U Double Level Fuse Terminal BlockTaufik MutwalliAún no hay calificaciones

- Service Manual: GR-D93US, GR-D94USDocumento22 páginasService Manual: GR-D93US, GR-D94USsilictronicAún no hay calificaciones

- AITC Technical Note 19Documento7 páginasAITC Technical Note 19klb75Aún no hay calificaciones

- DG2/40 HS: Flat Transmission Belts Technical Data SheetDocumento2 páginasDG2/40 HS: Flat Transmission Belts Technical Data Sheetdirkz26Aún no hay calificaciones

- Backer Rod Brochures - 2pagesDocumento2 páginasBacker Rod Brochures - 2pageszultrsb689Aún no hay calificaciones

- Cable MT NFC 33-226 18/30 (36) KV: DescriptionDocumento2 páginasCable MT NFC 33-226 18/30 (36) KV: DescriptionIbrahim LANDOZIAún no hay calificaciones

- CGX Wharf - Superstructure - v1 - 7feb2020Documento67 páginasCGX Wharf - Superstructure - v1 - 7feb2020Camilo AlvarezAún no hay calificaciones

- Service Manual: Floor Standing Air ConditionerDocumento51 páginasService Manual: Floor Standing Air ConditionerdixlopAún no hay calificaciones

- 33kV Cable GTPDocumento2 páginas33kV Cable GTPVipin Kr DhimanAún no hay calificaciones

- Mitd1 PDFDocumento4 páginasMitd1 PDFwizaarzAún no hay calificaciones

- En Brochure Terminal Blocks and Connectors 06 2017Documento20 páginasEn Brochure Terminal Blocks and Connectors 06 2017roby holmesAún no hay calificaciones

- Paper Paper Paper Paper Paper: MomentDocumento6 páginasPaper Paper Paper Paper Paper: MomentResearch1 amtdcAún no hay calificaciones

- On7eq Coax TrapsDocumento5 páginasOn7eq Coax Trapssaric_terrill4785Aún no hay calificaciones

- 5831 - PVC Insulation & SheathDocumento6 páginas5831 - PVC Insulation & SheathvurumuuAún no hay calificaciones

- Emboss Tape and Radial Tape Connector SpecsDocumento5 páginasEmboss Tape and Radial Tape Connector SpecspaulpuscasuAún no hay calificaciones

- Cylindrical Compression Helix Springs For Suspension SystemsDe EverandCylindrical Compression Helix Springs For Suspension SystemsAún no hay calificaciones

- Electronic Components, Tubes and Transistors: The Commonwealth and International Library: Electrical Engineering DivisionDe EverandElectronic Components, Tubes and Transistors: The Commonwealth and International Library: Electrical Engineering DivisionAún no hay calificaciones

- 6MD663 64 ManualDocumento224 páginas6MD663 64 Manualdilipeline100% (1)

- SLD - I R StatorDocumento1 páginaSLD - I R Statornandhagopal2010Aún no hay calificaciones

- Test On Instrument Transformers: Training Booklet: 4Documento8 páginasTest On Instrument Transformers: Training Booklet: 4nandhagopal2010Aún no hay calificaciones

- Data SheetDocumento2 páginasData Sheetnandhagopal2010Aún no hay calificaciones

- 7SA6xx Manual V4.30.04Documento708 páginas7SA6xx Manual V4.30.04wildor01Aún no hay calificaciones

- 05.vector Group TestDocumento2 páginas05.vector Group Testnandhagopal2010Aún no hay calificaciones

- 04.turn Ratio & Magnetizing Current TestDocumento6 páginas04.turn Ratio & Magnetizing Current Testnandhagopal2010Aún no hay calificaciones

- 7SA513 ManualDocumento396 páginas7SA513 Manualionecir100% (1)

- 06.measurement of Winding ResistanceDocumento9 páginas06.measurement of Winding Resistancenandhagopal2010Aún no hay calificaciones

- Calculate Size of Capacitor Bank - Annual Saving & Payback Period - Electrical Notes & ArticlesDocumento4 páginasCalculate Size of Capacitor Bank - Annual Saving & Payback Period - Electrical Notes & Articlesnandhagopal2010Aún no hay calificaciones

- 07.measurement of Tan Delta & CapacitanceDocumento7 páginas07.measurement of Tan Delta & Capacitancenandhagopal2010Aún no hay calificaciones

- 09.magnetic Balance TestDocumento1 página09.magnetic Balance Testnandhagopal2010Aún no hay calificaciones

- Attachment-9 - Air Circuit Breaker Test ReportDocumento3 páginasAttachment-9 - Air Circuit Breaker Test Reportnandhagopal2010100% (1)

- Ret 670Documento4 páginasRet 670nadalllabeedAún no hay calificaciones

- What Is Earthing - Electrical Notes & ArticlesDocumento6 páginasWhat Is Earthing - Electrical Notes & Articlesnandhagopal2010Aún no hay calificaciones

- Cable Tray Size As Per National Electrical Code-2002 PDFDocumento3 páginasCable Tray Size As Per National Electrical Code-2002 PDFnandhagopal2010Aún no hay calificaciones

- Abstract of NEC For Size of Cable For Single or Group of Motors - Electrical Notes & ArticlesDocumento2 páginasAbstract of NEC For Size of Cable For Single or Group of Motors - Electrical Notes & Articlesnandhagopal2010Aún no hay calificaciones

- 1 List of Testing Equipment: 1. General Data and InformationDocumento3 páginas1 List of Testing Equipment: 1. General Data and Informationnandhagopal2010Aún no hay calificaciones

- Application Guide For High Impedance ProtectionDocumento12 páginasApplication Guide For High Impedance Protectionjavedsmg1Aún no hay calificaciones

- Fuse FailureDocumento3 páginasFuse Failurenandhagopal2010Aún no hay calificaciones

- TDS-BS 3262 ThermoplasticsDocumento2 páginasTDS-BS 3262 ThermoplasticstimphAún no hay calificaciones

- Fan Drive System: Systems OperationDocumento5 páginasFan Drive System: Systems Operationallan lariosaAún no hay calificaciones

- Group - 6 MobileyeDocumento14 páginasGroup - 6 MobileyevAún no hay calificaciones

- RADIOLINEDocumento198 páginasRADIOLINERavenShieldXAún no hay calificaciones

- Materials Science and Engineering - Stanford UniversityDocumento22 páginasMaterials Science and Engineering - Stanford Universityteerth_brahmbhattAún no hay calificaciones

- My Green Trips 2Documento12 páginasMy Green Trips 2api-376387010Aún no hay calificaciones

- Dishwasher: Model ESI 6105Documento24 páginasDishwasher: Model ESI 6105Ivan ZindovicAún no hay calificaciones

- Ez 402HS PDSDocumento2 páginasEz 402HS PDSSiva KumarAún no hay calificaciones

- Induced Roll Magnetic Separator: Data Sheet - IRMDocumento5 páginasInduced Roll Magnetic Separator: Data Sheet - IRMMIzan NursiadiAún no hay calificaciones

- AD355 Builders Manual ExampleDocumento15 páginasAD355 Builders Manual Examplejntramey100% (1)

- Proposed Rates for Sukowati Pad C Well ConstructionDocumento11 páginasProposed Rates for Sukowati Pad C Well ConstructionReza WahyuantoAún no hay calificaciones

- Reliability Measures: Failure and Root Cause Analysis (FRCA) For GIS Early FailureDocumento5 páginasReliability Measures: Failure and Root Cause Analysis (FRCA) For GIS Early Failuredes1982Aún no hay calificaciones

- Structured Cataalists and Reactors Ceramic CatalistDocumento55 páginasStructured Cataalists and Reactors Ceramic CatalistBoby Royan Naira AzdlilAún no hay calificaciones

- LZ 7077 Pds PDFDocumento4 páginasLZ 7077 Pds PDFNadia SalemAún no hay calificaciones

- SsangyongDocumento1991 páginasSsangyongmichaeltiboche100% (2)

- King Abdulaziz International Airport Jeddah Kingdom of Saudi Arabia 1Documento2 páginasKing Abdulaziz International Airport Jeddah Kingdom of Saudi Arabia 1Ahmed ElaminAún no hay calificaciones

- Electrical Engineer Job Jebel AliDocumento1 páginaElectrical Engineer Job Jebel AliPrakash SelvarajAún no hay calificaciones

- 5kv CableDocumento2 páginas5kv Cableencarn1092Aún no hay calificaciones

- Nokia 1680 Service Manual Level 1 2Documento13 páginasNokia 1680 Service Manual Level 1 2esausmanAún no hay calificaciones

- Dl8000 Preset ControllerDocumento74 páginasDl8000 Preset ControllerFIRMANSYAHAún no hay calificaciones

- Maeda LC785Documento4 páginasMaeda LC785enggmohanAún no hay calificaciones

- Summat IveDocumento10 páginasSummat IveNorma Panares100% (1)

- PSM 1200535 PSM PDFDocumento1 páginaPSM 1200535 PSM PDFPaoloFregonaraAún no hay calificaciones

- Gpsa 15Documento28 páginasGpsa 15David Cortez Peralta100% (1)

- Tulasi Rao - MECHANICAL ENGINEER 9 Yeras Experience CswipDocumento3 páginasTulasi Rao - MECHANICAL ENGINEER 9 Yeras Experience Cswiptulasirao.nammiAún no hay calificaciones

- t4 Hitech 03-06Documento364 páginast4 Hitech 03-06Nicoleta Costea100% (1)

- Road RollerDocumento1 páginaRoad RollerSafety ManagerAún no hay calificaciones

- Reliance East West Pipeline Punj LoydDocumento3 páginasReliance East West Pipeline Punj LoydPuneet Zaidu100% (1)

- Encyclopedia of Machine Shop Practice PDFDocumento572 páginasEncyclopedia of Machine Shop Practice PDFpetyagleis0% (1)

- Sigma Marine Coatings Manual - Part106Documento2 páginasSigma Marine Coatings Manual - Part106Tommy2020Aún no hay calificaciones